I

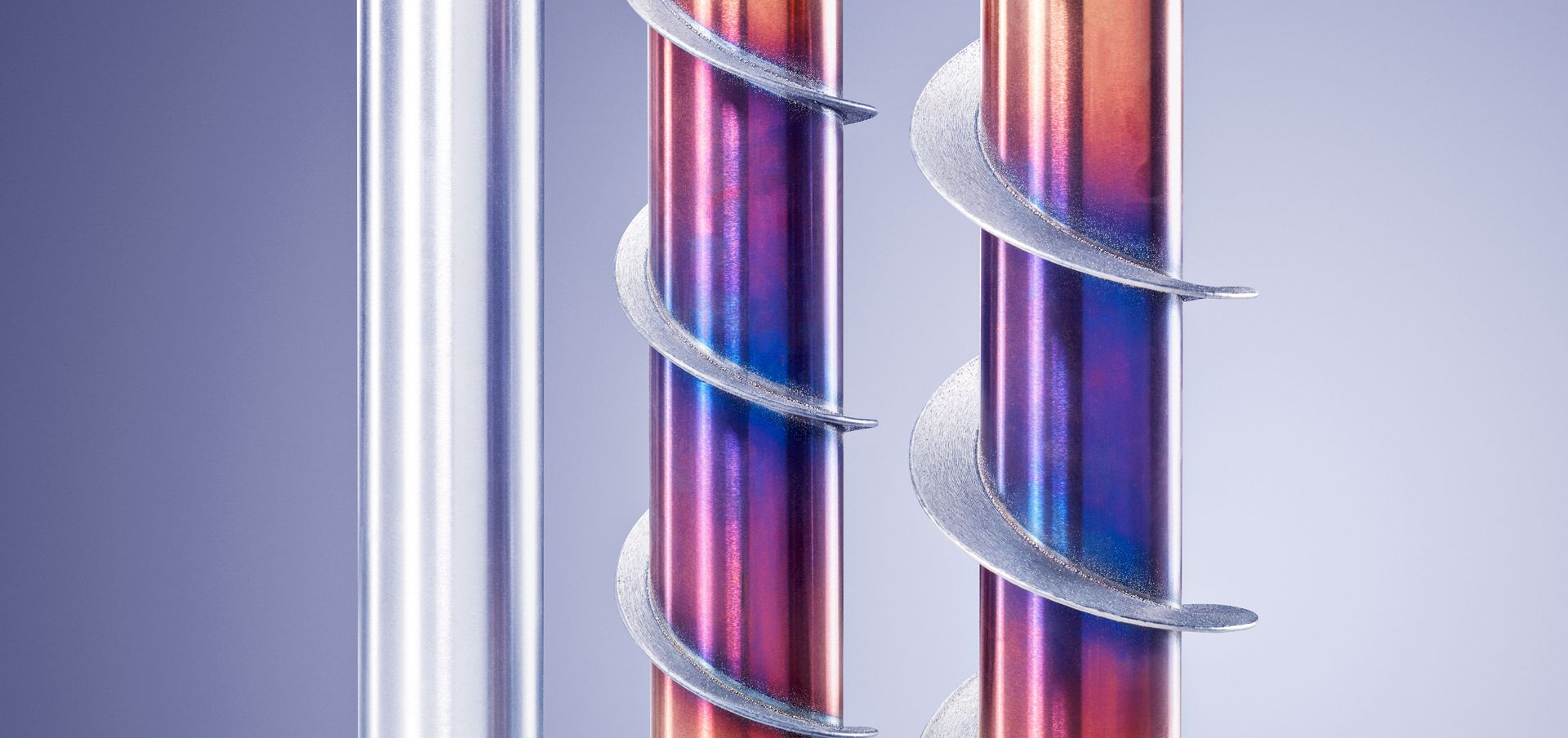

ndustrial manufacturing can involve a wealth of different tasks. To take just one example, it may be necessary to attach a mounting surface to a tube. In order to maintain the required geometry, the previous method of doing this was often to manufacture a tube with a larger diameter than was actually required, and then to machine off everything all around apart from the connection – a crazy waste of material. The laser metal deposition (LMD) additive manufacturing method takes a quite different approach. Instead of removing unnecessary material, you add additional material to a base body.

What is LMD?

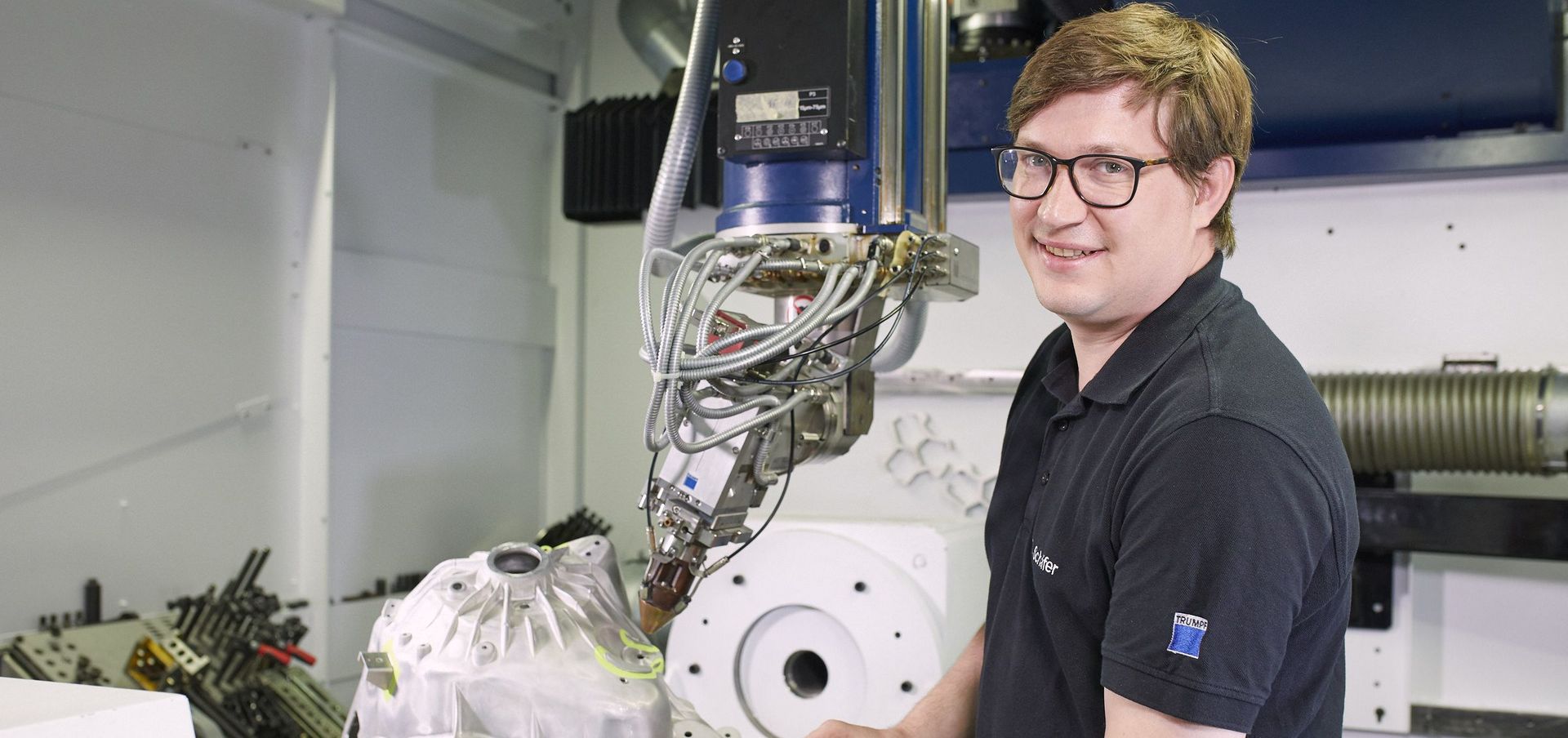

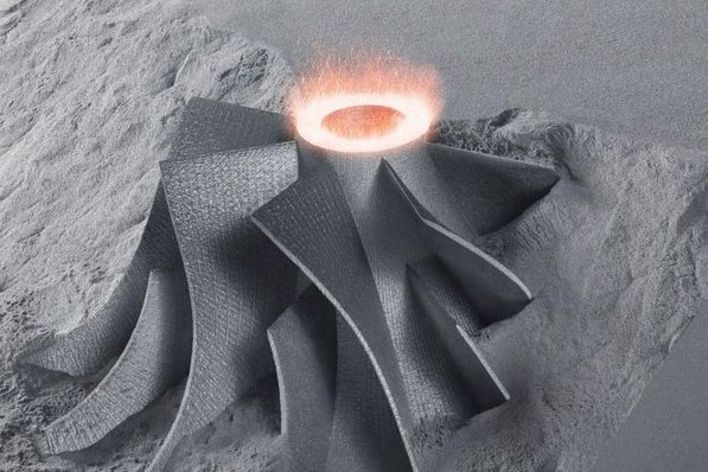

Laser metal deposition (LMD) is also known as generative laser welding. In contrast to laser metal fusion (LMF), where the process takes place inside a 3D printer, LMD takes place in the open air. TRUMPF has thus mastered both important methods for metal 3D printing: laser metal deposition (LMD) and laser metal fusion (LMF).

How does LMD work?

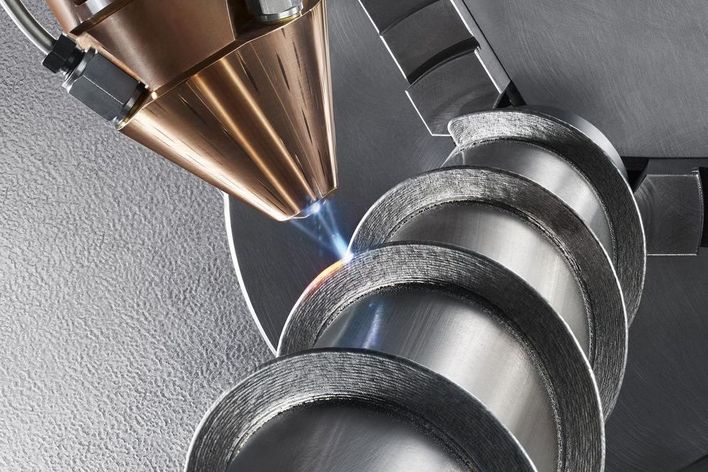

- The laser generates a weld pool on the surface of the existing component. A nozzle is used to add powder at the same time, which is melted on to produce the desired shape.

- The nozzle sprays the fine metal powder onto the base body. The laser beam comes from the center of the nozzle.

- The material that is applied can extend and grow in any direction.

What are the benefits of LMD?

- LMD saves time: Compared against other additive methods it enables higher build rates, which speeds up the process.

- LMD enables you to switch between different materials in additive manufacturing. Several different powder containers can be active, which means alloys can also be formed. The spectrum ranges from nickel, cobalt, and aluminum through to copper and titanium. By combining different materials, it is also possible to create structures similar to a sandwich design.

- Great creative freedom: Since there is no need for a build chamber, it is also possible to build large components. The laser also has unrestricted access to the base body.

What is LMD suitable for?

- For coating components, for example anti-wear or anti-corrosion coatings.

- For repairing damaged metal components.

- For relatively straightforward prototypes and one-off designs.

Which industries use LMD?

- LMD can be found in many industries, for example the aviation and aerospace, energy, petrochemical, automotive, and medical technology sectors.