Individualized series production of high-quality implants is a main application area for additive manufacturing in medical technology. Individualized patient solutions require prompt delivery of the implant to the operating room. The complete manufacturing process, including data generation using imaging techniques (CT scan), 3D printing and post-processing, usually takes up to a week. Availability can however be improved by adding a second laser to the TruPrint 2000. The multilaser option increases productivity and can have a positive effect on the cost per part. Manufacturing medical technology products, particularly products from risk class III, requires qualified equipment and a validated process. TRUMPF offers extended services which support customers working in certified environments in questions of equipment qualification and process validation. The latest developments in process monitoring and a sophisticated concept for powder handling and preparation also contributes to the process and the quality of the powder and component.

Additive manufacturing of personalized implants for craniofacial applications

Tumour patients and patients with congenital or acquired malformations caused by trauma or atrophy often benefit greatly from an individualized patient solution (IPS). Additive manufacturing now makes it possible to produce high-quality implants with fast availability at acceptable costs – even for one-off lot sizes. Optimum patient care is guaranteed. The implants are based on the patient's anatomical data, which means faster recovery and significantly fewer surgical procedures. In many cases, the implant can even be subjected to loads immediately after surgery.

One-off medical devices can be produced cost-effectively. TruPrint machines and systems provide the ability to scale your production from one-off to mass-produced medical devices.

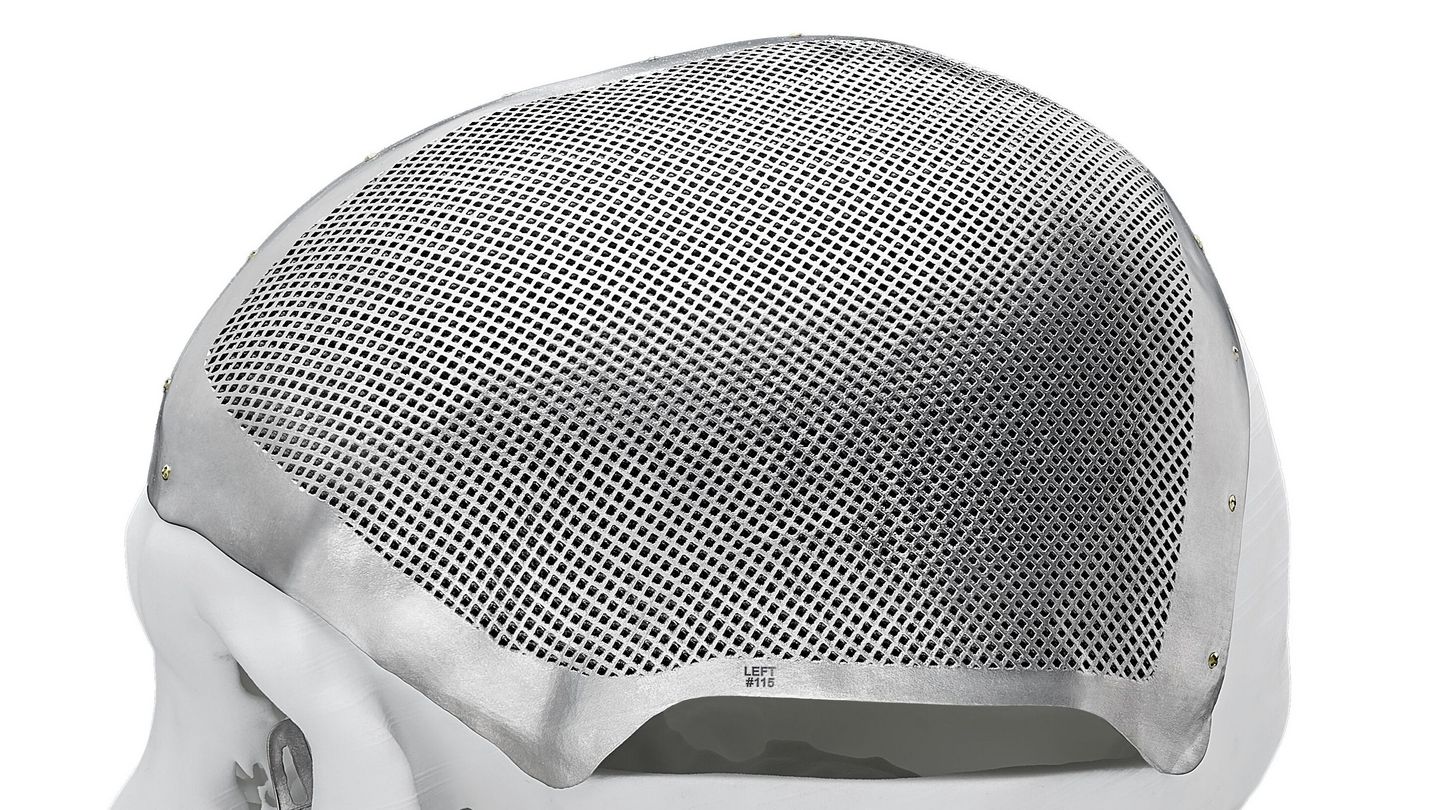

Benefit from individualized part design adapted to the patient's anatomy. Lattice and porous structures can also be incorporated into the implant to improve fluid and heat exchange.

Additive manufacturing enables the patient's anatomy to be reconstructed without bone augmentation. This means fewer surgical procedures and therefore less stress for the patient.

One-off productions can be manufactured on request within a short period of time to get them promptly to the operating room.

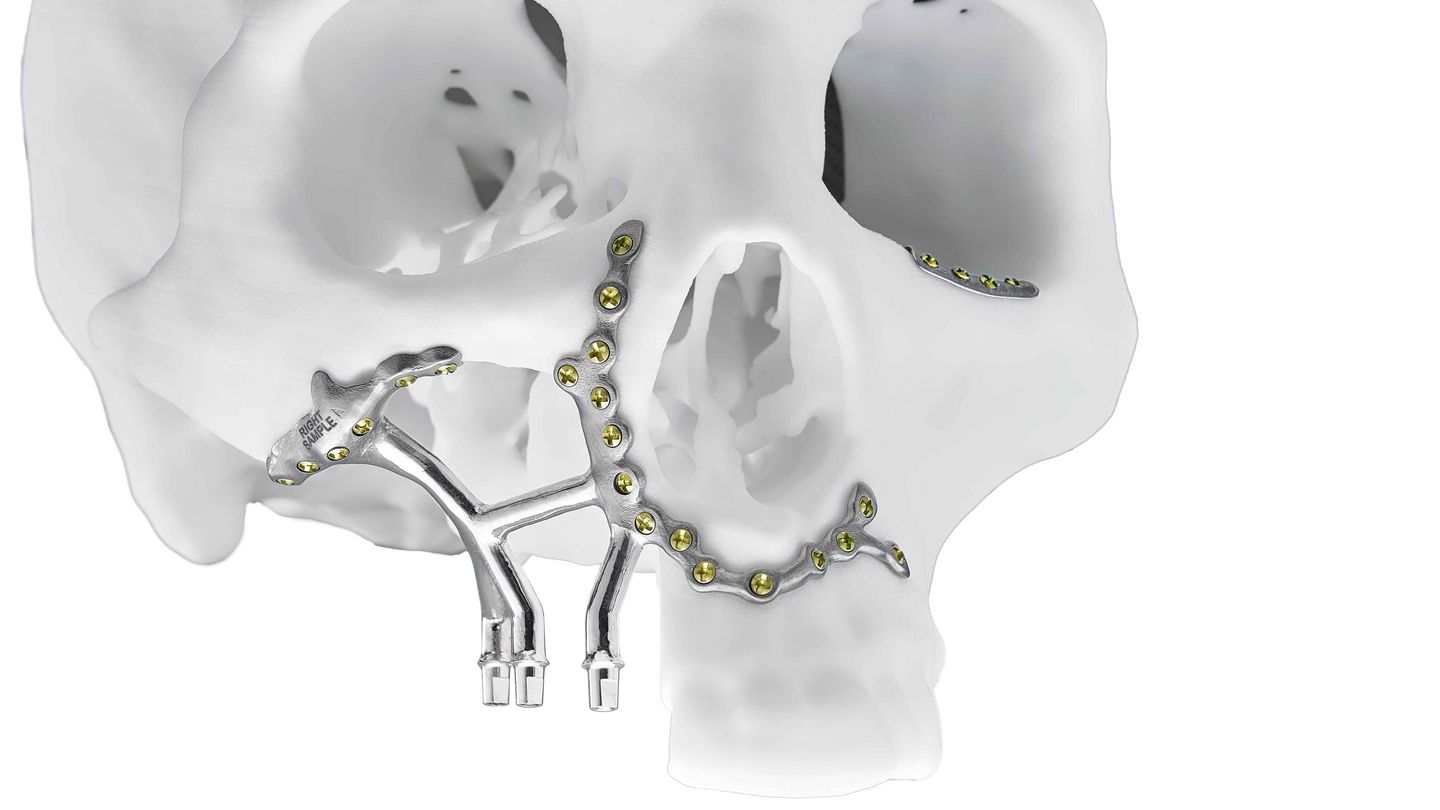

Examples of personalized implants in oral and maxillofacial surgery

How is a CMF implant created using laser metal fusion?

Arrange your consultation today!

Do you also have a component that would be a good candidate for additive manufacturing? Would you like to know what savings and advantages you can benefit from with additive manufacturing? Then get in touch with us today to arrange an individual consultation with our experts.

Component facts & figures

- Component dimensions: Jaw implant: 176 mm x 94 mm x 135 mm, Pre-prosthetic implant: 55 mm x 55 mm x 55 mm, Orbital implant: 41 mm x 18 mm x 34 mm

- Total build time (all components / substrate plate): 29 h (multilaser), 44 h (single laser)

- Layer thickness: 30 µm

- Number of layers: 4677

- Weight: Jaw implant: 113 g, Pre-prosthetic implant: 10 g, Orbital implant: 1 g

- Volume: Jaw implant: 25.5 cm³, Pre-prosthetic implant: 2.3 cm³, Orbital implant: 0.3 cm³

- Customer: KARL LEIBINGER MEDIZINTECHNIK, a KLS Martin Group company