Nutzen Sie die Option Multilaser für maximale Produktivität: Zwei 200 W TRUMPF Faserlaser (Wellenlänge 1.070 nm) belichten zeitgleich mit vollem Überlapp im gesamten Bauraum und generieren so flexibel bis zu 80 % mehr Teile in gleicher Zeit - bei bester Qualität. Auf diese Weise erzielen Sie eine schnellere Teileverfügbarkeit sowie höchste Flexibilität bei Kundenaufträgen.

3D-Druck in Premiumqualität: hochproduktiv und kompakt

Mit der nächsten Generation der TruPrint 1000 schreiben wir eine Erfolgsgeschichte fort – mit noch höherer Produktivität und Premiumqualität dank Fullfield Multilaser und einer völlig neu gestalteten Homogenität des Gasflusses. Der 3D-Drucker ist prädestiniert für die Verarbeitung von Metallpulvern nach dem Laser Metal Fusion-Verfahren, auch Powder Bed Fusion genannt. Auf Grund der hohen Robustheit und Qualität im 3D-Druck ist die TruPrint 1000 nicht nur für den Dentalmarkt perfekt geeignet, sondern besticht auch im R&D-Bereich oder in kleinen Serienbaureihen.

Das neue Design der TruPrint 1000 ist optimal darauf ausgelegt, dass die Maschine durch eine Standardtüre passt und in jedem Labor, z.B. im Dentalbereich oder in Universitäten, Platz findet.

Durch Multilaser 2 x 200 W und automatischen Substratplattenwechsel

Durch neu entwickelten Gasfluss und verbesserte Laserfokus-Stabilität

Inerter Pulverkreislauf mit Glovebox und austauschbaren Zylindern

Durch die einstellbare Spotgröße (55/80 µm) und detaillierte Prozessanalyse

Niedrigere Teilekosten durch Preform, Multiplate und hybride, digitale Kette

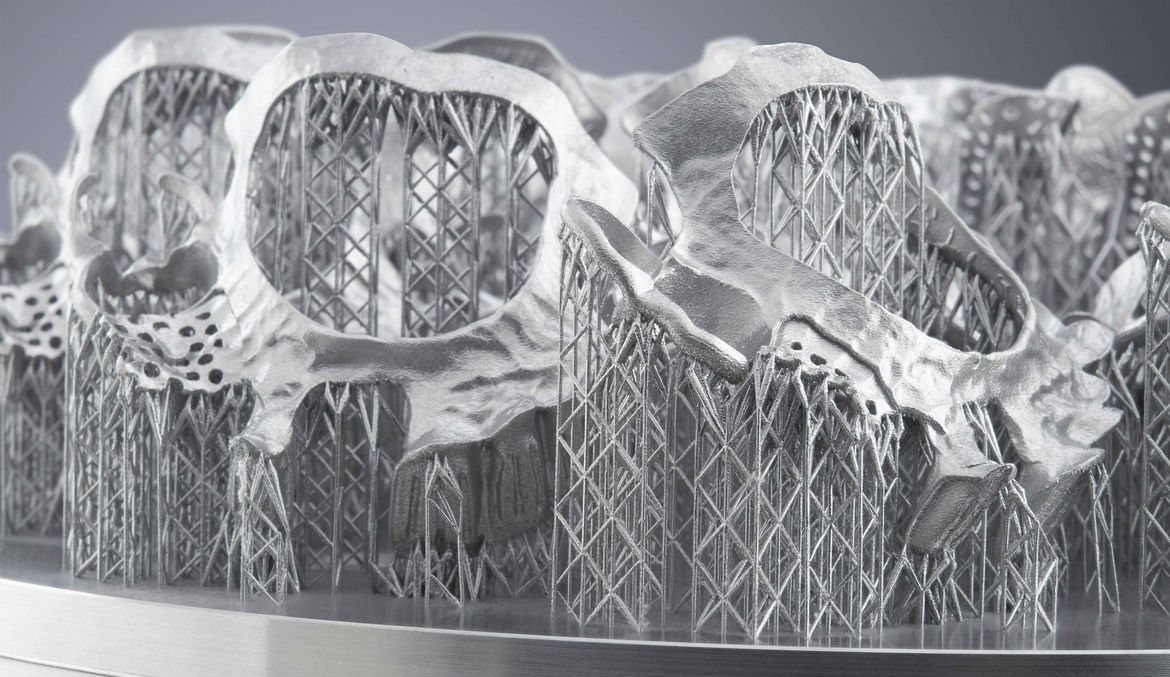

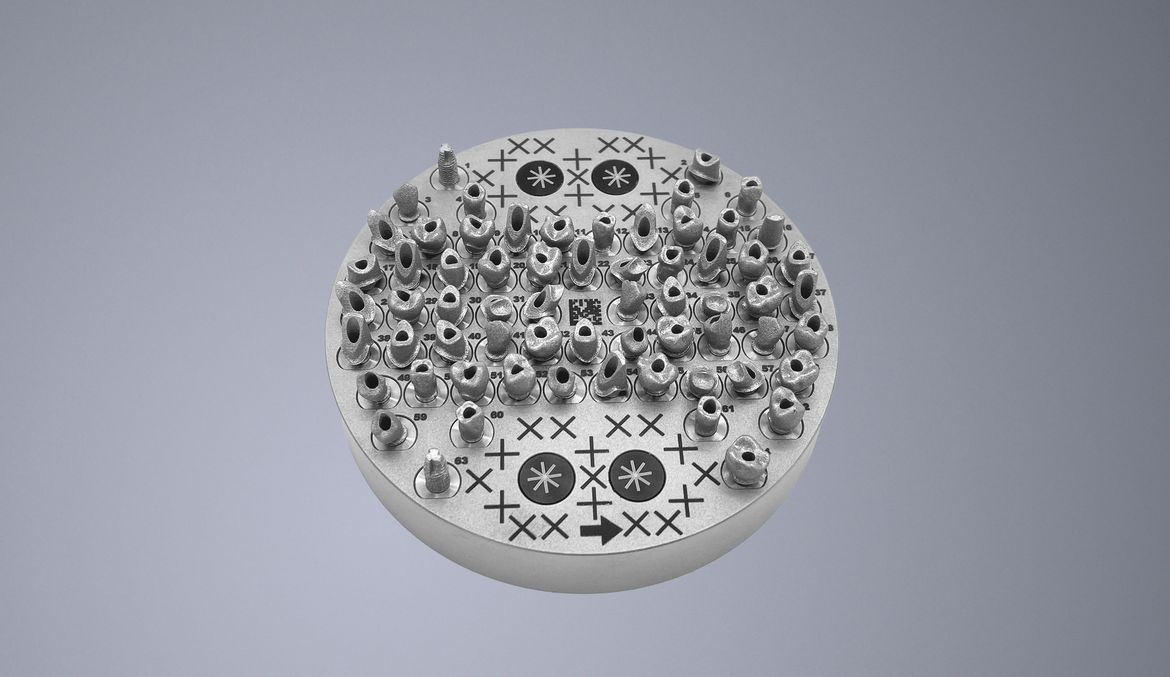

Dentalplatte

Die Dentalplatte zeigt unterschiedliche Dentalapplikationen, die mit der neuen TruPrint 1000 gedruckt wurden: mit deutlich gesteigerter Performance und Bauteilqualität.

Medizinische Applikationen

Die neue TruPrint 1000 ist dank des inerten Pulverkreislaufs sowie der hohen Dichte und glatten Oberfläche, die sie bei den gedruckten Teilen erzielen kann, auch für medizinische Anwendungen ideal. Die Aufbewahrung von Titanpulver in einer geschützten Umgebung ist wichtig, um die Qualität des Pulvers zu erhalten und dem Bediener zu ermöglichen, in einer sicheren Umgebung zu arbeiten. Die TruPrint 1000 kann mit einem Sauerstoffgehalt von 100 ppm in der Prozesskammer arbeiten, wodurch die perfekte Qualität für medizinische Teile gewährleistet wird. Die hohe Baurate ermöglicht es, mehrere kundenspezifische Implantate in nur wenigen Stunden zu drucken.

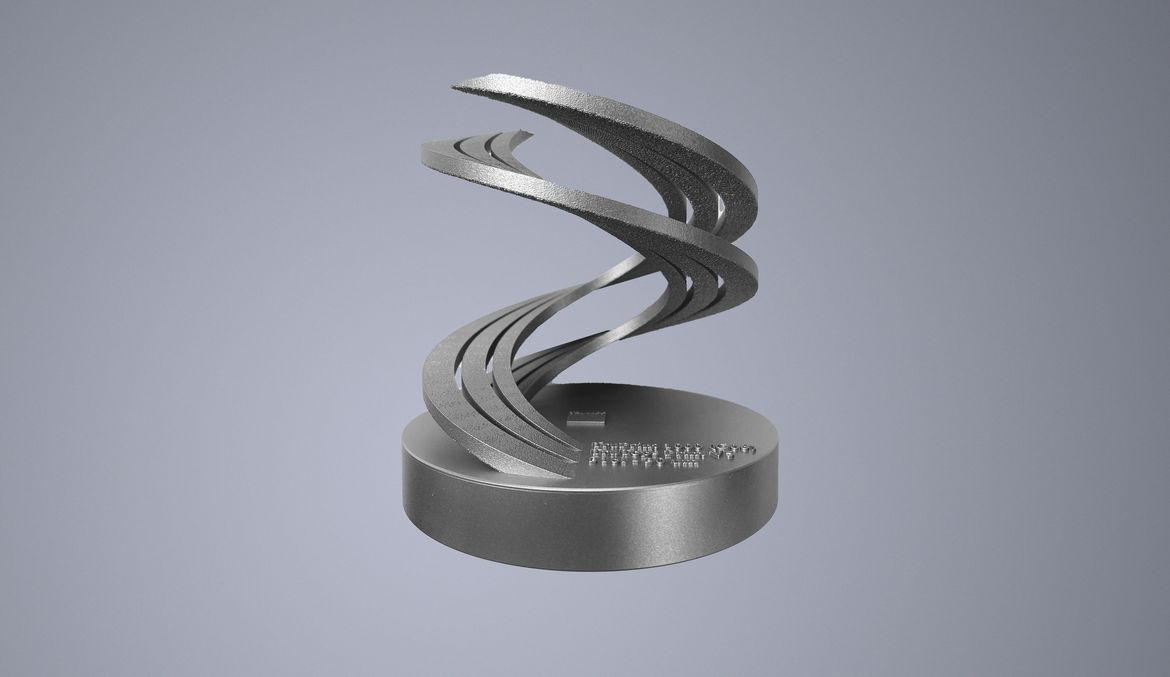

Demonstrator mit spiralförmigem Überhang

Das Bauteil zeigt, wie die verbesserte Maschinenleistung und die optimierte Laserstrategie des TruTops Print Build Processors es ermöglichen, sehr niedrige Überhänge (15°-25°) zu erreichen und die Teile- und Oberflächenqualität zu garantieren.

Dentalplatte mit Vorbereitung zum Nachfräsen

Die Dentalplatte ist mit Messpunkten für die Fräsmaschine versehen. Auf diese Weise können definierte Passungsbereiche der Dentalplatte nachgefräst werden. Hier zeigt sich eine Möglichkeit der dentalen hybriden Prozesskette.

Lüfterrad / Flügelrad aus Edelstahl 316L

Die Überhänge (bis hin zu 10°) des abgebildeten Lüfterrades konnten in Verbindung mit TruTops Print ohne Supportstrukturen gedruckt werden, was Nacharbeitsaufwand einspart.

Modellguss-Prothesen (RPDs)

Mit der TruPrint 1000 können die filigranen Strukturen von beispielsweise Modellguss-Prothesen (RPDs) mit völliger Designfreiheit aus Kobalt-Chrome gedruckt werden. Neuartige Supportstrukturen vereinfachen zusätzlich die Nacharbeit.

Dentalplatte mit Preform

Für die präzise und schnelle Produktion individueller Single Abutments eignet sich die Option Preform der TruPrint 1000. Da nur der patientenindividuelle Anteil gedruckt wird, reduzieren sich die Bauteilkosten deutlich. Bis zu 64 individuelle Single Abutments können auf einer Preform gedruckt und einfach aus der Platte herausgenommen werden.

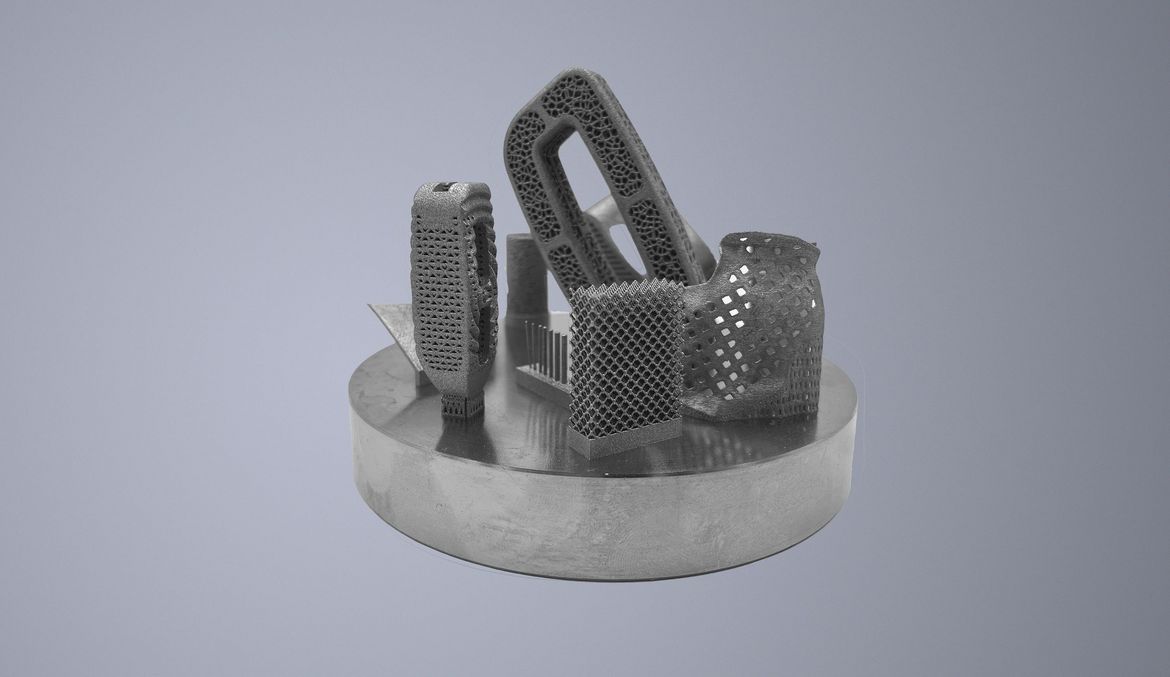

Kleinserienfertigung mit Preform

Die TruPrint 1000 ermöglicht die schnelle und wirtschaftliche Kleinserienfertigung. Auf eine Preform wird das Bauteil additiv ohne Stützstrukturen aufgebaut. Feinste Gitterstrukturen, filigrane Kanäle und integrierte Funktionen werden in nur einem Schritt realisiert. Über ein innenliegendes Gelenk rotiert z. B. die Weltkugel auf ihrer Halterung.

|

TruPrint 1000

|

|

|---|---|

| Effektives Bauvolumen (Standard) | Durchmesser 98 mm x 100 mm Höhe |

| Effektives Bauvolumen (Option: Verkleinerung des Bauzylindervolumens) | Durchmesser 48 mm x 100 mm Höhe |

| Verarbeitbare Werkstoffe | Schweißbare Metalle in Pulverform, wie z.B.: Edelstähle, Werkzeugstähle, Aluminium- [1], Nickelbasis-, Kobalt-Chrom-, Kupfer-, Titan [1] oder Edelmetall- Legierungen, amorphe Metalle. Aktuelle Werkstoff- und Parameterverfügbarkeit auf Anfrage. [1] Nur mit Option Glove-Box + Sauerstoffsensor hochauflösend. |

| Maximale Laserleistung am Werkstück (TRUMPF Faserlaser) | 200 W |

| Strahldurchmesser (Standard) | 80 μm |

| Strahldurchmesser (Motorische Optik) | 55/80 μm |

| Schichtdicke (individuell einstellbar) | 20 - 60 μm |

| Aufbaurate | 10 - 50 cm³/h |

| Anschluss und Verbrauch | |

| Elektrischer Anschluss (Spannung) | 230 V |

| Elektrischer Anschluss (Stromstärke) | 7 A |

| Elektrischer Anschluss (Stromstärke - Option Multilaser) | 9 A |

| Elektrischer Anschluss (Frequenz) | 50/60 Hz |

| Schutzgas | Stickstoff, Argon |

| Bauform | |

| Abmessungen (B x H x T) | 780 mm x 2050 mm x 1160 mm |

| Gewicht (mit Option Multilaser) | Max. 900 kg |

Die technischen Daten aller Produktvarianten als Download.

TruTops Print

Mit TruTops Print bietet TRUMPF die passende Software-Lösung, um das Beste aus den TruPrint-Maschinen herauszuholen.

Die moderne Benutzeroberfläche fasst alle Funktionalitäten übersichtlich zusammen und ermöglicht einen schnellen Zugriff auf alle Funktionen. Durch die hohe Flexibilität und die individuellen Möglichkeiten zur Datenvorbereitung, wie beispielsweise die z-Segmentierung, sowie das intuitive und übersichtliche Parametermanagement mit vollständig zugänglichen Parametern, werden höchste Effizienz und Produktivität bei bester Druckqualität und Reproduzierbarkeit sowie supportreduzierte Überhangbaubarkeit gewährleistet. Die hohe Güte der erstellten Vektordaten im WZA-Format kann mit dem integrierten BuildJob Viewer verifiziert werden.

Datenvorbereitung passend zu Ihrem Workflow

Für einen nahtlosen Datenvorbereitungs-Workflow ist TruTops Print bereits an zahlreiche CAD/CAM-Systeme angebunden. Dies bietet Ihnen die größtmögliche Flexibilität bei der Auswahl der Datenaufbereitungssoftware. Entscheiden Sie selbst, welche Lösung perfekt zu Ihrem Workflow passt.

Je nachdem, welche technischen Ansprüche Ihre Anwendung stellt, können Sie die TruPrint 1000 mit entsprechenden Optionen ausstatten.

Steigern Sie Ihre Produktivität um bis zu 80 % mit der Option Multilaser: Zwei TRUMPF Faserlaser mit je 200 W und 55 bzw. 80 µm Strahldurchmesser belichten zeitgleich im Bauraum und generieren so flexibel bis zu 80 % mehr Teile in gleicher Zeit. Auf diese Weise erzielen Sie eine schnellere Teileverfügbarkeit sowie höchste Flexibilität bei Kundenaufträgen. Da zudem jede Kontur von einem Laser belichtet wird, entstehen keinerlei "Nahtstellen". Sie arbeiten mit dem Fullfield Multilaser mit 100 % Überlapp.

Profitieren Sie von der Möglichkeit der Umschaltung zwischen 55 oder 80 µm Strahldurchmesser. So können Sie zwischen besten Oberflächenqualitäten oder höherer Produktivität priorisieren und Materialien verarbeiten, die eine höhere Energiedichte erfordern, wie beispielsweise hochreflektierende Materialien.

Das Paket ermöglicht professionelles Pulverhandling auch im Kleinformat. Dank Standardschnittstellen können externe Siebstationen, wie z.B. von assonic oder auch die Pulvervorbereitungsstation angebunden werden. Durch die Minimierung des Pulverkontakts erhöht sich automatisch die Sicherheit des Pulverhandlings. Der inerte Pulverkreislauf ermöglich auch die Verarbeitung reaktiver Materialien wie Titan dank Reduzierung und Kontrolle des Sauerstoffgehalts bis zu 100 ppm. Das Pulver kann im Vorratszylinder oder Überlaufbehälter unter Schutzgasatmosphäre transportiert und in einen extra Behälter gesiebt werden.

Sie möchten Auftragsspitzen flexibel ausgleichen und die Maschinenzeit ohne Bedienereingriff verlängern? Mit der Option Multiplate können bis zu vier Substratplatten im Bauzylinder aufgenommen werden, sodass die Substratplatte ohne Stopp des Bauprozesses automatisch gewechselt werden kann. Außerdem profitieren Sie von einer vollautomatischen Unterstützung der Maschinensoftware zum Beenden des ersten und Starten des nachfolgenden Baujobs. Fertige Baujobs werden im Überlaufbehälter gesammelt.

Für die präzise und schnelle Produktion individueller Single Abutments eignet sich die Option Preform. Da nur der patientenindividuelle Anteil gedruckt wird, reduzieren sich zudem die Bauteilkosten deutlich. Bis zu 64 individuelle Single Abutments können auf einer Preform gedruckt und einfach aus der Platte herausgenommen werden. Die automatisierte Preform-Erkennung ist ein wichtiger Meilenstein in der Industrialisierung der additiven Technologie in der Dentalindustrie.

Über eine integrierte Kamera in der TruPrint Baukammer und die automatische Bildverarbeitung können Sie das Pulverbett automatisch überwachen. Auf diese Weise erhalten Sie jederzeit eine Übersicht über den Bauteilezustand und können die Qualitätsparameter schichtweise analysieren.

Für Ihre TruPrint stehen verschiedene Optionen zur Verfügung, um der Nachweispflicht nachzukommen: Dank Laserleistungskalibrierung – auch für Multilaser und Scanfeldkalibrierung – können Sie rekalibrieren und Ihre Messergebnisse dokumentieren.

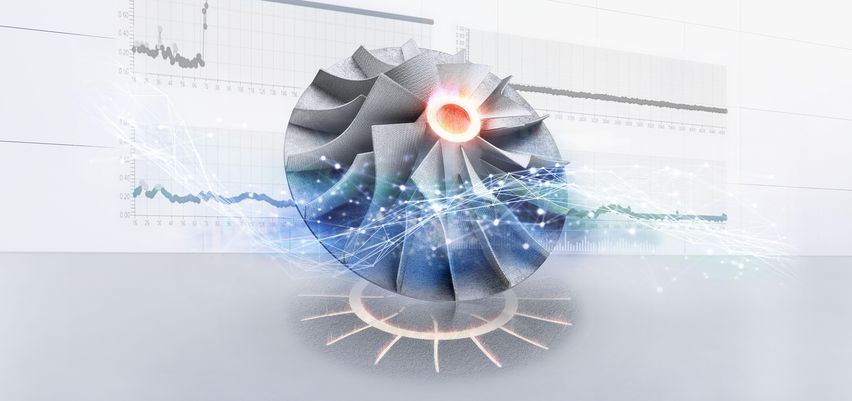

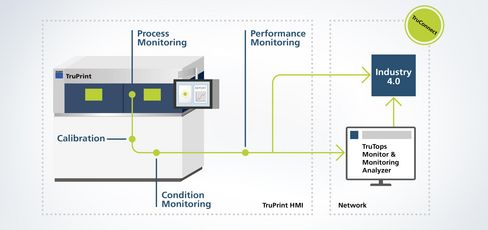

Monitoring TruPrint

Mit den intelligenten Monitoringlösungen von TRUMPF können Sie den Bauprozess der TruPrint Maschinen einfach überwachen, analysieren und kalibrieren - damit fertigen Sie noch effizienter und erzielen eine höhere Bauteilqualität. Das professionelle Monitoring ermöglicht die Darstellung und Auswertung von sensorgestützten Daten. Das Angebot umfasst Lösungen für Process, Condition sowie Performance Monitoring. Die Ergebnisse des Monitorings können direkt an der HMI der TruPrint Maschine eingesehen oder offline mittels Monitoring Analyzer ausgewertet werden. Mit TruTops Monitor erhalten Sie neben der Transparenz die Möglichkeit eines Fernzugriffs via PC oder Tablet. Das OPC UA Interface bietet Ihnen zudem volle Flexibilität mit der Anbindung in eine eigene Softwarelösung. Mit den zusätzlich verfügbaren Calibration Funktionen überprüfen Sie vor Baujobbeginn die prozessrelevanten Kenngrößen für eine optimale Produktionsbedingung.

Pulver und Parameter

Hochwertige Metallpulver sind die Grundlage für zuverlässige Prozessbedingungen bei der additiven Fertigung. Die Kombination von empfohlenen Pulvern und den richtigen Parametern führt zu hochwertigen Materialeigenschaften bei 3D-gedruckten Bauteilen.

Je nach Land sind Abweichungen von diesem Produktsortiment und von diesen Angaben möglich. Änderungen in Technik, Ausstattung, Preis und Zubehörangebot sind vorbehalten. Bitte setzen Sie sich mit Ihrem Ansprechpartner vor Ort in Verbindung, um zu erfahren, ob das Produkt in Ihrem Land verfügbar ist.

Das Beste kommt kostenlos dazu - Sichern Sie sich jetzt die Option Preform oder Multiplate!

Auf der Suche nach einem neuen 3D-Metalldrucker für Ihr Dentallabor? Beim Kauf eines neuen TruPrint 1000 erhalten Sie die Multiplate- oder Preform-Option kostenlos dazu! Das Angebot ist gültig bis 31.05.2024.

Finden Sie jetzt Ihre additive Fertigungslösung für die Zahntechnik!

Welche TruPrint Maschine am besten zu Ihrer Anwendung in der Zahntechnik passt, erfahren Sie mit Hilfe des TruPrint Produktfinders!