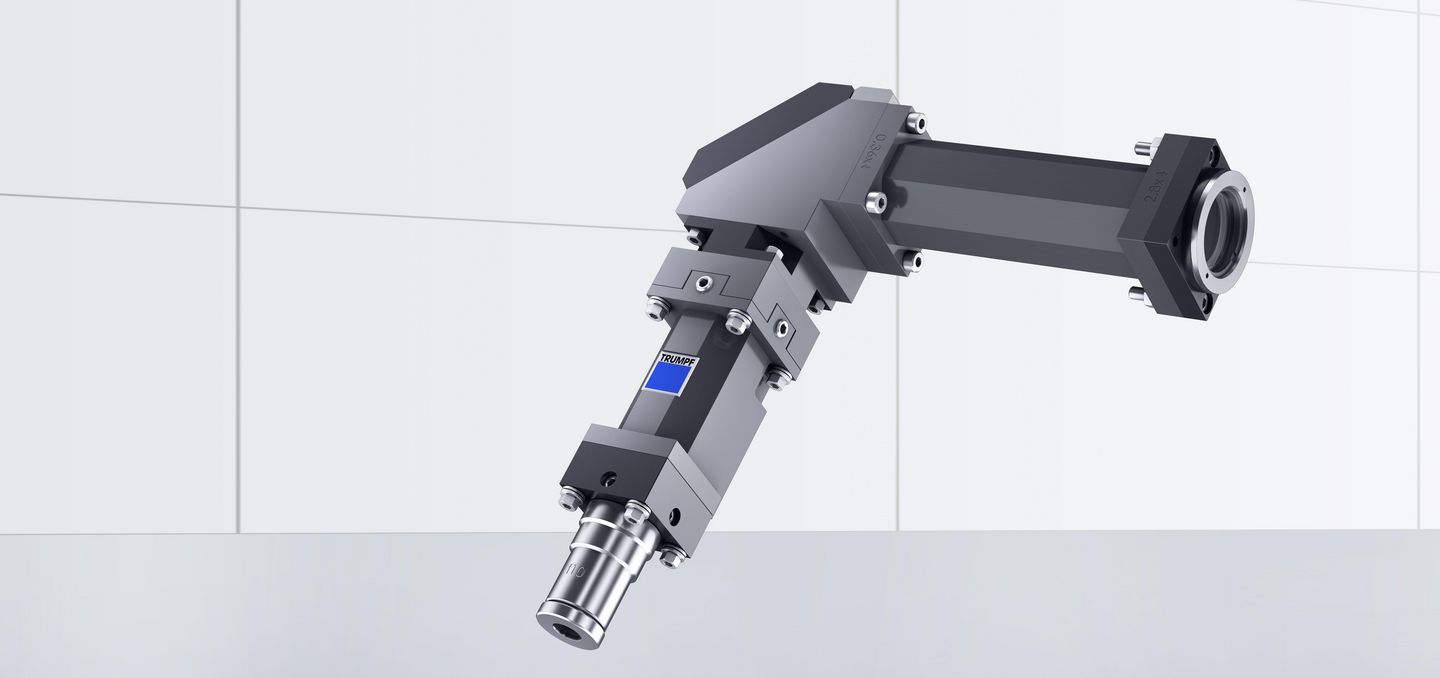

Das Design der TOP Serie zeichnet sich durch eine besonders kompakte, leichte und robuste Bauweise aus und kann daher hohen Beschleunigungen ausgesetzt werden.

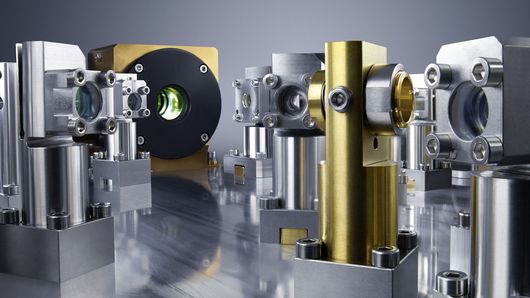

Optiken zur Strahlformung

Mit unseren Strahlformungselementen der TOP Baureihe sind Sie für jede Aufgabe in der Lasermaterialbearbeitung bestens gerüstet. Ob zum Glasschneiden, Schweißen transparenter Materialien und Löten von verzinkten Blechteilen – TOP Cleave-2, TOP Cleave-2 PRO, TOP Weld und TOP Braze überzeugen allesamt durch eine sehr hohe Bearbeitungsqualität und -geschwindigkeit bei einer Vielzahl an Werkstoffen. Bei Bedarf entwickeln wir eine an Ihre Anforderungen angepasste Lösung zur Strahlformung.

Beim Schweißen mit TOP Weld werden hochtransparente Nähte erzeugt. Die hohe Dichtheit ermöglicht das Verkapseln von Flüssigkeiten oder Gasen.

Durch den Verzicht auf komplexe Prozessschritte und zusätzliche Materialien schonen Sie mit der TOP Baureihe Ressourcen und Ihr Budget

Profitieren Sie von schnellem Schneiden mit TOP Cleave-2, das so gut wie keine Nacharbeiten mehr erfordert.

Laser, Bearbeitungskopf, Optik, Strahlformung – bei TRUMPF haben wir alles in unserem Portfolio, perfekt aufeinander abgestimmt für Ihren Bedarf.

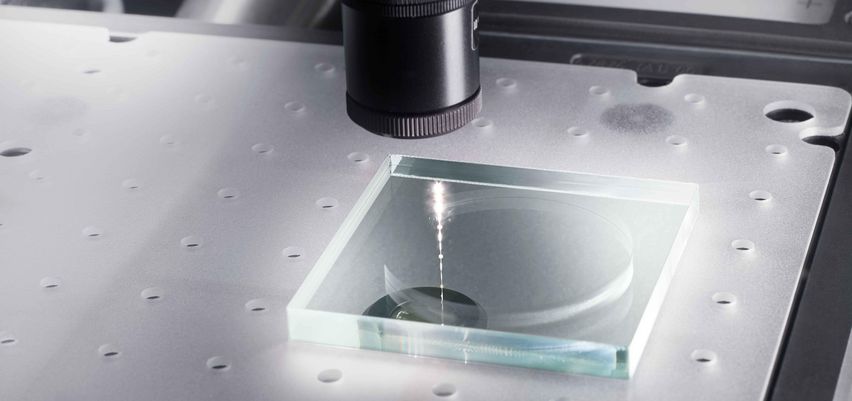

Trennen von ultradünnem Glas

Laser-Modifikationsschneiden ermöglicht das Trennen von ultradünnem Glas (50 µm) mit höchster Kantenqualität. Dadurch wird die Biegefestigkeit deutlich erhöht.

Modifizierung von Glas

Extreme Dicken von mehr als 8 mm lassen sich mit TRUMPF TruMicro Lasern und den TOP Cleave Optiken effizient bearbeiten und anschließend trennen. Nach dem Trennen ist keine Nachbearbeitung der Schnittkante, wie Schleifen oder Polieren, notwendig.

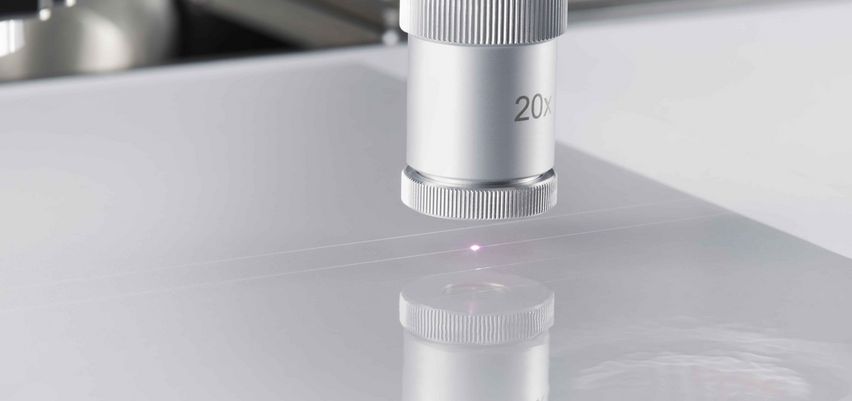

Glasschweißen

TRUMPF TOP Weld Optiken fokussieren Femtosekunden-Laserpulse, um Glas mit Glas oder auch Glas mit Metall hochpräzise zu verschweißen. Das Ergebnis ist eine hochfeste und nahezu unsichtbare Verbindung.

Beliebeige Konturen und kleinste Geometrien

Mit der Fokussieroptik TOP Cleave schneiden Sie völlig frei Konturen auf den Hundertstelmillimeter genau. Mit ultrakurzen Laserpulsen modifizieren Sie eine schmale Fläche entlang der gewünschten Trennlinie. Die Veränderung erzeugt eine intrinsische Schwächung, das Glas reißt kontrolliert und weist glatte Kanten auf.

Laserschneiden von Glasröhren

Rückstandsfreies Laserschneiden von Glasröhren mit den TOP Cleave Optiken. Die Glasröhren werden dabei mit aberrationskorrigierten nichtbeugenden Strahlen und ultrakurzen Laserpulsen bearbeitet. Damit sind Zykluszeiten für Glasrohre mit weniger als 15mm Durchmesser im Bereich von 0,1s pro Schnitt möglich. Typische Anwendungsfälle sind hierbei in der Medizintechnik mit Produkten wie Ampullen, Spritzen und Fläschchen.

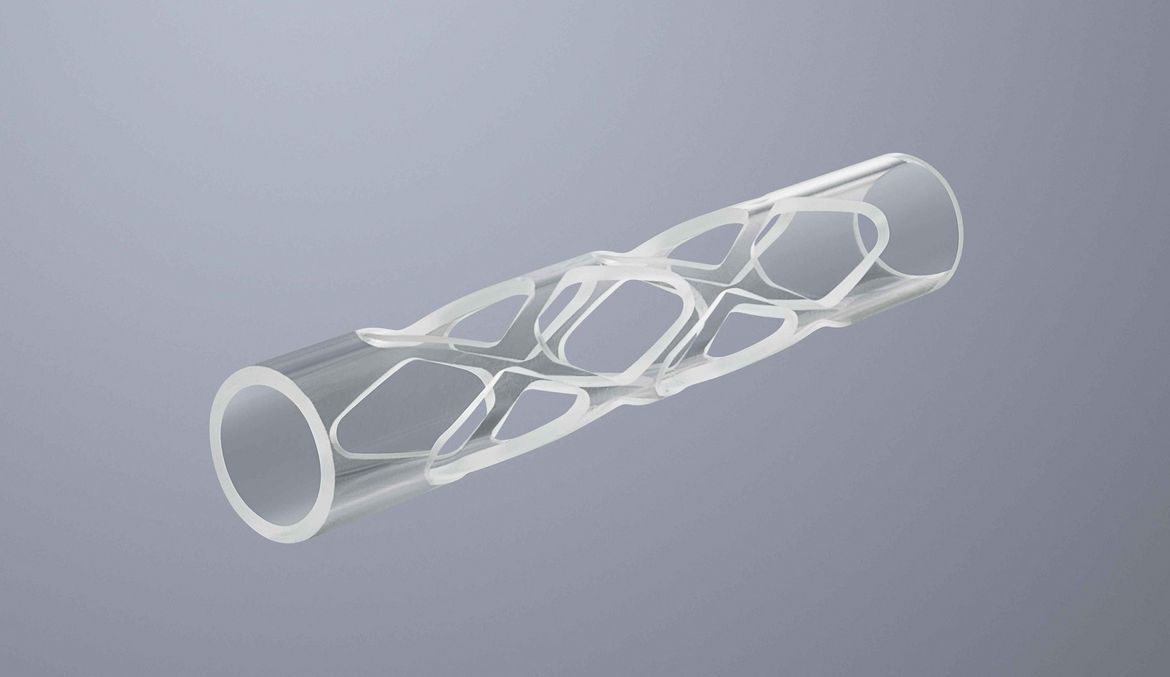

Selektives Laserätzen komplexer Innenkonturen in Glasröhren

Mittels aberrationskorrigierter, nichtbeugender Strahlen modifizierte Glasrohre lassen sich in Kombination mit einem selektiven Ätzverfahren auch komplexe Innenkonturen herstellen.

Glasschweißen mit TruMicro und TOP Weld

Mit TOP Weld können Materialien in industrieller Umgebung permanent mit hoher Festigkeit verschweißt werden. Darüber hinaus sind die Schweißnähte wasser- und gasdicht.

Hartlöten im Karosseriebau

Ob für die Dachnaht oder Heckklappe – die Fokussieroptik TOP Braze ermöglicht das Hartlöten feuerverzinkter Bleche mit in situ Vorbehandlung durch den Bearbeitungslaser.

|

TOP Cleave

|

TOP Cleave-2

|

TOP Weld

|

|

|---|---|---|---|

| Laserparameter | |||

| Wellenlänge | 1030 nm | 1030 nm | 1030 nm |

| Max. Pulsenergie | 500 µJ | 500 µJ | 500 µJ |

| Optikkonfiguration 1 | |||

| Aufweitungen |

1 x

1,5 x 2 x 2,8 x |

0,36 x

0,5 x 0,67 x 1,5 x 2 x 2,8 x |

0.5 x

0.36 x |

| Verfügbare Objektive |

10 x (f = 20 mm)

20 x (f = 10 mm) |

f = 20 mm, NA=0,2

f = 10 mm, NA=0,4 |

20 x (f = 10 mm) |

| Konstruiert für Rohstrahldurchmesser | - | 5 mm | 5 mm |

| Bauform | |||

| Abmessungen (B x H x T) | 98 mm x 480 mm x 86 mm | 40 mm x 240 mm x 40 mm (Beispielskonfiguration) | 40 mm x 240 mm x 40 mm (Beispielskonfiguration) |

| Gewicht | < 5 kg | je nach Konfiguration ab 0,62 kg | je nach Konfiguration ab 0,62 kg |

| Kompatibilität | |||

| Verfügbare Laser | TruMicro Serie 5000, TruMicro Serie 2000 | TruMicro Serie 5000, TruMicro Serie 2000 | TruMicro Serie 5000, TruMicro Serie 2000 |

Die technischen Daten aller Produktvarianten als Download.

TOP Cleave-2

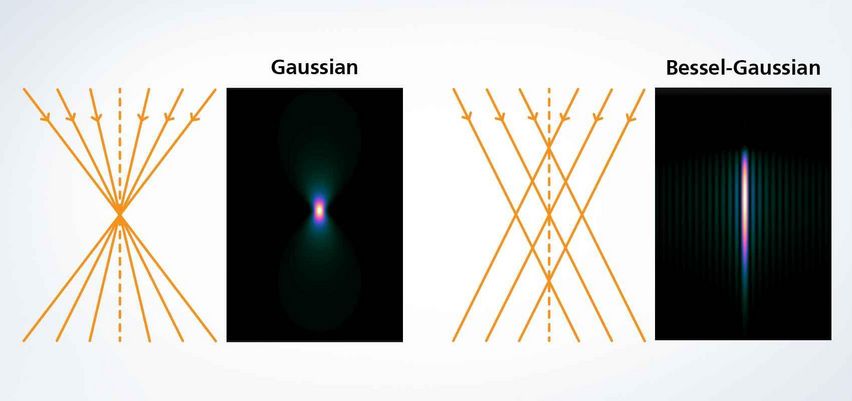

Mit TOP Cleave-2 sparen Sie Prozessschritte, denn die großen Scheiben können direkt beschichtet werden und die Vereinzelung kann nachträglich erfolgen. Vor allem sehr dünne, gehärtete Gläser lassen sich perfekt bearbeiten. Die Fokussieroptik zum hochdynamischen Schneiden verteilt die Intensität des Laserlichts entlang der Strahlachse wodurch der Fokus in die Länge gezogen wird. Die Laserpulse modifizieren je nach Pulsenergie mit einer einzigen Überfahrt die komplette innere Trennfläche einer beispielsweise 700 µm dicken Scheibe. Mit der TruMicro Serie erreichen Sie Trenngeschwindigkeiten von bis zu 1000 mm/s; TOP Cleave-2 sorgt für eine hervorragende Kantenqualität.

TOP Cleave-2 PRO

Das PRO-Modul ergänzt die TOP Cleave-2 Optik zum Trennen transparenter Materialien. Durch die Vorzugsrichtung im Strahlprofil kann der Aufwand im nachgelagerten Trennschritt am Werksstück deutlich reduziert werden. Zudem ermöglicht das PRO-Modul durch die gezielte Rissführung zwischen den einzelnen Lasermodifikationen einen erhöhten Abstand der Modifikationen zueinander und somit erhöhte Vorschubgeschwindigkeiten. Die TOP Cleave-2 mit PRO-Modul kann im gesamten Dickenspektrum für Prozesse mit erhöhtem Anspruch eingesetzt werden. Sowohl schwer trennbare Werkstücke, wie Architekturglas mit Dicken im Bereich von 8 mm, als auch Ultradünnglas, bei dem extrem geringe Trennkräfte gefordert sind, können mit der Fokussieroptik bearbeitet werden.

TOP Weld

TOP Weld ist die erste Bearbeitungsoptik zum zwischenschichtfreien Schweißen transparenter oder transparenter zu opaken Materialen (z.B. Glas zu Metall). Noch nie zuvor konnten Materialien in industrieller Umgebung permanent mit hoher Festigkeit verschweißt werden. Die Materialeigenschaften müssen dabei nicht aufeinander abgestimmt sein. Die Fokussieroptik verteilt die Laserenergie maßgeschneidert auf die Fügezone während Fokuslagetoleranzen maximiert werden. Gegenüber bestehenden Methoden lassen sich größere Spalten bis zu 10 µm überbrücken.

TOP Braze

TOP Braze ermöglicht das spritzer- und porenfreie Hartlöten von feuerverzinkten Blechen oder Aluminiumbauteilen im Karosseriebereich, beispielsweise für die Dachnaht und Heckklappe. Gleichmäßig und großflächig können diese unterschiedlichen Werkstoffe mit einer hohen Prozessgeschwindigkeit von über 4 m/min bearbeitet werden. Das Ergebnis: glatte Oberflächen und scharfe Ränder. Mit der TruDisk Serie, dem LLK und Bearbeitungskopf inklusive Strahlformungs-Optik erhalten Sie von TRUMPF die Komplettlösung aus einer Hand.

TRUMPF bietet Ihnen neben einer Vielzahl an Bearbeitungsoptiken auch die dazu passender Strahlquellen. So finden Sie für Ihre Anwendung und Ihre Anforderungen genau die richtige Kombination – und das aus einer Hand. Im Bereich der Strahlquellen verfügt TRUMPF über alle industriell relevanten Laser. Verlassen Sie sich auf unsere Experten und vertrauen Sie uns. Wir haben stets die beste Lösung für Ihre Fertigungsaufgaben im Blick und beraten Sie völlig unabhängig von einer präferierten Technologie.

Je nach Land sind Abweichungen von diesem Produktsortiment und von diesen Angaben möglich. Änderungen in Technik, Ausstattung, Preis und Zubehörangebot sind vorbehalten. Bitte setzen Sie sich mit Ihrem Ansprechpartner vor Ort in Verbindung, um zu erfahren, ob das Produkt in Ihrem Land verfügbar ist.

Fußnoten-

Weitere Optikkonfigurationen auf Anfrage möglich.