Von der Kleinserienfertigung bis zur 24/7-Produktion: der TruDisk bietet immer das beste Preis-Leistungs-Verhältnis. Die TruDisk S Serie versorgt bis zu vier Maschinen oder Prozesszellen – maximale Auslastung der Anlagen im Dauerbetrieb garantiert. Darüber hinaus erhalten Sie mit der TruDisk P Serie die optimale Lösung für die Versorgung einer einzelnen Maschine bei Standardauslastung. Wählen Sie so den passenden Laser für Ihre Produktionsanforderung.

Hochleistungsfestkörperlaser

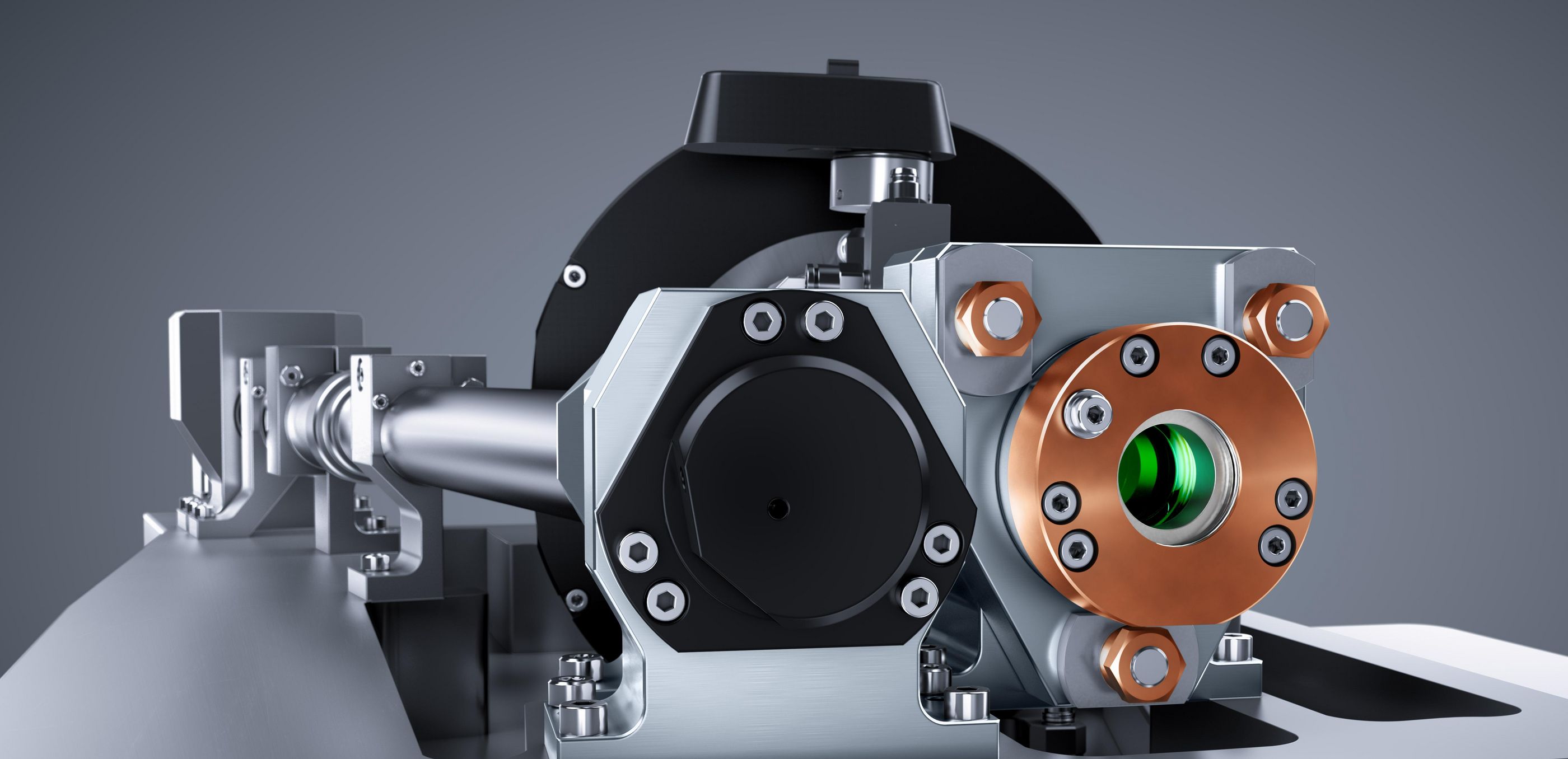

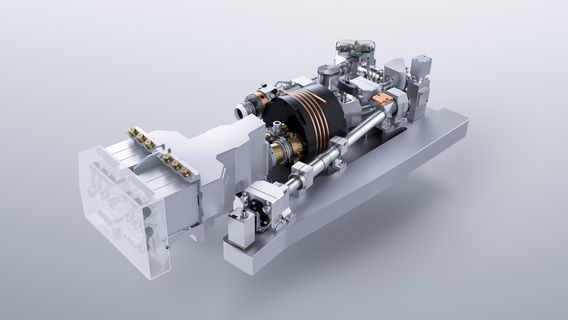

Der TruDisk ist ein Hochleistungsfestkörperlaser zum Schweißen, Schneiden und zur Oberflächenbearbeitung von Metallen. Er überzeugt vor allem dort, wo hohe Leistung bei gleichzeitig höchster Strahlqualität gefragt ist. Die neue Generation der TruDisk Laser bietet Ihnen vor allem durch die deutlich kompaktere Aufstellfläche und die nochmals gesteigerte Robustheit große Vorteile. Zudem besitzt sie ein intelligentes Innenleben. Die Datenqualität der Sensoren, welche im Laser alle wichtigen Parameter überwachen, wurde signifikant erhöht, sodass die neuen TruDisk Laser optimal für zukünftige Industrie 4.0-Services wie das Condition Monitoring vorbereitet sind. Dank erhöhtem Wirkungsgrad, neuer energieeffizienter Pulsfunktion und intelligentem Energiemanagement arbeitet der TruDisk in allen Zuständen des Lasers sparsam.

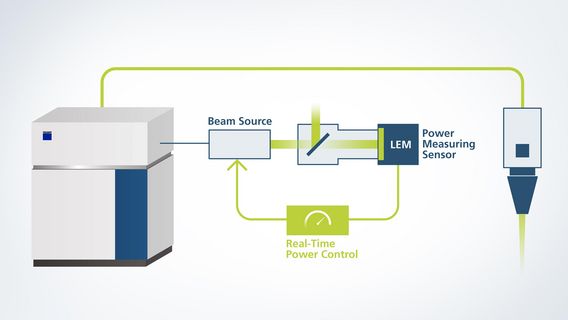

Stabile Prozesse durch integrierte, aktive Laserleistungsregelung sorgen für reproduzierbare Ergebnisse.

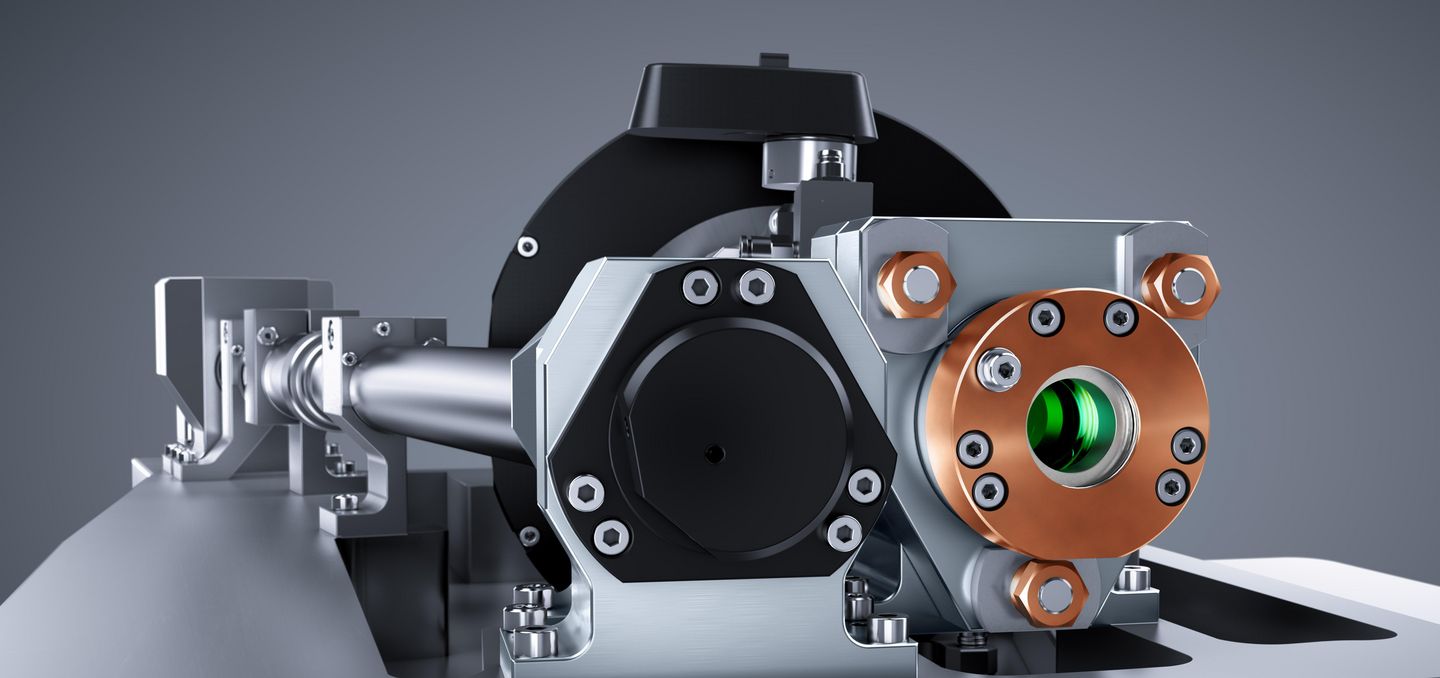

Die Scheibe als Lasermedium sorgt beim TruDisk für brillante Strahlqualität bis zu 2 mm·mrad.

Dank patentiertem Resonatordesign bearbeitet Ihr TruDisk auch hochreflektierende Materialien.

Mehrere Energiesparmodi und die Leistungsfaktorkorrektur senken den Strombedarf.

Wählen Sie zwischen integriertem Wärmetauscher (Standard)und Kompressorkühler (Option).

Mit BrightLine Weld erzielen Sie hochqualitative Schweißnähte bei minimaler Spritzerbildung.

Tiefschweißen

Der Hochleistungslaser TruDisk eignet sich für zahlreiche Anwendungen in der Automobilindustrie wie z.B. beim Antriebsstrang – hier ein Schaltrad. Die Anforderungen an Genauigkeit und Reproduzierbarkeit der Schweißergebnisse sind hier besonders hoch. Dank exakt einstellbarer und überwachter Laserleistung meistert der Scheibenlaser dies spielend.

Schneiden unterschiedlichster Materialien und Blechdicken

Laserschneiden ermöglicht nahezu jede – auch filigrane bzw. komplexe – Konturform ohne Werkzeugwechsel. Die Kanten sind glatt und gratfrei, weshalb die Nachbearbeitung entfällt. Dank kleiner Wärmeeinflusszone entsteht überdies kaum Verzug. Der TruDisk schneidet eine Vielzahl von Blechdicken und Materialarten – sogar hochreflektierende Buntmetalle.

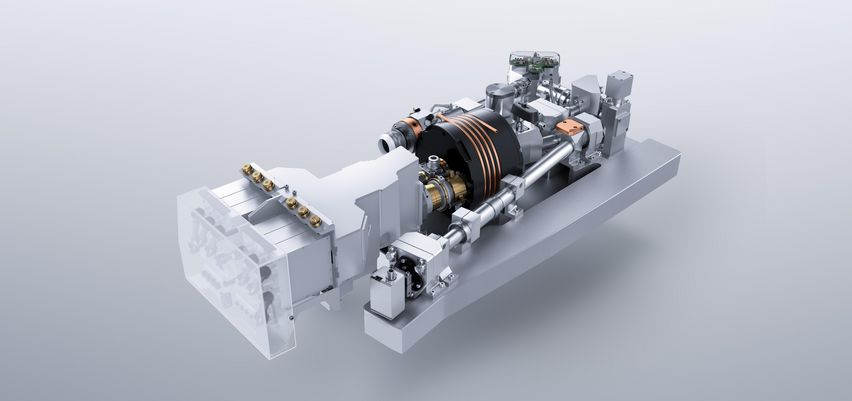

Scannerschweißen einer Automobiltür

Im Zusammenspiel mit Fokussieroptiken z. B. der programmierbaren Fokussieroptik PFO 3D dienen TruDisk Laser als Strahlquelle für das Scannerschweißen. Bei diesem Verfahren lenken bewegliche Spiegel den Laserstrahl. Winkeländerungen führen den Strahl über das Werkstück. Es entsteht ein Bearbeitungsfeld, in dem hochdynamisch und präzise geschweißt werden kann. Durch die sehr schnellen Versatzbewegungen der Spiegel entfallen Nebenzeiten nahezu vollständig und das Lasergerät kann in fast 100 Prozent der verfügbaren Fertigungszeit produzieren.

Hybridschweißen von riesigen Schiffsdecks

Das Laser-Hybridschweißen verbindet selbst dicke Bleche von bis zu 20 mm mit großen Fügespalten. Der TruDisk ist unempfindlich gegenüber Rückreflexionen, die anderen Lasern hier Probleme bereiten würden und eignet sich daher hervorragend für diese Anwendung. Typische Einsatzgebiete des Hybridschweißens finden sich im Automobilbau, Schiffbau, Kranbau, Schwermaschinenbau, Baumaschinen und in vielen anderen Bereichen.

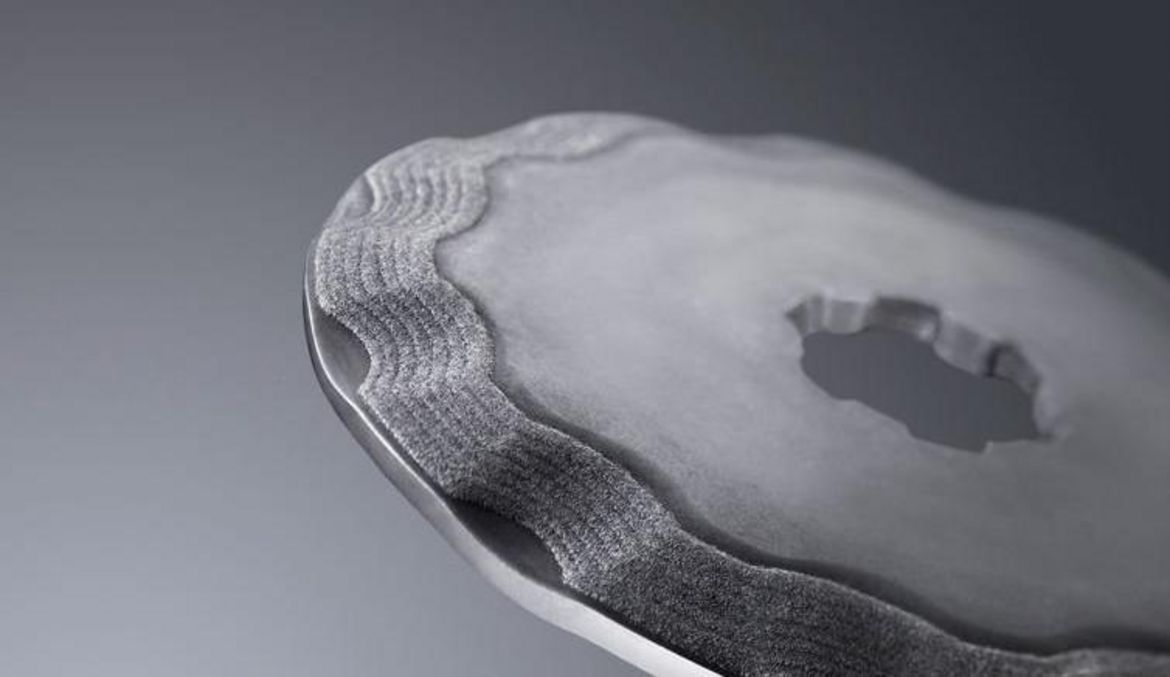

Häckselscheibe mit auftragsgeschweißter Kontur

Ist ein Bauteil hohen Temperaturen, Druck, Abrieb oder Feuchtigkeit ausgesetzt, müssen spezielle Materialien zum Einsatz kommen. Dabei muss aber nicht immer das ganze Bauteil aus dem entsprechenden Material bestehen. Es reicht eine mittels Auftragsschweißen aufgebrachte Schutzschicht am Rand der Belastungszone. Wie hier zu sehen bei einer Häckselscheibe. Der Laser erzeugt beim Laserauftragsschweißen ein Schmelzbad auf der Oberfläche des Bauteils. Durch eine Düse wird Matallpulver Spur um Spur zugeführt, bis die gewünschte Schichtdicke erreicht ist.

Laserauftragschweißen als additives Fertigungsverfahren

Beim Laserauftragschweißen (kurz LMD für Laser Metal Deposition) erzeugt der Laser auf der Bauteiloberfläche ein Schmelzbad. Durch eine Düse wird Metallpulver automatisiert eingebracht. Es entstehen miteinander verschweißte Raupen, die Strukturen an bestehenden Grundkörpern oder ganzen Bauteile aufbauen. Hier wird eine Förderschnecke mittels LMD auf ein Rohr Schicht um Schicht aufgetragen. Im Vergleich zu anderen generativen Verfahren sind bei LMD die Aufbauraten und damit das Prozesstempo hoch.

|

TruDisk 1000

Produkt vergleichen

|

TruDisk 2000

Produkt vergleichen

|

TruDisk 3000

Produkt vergleichen

|

TruDisk 3001

Produkt vergleichen

|

TruDisk 3001 P

Produkt vergleichen

|

TruDisk 3002

Produkt vergleichen

|

TruDisk 3006

Produkt vergleichen

|

TruDisk 4000

Produkt vergleichen

|

TruDisk 4001

Produkt vergleichen

|

TruDisk 4001 P

Produkt vergleichen

|

TruDisk 4002

Produkt vergleichen

|

TruDisk 4006

Produkt vergleichen

|

TruDisk 5000

Produkt vergleichen

|

TruDisk 5001

Produkt vergleichen

|

TruDisk 5002

Produkt vergleichen

|

TruDisk 5006

Produkt vergleichen

|

TruDisk 6000

Produkt vergleichen

|

TruDisk 6001

Produkt vergleichen

|

TruDisk 6001 P

Produkt vergleichen

|

TruDisk 6002

Produkt vergleichen

|

TruDisk 6006

Produkt vergleichen

|

TruDisk 8000

Produkt vergleichen

|

TruDisk 8001

Produkt vergleichen

|

TruDisk 8002

Produkt vergleichen

|

TruDisk 10001

Produkt vergleichen

|

TruDisk 12001

Produkt vergleichen

|

TruDisk 16001

Produkt vergleichen

|

TruDisk 20001

Produkt vergleichen

|

TruDisk 24001

Produkt vergleichen

|

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Laserparameter | |||||||||||||||||||||||||||||

| Laserleistung | 1000 W 1 | 2000 W 1 | 3000 W 1 | 3000 W 1 | 3000 W 1 | 3000 W 1 | 3000 W 1 | 4000 W 1 | 4000 W 1 | 4000 W 1 | 4000 W 1 | 4000 W 1 | 5000 W 1 | 5000 W 1 | 5000 W 1 | 5000 W 1 | 6000 W 1 | 6000 W 1 | 6000 W 1 | 6000 W 1 | 6000 W 1 | 8000 W 1 | 8000 W 1 | 8000 W 1 | 10000 W 1 | 12000 W 1 | 16000 W 1 | 20000 W 1 | 24000 W 1 |

| Typ. Leistungskonstanz bei Nennleistung über 8 Std. bei konstanter Umgebungstemperatur | ± 0,5 % | ± 0,5 % | ± 0,5 % | ± 0,5 % | ± 1 % | ± 0,5 % | ± 0,5 % | ± 0,5 % | ± 0,5 % | ± 1 % | ± 0,5 % | ± 0,5 % | ± 0,5 % | ± 0,5 % | ± 0,5 % | ± 0,5 % | ± 0,5 % | ± 0,5 % | ± 1 % | ± 0,5 % | ± 0,5 % | ± 0,5 % | ± 0,5 % | ± 0,5 % | ± 0,5 % | ± 0,5 % | ± 0,5 % | ± 0,5 % | ± 0,5 % |

| Max. Leistungskonstanz bei Nennleistung über 8 Std. bei konstanter Umgebungstemperatur | ± 1 % | ± 1 % | ± 1 % | ± 1 % | ± 2 % | ± 1 % | ± 1 % | ± 1 % | ± 1 % | ± 2 % | ± 1 % | ± 1 % | ± 1 % | ± 1 % | ± 1 % | ± 1 % | ± 1 % | ± 1 % | ± 2 % | ± 1 % | ± 1 % | ± 1 % | ± 1 % | ± 1 % | ± 1 % | ± 1 % | ± 1 % | ± 1 % | ± 1 % |

| Kontinuierlich einstellbarer Leistungsbereich | 60 W - 1000 W bei aktiver Leistungsregelung | 60 W - 2000 W bei aktiver Leistungsregelung | 80 W - 3000 W bei aktiver Leistungsregelung | 80 W - 3000 W bei aktiver Leistungsregelung | - | 80 W - 3000 W bei aktiver Leistungsregelung | 80 W - 3000 W bei aktiver Leistungsregelung | 80 W - 4000 W bei aktiver Leistungsregelung | 80 W - 4000 W bei aktiver Leistungsregelung | - | 80 W - 4000 W bei aktiver Leistungsregelung | 80 W - 4000 W bei aktiver Leistungsregelung | 100 W - 5000 W bei aktiver Leistungsregelung | 120 W - 5000 W bei aktiver Leistungsregelung | 120 W - 5000 W bei aktiver Leistungsregelung | 120 W - 5000 W bei aktiver Leistungsregelung | 120 W - 6000 W bei aktiver Leistungsregelung | 120 W - 6000 W bei aktiver Leistungsregelung | - | 120 W - 6000 W bei aktiver Leistungsregelung | 120 W - 6000 W bei aktiver Leistungsregelung | 160 W - 8000 W bei aktiver Leistungsregelung | 160 W - 8000 W bei aktiver Leistungsregelung | 160 W - 8000 W bei aktiver Leistungsregelung | 200 W - 10000 W bei aktiver Leistungsregelung | 240 W - 12000 W bei aktiver Leistungsregelung | 320 W - 16000 W bei aktiver Leistungsregelung | 400 W - 20000 W bei aktiver Leistungsregelung | 480 W - 24000 W bei aktiver Leistungsregelung |

| Strahlqualität an der Einkopplung in das LLK | 2 mm▪mrad | 2 mm▪mrad | 2 mm▪mrad | 4 mm▪mrad | 4 mm▪mrad | 8 mm▪mrad | 25 mm▪mrad | 2 mm▪mrad | 4 mm▪mrad | 4 mm▪mrad | 8 mm▪mrad | 25 mm▪mrad | 2 mm▪mrad | 4 mm▪mrad | 8 mm▪mrad | 25 mm▪mrad | 2 mm▪mrad | 4 mm▪mrad | 4 mm▪mrad | 8 mm▪mrad | 25 mm▪mrad | 2 mm▪mrad | 4 mm▪mrad | 8 mm▪mrad | 4 mm▪mrad | 4 mm▪mrad | 4 mm▪mrad | 4 mm▪mrad | 4 mm▪mrad |

| Numerische Apertur an der Auskopplung nach LLK | 0,1 | 0,1 | 0,1 | 0,1 | 0,1 | 0,1 | 0,1 | 0,1 | 0,1 | 0,1 | 0,1 | 0,1 | 0,1 | 0,1 | 0,1 | 0,1 | 0,1 | 0,1 | 0,1 | 0,1 | 0,1 | 0,1 | 0,1 | 0,1 | 0,1 | 0,1 | 0,1 | 0,1 | 0,1 |

| Wellenlänge | 1030 nm | 1030 nm | 1030 nm | 1030 nm | 1030 nm | 1030 nm | 1030 nm | 1030 nm | 1030 nm | 1030 nm | 1030 nm | 1030 nm | 1030 nm | 1030 nm | 1030 nm | 1030 nm | 1030 nm | 1030 nm | 1030 nm | 1030 nm | 1030 nm | 1030 nm | 1030 nm | 1030 nm | 1030 nm | 1030 nm | 1030 nm | 1030 nm | 1030 nm |

| Min. Durchmesser Laserlichtkabel | 50 μm | 50 μm | 50 μm | 100 μm | 100 μm | 200 μm | 600 μm | 50 μm | 100 μm | 100 μm | 200 μm | 600 μm | 50 μm | 100 μm | 200 μm | 600 μm | 50 μm | 100 μm | 100 μm | 200 μm | 600 μm | 50 μm | 100 μm | 200 μm | 100 μm | 100 μm | 100 μm | 100 μm | 100 μm |

| Bauform | |||||||||||||||||||||||||||||

| Breite | 1175 mm | 1175 mm | 1175 mm | 1175 mm | 1175 mm | 1175 mm | 1175 mm | 1175 mm | 1175 mm | 1175 mm | 1175 mm | 1175 mm | 1175 mm | 1175 mm | 1175 mm | 1175 mm | 1620 mm | 1175 mm | 1175 mm | 1175 mm | 1175 mm | 1620 mm | 1175 mm | 1175 mm | 1620 mm | 1620 mm | 2150 mm | 2150 mm | 2150 mm |

| Höhe | 1430 mm | 1430 mm | 1430 mm | 1430 mm | 1430 mm | 1430 mm | 1430 mm | 1430 mm | 1430 mm | 1430 mm | 1430 mm | 1430 mm | 1430 mm | 1430 mm | 1430 mm | 1430 mm | 1475 mm | 1430 mm | 1430 mm | 1430 mm | 1430 mm | 1475 mm | 1430 mm | 1430 mm | 1475 mm | 1475 mm | 1600 mm | 1600 mm | 1600 mm |

| Tiefe | 725 mm | 725 mm | 725 mm | 725 mm | 725 mm | 725 mm | 725 mm | 725 mm | 725 mm | 725 mm | 725 mm | 725 mm | 725 mm | 725 mm | 725 mm | 725 mm | 920 mm | 725 mm | 725 mm | 725 mm | 725 mm | 920 mm | 725 mm | 725 mm | 920 mm | 920 mm | 1200 mm | 1200 mm | 1200 mm |

| Max. Anzahl Laserlichtkabel | 2 | 2 | 2 | 2 | 1 | 2 | 2 | 2 | 2 | 1 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 1 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| Max. Anzahl Laserlichtkabel bei Gerätegröße Extended | 4 | 4 | 4 | 4 | - | 4 | 4 | 4 | 4 | - | 4 | 4 | 4 | 4 | 4 | 4 | - | 4 | - | 4 | 4 | - | 4 | 4 | - | - | - | - | - |

| Aufstellung | |||||||||||||||||||||||||||||

| Schutzart | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 |

| Umgebungstemperatur | 10 °C - 50 °C | 10 °C - 50 °C | 10 °C - 50 °C | 10 °C - 50 °C | 10 °C - 45 °C | 10 °C - 50 °C | 10 °C - 50 °C | 10 °C - 50 °C | 10 °C - 50 °C | 10 °C - 45 °C | 10 °C - 50 °C | 10 °C - 50 °C | 10 °C - 50 °C | 10 °C - 50 °C | 10 °C - 50 °C | 10 °C - 50 °C | 10 °C - 50 °C | 10 °C - 50 °C | 10 °C - 45 °C | 10 °C - 50 °C | 10 °C - 50 °C | 10 °C - 50 °C | 10 °C - 50 °C | 10 °C - 50 °C | 10 °C - 50 °C | 10 °C - 50 °C | 10 °C - 50 °C | 10 °C - 50 °C | 10 °C - 50 °C |

|

TruDisk 1000

|

TruDisk 2000

|

TruDisk 3000

|

TruDisk 3001

|

TruDisk 3001 P

|

TruDisk 3002

|

TruDisk 3006

|

TruDisk 4000

|

TruDisk 4001

|

TruDisk 4001 P

|

TruDisk 4002

|

TruDisk 4006

|

TruDisk 5000

|

TruDisk 5001

|

TruDisk 5002

|

TruDisk 5006

|

TruDisk 6000

|

TruDisk 6001

|

TruDisk 6001 P

|

TruDisk 6002

|

TruDisk 6006

|

TruDisk 8000

|

TruDisk 8001

|

TruDisk 8002

|

TruDisk 10001

|

TruDisk 12001

|

TruDisk 16001

|

TruDisk 20001

|

TruDisk 24001

|

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Laserparameter | |||||||||||||||||||||||||||||

| Laserleistung | 1000 W 1 | 2000 W 1 | 3000 W 1 | 3000 W 1 | 3000 W 1 | 3000 W 1 | 3000 W 1 | 4000 W 1 | 4000 W 1 | 4000 W 1 | 4000 W 1 | 4000 W 1 | 5000 W 1 | 5000 W 1 | 5000 W 1 | 5000 W 1 | 6000 W 1 | 6000 W 1 | 6000 W 1 | 6000 W 1 | 6000 W 1 | 8000 W 1 | 8000 W 1 | 8000 W 1 | 10000 W 1 | 12000 W 1 | 16000 W 1 | 20000 W 1 | 24000 W 1 |

| Typ. Leistungskonstanz bei Nennleistung über 8 Std. bei konstanter Umgebungstemperatur | ± 0,5 % | ± 0,5 % | ± 0,5 % | ± 0,5 % | ± 1 % | ± 0,5 % | ± 0,5 % | ± 0,5 % | ± 0,5 % | ± 1 % | ± 0,5 % | ± 0,5 % | ± 0,5 % | ± 0,5 % | ± 0,5 % | ± 0,5 % | ± 0,5 % | ± 0,5 % | ± 1 % | ± 0,5 % | ± 0,5 % | ± 0,5 % | ± 0,5 % | ± 0,5 % | ± 0,5 % | ± 0,5 % | ± 0,5 % | ± 0,5 % | ± 0,5 % |

| Max. Leistungskonstanz bei Nennleistung über 8 Std. bei konstanter Umgebungstemperatur | ± 1 % | ± 1 % | ± 1 % | ± 1 % | ± 2 % | ± 1 % | ± 1 % | ± 1 % | ± 1 % | ± 2 % | ± 1 % | ± 1 % | ± 1 % | ± 1 % | ± 1 % | ± 1 % | ± 1 % | ± 1 % | ± 2 % | ± 1 % | ± 1 % | ± 1 % | ± 1 % | ± 1 % | ± 1 % | ± 1 % | ± 1 % | ± 1 % | ± 1 % |

| Kontinuierlich einstellbarer Leistungsbereich | 60 W - 1000 W bei aktiver Leistungsregelung | 60 W - 2000 W bei aktiver Leistungsregelung | 80 W - 3000 W bei aktiver Leistungsregelung | 80 W - 3000 W bei aktiver Leistungsregelung | - | 80 W - 3000 W bei aktiver Leistungsregelung | 80 W - 3000 W bei aktiver Leistungsregelung | 80 W - 4000 W bei aktiver Leistungsregelung | 80 W - 4000 W bei aktiver Leistungsregelung | - | 80 W - 4000 W bei aktiver Leistungsregelung | 80 W - 4000 W bei aktiver Leistungsregelung | 100 W - 5000 W bei aktiver Leistungsregelung | 120 W - 5000 W bei aktiver Leistungsregelung | 120 W - 5000 W bei aktiver Leistungsregelung | 120 W - 5000 W bei aktiver Leistungsregelung | 120 W - 6000 W bei aktiver Leistungsregelung | 120 W - 6000 W bei aktiver Leistungsregelung | - | 120 W - 6000 W bei aktiver Leistungsregelung | 120 W - 6000 W bei aktiver Leistungsregelung | 160 W - 8000 W bei aktiver Leistungsregelung | 160 W - 8000 W bei aktiver Leistungsregelung | 160 W - 8000 W bei aktiver Leistungsregelung | 200 W - 10000 W bei aktiver Leistungsregelung | 240 W - 12000 W bei aktiver Leistungsregelung | 320 W - 16000 W bei aktiver Leistungsregelung | 400 W - 20000 W bei aktiver Leistungsregelung | 480 W - 24000 W bei aktiver Leistungsregelung |

| Strahlqualität an der Einkopplung in das LLK | 2 mm▪mrad | 2 mm▪mrad | 2 mm▪mrad | 4 mm▪mrad | 4 mm▪mrad | 8 mm▪mrad | 25 mm▪mrad | 2 mm▪mrad | 4 mm▪mrad | 4 mm▪mrad | 8 mm▪mrad | 25 mm▪mrad | 2 mm▪mrad | 4 mm▪mrad | 8 mm▪mrad | 25 mm▪mrad | 2 mm▪mrad | 4 mm▪mrad | 4 mm▪mrad | 8 mm▪mrad | 25 mm▪mrad | 2 mm▪mrad | 4 mm▪mrad | 8 mm▪mrad | 4 mm▪mrad | 4 mm▪mrad | 4 mm▪mrad | 4 mm▪mrad | 4 mm▪mrad |

| Numerische Apertur an der Auskopplung nach LLK | 0,1 | 0,1 | 0,1 | 0,1 | 0,1 | 0,1 | 0,1 | 0,1 | 0,1 | 0,1 | 0,1 | 0,1 | 0,1 | 0,1 | 0,1 | 0,1 | 0,1 | 0,1 | 0,1 | 0,1 | 0,1 | 0,1 | 0,1 | 0,1 | 0,1 | 0,1 | 0,1 | 0,1 | 0,1 |

| Wellenlänge | 1030 nm | 1030 nm | 1030 nm | 1030 nm | 1030 nm | 1030 nm | 1030 nm | 1030 nm | 1030 nm | 1030 nm | 1030 nm | 1030 nm | 1030 nm | 1030 nm | 1030 nm | 1030 nm | 1030 nm | 1030 nm | 1030 nm | 1030 nm | 1030 nm | 1030 nm | 1030 nm | 1030 nm | 1030 nm | 1030 nm | 1030 nm | 1030 nm | 1030 nm |

| Min. Durchmesser Laserlichtkabel | 50 μm | 50 μm | 50 μm | 100 μm | 100 μm | 200 μm | 600 μm | 50 μm | 100 μm | 100 μm | 200 μm | 600 μm | 50 μm | 100 μm | 200 μm | 600 μm | 50 μm | 100 μm | 100 μm | 200 μm | 600 μm | 50 μm | 100 μm | 200 μm | 100 μm | 100 μm | 100 μm | 100 μm | 100 μm |

| Bauform | |||||||||||||||||||||||||||||

| Breite | 1175 mm | 1175 mm | 1175 mm | 1175 mm | 1175 mm | 1175 mm | 1175 mm | 1175 mm | 1175 mm | 1175 mm | 1175 mm | 1175 mm | 1175 mm | 1175 mm | 1175 mm | 1175 mm | 1620 mm | 1175 mm | 1175 mm | 1175 mm | 1175 mm | 1620 mm | 1175 mm | 1175 mm | 1620 mm | 1620 mm | 2150 mm | 2150 mm | 2150 mm |

| Höhe | 1430 mm | 1430 mm | 1430 mm | 1430 mm | 1430 mm | 1430 mm | 1430 mm | 1430 mm | 1430 mm | 1430 mm | 1430 mm | 1430 mm | 1430 mm | 1430 mm | 1430 mm | 1430 mm | 1475 mm | 1430 mm | 1430 mm | 1430 mm | 1430 mm | 1475 mm | 1430 mm | 1430 mm | 1475 mm | 1475 mm | 1600 mm | 1600 mm | 1600 mm |

| Tiefe | 725 mm | 725 mm | 725 mm | 725 mm | 725 mm | 725 mm | 725 mm | 725 mm | 725 mm | 725 mm | 725 mm | 725 mm | 725 mm | 725 mm | 725 mm | 725 mm | 920 mm | 725 mm | 725 mm | 725 mm | 725 mm | 920 mm | 725 mm | 725 mm | 920 mm | 920 mm | 1200 mm | 1200 mm | 1200 mm |

| Max. Anzahl Laserlichtkabel | 2 | 2 | 2 | 2 | 1 | 2 | 2 | 2 | 2 | 1 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 1 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| Max. Anzahl Laserlichtkabel bei Gerätegröße Extended | 4 | 4 | 4 | 4 | - | 4 | 4 | 4 | 4 | - | 4 | 4 | 4 | 4 | 4 | 4 | - | 4 | - | 4 | 4 | - | 4 | 4 | - | - | - | - | - |

| Aufstellung | |||||||||||||||||||||||||||||

| Schutzart | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 |

| Umgebungstemperatur | 10 °C - 50 °C | 10 °C - 50 °C | 10 °C - 50 °C | 10 °C - 50 °C | 10 °C - 45 °C | 10 °C - 50 °C | 10 °C - 50 °C | 10 °C - 50 °C | 10 °C - 50 °C | 10 °C - 45 °C | 10 °C - 50 °C | 10 °C - 50 °C | 10 °C - 50 °C | 10 °C - 50 °C | 10 °C - 50 °C | 10 °C - 50 °C | 10 °C - 50 °C | 10 °C - 50 °C | 10 °C - 45 °C | 10 °C - 50 °C | 10 °C - 50 °C | 10 °C - 50 °C | 10 °C - 50 °C | 10 °C - 50 °C | 10 °C - 50 °C | 10 °C - 50 °C | 10 °C - 50 °C | 10 °C - 50 °C | 10 °C - 50 °C |

Die technischen Daten aller Produktvarianten als Download.

TruControl

TruControl ist die Steuerungssoftware für Ihren TRUMPF Festkörperlaser – für die schnelle und einfache Bedienung. Pulsformen programmieren Sie individuell passend für ihre Anwendung. Die Laserleistung wird in Echtzeit geregelt für höchste Reproduzierbarkeit Ihrer Prozessergebnisse. Um wichtige Qualitätsdaten Ihrer produzierten Teile auch nach Jahren zurückverfolgen zu können, zeichnet das optionale Software Modul DataStore alle qualitätsrelevanten Daten auf.

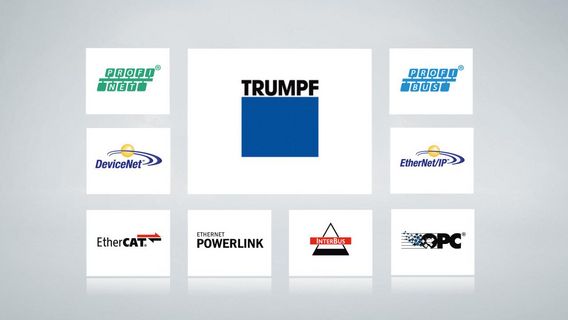

Sind externe Steuerungen vorhanden, kommuniziert TruControl mit Ihnen über alle gängigen Schnittstellen. Eingaben erfolgen über den Touchscreen des Bedienpanels oder einen Panel-Computer. Über Ethernet binden Sie Ihren Laser ins Netzwerk ein und schließen mehrere PCs an.

Mit TRUMPF haben Sie die Möglichkeit, Ihren Festkörperlaser flexibel an Ihre Einbau- und Betriebssituation anzupassen. Das gilt etwa für alle Strahlführungskomponenten und die Ansteuerung. Auch bei der Kühlwasserversorgung haben Sie mehrere Optionen. Schnittstellen für verschiedene Optiken sind bereits von vornherein vorgesehen. Um Kosten zu sparen kann Ihre Strahlquelle auch mehrere Arbeitsstationen gleichzeitig versorgen. Der TRUMPF Remote-Service hilft Ihnen überall und jederzeit, die Verfügbarkeit Ihrer Anlagen sicherzustellen.

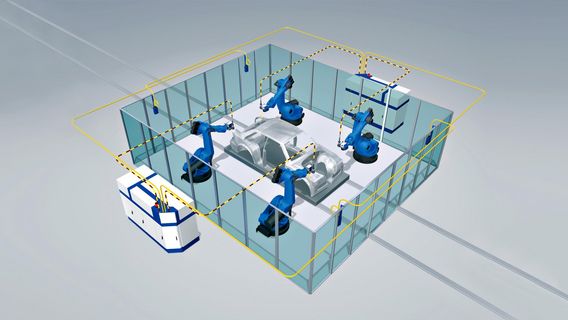

Um flexibel mit Ihrem Laser planen zu können, haben Sie eine Vielzahl an Möglichkeiten bei der Strahlführung. Per Plug & Play schließen Sie Laserlichtkabel ganz einfach an verschiedene Arbeitsstationen an. Sie wählen dabei die Anzahl der bis zu sechs Faserabgänge. Die Laserleistung kann flexibel auf die Abgänge verteilt werden. Mehrere Arbeitsstationen arbeiten so gleichzeitig mit geteilter Laserleistung oder nacheinander mit voller Laserleistung. Dank des modularen Aufbaus lässt sich sowohl die Laserleistung als auch die Anzahl der Abgänge jederzeit im Feld nachrüsten.

Statt manueller Steuerung lässt sich die Leistung des TruDisks in Echtzeit regeln. Die aktive Laserleistungsregelung stabilisiert die Laserleistung auf Abweichungen von +/- 1% und hält so den Prozess unabhängig von Umgebungseinflüssen konstant. Dadurch profitieren Sie von der höchsten Leistungsstabilität am Markt – und das über die gesamte Lebensdauer Ihres Lasers.

Profitieren Sie mit der Option BrightLine Weld von nahezu spritzerfreiem Laserschweißen und höchster Schweißnahtqualität. Sie haben die Wahl – steigern Sie Ihre Produktivität aufgrund der deutlich höheren Vorschubgeschwindigkeiten erheblich oder senken Sie Ihre Energiekosten um bis zu 40 %. Auf diese Weise reduzieren sich Ihre Maschinenstillstandzeiten sowie Ihre Betriebskosten, da die Nachbearbeitungen sinkt.

Für die Integration eines TruDisk Lasers in Ihre Maschine oder Fertigungslinie sind die Schnittstellen entscheidend. Daher bieten Festkörperlaser von TRUMPF Schnittstellen zu allen gängigen Feldbussystemen. Weiterhin sind erhältlich: Echtzeitschnittstelle, Parallel Digital I/O, Schnittstelle für Prozesssensorik, OPC UA Softwareschnittstelle, analoge Eingangskarte, Schnittstelle für intelligente TRUMPF Optiken (CFO, PFO).

Über eine eigene Schnittstelle synchronisieren Sie intelligente Optiken mit Ihrem Laser. So können Sie etwa die Fokussieroptik CFO oder die Scanneroptik PFO optimal für Ihre Zwecke nutzen. Die Programmierung der Bearbeitungsoptik erfolgt bequem über die Lasersteuerung. Zusätzliche PCs oder Steuerungen sind unnötig.

Im Störungsfall greifen TRUMPF Serviceexperten über eine sichere Remote-Verbindung aktiv auf Ihren Laser zu. Häufig wird so die Störung direkt behoben oder die Konfiguration des Lasers so verändert, dass Sie bis zum Eintreffen des Ersatzteils weiter produzieren können. Dies ermöglicht Ihnen maximale Verfügbarkeit.

Im Lasernetzwerk vernetzen Sie einen oder mehrere Laser mit jeweils bis zu sechs Arbeitsstationen. Ihr Laser teilt dabei entweder seine Leistung auf mehrere Stationen auf oder versorgt sie mit voller Leistung abwechselnd. Das erlaubt Ihnen sogar, unterschiedliche Anwendungen wie Schweißen oder Schneiden miteinander zu kombinieren.

Mit dem integrierten Kompressorkühler profitieren Sie von einer maximalen Zulauftemperatur des Kühlwassers von 38°C – auf einen externen Kühler können Sie komplett verzichten. Dabei bleibt der Laser platzsparend, da sich die Gesamtaufstellfläche auch mit integriertem Kompressorkühler nicht erhöht. Die Steuerung und Überwachung des Kühlers erfolgt bequem über TruControl. Wechseln Sie zudem schnell und flexibel den gesamten Kühler oder den Kältekreis aus.

Bearbeitungsoptiken und Laserlichtkabel können einfach und komfortabel über das Kühlwasser des Lasers gekühlt werden. Eine separate Kühlung ist somit nicht notwendig.

Produzieren Sie jederzeit effektiv und wirtschaftlich dank TRUMPF Sensorik. Die Sensorikprodukte VisionLine, CalibrationLine oder integrierte Pyrometer stellen stabile Prozesse sicher, indem sie sämtliche Vorgänge in der Laserproduktion überwachen und so einen wichtigen Beitrag für Ihre Prozesssicherheit liefern. Die Bearbeitung läuft während der Messung ungestört weiter – Unterbrechungen sind nicht nötig. Das spart Ihnen wertvolle Produktionszeit.

Bilderverarbeitung

Die TRUMPF Bildverarbeitung VisionLine erkennt Merkmale auf den Bauteilen und sorgt dafür, dass stets an der richtigen Stelle geschweißt wird.

Kalibration

Das TRUMPF Kalibrationswerkzeug CalibrationLine überprüft und korrigiert in regelmäßigen, individuell definierbaren Abständen Fokuslage und Laserleistung am Werkstück.

Nahtlageregelung

Die Sensorik findet den Fügespalt und regelt während des Schweißprozesses die Lage der Schweißposition.

Temperaturregelung

Die TRUMPF Temperaturregelung sorgt beim Kunststoffschweißen für optisch hochwertige Ergebnisse.

Einschweißtiefenüberwachung

Die TRUMPF Einschweißtiefenüberwachung warnt den Anwender, wenn der Prozess von der voreingestellten Einschweißtiefe abweicht.

Laser und Lasersystem – bei uns ein perfektes Paar. Alle Strahlquellen sind optimal auf die Anforderungen der TRUMPF Lasersysteme abgestimmt. Wählen Sie unter zahlreichen Varianten und Optionen. So bekommen Sie eine genau auf Ihre Aufgabe zugeschnittene Anlage. Natürlich ist es auch möglich, unsere Laser direkt in Ihre Fertigungslinien zu integrieren.

.TRUMPF bietet Ihnen alle Komponenten, die Sie zur Strahlführung vom Laser bis zum Werkstück benötigen. So auch diverse Fokussieroptiken, die sich in vielen Jahren industriellen Einsatzes als präzise und zuverlässig bewährt haben. Die Optiken sind leicht integrierbar - sowohl in Stand-Alone-Bearbeitungsstationen als auch in kompletten Fertigungslinien. Der modulare Aufbau ermöglicht es die Optiken stets an den Lasertypen sowie an die unterschiedlichen Bearbeitungssituationen anzupassen.

Fokussieroptiken

Ob beim Schweißen, Schneiden, Abtragen, Aufheizen oder Bohren: Mit robusten Fokussieroptiken von TRUMPF erreichen Sie hochwertige Prozessergebnisse!

Programmierbare Fokussieroptiken

Die idealen Optiken für die Remotebearbeitung

Je nach Land sind Abweichungen von diesem Produktsortiment und von diesen Angaben möglich. Änderungen in Technik, Ausstattung, Preis und Zubehörangebot sind vorbehalten. Bitte setzen Sie sich mit Ihrem Ansprechpartner vor Ort in Verbindung, um zu erfahren, ob das Produkt in Ihrem Land verfügbar ist.

Fußnoten-

Die Laserleistung am Werkstück kann je nach Optikkonfiguration von der Nennleistung abweichen.