Take advantage of the multilaser option to maximize your productivity: Two 200 W TRUMPF fiber lasers (wavelength: 1,070 nm) simultaneously scan the entire build volume with complete overlap, thereby generating up to 80% more parts - in the same amount of time and with the utmost flexibility. As such, you can ensure that parts are available more quickly and maximize flexibility when processing customer orders.

3D printing in premium quality: highly productive and compact

With the next generation of the TruPrint 1000, we are continuing our success story - with even higher productivity and premium quality thanks to the full-field multi-laser and completely redesigned homogeneity of the gas flow. The 3D printer is intended for processing metal powders using the laser metal fusion process, also known as Power Bed Fusion. Due to the high level of robustness and quality in 3D printing, the TruPrint 1000 is not only perfectly suited for the dental market, but also impressive in the R&D area or in small series production.

The new design of the TruPrint 1000 is optimally structured so that the machine fits through a standard door and can find its place in any laboratory, e.g. in the dental field or in universities.

With multilaser 2 x 200 W and automatic substrate plate change

Through redeveloped gas flow and improved laser focus stability

Inert powder cycle with glove box and interchangeable cylinders

With the adjustable spot diameter (55/80 µm) and detailed process analysis

Lower part costs through preform, multiplate and hybrid, digital chain

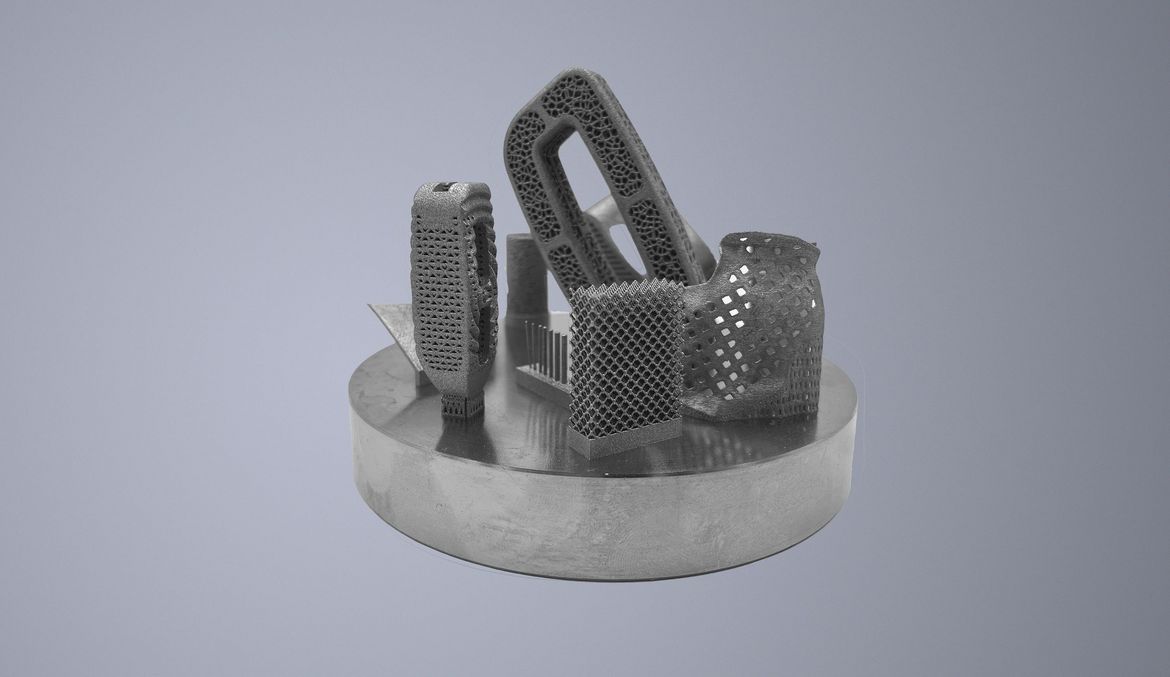

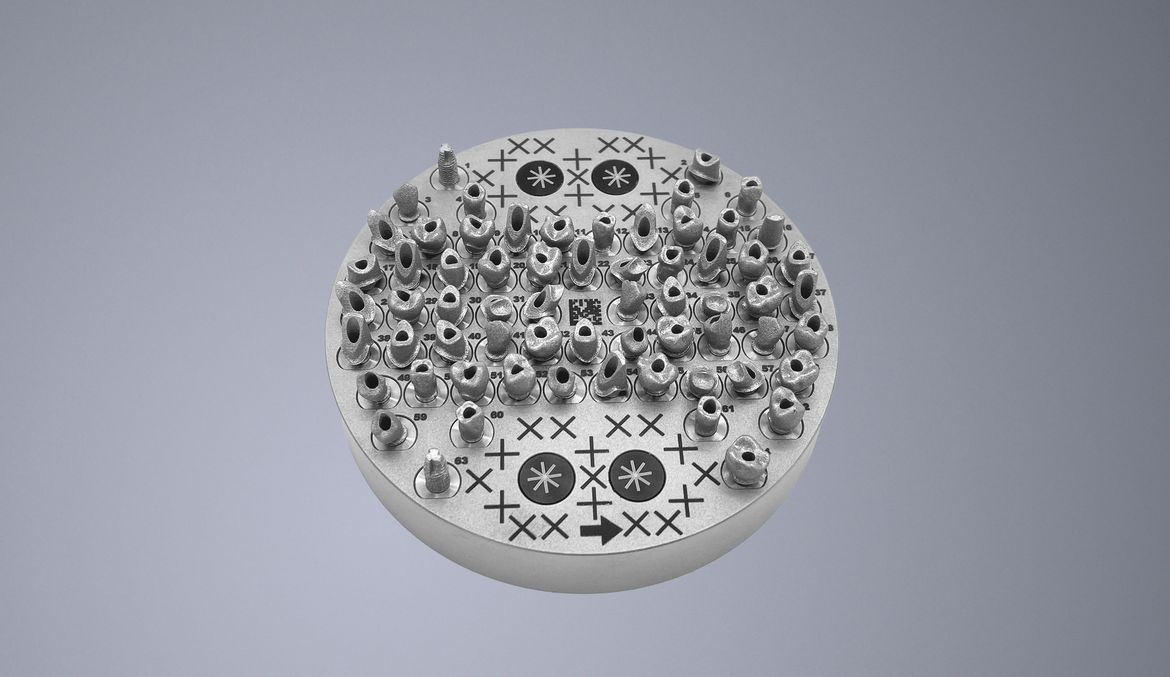

Dental plates

The dental plate shows different dental applications that were printed with the new TruPrint 1000: with significantly increased performance and component quality.

Medical applications

The new TruPrint 1000 is also ideal for medical applications thanks to the inert powder circuit and the high density and smooth surface it can achieve in the printed parts. It is important to store titanium powder in a protected environment in order to maintain the quality of the powder and allow the operator to work safely. In the process chamber the TruPrint 1000 can operate with an oxygen content of 100 ppm, which ensures the perfect quality for medical parts. The high build rate makes it possible to print multiple custom implants in just a few hours.

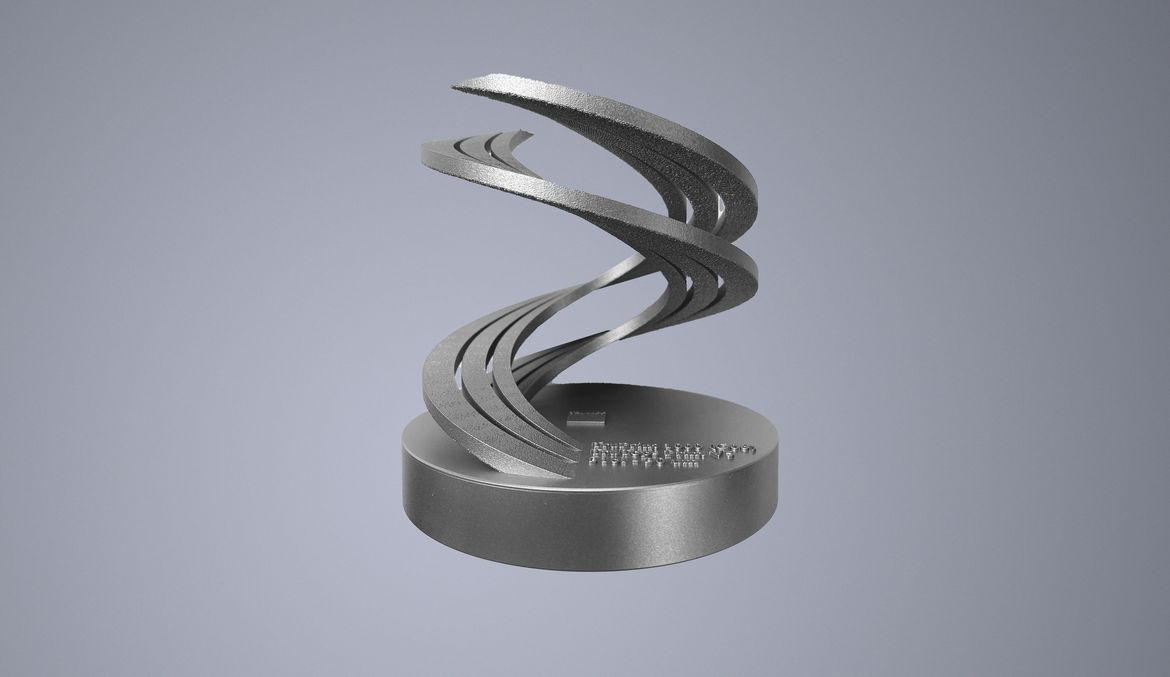

Demonstrator with a spiral overhang

The part shows how the improved machine performance and optimized laser strategy of the TruTops Print Build Processor make it possible to achieve very low overhangs (15°-25°) and guarantee part and surface quality.

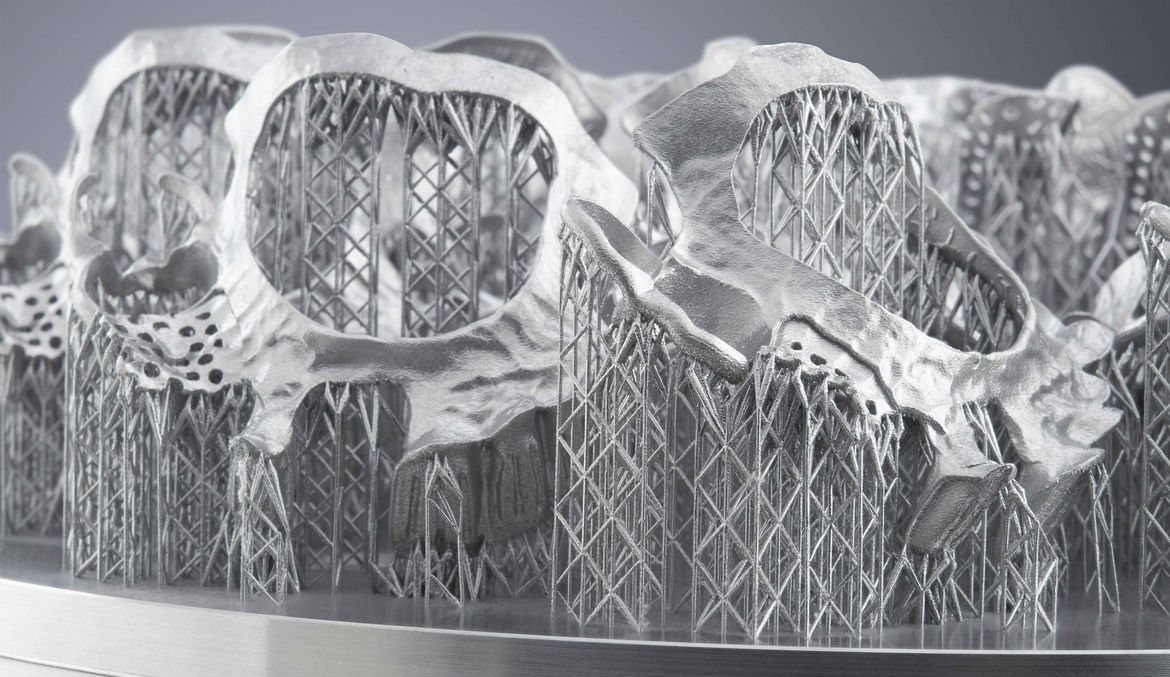

Dental plate with preparation for remilling

Measuring points are applied to the dental plate for the milling machine. This means that defined fit sections of the dental plate can be remilled. This demonstrates a dental hybrid process chain option.

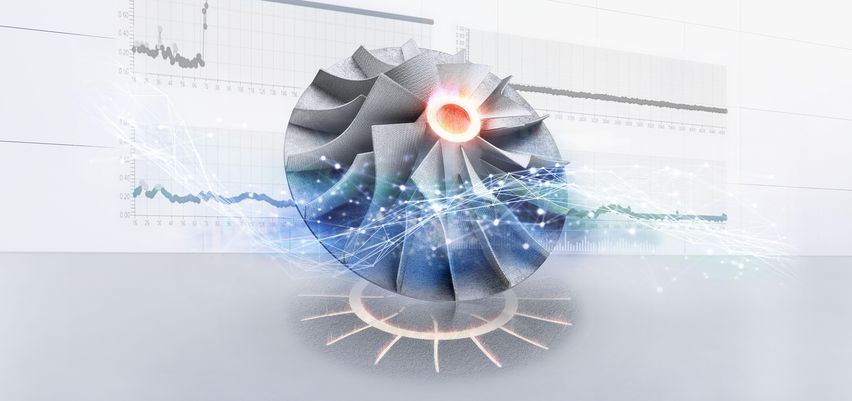

Stainless steel fan wheel/impeller 316L

The overhangs (up to 10°) of the fan wheel shown could be printed in conjunction with TruTops Print without support structures, which saves on reprocessing efforts.

Removable partial denture (RPD)

With the TruPrint 1000, you have complete freedom to design and manufacture the intricate structures of removable partial dentures (RPDs), for example, in cobalt chrome. New supporting structures also simplify the reprocessing.

Dental plate with preform

The Preform option of the TruPrint 1000 is suitable for the precise and quick production of individual single abutments. The part costs are also reduced significantly as only the patient-specific portion is printed. Up to 64 individual single abutments can be printed on one preform. It is easy to remove them from the plate.

Small series production with preform

The TruPrint 1000 can be used for fast and cost-efficient small series production. The component is made through additive manufacturing, using a preform without support structures. The finest lattice structures, intricate channels, and integrated functions are implemented in just one step. Via an inside joint, the planet rotates on its axis, for example.

|

TruPrint 1000

|

|

|---|---|

| Effective build volume (standard) | Diameter 98 mm x 100 mm Height |

| Effective build volume (option: build volume reduction) | Diameter 48 mm x 100 mm Height |

| Processable materials | Metal powders for welding, such as stainless steels, tool steels, and aluminum [1], nickel basis, cobalt-chrome, copper, titanium [1] or precious metal alloys, amorphous metals. Current availability of materials and their parameters available on request. [1] Only with option glove box + oxygen sensor, high resolution. |

| Maximum laser power at the workpiece (TRUMPF fiber laser) | 200 W |

| Beam diameter (standard) | 80 μm |

| Beam diameter (motorized optics) | 55/80 μm |

| Layer thickness | 20 - 60 μm |

| Build rate | 10 - 50 cm³/h |

| Connection and consumption | |

| Electrical connection (voltage) | 230 V |

| Electrical connection (current intensity) | 7 A |

| Electrical connection (current intensity - multilaser option) | 9 A |

| Electrical connection (frequency) | 50/60 Hz |

| Shielding gas | Nitrogen, argon |

| Structural design | |

| Dimensions (W x H x D) | 780 mm x 2050 mm x 1160 mm |

| Weight (with multilaser option) | Max. 900 kg |

The technical data of all product versions as a download.

TruTops Print

TRUMPF provides the suitable software solution with TruTops Print so you can get the best out of the TruPrint machines.

The modern user interface summarizes all functionalities in a clear overview and facilitates quick access to all functions. Maximum efficiency and productivity with optimum printing quality, reproducibility and support-reduced overhang construction are ensured thanks to the high degree of flexibility and the individual options for data preparation, such as z-segmentation, as well as the intuitive and clearly arranged parameter management with fully accessible parameters. The high quality of the generated vector data in the WZA file format can be verified with the integrated BuildJob Viewer.

Data preparation suitable for your workflow

TruTops Print is already connected with numerous CAD/CAM systems for a seamless data preparation workflow. This offers you the greatest possible flexibility when selecting the data preparation software. Decide for yourself which solution suits your workflow perfectly.

You can equip the TruPrint 1000 with corresponding options to suit the technical requirements of you application.

Increase your productivity by up to 80% with the multilaser option: two TRUMPF fiber lasers, each with an output of 200 W and a 55 or 80 µm beam diameter, respectively, can expose simultaneously in the build area and generate up to 80% more parts in the same amount of time and with a high level of flexibility. As such, you can ensure that parts are available more quickly and maximize flexibility when processing customer orders. As every contour is exposed by a laser, no "seam marks" are created. With the fullfield multilaser you can achieve 100% overlap coverage.

Take advantage of the option to switch between a 55 or 80 µm beam diameter. This enables you to prioritize between the best surface quality or higher productivity to process materials that require higher energy density, such as highly reflective materials.

The package enables professional powder handling, even in small format. Thanks to standard interfaces, connections can be made to external sieving stations, e.g. from assonic, or the powder preparation station. Minimizing powder contact automatically increases the safety of powder handling. The inert powder cycle also enables the processing of reactive materials such as titanium by reducing and controlling oxygen levels up to 100 ppm. The powder can be transported in a supply cylinder or overflow bin under a shielding gas atmosphere and sieved into an extra container.

Need to manage spikes in demand in a flexible way and extend your machine time without any operator interventions? Thanks to the Multiplate option, this is possible because the build cylinder can optionally accommodate up to four substrate plates, meaning the substrate plate can be exchanged automatically without stopping the LMF process. You also benefit from the fully automatic support provided by the machine software when completing the first build job and starting the next one. Completed build jobs are collected in the overflow bin.

The Preform option is suitable for the precise and quick production of individual single abutments. The part costs are also reduced significantly as only the patient-specific portion is printed. Up to 64 individual single abutments can be printed on one preform. It is easy to remove them from the plate. Automated preform detection is an important milestone in the industrialization of additive technology in the dental sector.

You can automatically monitor the powder bed via an integrated camera in the TruPrint component chamber and the automatic image processing function. This means that you have a constant overview of the state of the component and can analyze the quality parameters layer-by-layer.

Various options are available for your TruPrint to meet verification requirements. Laser power calibration - which is also for multilasers, focus position measurement and scan field calibration - enables you to recalibrate and document your measurement results.

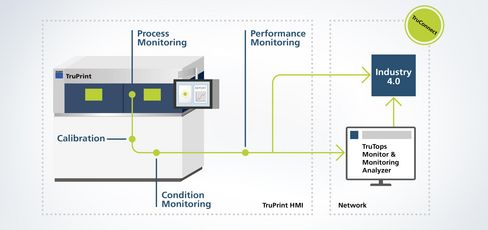

TruPrint monitoring

Using TRUMPF's intelligent monitoring solutions, you can monitor, analyze and calibrate the LFM process of the TruPrint machines with ease. You can then produce even more efficiently and achieve higher component quality. The professional monitoring process makes it possible to display and analyze sensor-based data. The offer comprises solutions for monitoring the process, condition, and performance. The monitoring results can be seen directly on the HMI of the TruPrint machine or can be analyzed offline via the Monitoring Analyzer. With TruTops Monitor, you get full transparency along with the option to have remote access via a PC or tablet. Furthermore, the OPC UA interface provides full flexibility to connect to your own software solution. With the additionally available calibration functions, you can check the process-relevant parameters for optimal production conditions before the start of the build job.

Powders and parameters

High-quality metal powders are the basis for reliable process conditions in additive manufacturing. The combination of recommended powders and the correct parameters creates high-quality material properties for 3D-printed components.

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price, and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.

The best is included free of charge – secure the Preform or Multiplate option now!

Are you on the look out for a new 3D printer your dental laboratory? When you purchase a new TruPrint 1000, the Multiplate or Preform option will be included free of charge! Offer valid until May 31 2024.

Find your additive manufacturing solution for dental technology now!

Use the TruPrint product finder to discover which TruPrint machine is best suited to your dental technology application!