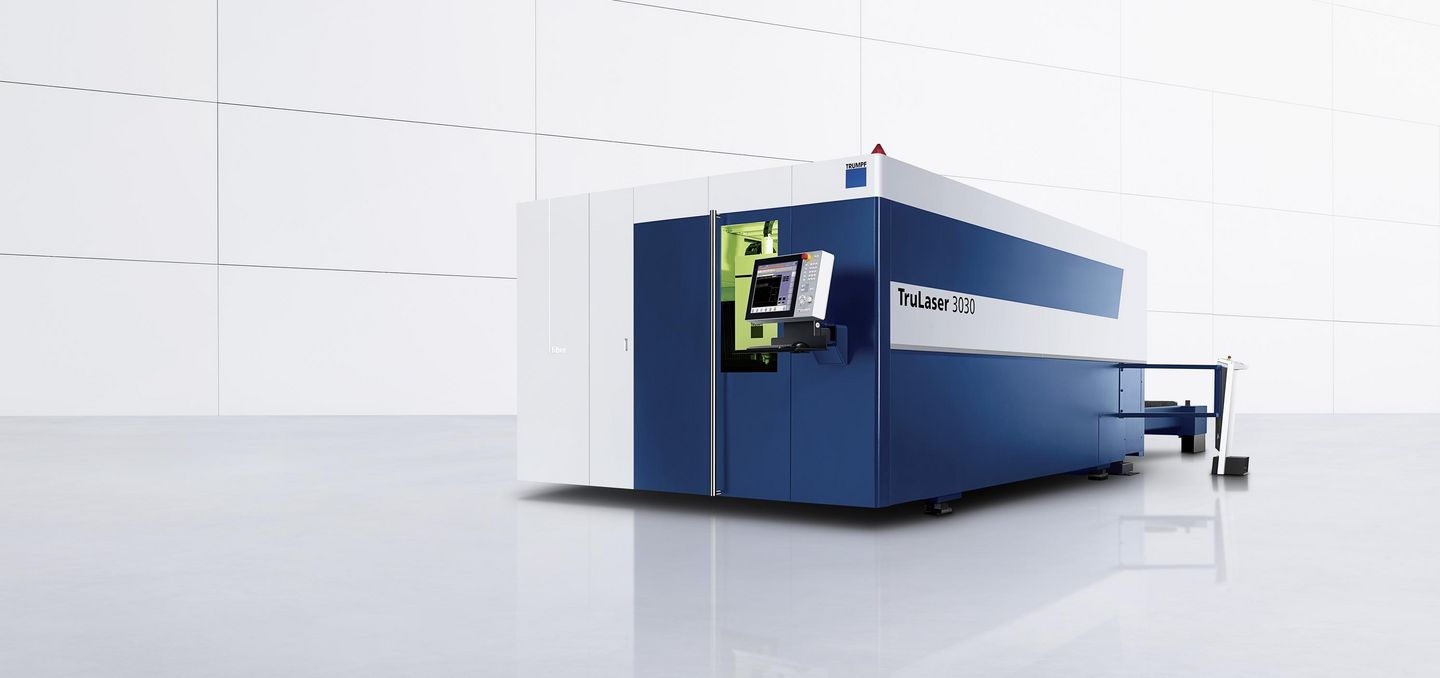

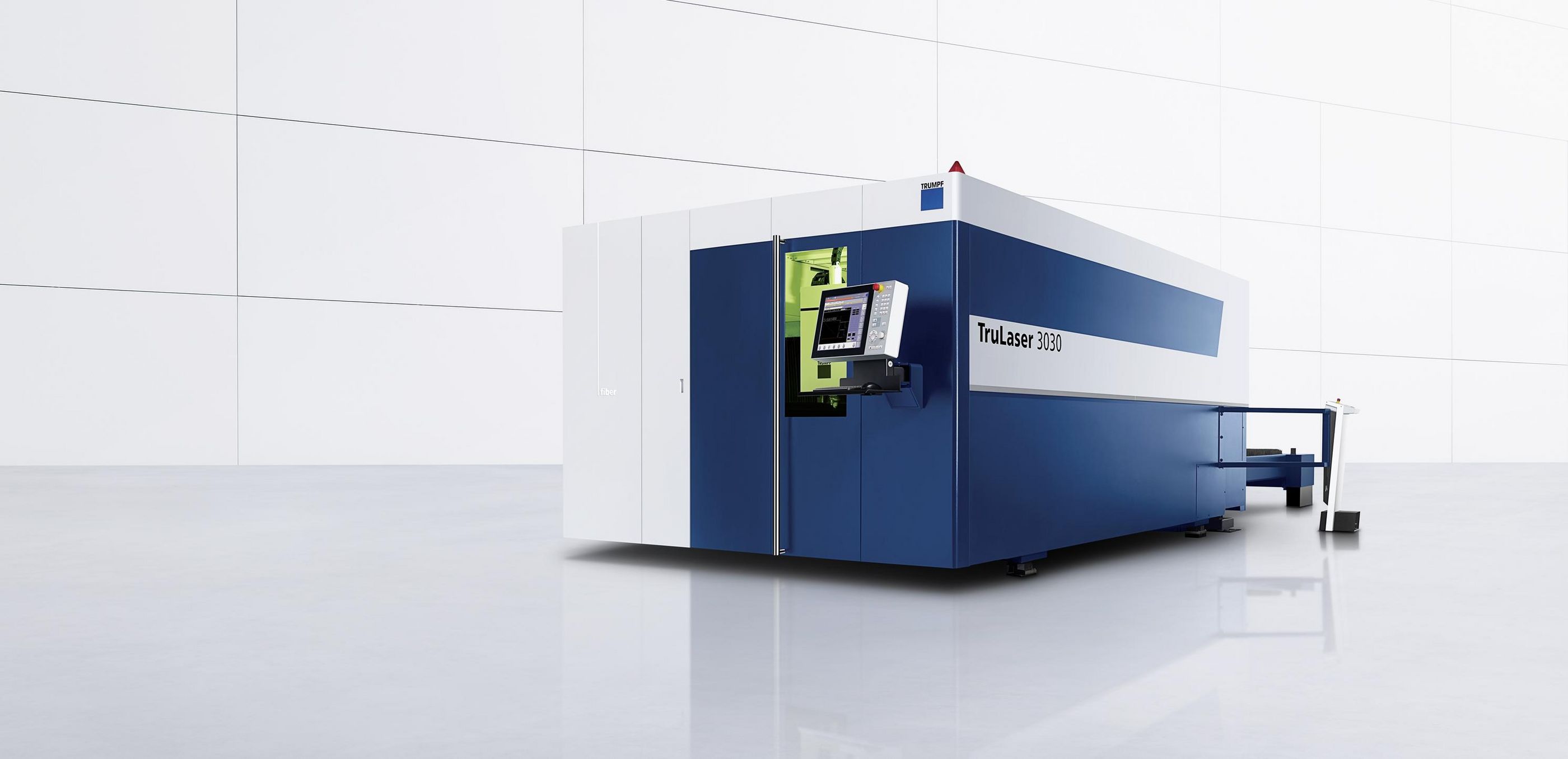

Flexible standard machine

The TruLaser 3030 fiber Prime Edition and the TruLaser 3040 fiber Prime Edition – fast machines for all of your cutting tasks. They impress with their high level of flexibility and cost-effectiveness: You can cut all sheet thickness profitably. The TruDisk solid-state laser enables the processing of non-ferrous metals and provides you with a productivity benefit in thin sheet. BrightLine fiber guarantees the highest edge quality and facilitates part removal. Numerous other functions ensure the highest reliability and performance possible.

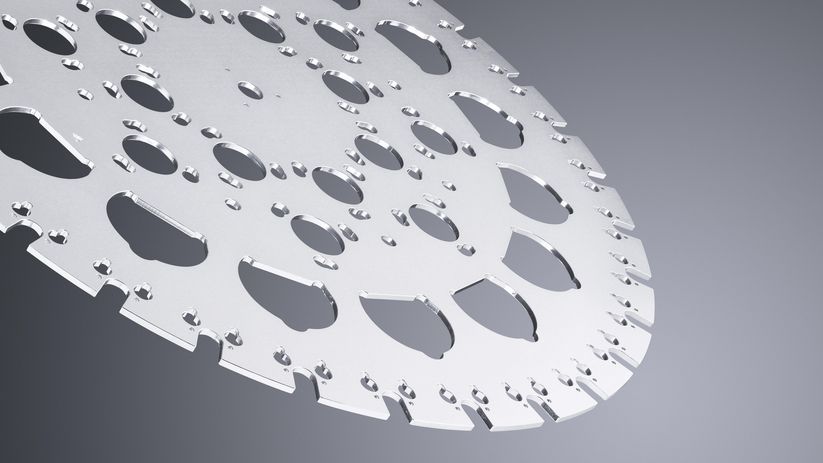

BrightLine fiber facilitates excellent part quality and seamless part removal.

Using Drop&Cut, you can easily post-produce parts from remainder sheets.

Thin mild steel part

Your TruLaser 3030 fiber Prime Edition cuts extremely quickly, particularly in thin sheet.

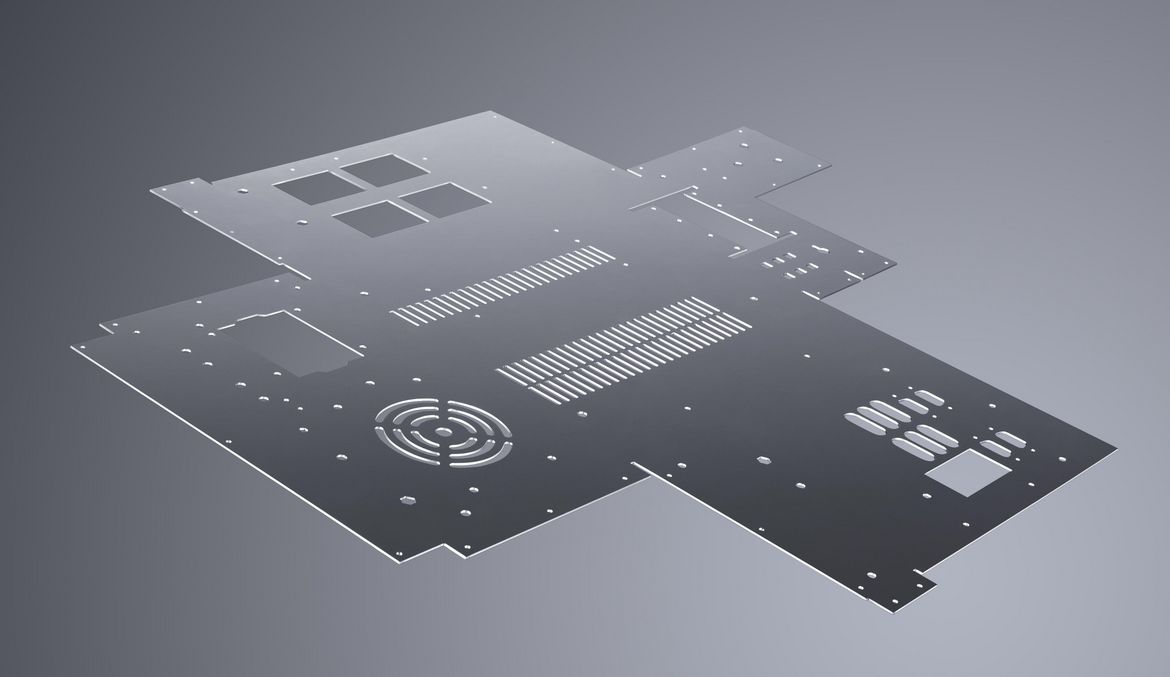

Parts which are easy to remove

With BrightLine fiber, a sophisticated combination of special optics, together with the flow-optimized BrightLine nozzles and other technical innovations, the TruLaser 3030 fiber / 3040 Prime Edition fiber provides the highest part quality. The highlight: Due to the high-quality cutting edges, parts do not get caught during removal. It is easy to remove the parts and you save a lot of time.

Cutting of all common materials

The construction of the TruDisk enables the processing of non-ferrous metals with nitrogen – without worrying about reflections. TRUMPF also makes the processing of film-coated sheets possible.

|

TruLaser 3030 fiber Prime Edition

|

TruLaser 3040 fiber Prime Edition

|

|

|---|---|---|

| Dimensions | ||

| Length | 13030 mm | 14480 mm |

| Width | 8050 mm | 8760 mm |

| Height | 2400 mm | 2400 mm |

| Maximum speed | ||

| Simultaneous | 140 m/min | 140 m/min |

| Working range | ||

| X axis | 3000 mm | 3000 mm |

| Y axis | 1500 mm | 1500 mm |

| Max. Werkstückgewicht | 900 kg | 1700 kg |

| Laser-specific data - TruDisk 3001 | ||

| Maximum laser power | 3000 W | 3000 W |

| Maximum sheet thickness, mild steel | 20 mm | 20 mm |

| Maximum sheet thickness, stainless steel | 15 mm | 15 mm |

| Maximum sheet thickness, aluminum | 15 mm | 15 mm |

| Maximum sheet thickness, copper | 6 mm | 6 mm |

| Maximum sheet thickness, brass | 6 mm | 6 mm |

| Laser-specific data - TruDisk 4001 | ||

| Maximum laser power | 4000 W | 4000 W |

| Maximum sheet thickness, mild steel | 25 mm | 25 mm |

| Maximum sheet thickness, stainless steel | 20 mm | 20 mm |

| Maximum sheet thickness, aluminum | 20 mm | 20 mm |

| Maximum sheet thickness, copper | 8 mm | 8 mm |

| Maximum sheet thickness, brass | 8 mm | 8 mm |

| Laser-specific data - TruDisk 6001 | ||

| Maximum laser power | 6000 W | 6000 W |

| Maximum sheet thickness, mild steel | 25 mm | 25 mm |

| Maximum sheet thickness, stainless steel | 25 mm | 25 mm |

| Maximum sheet thickness, aluminum | 25 mm | 25 mm |

| Maximum sheet thickness, copper | 10 mm | 10 mm |

| Maximum sheet thickness, brass | 10 mm | 10 mm |

| Consumption values | ||

| Average power input in production - TruDisk 3001 | 13 kW | 15 kW |

| Average power input in production - TruDisk 4001 | 14 kW | 14 kW |

| Average power input in production - TruDisk 6001 | 18 kW | 18 kW |

The technical data of all product versions as a download.

Process reliability

AdjustLine enables the easy adjustment of the cutting process to materials of different quality. The function increases process reliability, above all when cutting material of a poor quality. For you this means less scrap and lower material costs. The operator can switch AdjustLine on or off at any time – programming is not required.

Clean protective glass ensures high cut quality for the long term. A sensor permanently monitors the condition of the protective glass so that you know when it must be changed. Cleaning and replacement are only performed when required, saving costs.

Quality

BrightLine fiber turns the solid-state laser into a universal tool: The function provides you with high-quality cutting results over the entire sheet thickness range. Furthermore, all of the advantages of the solid-state laser are retained, in particular the high speeds, during thin sheet processing.

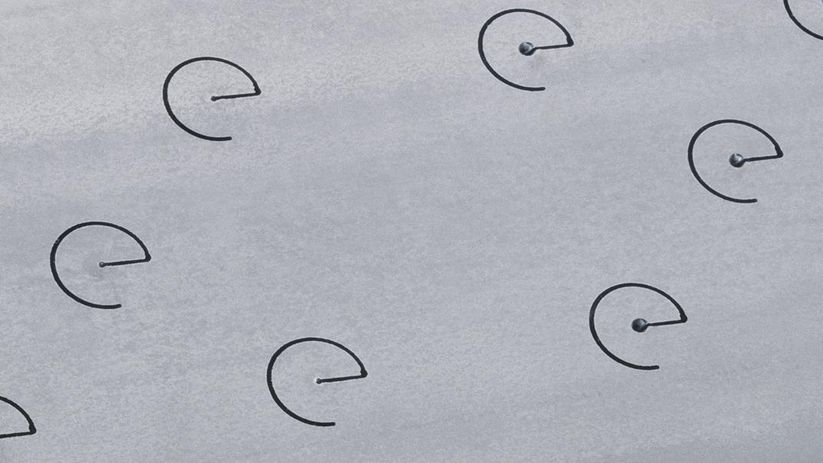

PierceLine monitors and controls the piercing process. This saves material and preserves the machine, increasing part quality and shortening the piercing time by up to 80%.

During fusion cutting in thin sheets, the innovative performance nozzles and the optimized cutting data of the performance package provide you with two advances at the same time: A jump forward in quality, and considerably higher productivity.

Productivity

Quick and economic – without compromising on quality: With Highspeed, you can set new records with the solid-state laser when it comes to cutting with nitrogen. As a result, you can almost double your sheet throughput for medium and thick mild steel and stainless steel sheets – the same goes for the feed rate. A special nozzle design also reduces your cutting gas consumption by up to 40%, and even prevents burr formation on contours with sharp edges.

Process interlinking and operator support

With Drop&Cut, remainder sheet is utilized more easily, intuitively, and efficiently. A camera ensures the live image of the machine interior appears directly on your user interface. You can position any number of part geometries on the remainder sheet. This saves time during the post-production of individual parts. Time-consuming process steps such as aligning the sheet, sheet position measurement or zero point displacement are not needed.

TruTops Boost

Construct and program your laser, punching, and combination punch laser machines intelligently with TruTops Boost, your all-in-one 3D solution. Numerous automated processes save you time-consuming routine processes and the joint nesting pool saves time and material. You also always have an overview of all manufacturing orders and order-based work.

TruTops Monitor

Reduce your idle time. Record and analyze machine data, including idle states, error messages, causes of malfunctions, and maintenance periods for all of your production workplaces. If an idle state or a malfunction occurs, TruTops Monitor will inform you immediately about the cause, allowing you to respond quickly.

Software

The extensive range of TruTops software supports you throughout the entire production process. Control your operational workflow in a simple and targeted manner, from managing your customer orders and purchasing processes to delivery of the produced parts. Through the direct coupling with the machine control, you can keep a constant eye on the status of your orders.

Choose the right automation components for your laser cutting machine from a large modular system. From semi-automatic loading to a fully automatic processing cell with storage connection, TRUMPF provides solutions which optimize your process chain.

Loading and unloading

The compact LiftMaster Compact loads and unloads your machine completely automatically and extremely fast. With the LiftMaster Linear Basic you have the option of multiple-machine connection.

Loading and unloading / Part sorting

The automation solution, LiftMaster, covers a broad range of functions. It loads and unloads, but is also suitable for pallet handling or part removal. The LiftMaster Sort also separates finished parts from the scrap skeleton. LiftMaster Store and LiftMaster Store Linear connect your system directly to the store. The SortMaster automatically sorts finished parts.

Loading and unloading / Part sorting

The LiftMaster Linear supplies material to up to three machines via a linear axis and provides storage options for cut sheet.

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price, and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.