Erfüllen höchste Ansprüche, auch in Serie

Die Ultrakurzpulslaser der TruMicro Serie 6000 ermöglichen dank Slab-Technologie Laserpulse, die auf sehr hohe Pulsenergien linear verstärkt werden können. Da sich die Parameter sehr flexibel wählen lassen, können Sie selbst anspruchsvolle Prozesse optimal realisieren. Setzen Sie die hochqualitativen und stabilen Laser der TruMicro Serie 6000 problemlos in Ihrer Serienproduktion ein, z.B. im Bereich Consumer Electronics zum Schneiden von Glas oder Trennen von flexiblen Leiterplatten.

Kombinieren Sie individuell anspruchsvolle Parameter wie hohe Pulsenergie bei ultrakurzer Pulsdauer.

Die Ultrakurzpulslaser ermöglichen Ihnen eine hohe mittlere Leistung durch hohe Pulsenergien.

Ob IR, grün oder UV – durch die Auswahl der richtigen Wellenlänge lassen sich unterschiedlichste Materialien optimal bearbeiten.

Mit der TruMicro Serie 6000 erhalten Sie industrielle, hochqualitative Serienprodukte, die auf etablierten Komponenten basieren.

Die interne Leistungsregelung sorgt für stabile Ausgangsparameter und ein homogenes Prozessergebnis.

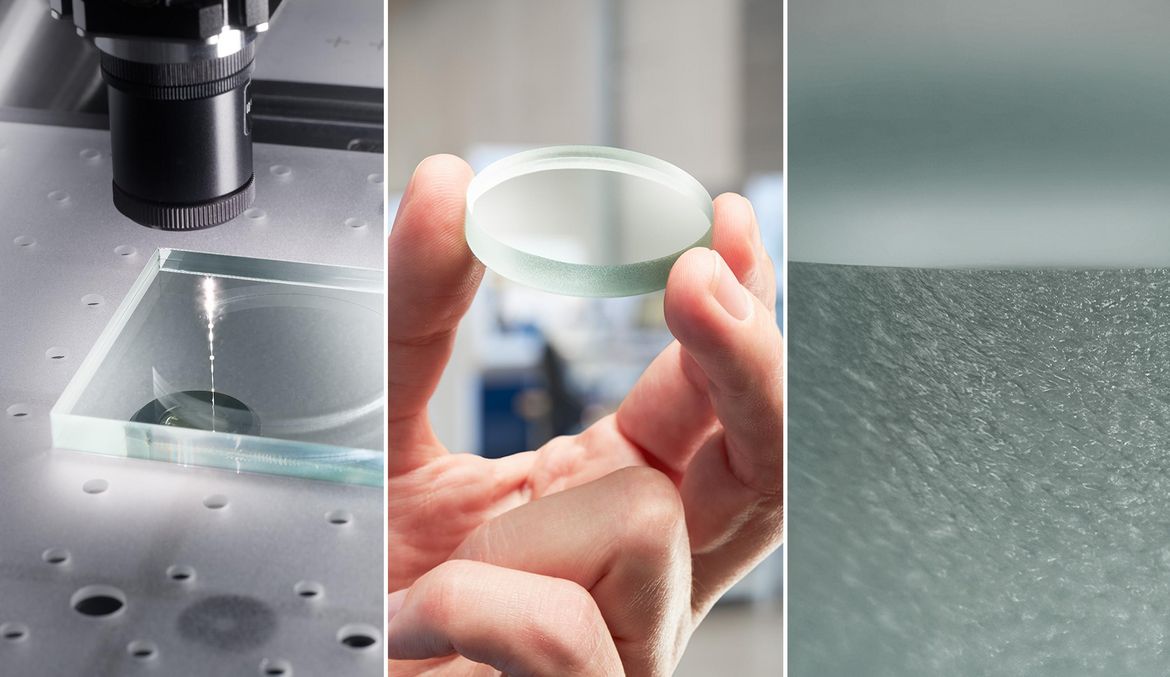

Glasmodifikation

Extreme Dicken von mehr als 10 mm lassen sich mit TRUMPF TruMicro Lasern und den TOP Cleave Optiken effizient bearbeiten und anschließend trennen. Nach dem Trennen ist keine Nachbearbeitung der Schnittkante, wie Schleifen oder Polieren, notwendig.

Schneiden von Kupferfolien

Feinste Strukturen in der Größenordnung von Mikrometern können mit einer minimalen Wärmeeinflusszone präzise geschnitten werden. Dies gilt selbst für Materialien mit hoher Reflektivität wie Kupferlegierungen.

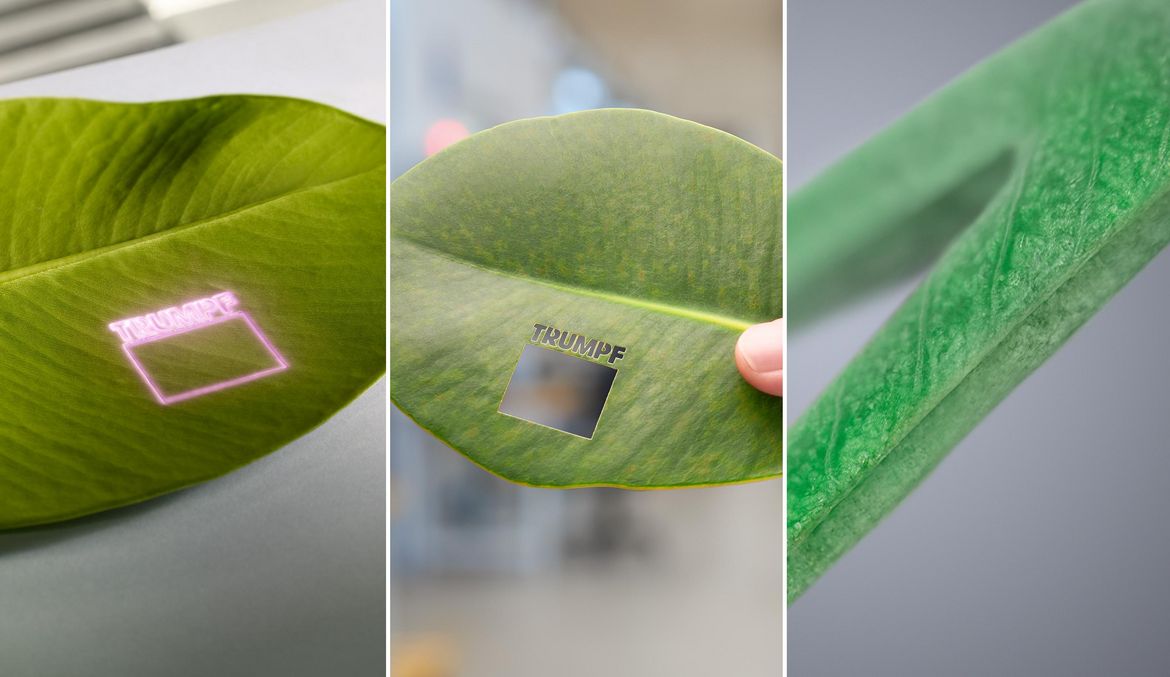

Schneiden von organischem Material

Die Kombination von ultrakurzen Dauern mit hohen Intensitäten ermöglicht eine Mikrobearbeitung mit unvergleichlicher Präzision. Selbst hochempfindliches organisches Material kann ohne beschädigte oder verbrannte Kanten geschnitten werden.

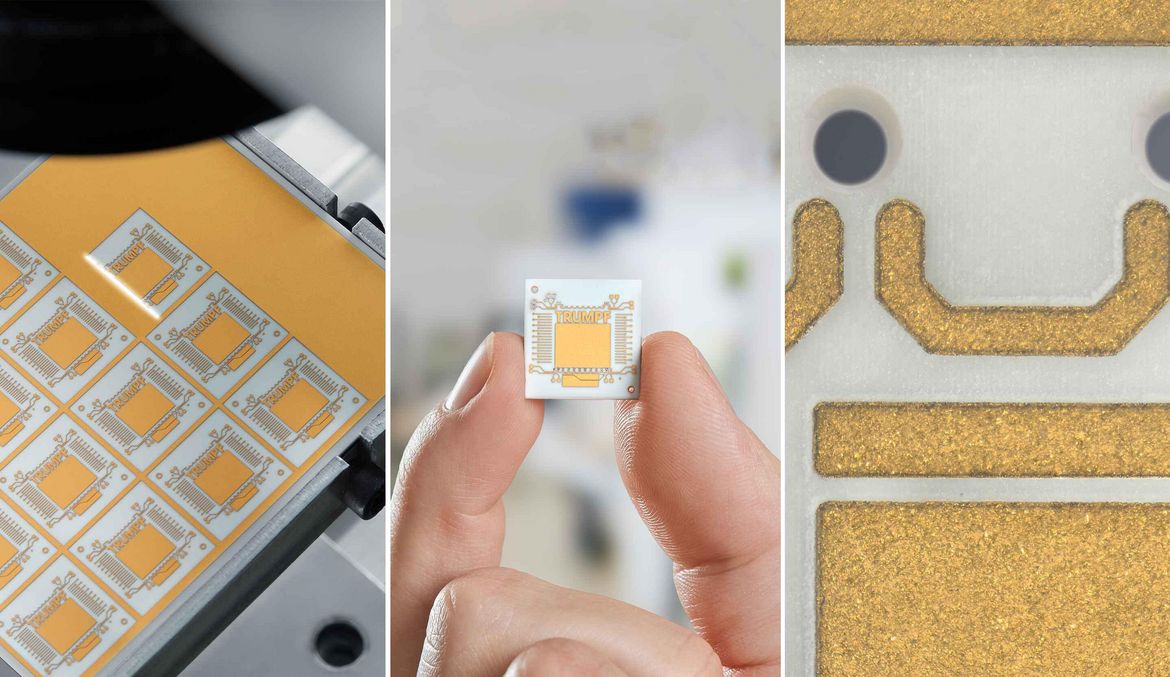

Abtragen von Gold und Keramik

Der TruMicro 6020 schneidet und bearbeitet technische Hochleistungskeramiken für Leistungselektronik und Consumer Electronics. Durch den präzisen Abtrag entstehen Leiterbahnen, Ätzprozesse werden ersetzt – ein umweltfreundlicher Fortschritt.

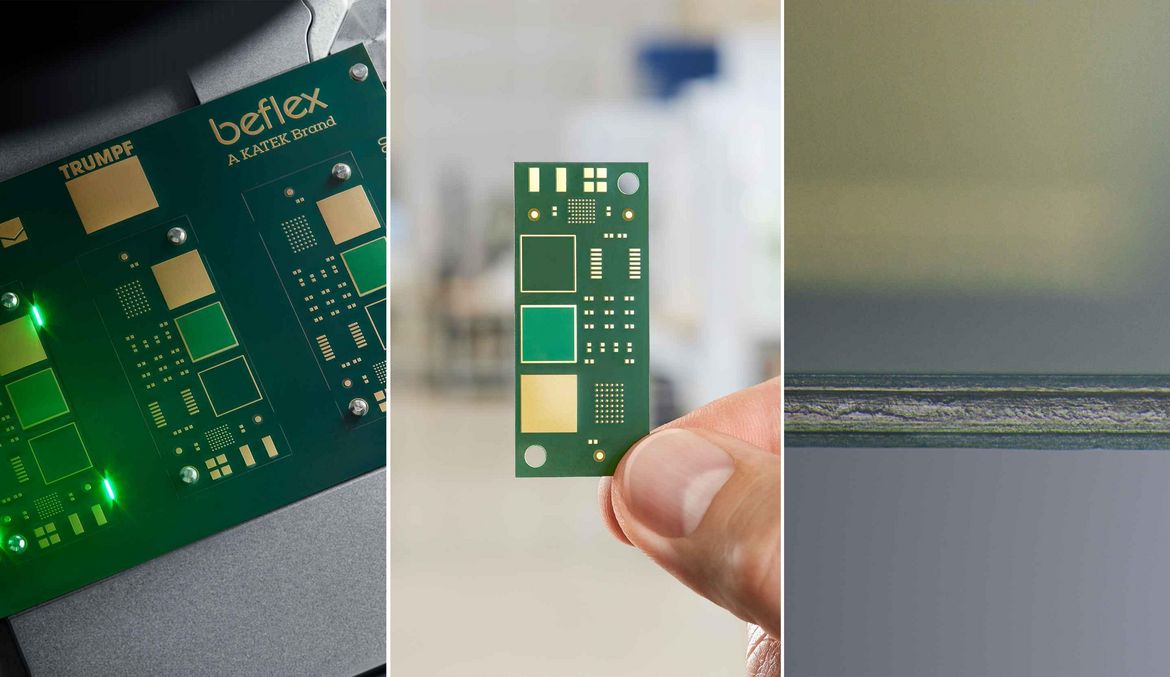

Schneiden von PCB und Leiterplatten

Mit der grünen Wellenlänge bearbeiten Sie flexible Leiterplatten (FPC) für die Elektronikindustrie und Medizintechnik. Der Laser garantiert schnelles und präzises Schneiden ohne Wärmeeinflusszone. Auch bei Kunststoffen werden beste Kantenqualitäten erzielt.

Schneiden von Holz

Mit dem TruMicro 6220 wird Holz präzise geschnitten. Dank fortschrittlicher Ultrakurzpulstechnologie werden organische Materialien rückstandslos bearbeitet.

|

TruMicro 6020

|

TruMicro 6220

|

TruMicro 6320

|

|

|---|---|---|---|

| Laserparameter | |||

| Mittlere Ausgangsleistung | 200 W | 100 W |

30 W (< 500 fs) oder

50 W (< 850 fs) |

| Strahlqualität (M²) | < 1,3 , optional < 1,2 | < 1,3 , optional < 1,2 | < 1,3 , optional < 1,2 |

| Wellenlänge | 1030 nm | 515 nm | 343 nm |

| Pulsdauer |

< 850 fs oder

< 5 ps |

< 850 fs |

< 500 fs oder

< 850 fs |

| Max. Pulsenergie |

200 µJ bei 1 MHz oder

2 mJ bei 100 kHz |

100 µJ bei 1000 kHz |

37,5 µJ bei 800 kHz (30 W)

50 µJ bei 1 MHz (50 W) |

| Max. Repetitionsrate |

2000 kHz

50000 kHz QCW-Mode |

2000 kHz | 2000 kHz |

| Bauform | |||

| Abmessungen Laserkopf (B x H x T) | 600 mm x 366 mm x 735 mm | 600 mm x 366 mm x 735 mm | 600 mm x 366 mm x 735 mm |

| Abmessungen Versorgungsgerät (B x H x T) | 446 mm x 915 mm x 725 mm | 446 mm x 915 mm x 725 mm | 446 mm x 915 mm x 725 mm |

| Aufstellung | |||

| Umgebungstemperatur | 15 °C - 35 °C | 15 °C - 35 °C | 15 °C - 35 °C |

Die technischen Daten aller Produktvarianten als Download.

TruControl

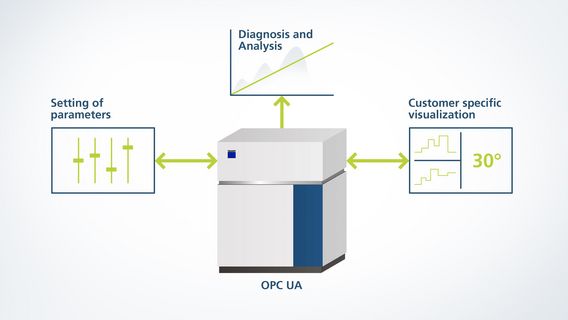

TruControl ist die schnelle und einfach bedienbare Steuerung für TRUMPF Festkörperlaser. Sie regelt die Laserleistung in Echtzeit für reproduzierbare Ergebnisse. TruControl verwaltet, steuert und visualisiert die Schnittstellenbelegung. Sie profitieren von einer einheitlichen Steuerungsarchitektur über alle Lasertechnologien hinweg. Die Laser verfügen über Schnittstellen zur Ansteuerung von intelligenten TRUMPF Optiken, z.B. der überwachten Fokussieroptik CFO oder der Scanneroptik PFO. Die Programmierung der Bearbeitungsoptik erfolgt bequem über die Lasersteuerung. Mit Remote Support von TRUMPF erhalten Sie außerdem in wenigen Sekunden per Fernwartung Unterstützung. Dadurch können Serviceeinsätze verhindert oder bestmöglich vorbereitet werden und die Verfügbarkeit des Lasergeräts steigt.

Für ein optimales Prozessergebnis ist die zeitlich präzise Definition der einzelnen Laserpulse relevant. Durch die lineare Slab-Verstärkung lässt sich der exakte Zeitpunkt und die Pulsenergie je Einzelpuls einstellen. Speziell in Kombination mit einem Scanner kann diese Funktion auch bei Beschleunigung oder Verzögerung äquidistante Pulse am Werkstück liefern.

Im Störungsfall greifen TRUMPF Serviceexperten über eine sichere Remote-Verbindung aktiv auf Ihren Laser zu. Häufig wird so die Störung direkt behoben oder die Konfiguration des Lasers so verändert, dass Sie bis zum Eintreffen des Ersatzteils weiter produzieren können.

Für die Integration eines TruMicro Lasers in Ihre Maschine oder Fertigungslinie sind die Schnittstellen entscheidend. Daher bieten Festkörperlaser von TRUMPF Schnittstellen zu allen gängigen Feldbussystemen. Weiterhin sind erhältlich: Echtzeitschnittstelle, Parallel Digital I/O, Schnittstelle für Prozesssensorik, OPC UA Softwareschnittstelle, analoge Eingangskarte, Schnittstelle für intelligente TRUMPF Optiken (CFO, PFO).

TOP Cleave Schneidoptik

Die Fokussieroptik TOP Cleave-2 ist eine Bearbeitungsoptik zum hochdynamischen Schneiden von transparenten Materialien wie Glas oder Saphir.

TOP Weld Bearbeitungsoptik

Die innovative Bearbeitungsoptik zum zwischenschichtfreien Schweißen transparenter Materilien.

Je nach Land sind Abweichungen von diesem Produktsortiment und von diesen Angaben möglich. Änderungen in Technik, Ausstattung, Preis und Zubehörangebot sind vorbehalten. Bitte setzen Sie sich mit Ihrem Ansprechpartner vor Ort in Verbindung, um zu erfahren, ob das Produkt in Ihrem Land verfügbar ist.