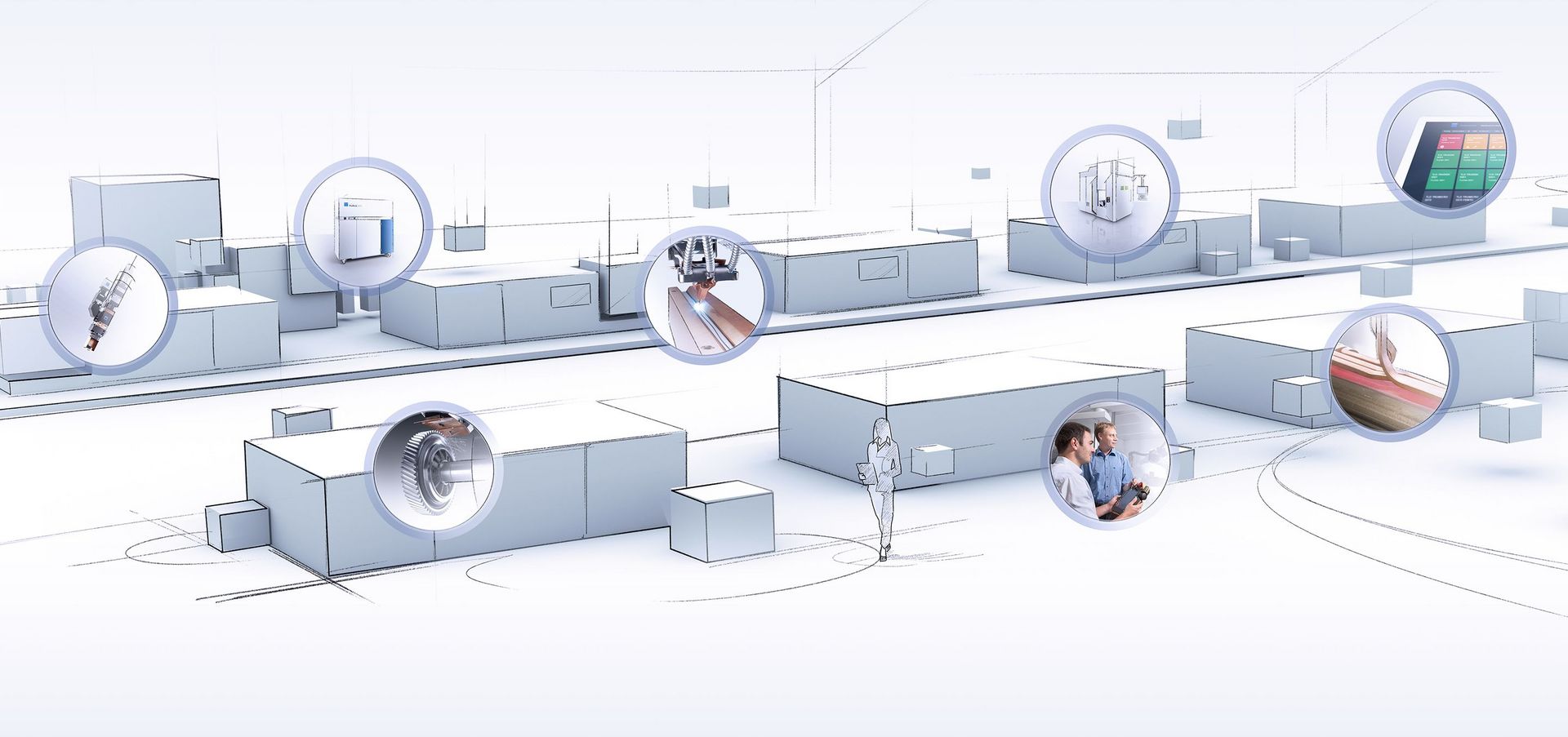

1. Processing optics

At TRUMPF, you can choose from a wide range of processing optics for various power classes, beam sources, and wavelengths. Through on-the-fly processing with TruTops I-PFO, you will benefit from intelligent component processing and a reduction in throughput. Our optics also have interfaces for status analysis.

2. Beam sources

Whether for cutting, welding, or laser metal deposition – at TRUMPF you can obtain a large range of beam sources for every processing application. From low power for plastic and high power for metal, to green, ultraviolet, or infrared for a range of other raw materials. We can provide you with the right beam sources for each material. They are Industry 4.0 ready and can be adjusted individually by way of parameters.

3. Sensor systems

For optimum processes and precise documentation. TRUMPF provides technology packages for laser metal deposition (DepositionLine), laser hardening with temperature control, and plastic welding with temperature control. These packages are specially designed for machine and systems engineering. For quality assurance at the end customer's plant, we provide sensor system data for documenting processes and product quality.

4. Laser systems

Perfect interplay: With our laser systems for cutting in 2D and 3D, welding, marking, and tube cutting, as well as for additive manufacturing, we provide you with coordinated complete solutions to get started immediately. Our laser cells can also be easily integrated into entire production lines. Due to the lifting doors, side or front accessibility to the TruLaser Cell 3000 is excellent. This makes it easy to completely integrate the machine into fully automatic systems.

5. Power electronics

A stable supply with a process flow: TRUMPF Hüttinger's product range offers everything that you need as a machine and systems engineering company. For example, generators for inductive preheating in the case of demanding laser welding tasks. This means that process times are shortened and results are optimized.

6. Services

Regardless of whether digital or analog technology is involved – with our services for the industry, we clearly set ourselves apart from the competition. Our dashboards can be customized precisely according to the requirements of your customers. You can also impress them with TRUMPF Technical Service directly on site. This means that the quality and functioning of the laser systems are ensured directly by the manufacturer.

7. Application service

Our laser application center is available for preliminary tests and optimizations, even after system configuration at the end customer's premises. Our experts work out the perfect laser parameters in consultation with you and the customer. In addition, our experts constantly search for new and even more effective solutions – including those that arise from thinking outside the box.