More than two million people in Germany struggle to breathe - usually while they are sleeping. An inconspicuous box, called "CPAP ventilation" (continuous positive airway pressure), helps them to breathe. At the outbreak of the coronavirus pandemic, staff at the Sleep Medical Center of the University of Marburg came up with the idea to retrofit the device to make a ventilator. After all, there is currently a great need for these ventilators all over the world. The Professor of the Semiconductor Phototonics department formed a task force for this purpose within just a few days. The goal: to be able to care for coronavirus patients using the CPAP devices by quickly and economically converting them.

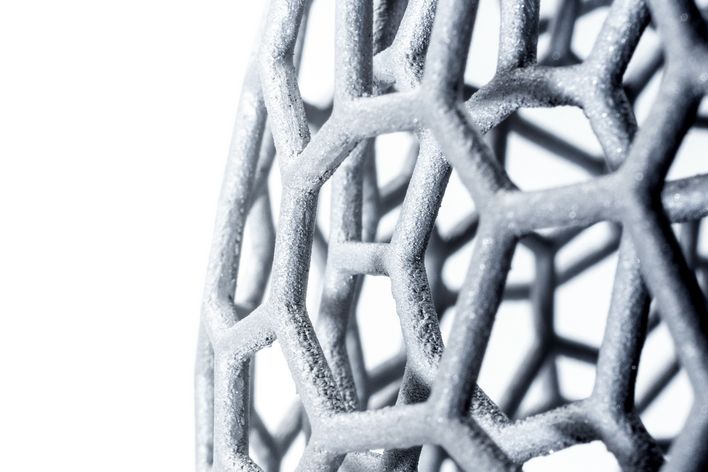

With the help of 3D printing, researchers from "The Breathing Project" have developed a device for converting an anti-snoring device into a ventilator. This is to be used in caring for coronavirus patients. (Source: University of Marburg)

3D printing is the first choice

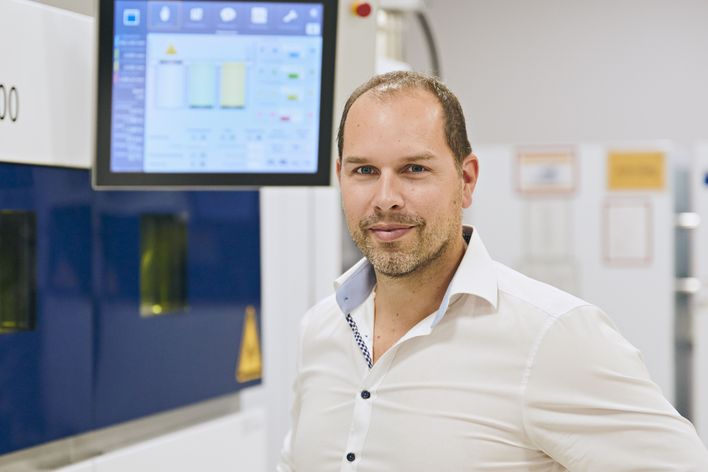

Developing this emergency solution is a race against time. Which is why the researchers are depending on a technology which helps them to try out new ideas quickly. A 3D printer seemed ideal for this. So they started looking for experts in additive manufacturing. By coincidence, the research team came across Bastian Leutenecker-Twelsiek from TRUMPF. "A member of the task force knew my boss from elementary school. Once he drew my attention to the project, I didn't waste a minute and drove straight to the university", says Leutenecker-Twelsiek.

Print data freely accessible worldwide

Since then Leutenecker-Twelsiek has spent every spare moment with the project team. He advises the researchers on suitable 3D printing methods and supports them in designing the relevant parts. He developed two valves himself which regulate the device pressure when breathing. His involvement in the crisis goes without saying: "We start in the morning on weekends and our working day is open ended. We know we can save lives, so we push ourselves to the limit", says the expert who lives in Marburg on weekends.

The project team has built seven prototypes in just two weeks. The objective now is to obtain emergency approval. At the same time, the researchers are checking if the design data and software codes can be made available online free of cost. This would mean that companies all over the world could manufacture and develop the devices. "The application is a very good example of the innovative nature of 3D printing. We would not achieve our objective as quickly using conventional methods", says Leutenecker-Twelsiek.

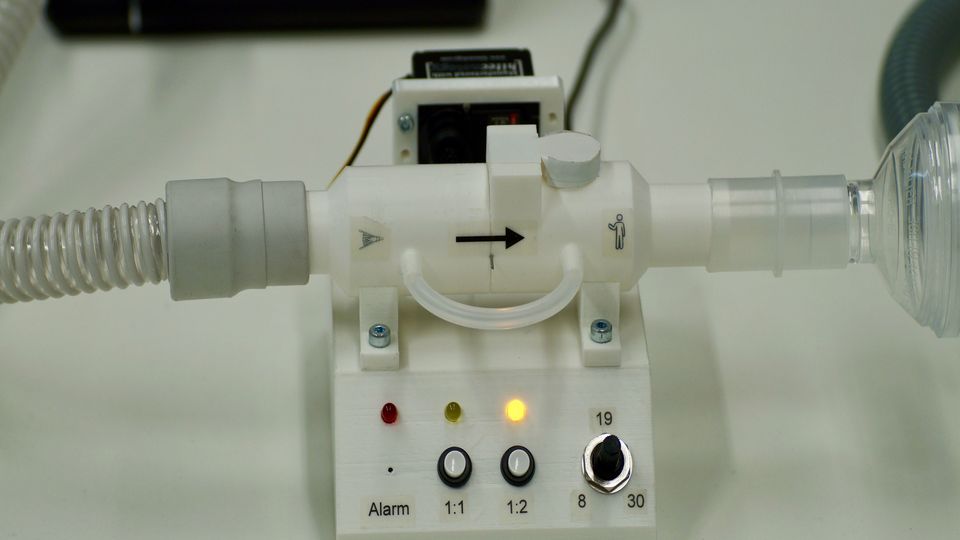

Researchers and medical professionals from the University of Marburg use a dummy to test the ventilator. (Source: University of Marburg)

More devices are planned in large quantities

The converted CPAP machines are not suitable for acute coronavirus cases with extreme breathing difficulties. However, patients can switch to them after only a few days of treatment. In the best case scenario, this can ease the shortage of conventional machines, which can then be used exclusively for emergency treatment. In addition, the researchers are aiming to develop a second machine in cooperation with local companies which can be manufactured in the traditional way. This would mean that individual manufacturers could mass-produce the machines in larger batch sizes.