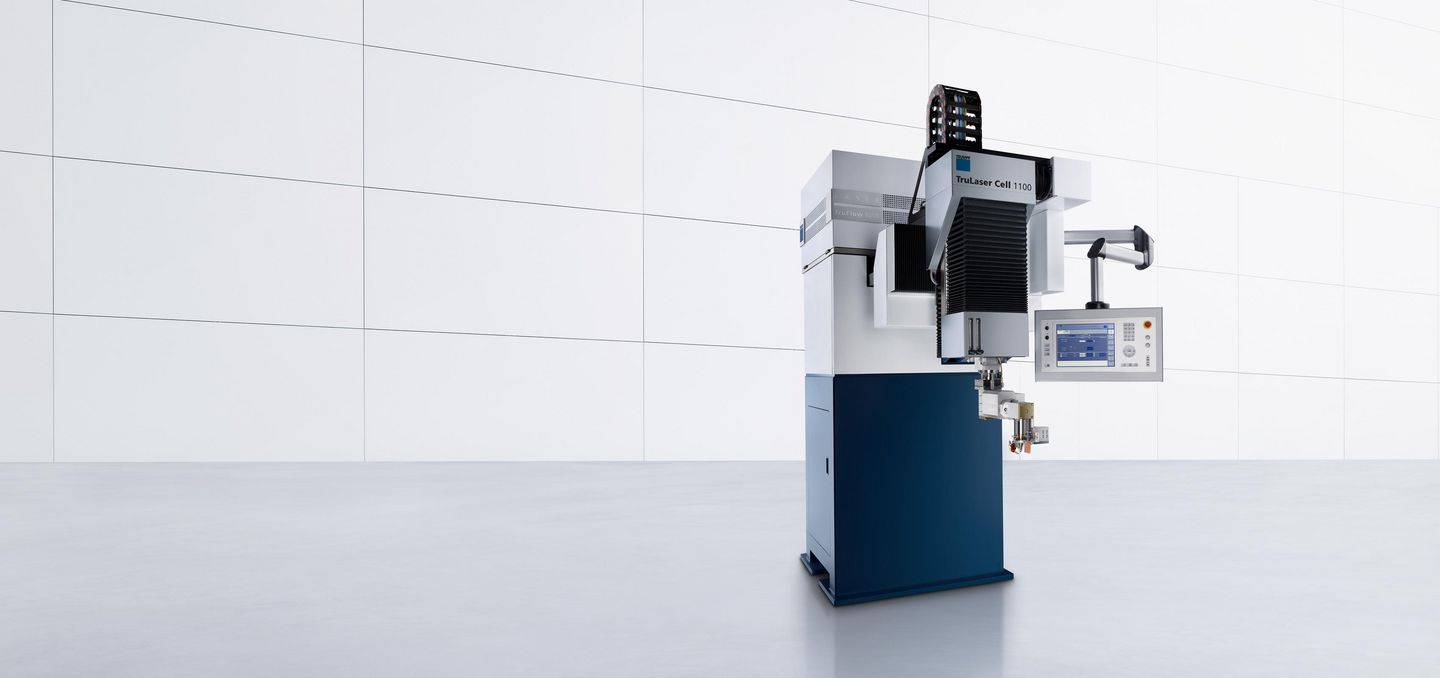

The TruLaser Cell 1100 impresses with its simple operation, different design variants and high welding speeds. Thanks to simple integration in roll forming systems, the TruLaser Cell 1100 facilitates your optimum introduction to laser tube welding.

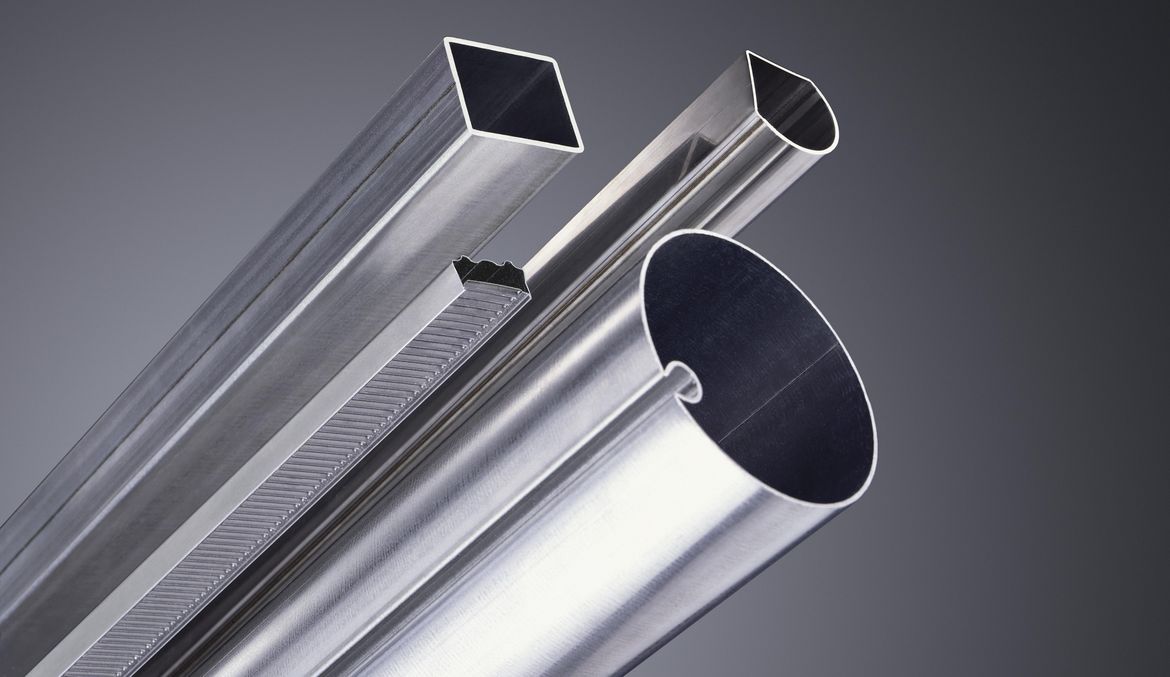

Expert for strips, tubes, and profiles

The TruLaser Cell 1100 is a flexible beam guidance system that you can integrate easily into your production line. It is specially designed for the endless welding of any seam geometry on strips, tubes, and profiles. You have a lot of freedom when it comes to the material. With the laser welding system you can weld steel, stainless steel, aluminum, and even non-ferrous metals, from a tenth of a millimeter up to several millimeters thick. The flexibility, quality, and reliability are increased through the wide range of welding optics with linear or swivel axes, as well as sensor systems for seam detection and tracking (e.g. SeamLine or SeamLine Pro). Depending on the application and material, either CO2 or solid-state lasers from TRUMPF are used.

Configure the machine that optimally adapts to you and your requirements.

State-of-the-art beam sources and sensor systems reduce operating costs and increase the speed.

The integrated operating panel ensures intuitive operation of your TruLaser Cell Series 1000.

The stroke of the linear axis, the working height, and the traverse paths adapt to your line.

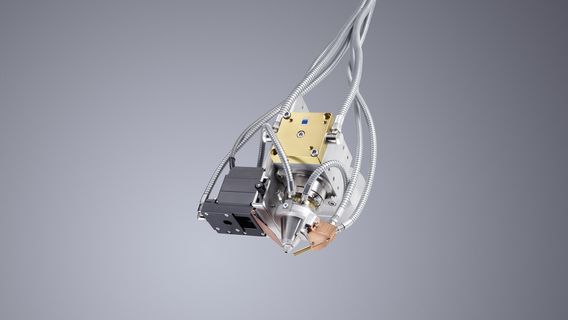

Welding optics with linear or swivel axes and sensor systems are the perfect addition to the machine.

Laser-welded profiles

The TruLaser Cell 1100 has been specially developed for the endless laser welding of tubes and profiles. Its compact structure enables it to be integrated problem-free into an existing profiling machine. The concept enables the tube/profile welding machine to be converted to various product geometries with minimal idle times. The solid structure and dust-proof encapsulated beam guidance system guarantee constant process conditions and maximum laser safety in an industrial environment.

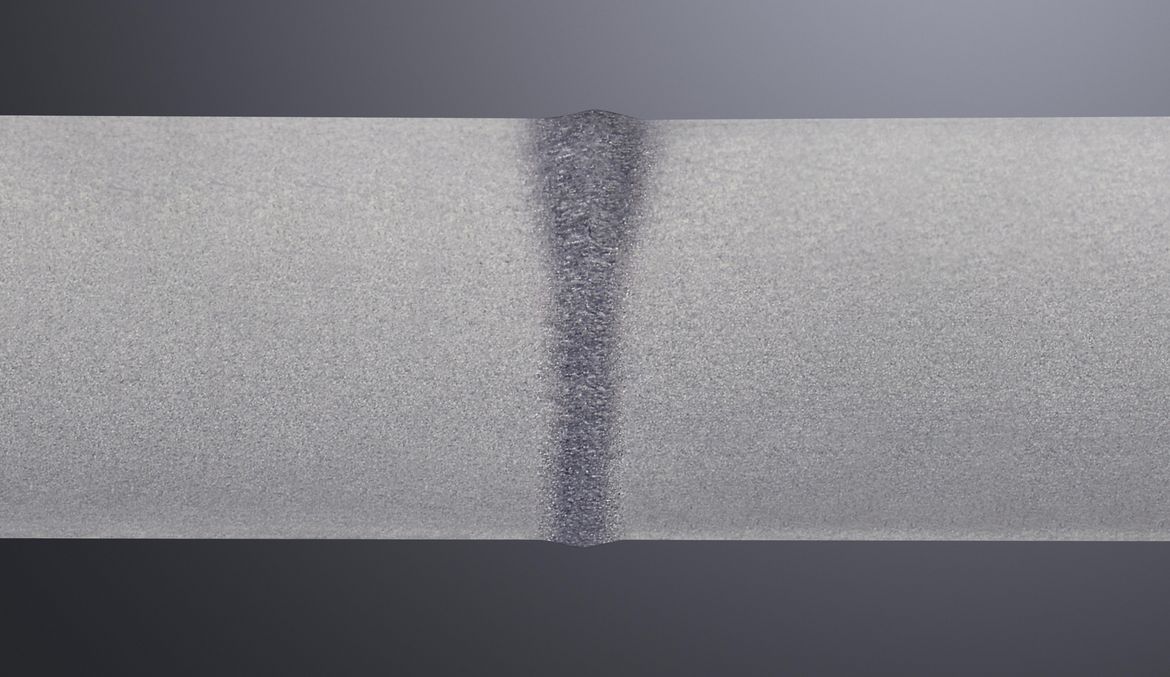

Leak-proof, non-porous weld seam

Due to the high beam quality of TRUMPF lasers and the resulting highly concentrated energy input to the workpiece, gas-tight and non-porous endless seams can be achieved without any melt deposits on the inside and outside walls of the tube.

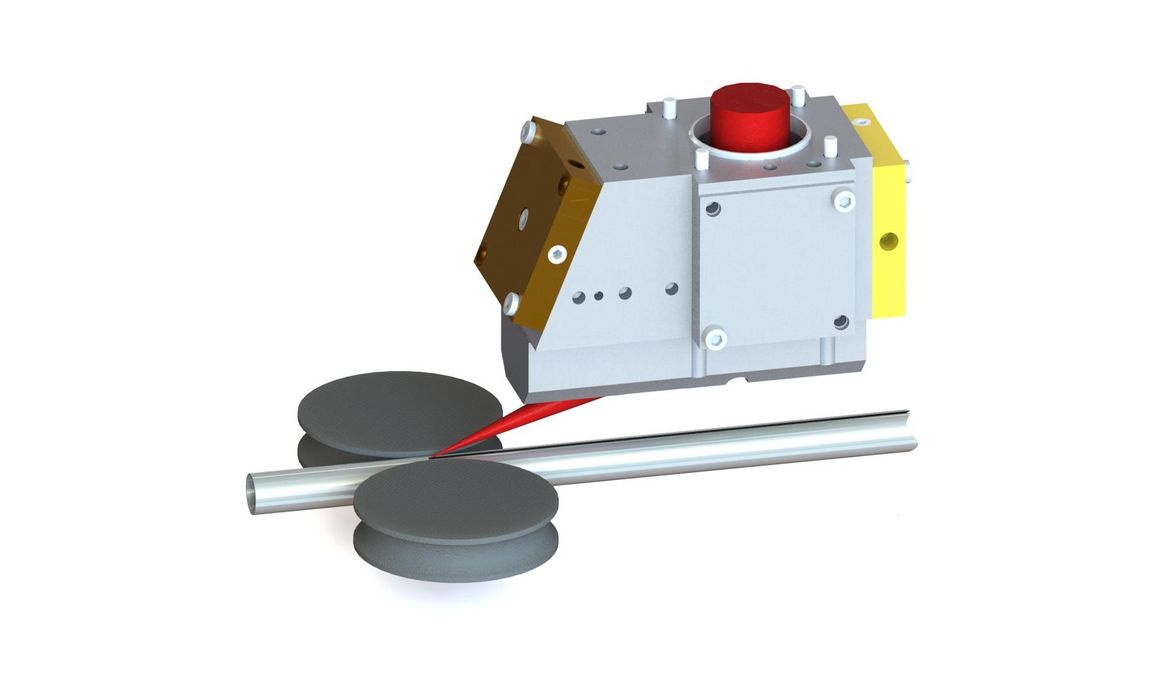

Highly productive heat conduction welding with SpeedLas

For thin materials up to 0.016 in., the SpeedLas optics from TRUMPF enable the highest process speeds. Using heat conduction welding, the physical effects of the so-called "Brewster angle" are used to obtain impressive increases in productivity.

|

TruLaser Cell 1100 (CO2-Laser)

|

TruLaser Cell 1100

|

|

|---|---|---|

| Axis travel range | ||

| X axis travel range | 300/500 mm | 300/500 mm |

| Z axis travel range | 300/500 mm | 300/500 mm |

| B axis travel range | ± 100 ° | ± 100 ° |

| Q axis travel range (weld joint position correction) | ± 25 mm | ± 25 mm |

| Maximum axis speeds | ||

| Maximum axis speed, axially parallel in X | 30 m/min | 30 m/min |

| Maximum axis speed, axially parallel in Z | 30 m/min | 30 m/min |

| Maximum axis speed of Q axis (weld joint position correction) | 3 m/min | 3 m/min |

| Maximum axis accelerations | ||

| Maximum axis acceleration, axially parallel in X | 1.5 m/s2 | 1.5 m/s2 |

| Maximum axis acceleration, axially parallel in Z | 1.5 m/s2 | 1.5 m/s2 |

| Maximum axis acceleration of B axis | 1.5 rad/s2 | 1.5 rad/s2 |

| Positioning accuracy | ||

| Positioning accuracy of linear axes (X, Z) | 0.1 mm | 0.1 mm |

| Positioning accuracy of rotary axes (B) | 0.015 ° | 0.015 ° |

| Laser | ||

| Maximum laser power | 3200 W - 15000 W | 2000 W - 8000 W |

| Available lasers | TruFlow | TruDiode, TruDisk |

The technical data of all product versions as a download.

The TLS mirror focusing optics have a clear aperture of 50 mm, as well as a special linear axis in order to define the position of the laser beam on the workpiece. The optics are equipped with welding nozzles to the coaxial and lateral gas supply. The focal lengths of the focusing mirror range from f = 100 mm to f = 300 mm.

Large working distances with small focal diameters – the BEO D70.

SeamLine takes care of seam position control for TRUMPF laser systems. The system reliably detects gaps or edges with an alternating incident light and light section procedure.

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price, and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.