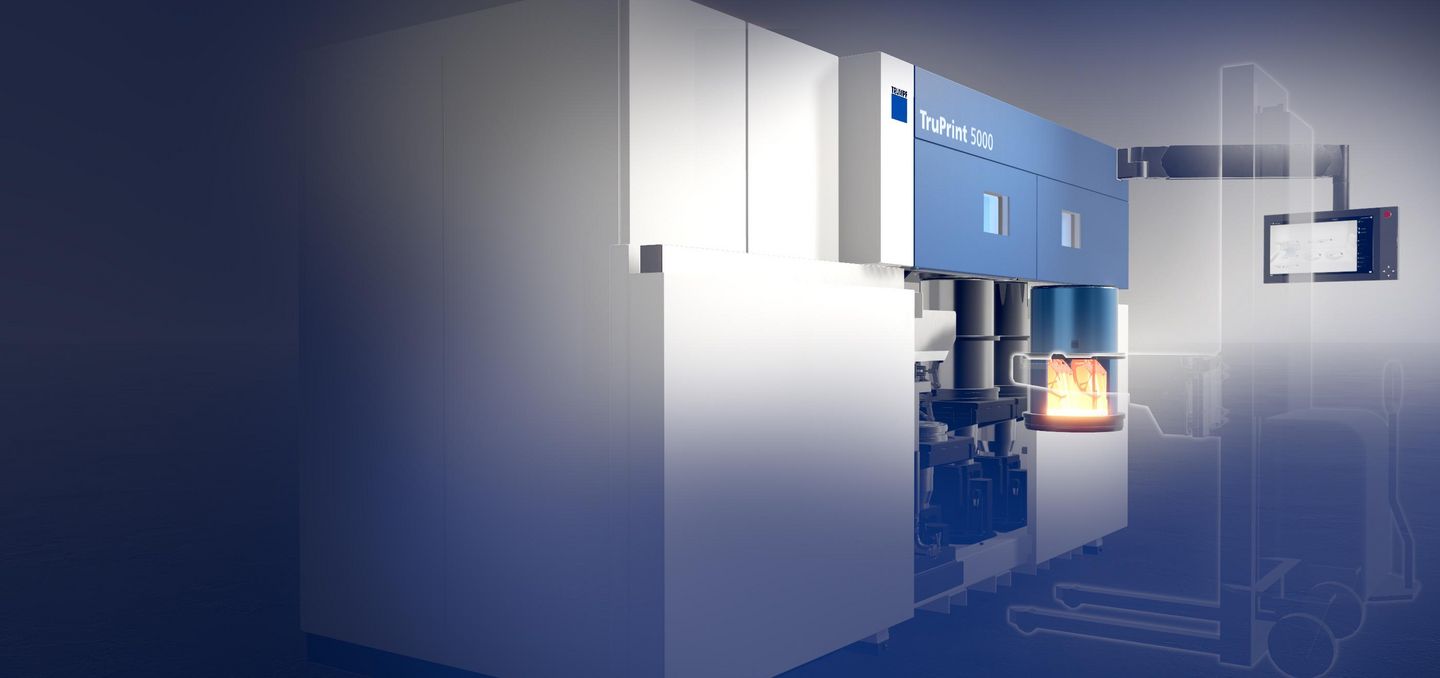

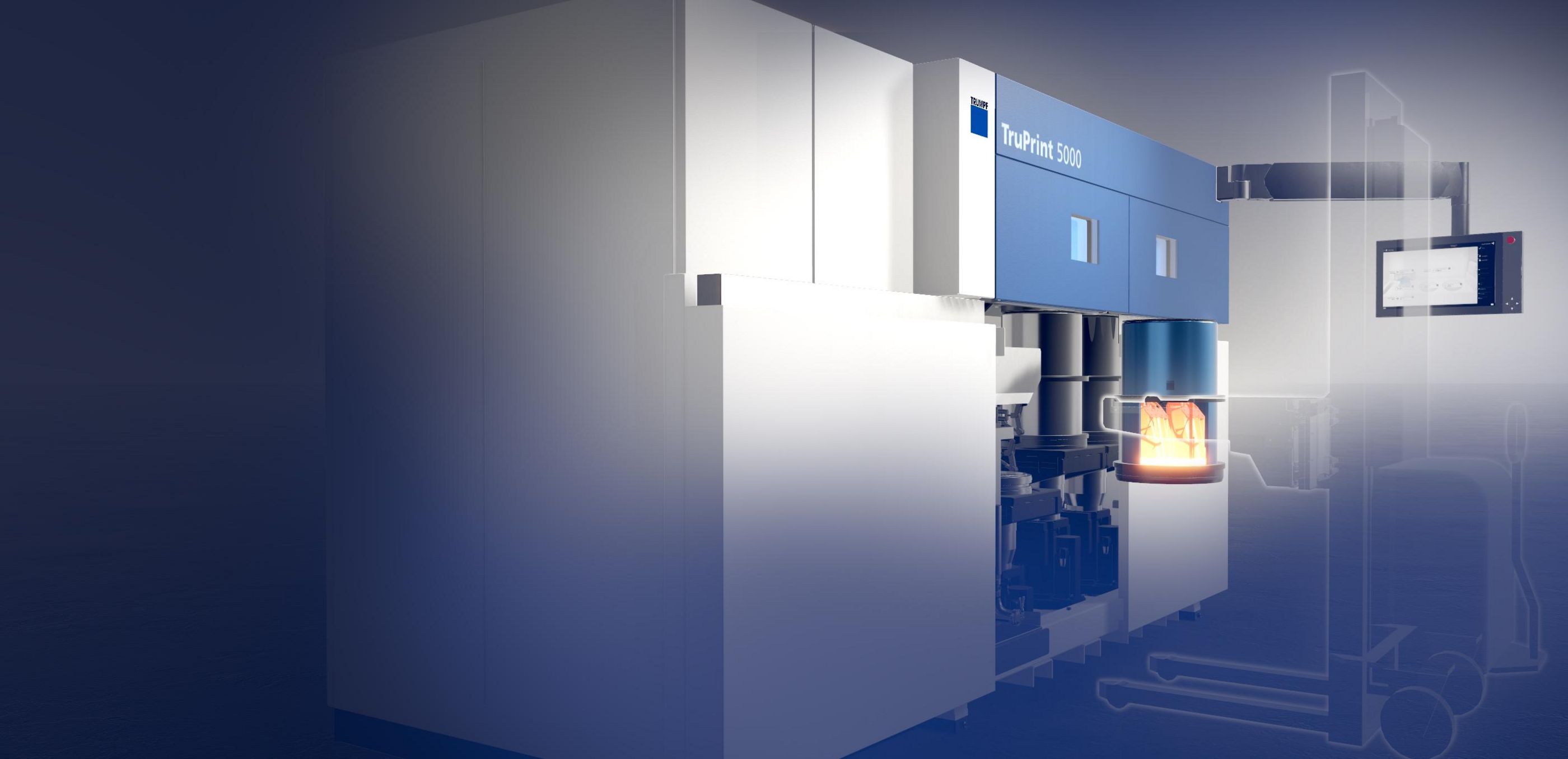

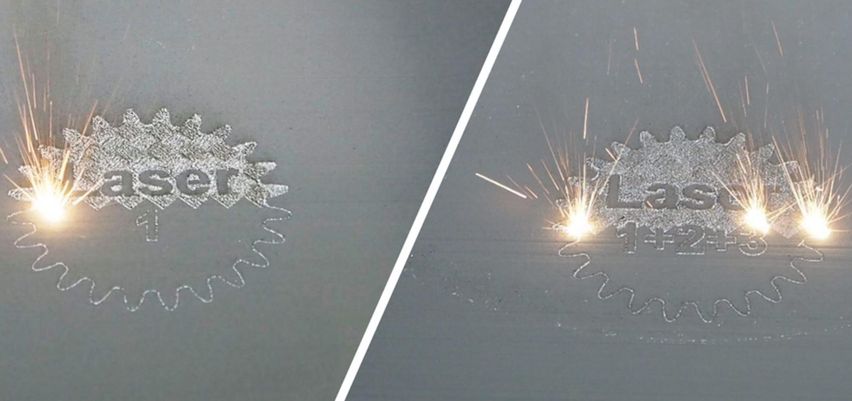

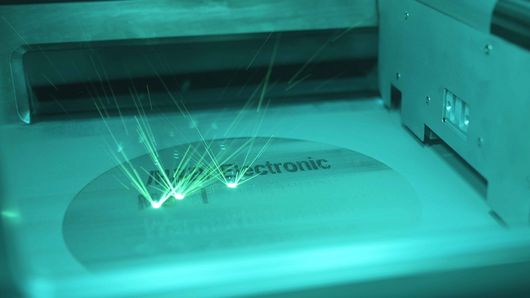

Drei 500 Watt Fullfield Multilaser belichten dank den hochdynamischen Scanstrategien mit SCANahead zeitgleich überall im Bauraum und garantieren so eine optimale Oberflächenqualität ohne Nahtstellen. Zudem wird mit Automatic Multilaser Alignment Plus automatisch die Positionierung der Laserstrahlquellen überwacht und bei Bedarf korrigiert, für eine reproduzierbare Bauteilqualität.

Schneller zum hochwertigen 3D-Bauteil

Das hochproduktive, teilautomatisierte 3D-Drucksystem TruPrint 5000 macht Sie fit für die industrielle Serienproduktion. Mit Features wie einer optionalen 500 °C-Vorheizung und der Fullfield Multilaser-Ausstattung mit drei 500 Watt TRUMPF Faserlasern sind Sie für höchst anspruchsvolle, industrielle Applikationen bestens gewappnet. Hochwertige Bauteile aus unterschiedlichen metallischen Materialien fertigt die Maschine schnell und zuverlässig – und erfüllt dabei die hohen Qualitätsansprüche im Werkzeug- und Formenbau auch mittels 3D-Druck auf Preformrohlinge, in der Luft- und Raumfahrt sowie in der Medizintechnik. Optional kann die gesamte Prozesskette unter Schutzgasatmosphäre stattfinden: Sieben, drucken, abkühlen, entpulvern. Kombiniert mit dem externen Teile- und Pulvermanagement und den Monitoringlösungen von TRUMPF ist sie prädestiniert für die industrielle additive Serienfertigung.

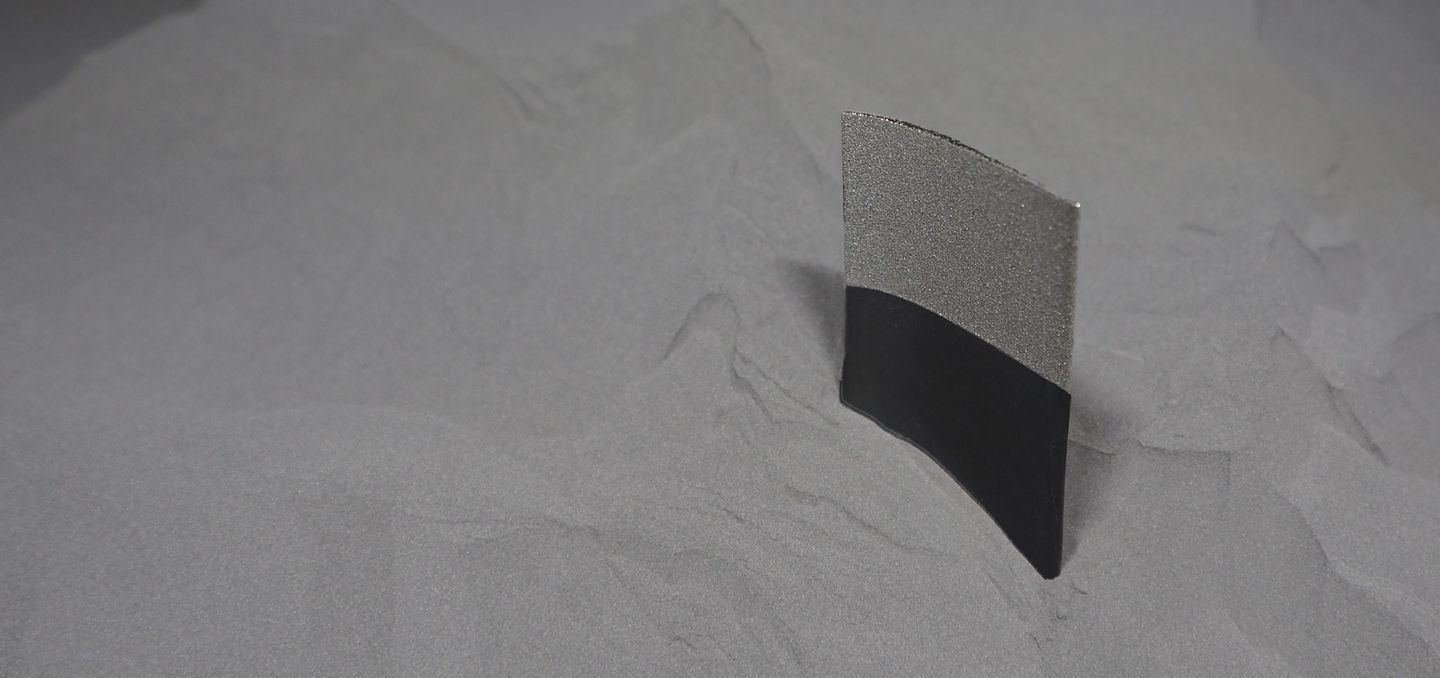

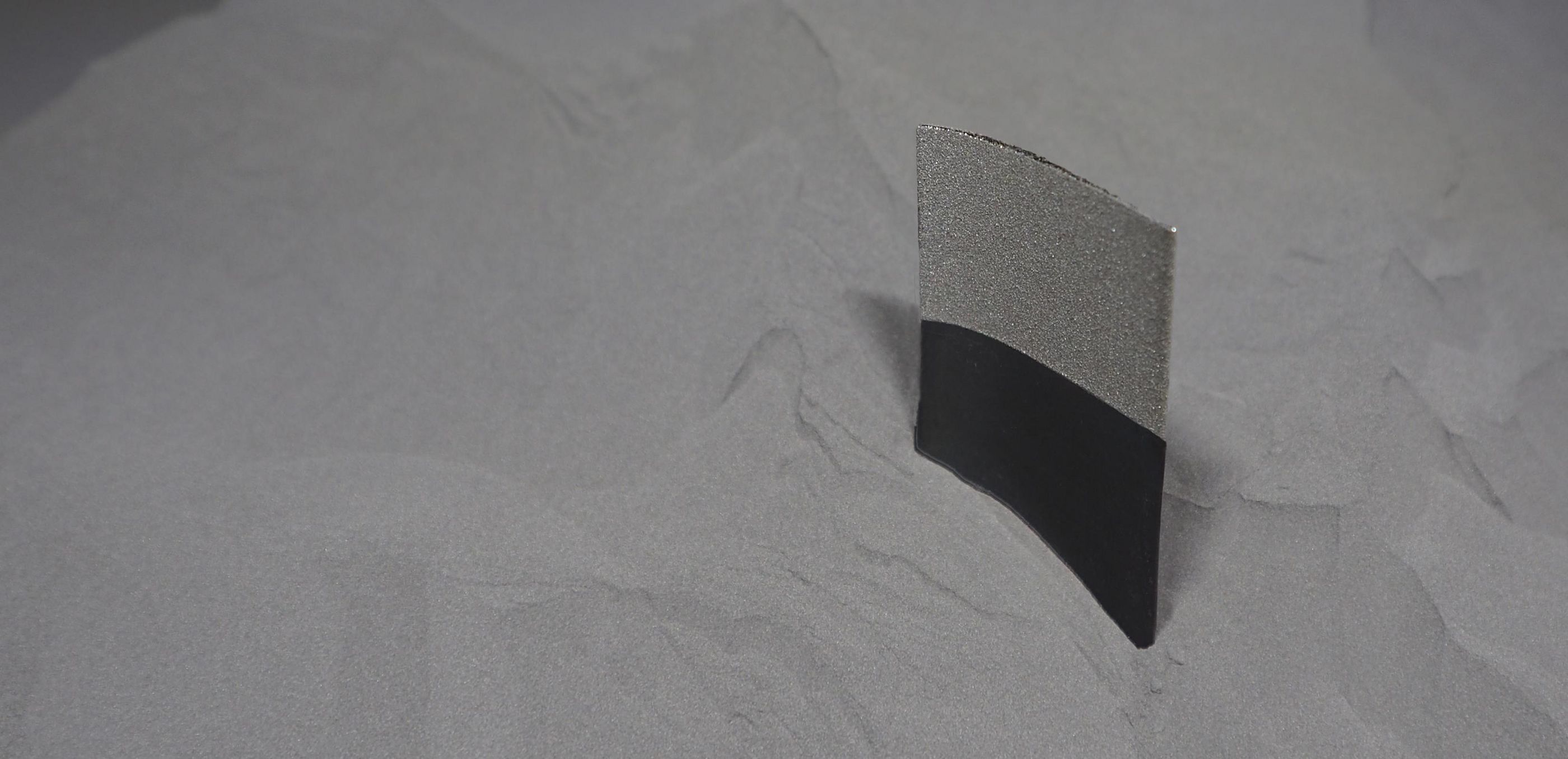

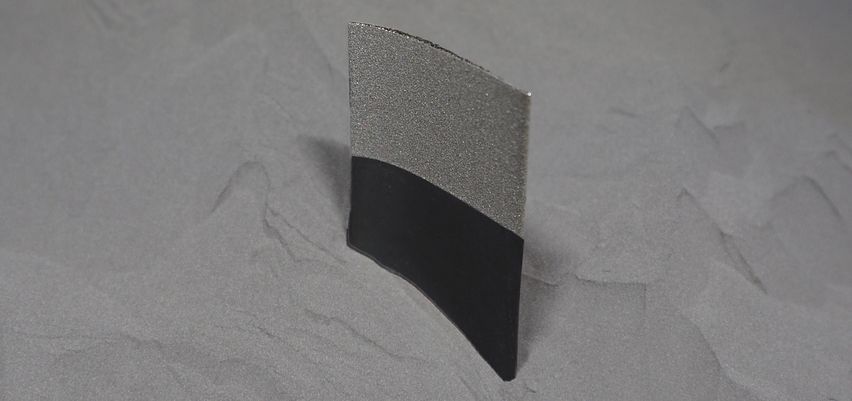

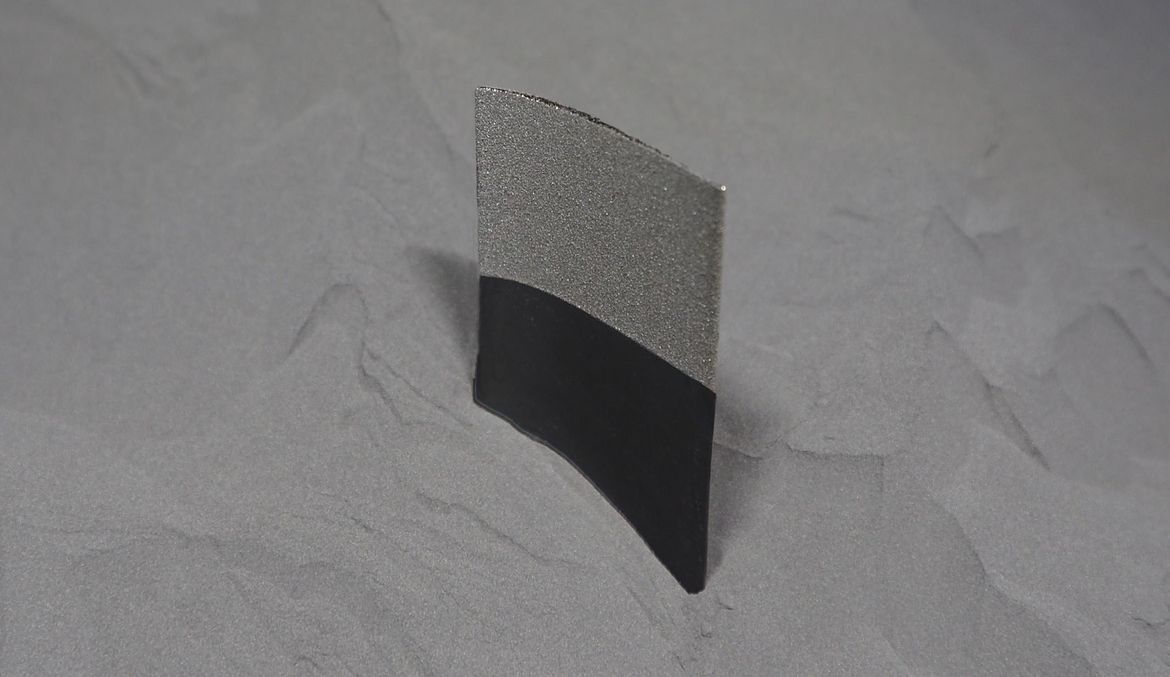

Dank der Option Preform unterstützt die TruPrint 5000 die hybride Bauteilproduktion. Die additiv zu fertigende Bauteilstrukturen werden hierzu auf einem Rohling aufgebracht. Die innovative Option ist besonders für einfaches Handling im Werkzeug- und Formenbau prädestiniert.

Drei 500 Watt Fullfield Multilaser belichten dank den hochdynamischen Scanstrategien mit SCANahead zeitgleich überall im Bauraum und garantieren so eine optimale Oberflächenqualität ohne Nahtstellen. Zudem wird automatisch die Positionierung der Laserstrahlquellen überwacht und bei Bedarf korrigiert.

Die optionale Vorheizung der Substratplatte auf bis zu 500 °C sorgt für eine hohe Bauteilqualität und einen robusten Bauprozess. Alle wichtigen Prozessschritte können unter Schutzgas betrieben werden.

Der automatische Prozessstart ermöglicht ein schnelles Rüsten und bietet eine hohe Prozesssicherheit.

Dank der Option Preform wird die hybride Bauteilproduktion unterstützt. Durch den Einsatz von Preform-Rohlingen sparen Sie Zeit und Kosten und profitieren gleichzeitig von den Vorteilen der additiven Fertigung.

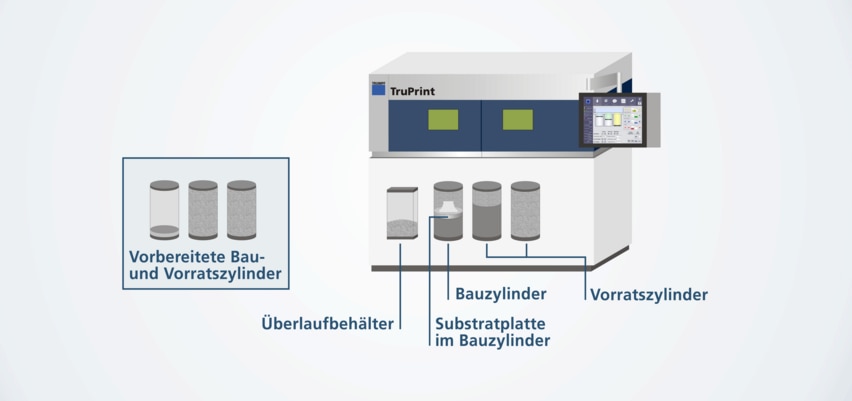

Die TruPrint 5000 ermöglicht hauptzeitparalleles Arbeiten: der Rüstprozess wird optimiert, die Produktivität erhöht und Kontakt mit Pulver vermieden.

Haben Sie Pulverauftrag, Schmelzbad, Maschinenzustand und -produktivität immer im Blick und Schicht für Schicht die volle Kontrolle über die Bauteilqualität.

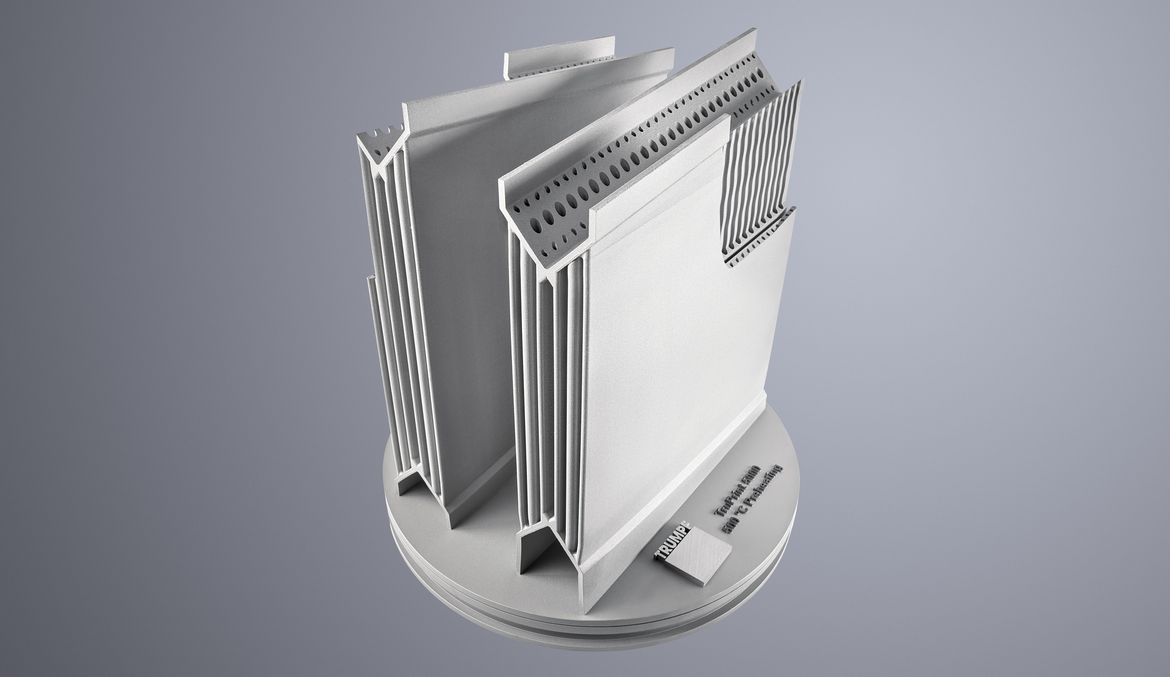

Wärmetauscher

In der Luft- und Raumfahrtindustrie können große Bauteile aus dem Metall 3D-Drucker ohne Risse oder Delaminierungsfehler hergestellt werden. Mit der TruPrint 5000 und der Option Vorheizung 500 °C drucken Sie zum Beispiel Heat Exchanger aus Titan (Ti64) hochqualitativ und kosteneffizient – ohne Ausschuss oder Materialverschwendung.

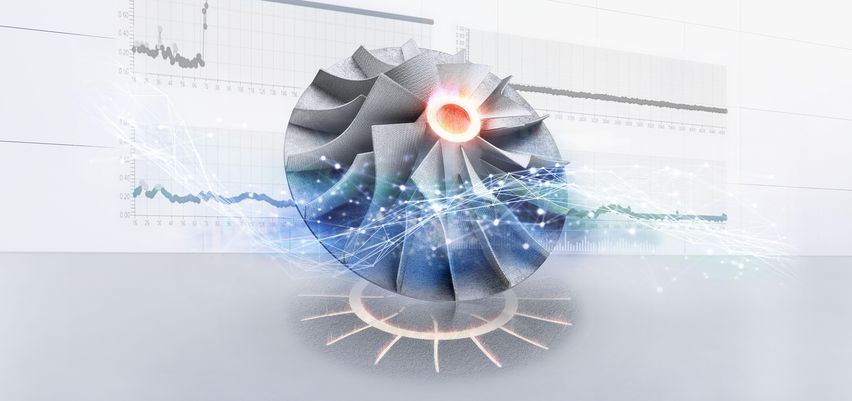

Einspritzdüsenring

Mit der TruPrint 5000 können Hochleistungsmaterialien im industriellen Produktionsmaßstab hochproduktiv verarbeitet werden. Die Luft- und Raumfahrtindustrie, Energiebranche und der Automobilbau profitiert durch das neue Material Ti6242, das durch die TruPrint 5000 mit 500 °C prozesssicher und ohne Eigenspannung im Bauteil verarbeitet werden kann, wie der Einspritzdüsenring der Firma Blasius GERG GmbH.

Hybrider Werkzeug- und Formenbau mit Preform und 3D-Druck

Die additive Fertigung ermöglicht die prozesssichere Herstellung von Gusswerkstücken mit tiefen Rippen. Durch konturnahe Kühlung wird das Überhitzen domförmiger Geometriebereiche von Schiebern effektiv vermieden, wodurch sich kürzere Zykluszeiten realisieren lassen. Gleichzeitig wird dadurch auch die mikrokristalline Struktur des Gussteils verbessert, wodurch es höher belastbar ist. Dank der Option Preform unterstützt die TruPrint 5000 die hybride Bauteilproduktion. Die additiv zu fertigende Bauteilstrukturen werden hierzu auf einen Rohling aufgebracht. Preform Basic ist dabei besonders für einfaches Handling im Werkzeug- und Formenbau prädestiniert.

Werkzeugproduktion mittels Preform und PBF

Durch die Option Preform wird der Fräser mit der TruPrint 5000 kosten- und materialsparend in Serie hergestellt, indem nur dort gedruckt wird, wo es wirklich notwendig ist. Preform Advanced ermöglicht automatisch ein hochgenaues positionieren der zu druckenden Fräsköpfe auf den konventionell gefertigten Rohlingen. Design by Paul Horn GmbH.

Bionisch optimierter Wärmetauscher

Computergestützte Entwicklung eines effizienten Wärmetauschers mittlerer Größe durch Hypergenic. Der Druckverlust wurde im Vergleich zu einem herkömmlichen Wärmetauscher um 50 % reduziert. Ziel war es, den Druckverlust zu minimieren und gleichzeitig die maximale Kühlleistung zu erreichen, was nur durch das additive Design ermöglicht wurde. Gedruckt wurde der Wärmetauscher in Ti6242. Designed by Hyperganic.

Hüftpfanne aus Titan Ti6Al4V ELI

Die verschiedenen Gitterdesigns auf einer Hüftpfanne wurden mit hoher Detailauflösung auf den TruPrint Maschinen gedruckt. Durch das Vorheizen auf 500 °C kann die Menge der Stützstruktur sehr stark reduziert werden, sogar das Stapeln von Teilen wird möglich. Beide Schritte wirken sich positiv auf die gesamte Prozesskette aus, indem sie die Materialkosten senken und den Produktionszyklus verkürzen.

Halterung am Satellit

Im Gegensatz zur konventionellen Herstellung durch Fräsen aus einem Block mit 95 % Materialabtrag, kann durch die additive Fertigung der Satellitenstruktur eine Gewichtsreduktion um 28 % sowie eine Steifigkeitserhöhung um 45 % erzielt werden.

Werkzeug- und Formenbau

Bei diesem mit Powder Bed Fusion optimierten Angussverteiler der Laupp GmbH wurden die Prozessschritte von fünf auf einen reduziert sowie Dichtstellen eliminiert. Die konturnahen Temperierkanäle des aus Titan und der Option Vorheizung 500 °C gefertigten Serienteils ermöglichen eine effizientere Leistung und eine Reduktion der Betriebskosten.

Luft- und Raumfahrt

Wird eine kardanische Aufhängung oder kardanische Lagerung (engl. "gimbal") mit der Vorheizungsoption 500 °C gedruckt, so reduziert sich die Eigenspannung im Ti6AI4V-Bauteil erheblich. Dies eröffnet völlig neue Möglichkeiten beim Design, besonders bei der Konstruktion von massiveren Bauteilen.

Werkzeug- und Formenbau

Das Druckergebnis der hochglanzpolierten Kerne der Reinhard Bretthauer GmbH, die mit der Option Vorheizung 500 °C aus H11 gedruckt wurden, ist rissfrei und weist eine Dichte von mehr als 99,9 % auf. Die Polierbarkeit ist entsprechend hoch - im Vergleich zur konventionellen Fertigung lässt sich kein Unterschied feststellen. Die Kühlperformance fällt gleichwertig zu Kupfer aus - durch die integrierten Kühlkanäle kann eine stabile Produktion von Plastikteilen im Spritzguss erfolgen und die Zykluszeit signifikant reduziert werden.

Turbinenlaufschaufel für Triebwerk in der Luft- und Raumfahrtindustrie

Bei einer Turbinenlaufschaufel, die von Verschleiß betroffen ist, steht oft die Entscheidung an: Wegschmeißen oder reparieren? Durch die hybride Fertigung mit der Option Preform Basic sparen Sie Kosten, Material und Zeit für die Wiederbeschaffung ein. Hierzu wird der defekte Teil der Turbinenlaufschaufel abgefräst; auf das bestehende Teil wird per Powder Bed Fusion 3D-gedruckt. Besonders bei angespannten Lieferketten ist dies ein erheblicher Vorteil.

|

TruPrint 5000

|

|

|---|---|

| Bauvolumen (Zylinder) | Durchmesser 300 mm x 400 mm Höhe |

| Effektives Bauvolumen (wenn Vorheizung >200 °C) | Durchmesser 290 mm x 390 mm Höhe |

| Verarbeitbare Werkstoffe | Schweißbare Metalle in Pulverform, wie z.B.: Edelstähle, Werkzeugstähle, Aluminium-, Nickelbasis-, Titan-Legierungen. Aktuelle Werkstoff- und Parameterverfügbarkeit auf Anfrage. |

| Vorheizung (Standard) | Bis zu 200 °C |

| Vorheizung (Option) | Bis zu 500 °C |

| Maximale Laserleistung am Werkstück (TRUMPF Faserlaser) | 500 W |

| Strahldurchmesser (Standard) | 80 μm |

| Schichtdicke (individuell einstellbar) | 30 - 150 μm |

| Aufbaurate | 5 - 180 cm³/h 1 |

| Anschluss und Verbrauch | |

| Elektrischer Anschluss (Spannung) | 400 V |

| Elektrischer Anschluss (Stromstärke) | 32 A |

| Elektrischer Anschluss (Frequenz) | 50 Hz |

| Schutzgas | Stickstoff, Argon |

| Bauform | |

| Gewicht (inkl. Filter, Schaltschrank, Pulver) | 7085 kg |

| Abmessungen (inkl. Filter, Schaltschrank) (B x H x T) | 4616 mm x 1645 mm x 2038 mm |

| Abmessungen (inkl. Filter, Schaltschrank) (B x T x H) mit Option Vorheizung 500 °C | 5266 mm x 1645 mm x 2038 mm |

Die technischen Daten aller Produktvarianten als Download.

TruTops Print

Mit TruTops Print bietet TRUMPF die passende Software-Lösung, um das Beste aus den TruPrint-Maschinen herauszuholen. Die moderne Benutzeroberfläche fasst alle Funktionalitäten übersichtlich zusammen und ermöglicht einen schnellen Zugriff auf alle Funktionen. Durch die hohe Flexibilität und die individuellen Möglichkeiten zur Datenvorbereitung, wie beispielsweise die z-Segmentierung, sowie das intuitive und übersichtliche Parametermanagement mit vollständig zugänglichen Parametern, werden höchste Effizienz und Produktivität bei bester Druckqualität und Reproduzierbarkeit sowie supportreduzierte Überhangbaubarkeit gewährleistet. Die hohe Güte der erstellten Vektordaten im WZA-Format kann mit dem integrierten BuildJob Viewer verifiziert werden.

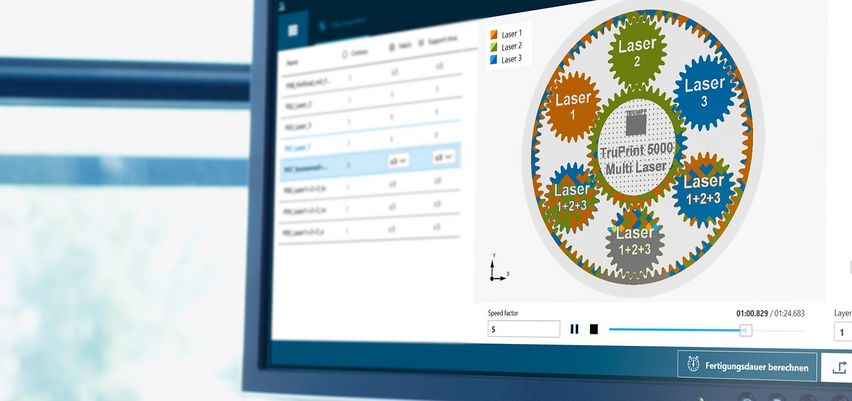

TruTops Print Multilaser Assistant

Um die drei Fullfield Multilaser der TruPrint 5000 optimal ausnutzen zu können, bedarf es einer intelligenten und flexiblen Steuermöglichkeit. Diese bietet der in TruTops Print integrierte Multilaser Assistant, in welchem die Laseraufteilung konfiguriert wird, um den Baujob hinsichtlich Produktivität oder Qualität zu optimieren. Zudem kann die Abarbeitungsreihenfolge visualisiert, und die Fertigungszeit vorhergesagt werden.

Datenvorbereitung passend zu Ihrem Workflow

Für einen nahtlosen Datenvorbereitungs-Workflow ist TruTops Print bereits an zahlreiche CAD/CAM-Systeme angebunden. Dies bietet Ihnen die größtmögliche Flexibilität bei der Auswahl der Datenaufbereitungssoftware. Entscheiden Sie selbst, welche Lösung perfekt zu Ihrem Workflow passt.

Erzielen Sie einen perfekten, einheitlichen Pulverauftrag und profitieren Sie dank der vier nutzbaren, unterschiedlichen Profilseiten von einer hohen Langlebigkeit des Beschichtermediums mit X-Profil und einem robusten Prozess.

Hinweis: Diese Option ist kompatibel bis 200 °C Vorheizung.

Die hitzebeständige Carbonbürste ermöglicht einen schnellen und robusten Pulverauftrag, insbesondere bei Vorheiztemperaturen ab 200 °C.

Eine hohe Bauteilqualität wird durch die optionale Vorheizung der Substratplatte auf bis zu 500 °C erreicht. Dies ermöglicht einen robusten Bauprozess für eine Vielzahl von Materialien - ideal für Branchen mit hohen Anforderungen an ihre Applikation (Vorheizung Basismaschine bis zu 200 °C). Mit dem industriellen Wechselzylinderprinzip in Kombination mit der Abkühlstation wird hauptzeitparalleles Abkühlen des heißen Baujobs möglich. So erhöhen Sie die Produktivität Ihres 3D-Druckers.

Mit der Option Preform Basic drucken Sie nur an der Stelle, wo es für das Bauteil wirklich notwendig ist. Dies spart neben Druckzeit auch Maschinen- und Pulverkosten und unterstützt eine nachhaltige hybride Fertigung sowie eine Wiederaufbereitung von defekten Bauteilen.

Für eine automatische und sensorbasierte Lösung über Marker nutzen Sie die Option Preform Advanced. So erzielen Sie reproduzierbare und hochgenaue Ergebnisse bei der Serienproduktion.

Über eine integrierte Kamera in der TruPrint Baukammer und die automatische Bildverarbeitung können Sie das Pulverbett automatisch überwachen. Auf diese Weise erhalten Sie jederzeit eine Übersicht über den Bauteilezustand und können die Qualitätsparameter schichtweise analysieren. Fehlendes Pulver wird mittels der Option automatisches Nachbeschichten detektiert und die betroffene Schicht automatisch durch eine neue Pulverbeschichtung korrigiert.

Abweichungen im Laserschmelzprozess lassen sich mittels Sensoren frühzeitig erkennen und kritische Bereiche am Bauteil visualisieren. Alle Schmelzbäder der drei Fullfield Multilaser lassen sich parallel überwachen.

Für Ihre TruPrint 5000 steht die Option Laser Power Measurement zur Verfügung. Prüfen Sie jederzeit die Laserleistung und stellen somit einen optimalen Prozess sicher. Weiterhin erfüllen Sie hiermit potentielle Nachweispflichten.

Monitoring TruPrint

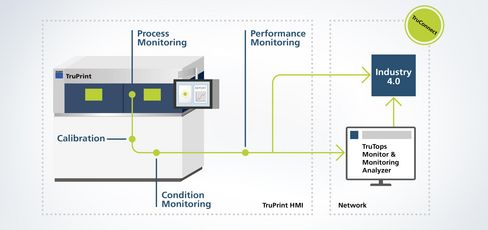

Mit den intelligenten Monitoringlösungen von TRUMPF können Sie den Bauprozess der TruPrint Maschinen einfach überwachen, analysieren und kalibrieren - damit fertigen Sie noch effizienter und erzielen eine höhere Bauteilqualität. Das professionelle Monitoring ermöglicht die Darstellung und Auswertung von sensorgestützten Daten. Das Angebot umfasst Lösungen für Process, Condition sowie Performance Monitoring. Die Ergebnisse des Monitorings können direkt an der HMI der TruPrint Maschine eingesehen oder offline mittels Monitoring Analyzer ausgewertet werden. Mit TruTops Monitor erhalten Sie neben der Transparenz die Möglichkeit eines Fernzugriffs via PC oder Tablet. Das OPC UA Interface bietet Ihnen zudem volle Flexibilität mit der Anbindung in eine eigene Softwarelösung. Mit den zusätzlich verfügbaren Calibration Funktionen überprüfen Sie vor Baujobbeginn die prozessrelevanten Kenngrößen für eine optimale Produktionsbedingung.

Entscheidend für eine industriereife Serienfertigung ist das optimale Handling des Pulvers und der Bauteile. Das industrielle Teile- und Pulvermanagement von TRUMPF ermöglicht hauptzeitparalleles Rüsten und Entpacken einer oder mehrerer Maschinen – das erhöht die Produktivität und Wirtschaftlichkeit für unsere Kunden. Standardschnittstellen und ein modularer Aufbau garantieren dabei höchste Flexibilität.

Pulver und Parameter

Hochwertige Metallpulver sind die Grundlage für zuverlässige Prozessbedingungen bei der additiven Fertigung. Die Kombination von empfohlenen Pulvern und den richtigen Parametern führt zu hochwertigen Materialeigenschaften bei 3D-gedruckten Bauteilen.

Je nach Land sind Abweichungen von diesem Produktsortiment und von diesen Angaben möglich. Änderungen in Technik, Ausstattung, Preis und Zubehörangebot sind vorbehalten. Bitte setzen Sie sich mit Ihrem Ansprechpartner vor Ort in Verbindung, um zu erfahren, ob das Produkt in Ihrem Land verfügbar ist.

Fußnoten-

Tatsächliche Aufbaurate bestehend aus Belichtung und Beschichtung. Abhängig von Anlagenkonfiguration, Verfahrensparameter, Werkstoff und Füllgrad.