Die benutzerfreundliche VisionLine Programmieroberfläche bietet einen intuitiven Assistenten, der Sie durch den Programmierprozess führt. Alle relevanten Produktionsinformationen sind übersichtlich dargestellt und unterstützende Funktionen helfen bei der optimalen Einstellung der Sensoreinheiten. Eine umfangreiche Online-Hilfe ist ebenfalls verfügbar.

Prozesssynchrone Qualitätskontrolle beim Schweißen

Die Prozess-Sensorik VisionLine OCT Check gewährleistet eine zuverlässige und präzise Einschweißtiefenüberwachung. Durch Anwendung der optischen Kohärenztomografie (OCT) ist es möglich, eine prozesssynchrone Qualitätssicherung zum Beispiel durch Messung der Dampfkapilartiefe bei Tiefschweißprozessen durchzuführen. Die Geometrie der erstarrten Schweißnaht wird durch einen zusätzlichen OCT Scann vermessen. Durch das optimale Zusammenspiel von PFO und OCT ist die prozesssynchrone Messung der Kapillartiefe im gesamten Arbeitsraum der PFO möglich, ohne Parameteranpassung durchzuführen.

Das robuste OCT Design und die geschickte Integration ins Optiksystem ermöglichen Messungen auch bei schwankenden Umgebungsbedingungen.

Für minimale Schnittstellen und einfache Anlagenintegration

Benutzerfreundliche Oberfläche der Software

Schnelle Verfügbarkeit der Ergebnisse für und geringe Taktzeiten

Prüfung jedes Bauteils mit 100%iger Rückverfolgbarkeit der Einschweißtiefe entlang der gesamten Schweißnaht

Alle Features von VisionLine Detect und VisionLine OCT Detect sind bereits enthalten.

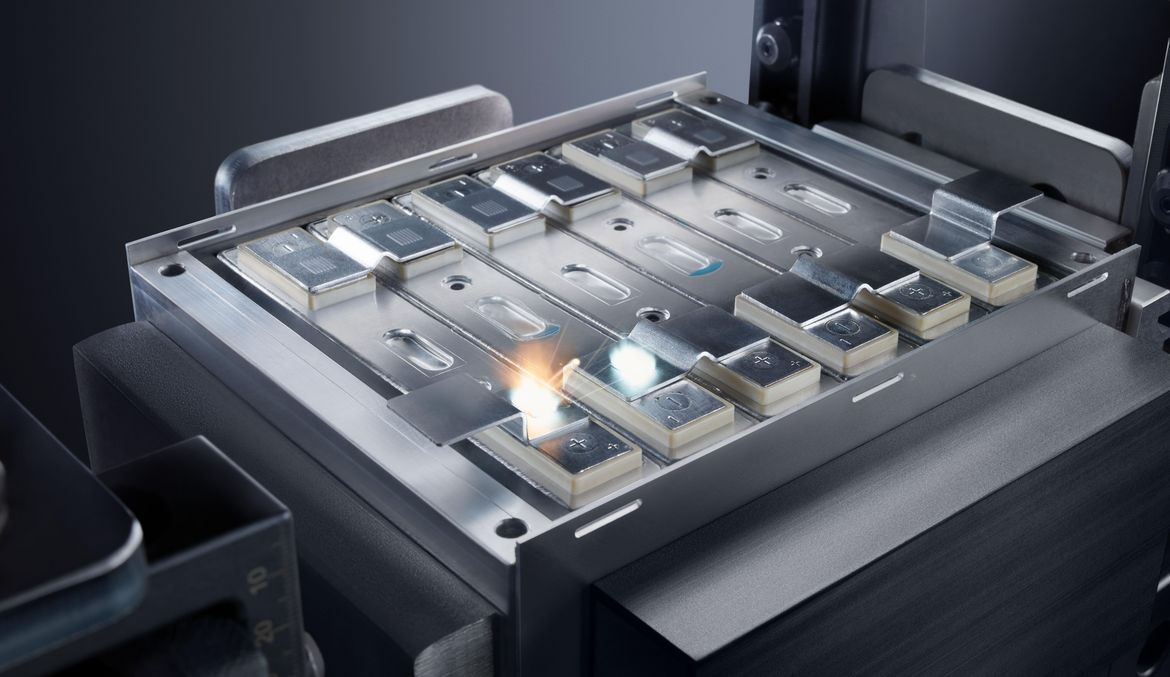

Schweißen von Busbars

Scannerschweißen an Autositzen

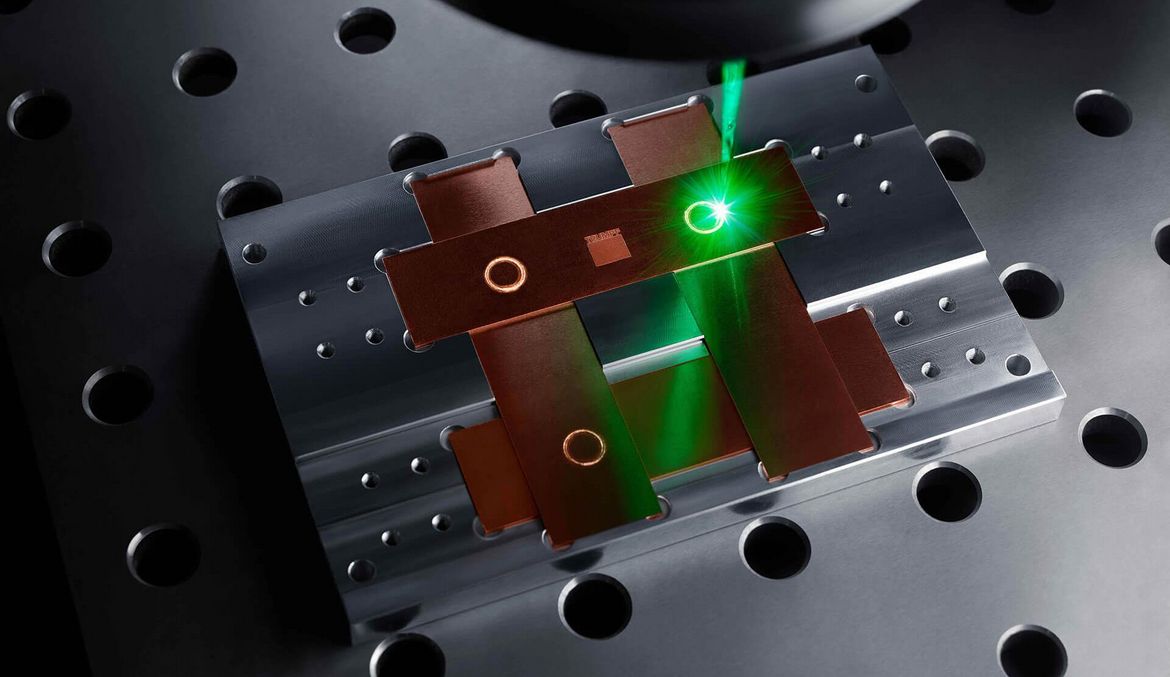

Kupferschweißen

Tiefschweißen von AIMg3 Gußgehäußen

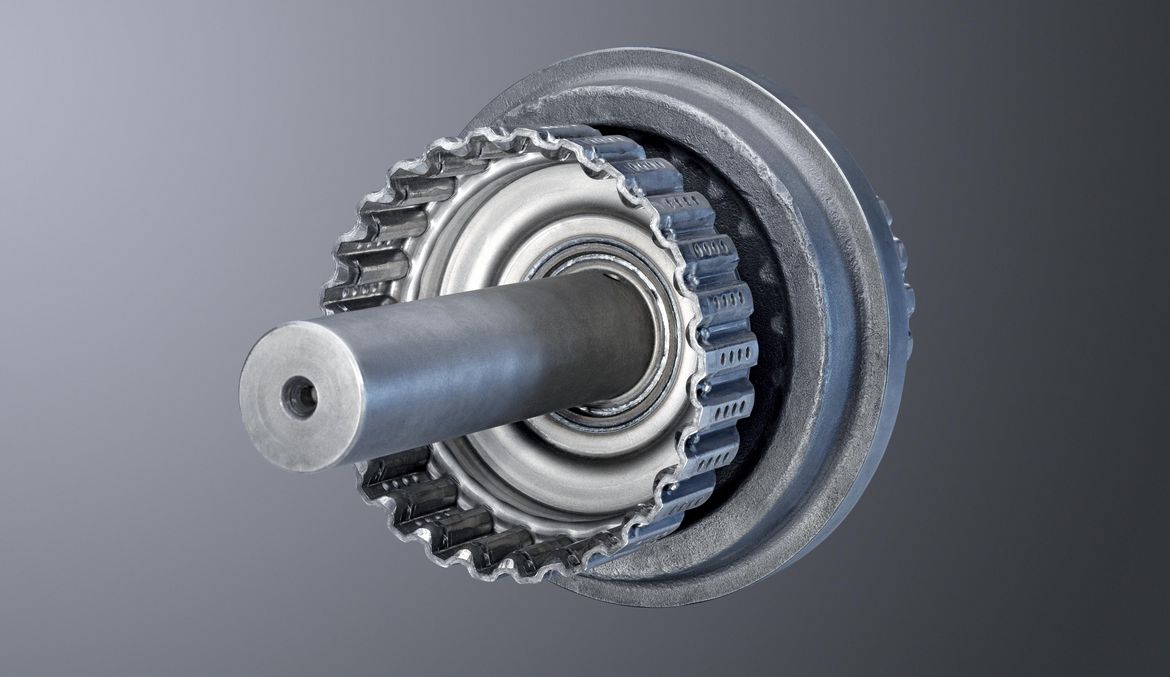

Schweißen von Antriebskomponenten

|

VisionLine OCT Check

|

|

|---|---|

| Konfiguration | |

| Verfügbare Laser | TruDisk (1030 nm, 515 nm), TruFiber (1075 nm, Multi Mode) |

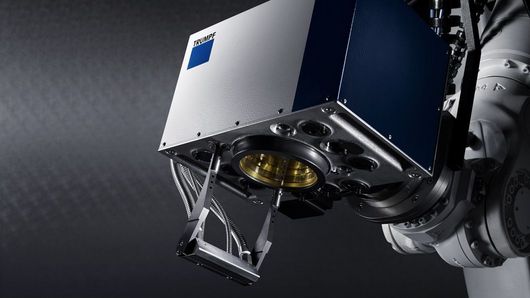

| Verfügbare Optiken | PFO 33 1 2 |

| Parameter | |

| Wellenlängenbereich OCT (Laserklasse) | λ = 820 nm - 860 nm (Klasse 3B) |

| Messrate OCT Sensor | 250 kHz |

| Axialer Messbereich | ± 5 mm (je nach Brennweite) |

| Lateraler Messbereich | Ø 15 mm - 25 mm (je nach Brennweite) |

| Axiale Auflösung | 12 μm |

| Seitliche Auflösung | ≥ 2 μm (abhänglig von Parametern und optischem Aufbau) |

| Typischer Messbereich Schweißtiefenmessung | 0,5 mm - 5 mm (je nach Prozessdesign und optischem Aufbau) |

Die technischen Daten aller Produktvarianten als Download.

Mit einem zusätzlichen Dienstleistungspaket liefert TRUMPF die Komplettlösung für komplexe OCT - oder Bildverarbeitungsaufgaben. Vorbehaltlich einer erfolgreich durchgeführten Machbarkeitsstudie erfolgt die Programmierung der zugeschnittenen Lösung inklusive ausführlicher Dokumentationen.

Je nach Land sind Abweichungen von diesem Produktsortiment und von diesen Angaben möglich. Änderungen in Technik, Ausstattung, Preis und Zubehörangebot sind vorbehalten. Bitte setzen Sie sich mit Ihrem Ansprechpartner vor Ort in Verbindung, um zu erfahren, ob das Produkt in Ihrem Land verfügbar ist.

Fußnoten-

Nur verfügbar mit PFO Generation 3.

-

Ausführliche Informationen über die verfügbaren optischen Einstellungen finden Sie im Datenblatt.