Für Ihre Anwendung die passende Optik

Ob beim Schweißen, Schneiden, Abtragen, Aufheizen oder Bohren: Mit robusten Fokussieroptiken von TRUMPF erreichen Sie hochwertige Prozessergebnisse. Die Optiken sind flexibel mit den TRUMPF Festkörperlasern einsetzbar und optimal auf die Laser abgestimmt. Durch den modularen Baukasten von TRUMPF können die Festoptiken individuell an Ihre Anforderungen angepasst werden.

TRUMPF Fokussieroptiken überzeugen durch hohe Lebenszeiten und Zuverlässigkeit.

Eine Vielzahl an Optionen garantiert Ihnen die richtige Lösung für jede Aufgabe.

Verschiedene Bauformen der Optiken sorgen für anlagenspezifische Anpassung an Arbeitssituation und Umgebung.

Die ausgereifte Technologie ermöglicht das Erzeugen kundenspezifischer Nähte in hervorragender Nahtqualität.

Wichtige Arbeitsparameter können einfach und individuell auf die Anwendung eingestellt werden.

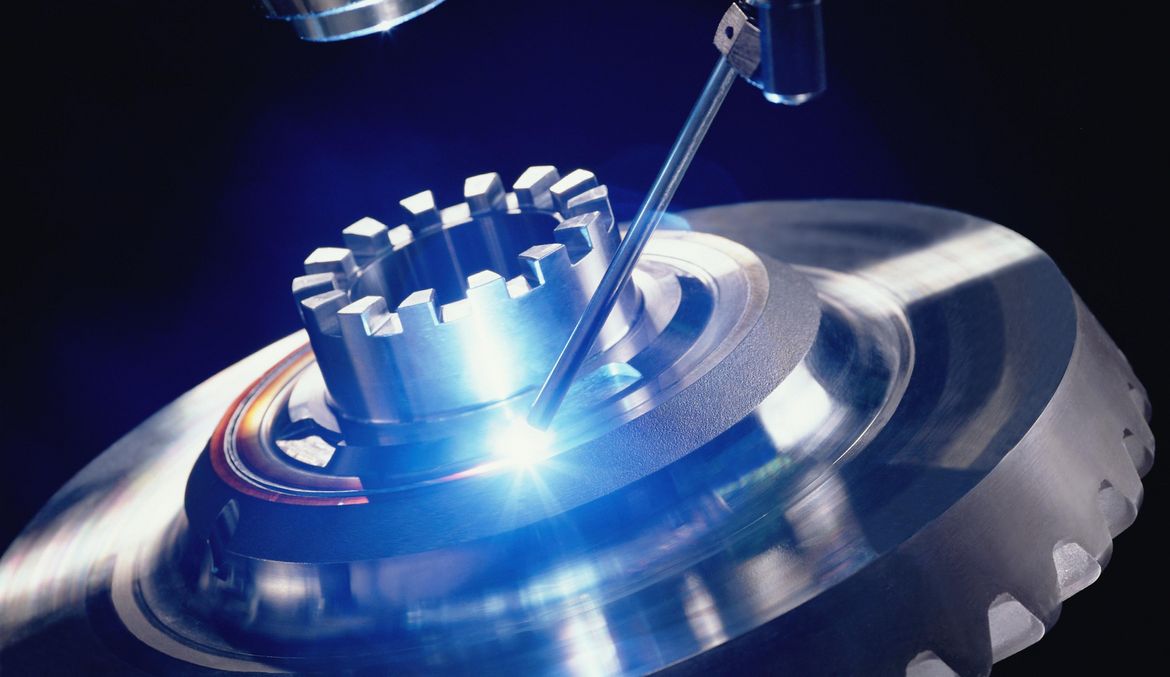

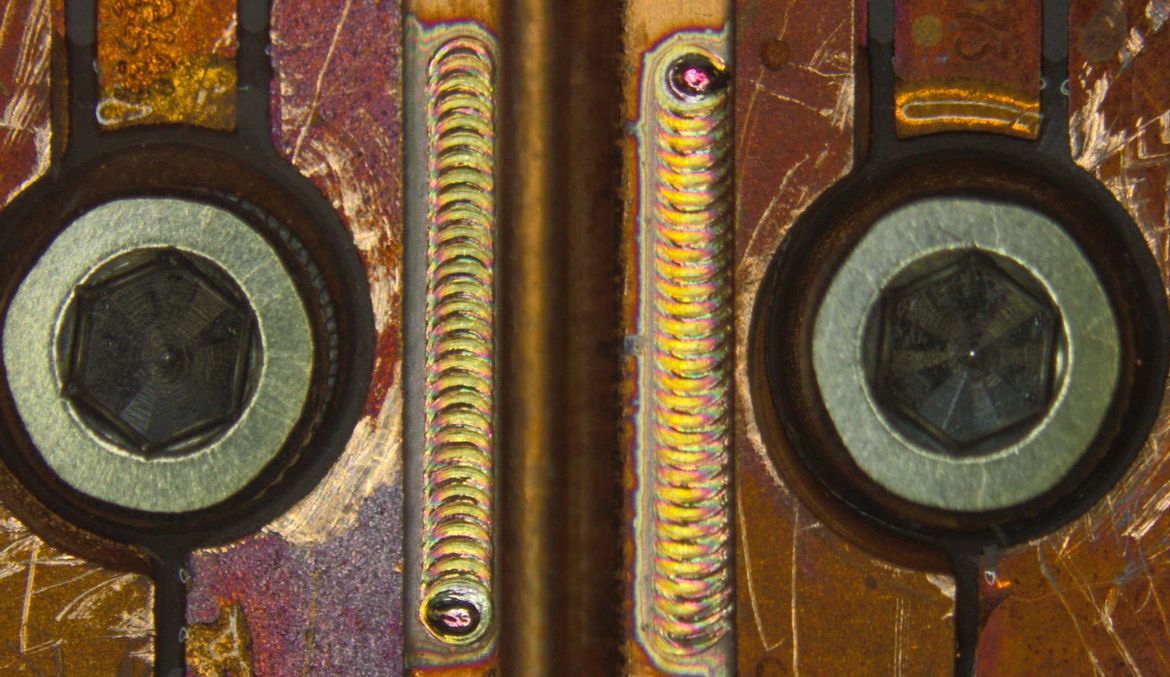

Getriebebauteile

Die Optik unterstützt Sie dabei, den Laserstrahl präzise auf die Schweißstelle zu fokussieren. Das gleichzeitig zugeführte Schutzgas sorgt für ein qualitativ noch hochwertigeres Schweißergebnis, so dass sich zeitaufwendige Nacharbeiten an der Schweißnaht reduzieren.

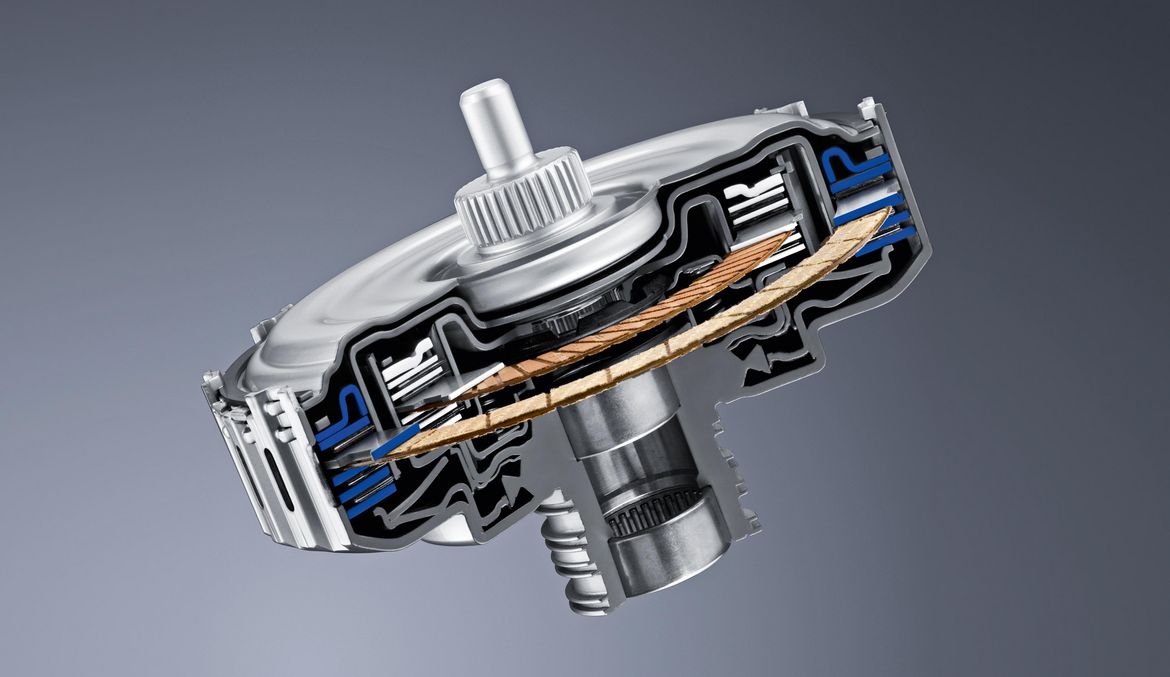

Doppelkupplungseinheit

Die TRUMPF Bearbeitungsoptiken liefern im 24 / 7 Betrieb beste Leistung und die Qualität Ihrer Schweißergebnisse bleibt dauerhaft stabil.

Mittendifferenzial

Gerade beim Schweißen im Stumpfstoß oder Überlappstoß ist eine präzise Fokussierung des Laserlichts wichtig. Die TRUMPF Fokussieroptiken spielen in diesem Feld ihre Stärken aus und schweißen beispielsweise ein Mittendifferenzial im Überlappstoß in hervorragender Qualität.

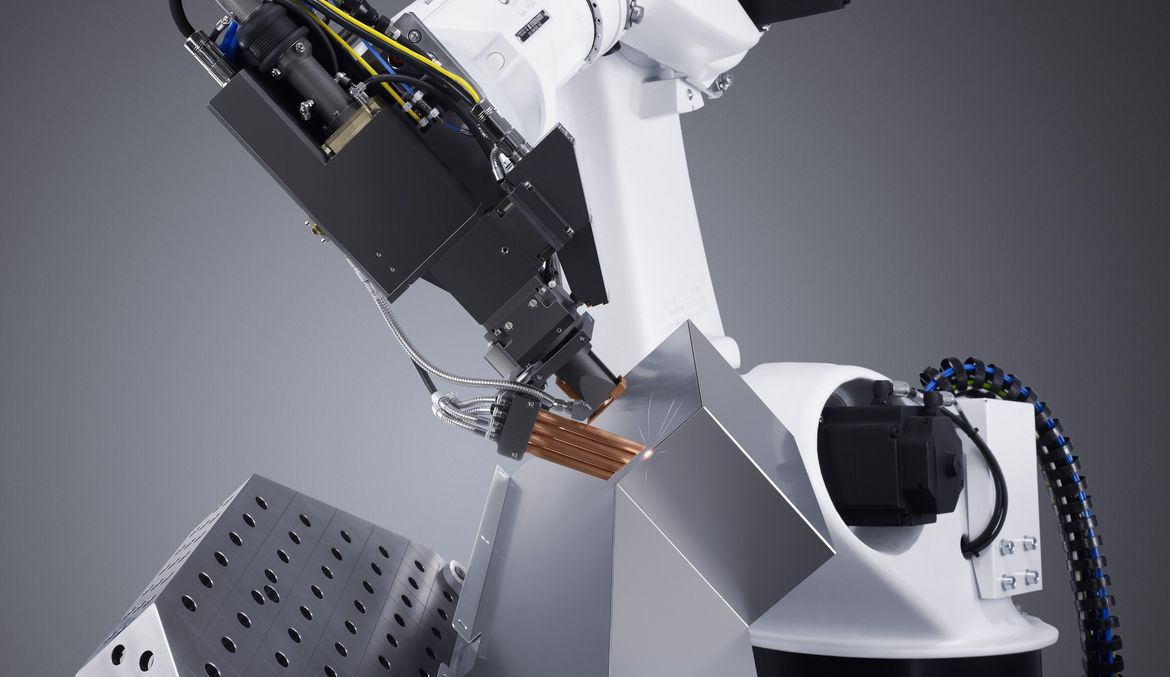

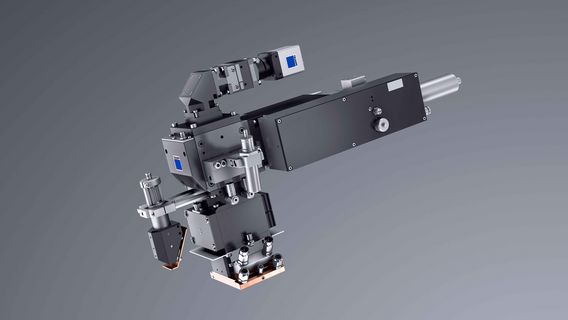

Roboterschweißen

Mit der Kombination einer TRUMPF Fokussieroptik, beispielsweise einer motorischen Fokussieroptik, und einem Roboter können Sie den Arbeitsraum ihrer Optik deutlich vergrößern und die guten Fokussiereigenschaften nutzen.

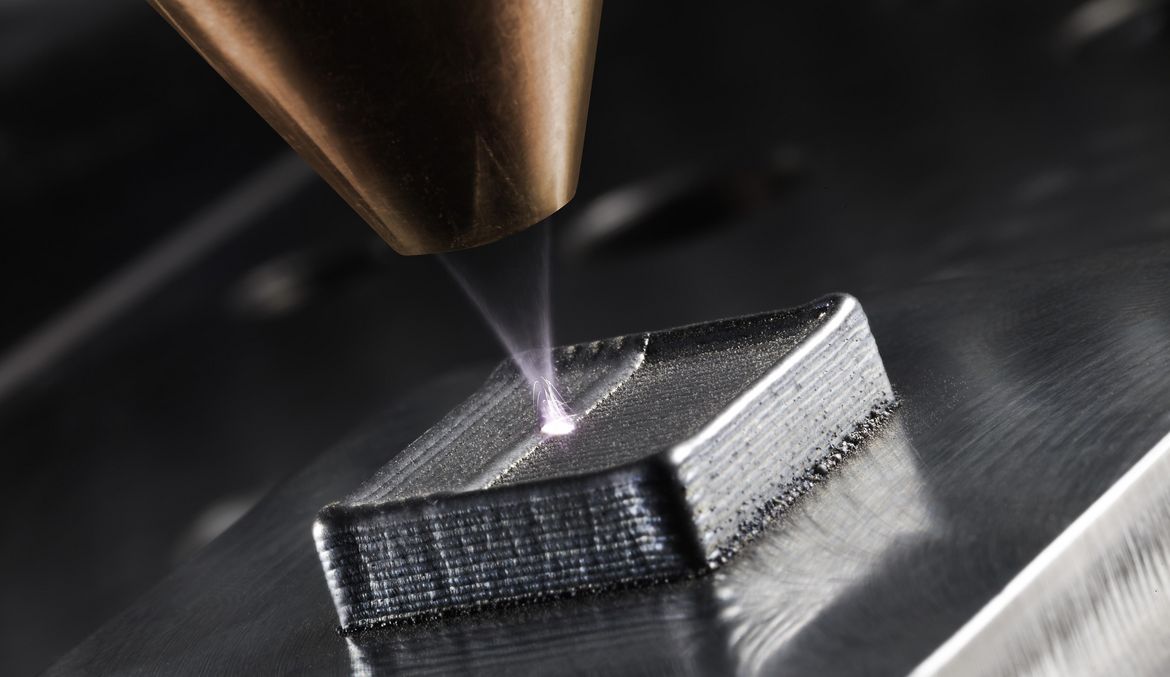

Laserauftragsschweißen

Generatives Laserauftragsschweißen mit TRUMPF Fokussieroptiken.

Kupferschweißen

Mit TRUMPF Fokussieroptiken können Sie auch Kupfer bearbeiten. So lassen sich zum Beispiel Kontakte auf Leiterplatten geschweißt werden.

|

BEO D25

Produkt vergleichen

|

BEO D35

Produkt vergleichen

|

BEO D50

Produkt vergleichen

|

BEO D70-2

Produkt vergleichen

|

RFO

Produkt vergleichen

|

CFO

Produkt vergleichen

|

|

|---|---|---|---|---|---|---|

| Laserparameter | ||||||

| Wellenlängenbereich | 1030 nm - 1064 nm | 515 / 930 nm - 1075 nm 1 |

515 nm

930 nm - 1085 nm 1 |

1030 nm - 1075 nm 1 | 1030 nm 1 | 930 nm - 1064 nm 1 |

| Leistung | bis 150 W (cw) | bis 4000 W (cw) | bis 8000 W (cw) | bis 24000 W (cw) | ab 16000 W (cw) | bis 8000 W (cw) |

| Numerische Apertur | typ. 0,11 / max. 0,12 | typ. 0,11 / max. 0,12 | typ. 0,11 / max. 0,12 | typ. 0,11 / max. 0,12 | typ. 0,11 / max. 0,12 | typ. 0,11 / max. 0,12 |

| Typ Laserlichtkabel | LLK-A | LLK-Q, LLK-D, LLK-B, LLK-A, PIPA-Q | LLK-D, LLK-B, LLK-A, PIPA-Q | LLK-D, LLK-X, LLK-B | LLK-D | LLK-D, LLK-B |

| Optikkonfiguration 2 2 | ||||||

| Kollimation | 90 mm | 35 / 80 / 100 mm | 35 / 100 / 125 / 150 / 200 mm | 150 / 175 / 200 mm | - | 200 mm |

| Brennweite | 48 / 60 / 90 / 135 mm | 70 / 100 / 140 / 200 / 300 mm | 150 / 200 / 250 / 300 mm | 200 / 300 / 400 / 600 mm | 600 mm | 100 / 150 / 200 / 300 / 400 / 600 mm |

| Bauform | ||||||

| Abmessungen (B x H x T) | 25 mm x 198 mm x 25 mm (Beispielkonfiguration) | 166 mm x 313 mm x 62 mm (Beispielkonfiguration mit Kamerabeobachtung und Crossjet) | 128 mm x 407 mm x 100 mm (Beispielkonfiguration mit Kamerabeobachtung und Crossjet) | 172 mm x 510 mm x 78 mm (Beispielkonfiguration mit Kamerabeobachtung und Crossjet) | 123 mm x 446 mm x 176 mm (Beispielkonfiguration mit Kamerabeobachtung und Crossjet) | 163 mm x 519 mm x 114 mm (Beispielkonfiguration mit Kamerabeobachtung und Crossjet) |

| Gewicht | 0,3 kg (Beispielkonfiguration) | 2,5 kg (Beispielkonfiguration mit Kamerabeobachtung und Crossjet) | 3,5 kg (Beispielkonfiguration mit Kamerabeobachtung und Crossjet) | 8 kg (Beispielkonfiguration mit Kamerabeobachtung und Crossjet) | 6,5 kg (Beispielkonfiguration mit Kamerabeobachtung und Crossjet) | 8,5 kg (Beispielkonfiguration mit Kamerabeobachtung und Crossjet) |

| Kompatibilität | ||||||

| Verfügbare Laser | TruPulse | TruDiode, TruDisk, TruFiber, TruPulse | TruDiode, TruDisk, TruFiber, TruPulse | TruDisk, TruPulse, TruFiber Multi Mode | TruDisk | TruDiode, TruDisk, TruPulse |

| Verfügbare Sensorik | - | - | VisionLine, CalibrationLine Power | VisionLine Cam/Basic/Detect/Project, CalibrationLine Power | - | VisionLine, CalibrationLine Power |

| Optionen | ||||||

| Verfügbare Optionen | 90°-Version, Bifokal-Modul, Kamerabeobachtung, Sensorikschnittstelle, 15g-Ausführung | 90°-Version, Crossjet, Schutzgaszufuhr, Bifokal-Modul, Kamerabeobachtung, Sensorikschnittstelle, Beleuchtung, Kassettenmodul, 15g-Ausführung | 90°-Version, Crossjet, MDE-Düse, Schutzgaszufuhr, Bifokal-Modul, Kamerabeobachtung, Sensorikschnittstelle, Beleuchtung, Kassettenmodul | 0°, 90° und 2x90° Version, Crossjet, MDE-Düse, Schutzgasversorgung, Sensoraufnahme, Koaxialbeleuchtung, Seitliche Beleuchtung, Bifokalmodul und Multifokuselement, Einstellbarer Linienlaser, Schutzglasverschmutzungsüberwachung, LLK-Streulicht- und Kühlwassertemperaturüberwachung, Programmierbare Motorische Fokussierung (PMF) | Crossjet, Kamerabeobachtung, Kassettenmodul, Schutzglasüberwachung | 90°-Version, Crossjet, MDE-Düse, Schutzgaszufuhr, Bifokal-Modul, Kamerabeobachtung, Sensorikschnittstelle, Beleuchtung, Kassettenmodul, Schutzglasüberwachung, Leistungsmesskassette, Pilotlaser, Kompensationskassette |

|

BEO D25

|

BEO D35

|

BEO D50

|

BEO D70-2

|

RFO

|

CFO

|

|

|---|---|---|---|---|---|---|

| Laserparameter | ||||||

| Wellenlängenbereich | 1030 nm - 1064 nm | 515 / 930 nm - 1075 nm 1 |

515 nm

930 nm - 1085 nm 1 |

1030 nm - 1075 nm 1 | 1030 nm 1 | 930 nm - 1064 nm 1 |

| Leistung | bis 150 W (cw) | bis 4000 W (cw) | bis 8000 W (cw) | bis 24000 W (cw) | ab 16000 W (cw) | bis 8000 W (cw) |

| Numerische Apertur | typ. 0,11 / max. 0,12 | typ. 0,11 / max. 0,12 | typ. 0,11 / max. 0,12 | typ. 0,11 / max. 0,12 | typ. 0,11 / max. 0,12 | typ. 0,11 / max. 0,12 |

| Typ Laserlichtkabel | LLK-A | LLK-Q, LLK-D, LLK-B, LLK-A, PIPA-Q | LLK-D, LLK-B, LLK-A, PIPA-Q | LLK-D, LLK-X, LLK-B | LLK-D | LLK-D, LLK-B |

| Optikkonfiguration 2 2 | ||||||

| Kollimation | 90 mm | 35 / 80 / 100 mm | 35 / 100 / 125 / 150 / 200 mm | 150 / 175 / 200 mm | - | 200 mm |

| Brennweite | 48 / 60 / 90 / 135 mm | 70 / 100 / 140 / 200 / 300 mm | 150 / 200 / 250 / 300 mm | 200 / 300 / 400 / 600 mm | 600 mm | 100 / 150 / 200 / 300 / 400 / 600 mm |

| Bauform | ||||||

| Abmessungen (B x H x T) | 25 mm x 198 mm x 25 mm (Beispielkonfiguration) | 166 mm x 313 mm x 62 mm (Beispielkonfiguration mit Kamerabeobachtung und Crossjet) | 128 mm x 407 mm x 100 mm (Beispielkonfiguration mit Kamerabeobachtung und Crossjet) | 172 mm x 510 mm x 78 mm (Beispielkonfiguration mit Kamerabeobachtung und Crossjet) | 123 mm x 446 mm x 176 mm (Beispielkonfiguration mit Kamerabeobachtung und Crossjet) | 163 mm x 519 mm x 114 mm (Beispielkonfiguration mit Kamerabeobachtung und Crossjet) |

| Gewicht | 0,3 kg (Beispielkonfiguration) | 2,5 kg (Beispielkonfiguration mit Kamerabeobachtung und Crossjet) | 3,5 kg (Beispielkonfiguration mit Kamerabeobachtung und Crossjet) | 8 kg (Beispielkonfiguration mit Kamerabeobachtung und Crossjet) | 6,5 kg (Beispielkonfiguration mit Kamerabeobachtung und Crossjet) | 8,5 kg (Beispielkonfiguration mit Kamerabeobachtung und Crossjet) |

| Kompatibilität | ||||||

| Verfügbare Laser | TruPulse | TruDiode, TruDisk, TruFiber, TruPulse | TruDiode, TruDisk, TruFiber, TruPulse | TruDisk, TruPulse, TruFiber Multi Mode | TruDisk | TruDiode, TruDisk, TruPulse |

| Verfügbare Sensorik | - | - | VisionLine, CalibrationLine Power | VisionLine Cam/Basic/Detect/Project, CalibrationLine Power | - | VisionLine, CalibrationLine Power |

| Optionen | ||||||

| Verfügbare Optionen | 90°-Version, Bifokal-Modul, Kamerabeobachtung, Sensorikschnittstelle, 15g-Ausführung | 90°-Version, Crossjet, Schutzgaszufuhr, Bifokal-Modul, Kamerabeobachtung, Sensorikschnittstelle, Beleuchtung, Kassettenmodul, 15g-Ausführung | 90°-Version, Crossjet, MDE-Düse, Schutzgaszufuhr, Bifokal-Modul, Kamerabeobachtung, Sensorikschnittstelle, Beleuchtung, Kassettenmodul | 0°, 90° und 2x90° Version, Crossjet, MDE-Düse, Schutzgasversorgung, Sensoraufnahme, Koaxialbeleuchtung, Seitliche Beleuchtung, Bifokalmodul und Multifokuselement, Einstellbarer Linienlaser, Schutzglasverschmutzungsüberwachung, LLK-Streulicht- und Kühlwassertemperaturüberwachung, Programmierbare Motorische Fokussierung (PMF) | Crossjet, Kamerabeobachtung, Kassettenmodul, Schutzglasüberwachung | 90°-Version, Crossjet, MDE-Düse, Schutzgaszufuhr, Bifokal-Modul, Kamerabeobachtung, Sensorikschnittstelle, Beleuchtung, Kassettenmodul, Schutzglasüberwachung, Leistungsmesskassette, Pilotlaser, Kompensationskassette |

Die technischen Daten aller Produktvarianten als Download.

BEO D25

BEO D25 ist die kleinste Optik im Portfolio und bestens für Laserschweißanwenungen mit gepulsten Lasern geeignet. Eine robuste Bauweise erlaubt Beschleunigungen bis 15g.

Laser: TruPulse

Laserleistung: max. 200 W

BEO D35

Die Fokussieroptik BEO D35 wird zum Schweißen und Schneiden mit gepulsten oder cw Festkörperlaser (Faser- und Disk Laser) bis in den Kilowattbereich verwendet.

Laser: TruDisk, TruPulse, TruFiber

Laserleistung: max. 4 kW

BEO D50

Mit der neuen Bearbeitungsoptik BEO D50 hat TRUMPF eine robuste und kompakte Optik entwickelt, die bis zu einer Leistung von 8 kW eingesetzt werden kann. Die Crossjet-Funktion wurde optimiert und um neue Funktionen wie Gas-, Wasserdurchfluss- und Temperaturüberwachung erweitert.

Laser: TruDisk, TruPulse, TruFiber, TruDiode

Laserleistung: max. 8 kW

BEO D70

Die robuste Fokussieroptik BEO D70 der 2.Generation spielt ihre Stärken beim Laserschweißen mit großen Arbeitsabständen und geringem Fokusdurchmesser aus. Mit der zusätzlichen Option des Multifokus Elements für die Optik werden gasdichte Schweißnähte ermöglicht. Die smarten Überwachungsfunktionen erhöhen die Sicherheit und die Prozessstabilität weiter.

Laser: TruDisk, TruFiber Multi-Mode, TruPulse

Laserleistung: max. 24 kW

BEO D70 Schwenkoptik

Die Schwenkoptik besteht aus der Fokussieroptik BEO D70 und dem Schwenkmodul. Durch einen kundenseitig anschließbaren Antrieb und einer Anbindung des Schwenkmoduls an Ihr Maschinensystem ist die Schwenkoptik OEM tauglich. Je nach Aufbau der Fokussieroptik kann die Schwenkoptik zum Schweißen für 2D- und 3D-Bearbeitungen eingesetzt werden.

Laser: TruDisk (1030nm), TruFiber, TruDiode, TruPulse

Laserleistung: bis 8 kW

CFO

Bei den überwachten Fokussieroptiken der CFO Reihe werden prozessrelevante Parameter wie Wassertemperatur und Schutzgasdurchfluss zu jedem Zeitpunkt der Bearbeitung aufgezeichnet. Komplettiert mit einer Schutzglasüberwachung ist diese Bearbeitungsoptik besonders für automatisierte Prozesse geeignet. Zahlreiche Optionen stehen Ihnen zur Verfügung: z.B. Crossjet, MDE-Düse (Metalldampf-Effekt), Schutzgaszufuhr, Schutzglasüberwachung, Leistungsmesskassette oder Kompensationskassette.

Laser: TruDisk, TruDiode, TruFiber, TruPulse

Laserleistung: max. 8 kW

RFO

Die Hochleistungs-Spiegeloptik RFO ist eine Optik für geringsten thermischen Shift. Mit ihr sind konstante, reproduzierbare Applikationsergebnisse selbst bei hohen Laserleistungen möglich.

Laser: TruDisk

Laserleistung: bis zu 16 kW

BEO Ringoptik

Die Fokussieroptik zum Simultanschweißen von Kunststoffen mit Ringfokus ist optimal für hochproduktive Systeme geeignet. Der Ringdurchmesser wird durch eine Baugruppe im BEO Baukastensystem Kundenindividuell berechnet. So können radiale oder axiale Schweißnähte ohne Bewegung des Bauteils oder des Laserstrahls erzielt werden.

Laser: TruDiode

Laserleistung: < 1kW

TRUMPF bietet Ihnen neben einer Vielzahl an Bearbeitungsoptiken auch die dazu passenden Maschinen und Strahlquellen. So finden Sie für Ihre Anwendung und Ihre Anforderungen genau die richtige Kombination – und das aus einer Hand. Im Bereich der Strahlquellen verfügt TRUMPF über alle industriell relevanten Laser. Verlassen Sie sich auf unsere Experten und vertrauen Sie uns, dass wir stets die beste Lösung für Ihre Fertigungsaufgaben im Blick haben und völlig unabhängig von einer präferierten Technologie beraten.

Durch die Vielzahl von Optionen können Sie Ihre Fokussieroptik für jeden Job anpassen. Darüber hinaus erhalten Sie Spezialoptiken zum Auftragschweißen mit Pulverzufuhr oder für linienförmige Laserspots.

Die Multifokus Option für die BEO D70 Optik bietet in Kombination mit BrightLine Weld die innovative Lösung für mediendichte Schweißnähte. Der Laserstrahl wird dabei in vier einzelne Strahlpunkte auf dem Werkstück geteilt. Das Ergebnis ist ein robuster und stabiler Schweißprozess mit verbesserter Schweißqualität durch weniger Poren, Spritzern und Rissbildung. Gleichzeitig werden Ihnen größere Einschweißtiefen ermöglicht.

Laser: TruDisk

Laserleistung: bis 16 kW

Dank der motorischen Positionierung der Kollimationslinse kann der Fokuspunkt in Z-Richtung komfortabel eingestellt werden. Änderungen geben Sie entweder direkt über die Lasersteuerung TruControl oder über eine externe Maschinensteuerung ein. Somit können Anwendungen, bei denen die Fokuslage häufig geändert werden muss, ohne Mehraufwand durchgeführt werden.

Die CCD-Kamera überwacht den Prozess an der Bearbeitungsstelle und ermöglicht ein komfortables Einrichten des Laserprozesses. Sie ist die Basis für die Prozessüberwachung.

Der Crossjet ist ein orthogonal zum Laserstrahl verlaufender Druckluftstrom. Er lenkt Schmutz und Spritzer ab und verlängert so die Schutzglasstandzeit. Die Optik wird robuster und der Laserprozess zuverlässiger.

Um Ihren Schweißprozess effizienter zu gestalten, schalten Sie zusätzlich zum Crossjet noch den Luftstrom aus der Metalldampfeffekt-Düse (MDE-Düse) hinzu. Der Luftstrom hält die beim Schweißen entstehende Metalldampffackel konstant und damit die in das Material eingebrachte Energie. Das stabilisiert die Einschweißtiefe für eine präzise Laser-Bearbeitung. Gleichzeitig reduzieren Sie Ihre Kosten durch höhere Schutzglasstandzeiten.

Für hochwertige Schweißergebnisse führt eine separate Düse Schutzgas hinzu. Die Schweißnaht oxidiert hierdurch weniger. Sie wählen aus verschiedenen Düsen: Perlator-Düse oder Linear-Düse.

Je nach Land sind Abweichungen von diesem Produktsortiment und von diesen Angaben möglich. Änderungen in Technik, Ausstattung, Preis und Zubehörangebot sind vorbehalten. Bitte setzen Sie sich mit Ihrem Ansprechpartner vor Ort in Verbindung, um zu erfahren, ob das Produkt in Ihrem Land verfügbar ist.

Fußnoten-

Weitere Wellenlängen auf Anfrage möglich.

-

Weitere Optikkonfigurationen auf Anfrage möglich.