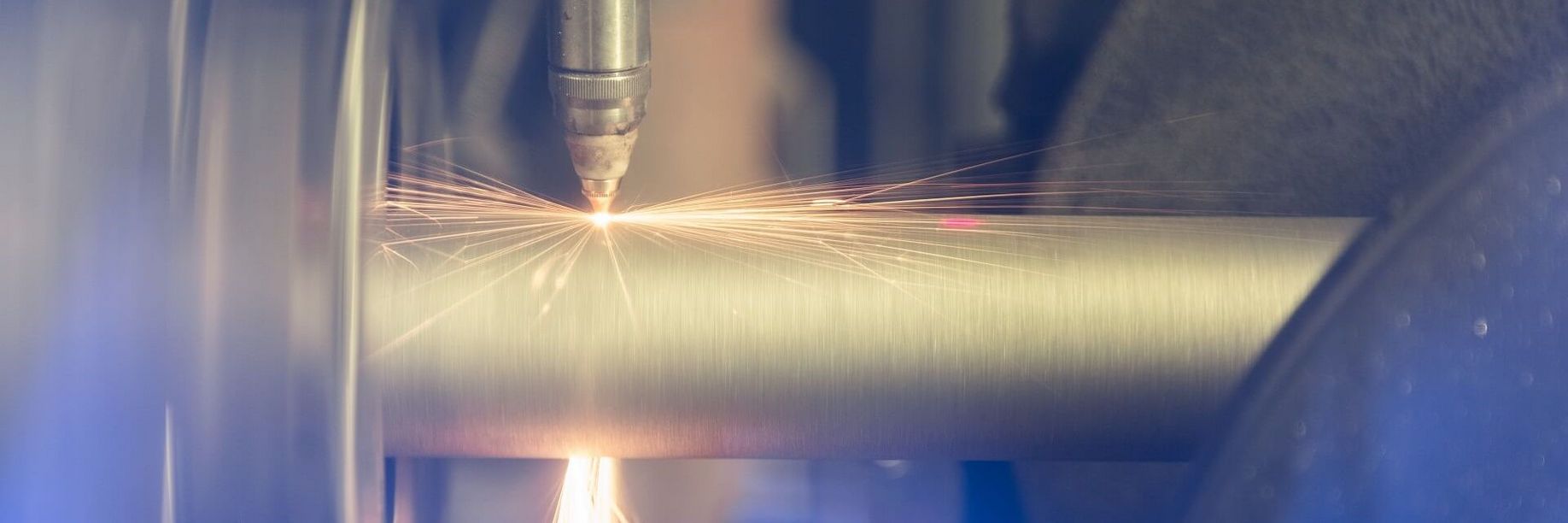

Ob gedruckt oder digital: Tauchen Sie mit unseren Kundenmagazinen noch tiefer ein in die Blech- und Laserwelt, Produktentwicklungen oder Geschichten von Anwendern auf der ganzen Welt.

Pressemitteilungen

Quicklinks

Social Media

Sie möchten sich unsere Social Media Wall ansehen?

Unsere Social Media Wall wird Ihnen nicht angezeigt, da Sie unseren Cookies nicht zugestimmt haben. Bitte passen Sie Ihre Privatsphäre-Einstellungen an.

TRUMPF Magazine