- Learning the production basics

- Identifying parts together

- Manufacturability analysis and business case evaluation

Consulting and training for additive manufacturing

Getting started with the technology, identifying and developing suitable components or optimising your production – at TRUMPF Additive Manufacturing (AM) you can always rely on competent support along the entire additive manufacturing process chain.

We provide a wide range of training and consulting services to enable you to quickly learn and apply new methods, thus optimally preparing you for the additive manufacturing of components.

We help you to become more economical and efficient and to achieve higher quality.

Identify your potential

Find out more about laser metal fusion (LMF) and powder bed fusion (PBF) technology and incorporate additive manufacturing expertise into your business. Identify initial uses where the potential of additive manufacturing components can be leveraged to create a business case for cost-effective production.

Customer example of part identification

After analysing the cutting properties of a 2D laser machine, diode cooling was identified as a component requiring optimisation.

Added value from metal 3D printing

- Improved cooling

- Component reduction through function integration

- Simplified assembly

- Weight reduction

Develop your part

Designs compatible for 3D printing are crucial in order to fully exploit the technology's potential. It is therefore important to know how to design 3D printed components to enable you to create solutions that are suitable for production. We also assist in selecting materials and powders and in preparing the build job data. This includes generating the right support structures and, where applicable, adjusting parameter settings.

- Designing components suitable for additive manufacturing

- Selecting appropriate materials and powders

- Preparing data and generating support

- Selecting and optimising parameters

Customer example of component design

The original design has been re-designed and re-engineered, resulting in an optimised 3D printed component.

Benefits of metal 3D printing

- Integrated flexure joint

- 75% fewer components

- 62% lower volume

- 10% lower costs

Produce your part

We support you from the initial production of a sample part in our application laboratory, through to prototype production and production on your own machine. Find out about the benefits of monitoring systems and how they can be used, and about quality assurance steps options to ensure material properties in additive manufacturing. Ensuring correct post-processing of your component is also important, beginning with the appropriate heat treatment, the removal of the support structure and ending with the surface treatment.

- Operating the machine

- Monitoring and data analysis

- Quality assurance

- Heat treatment and post-processing

Customer example for additive manufacturing series production

Additive manufacturing has not only reduced production costs but also significantly simplified assembly.

Motor cooling element for TRUMPF cutting unit

- 400 units per year produced from 316L stainless steel on a TruPrint 3000

- Post-processing: Milling threads for inlets and outlets

- 40% reduction in manufacturing costs compared to conventional production

- Quality testing in series production on accompanying samples gives a relative density of 99.8% and a tensile strength of 700 MPa

- Simplified assembly due to integrated flexure joint

Establish & improve your process

Work with us to optimise your production process. Benefit from our continuous development of machine functions, software, materials and parameters. Find out the main factors influencing component costs and increase your additive manufacturing's profitability. How to successfully series produce additive manufacturing components.

- Ramp up series production

- Process optimisation

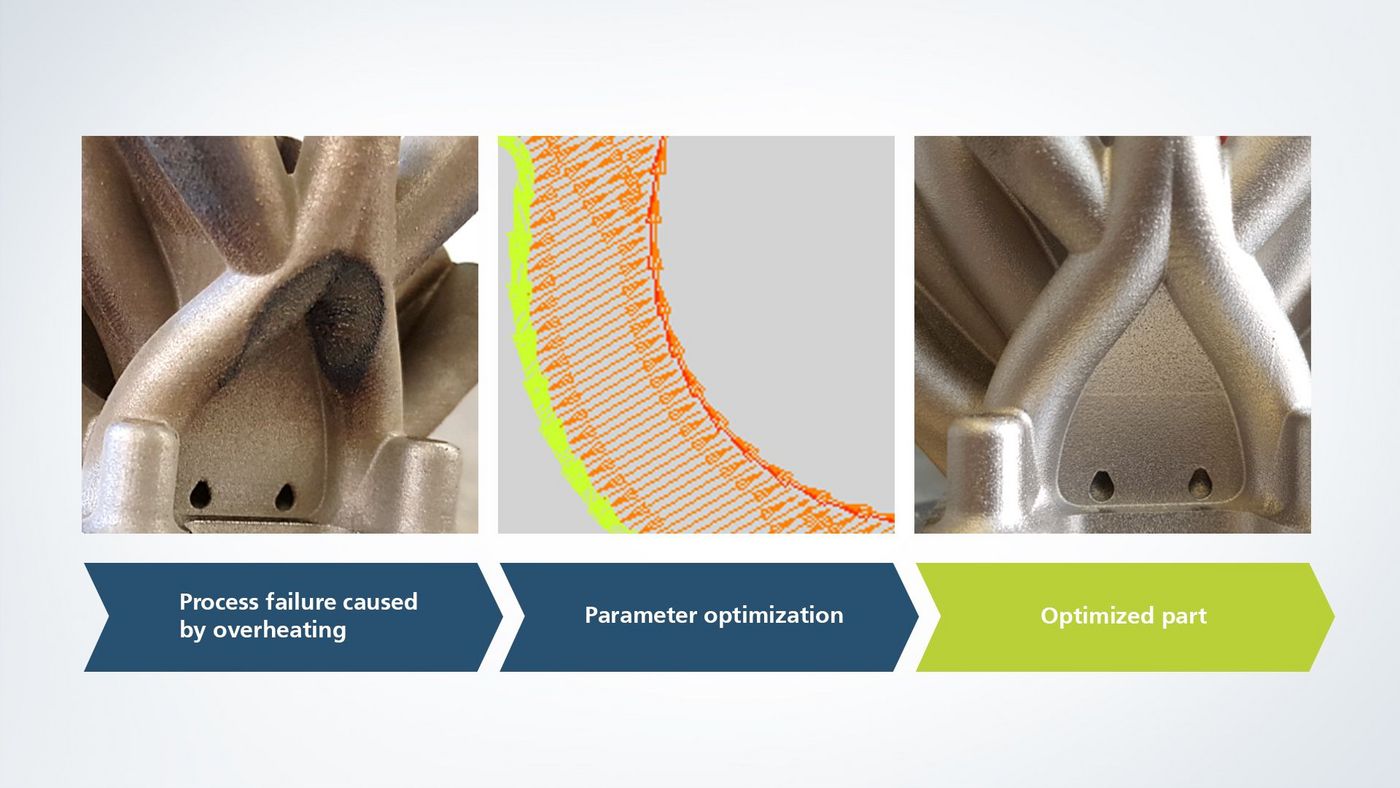

Customer example of process optimisation

Overheating of the original component has resulted in poor surface quality and process defects. Parameter optimisation and various test runs has resulted in an optimised, higher-quality component.

Benefits of process optimisation

- Improved surface quality

- Improved overhang construction

- Increased build rate

Contact our additive manufacturing experts!

Fill in our request form right now to secure yourself a personal consultation on additive manufacturing. Our experts are happy to help!

White paper for you

A process parameter analysis of 3D printed applications with green laser light.

![[Translate to en_GB:]](/filestorage/TRUMPF_Master/_processed_/e/1/csm_Additive-Manufacturing-Beispielteile-Keyvisual-2024_15ecd38ceb.png)