TruTops Cell is a true all-rounder for your daily production. With our innovative software, you can generate optimised 3D machine programs in a flash. TruTops Cell can be used with a uniquely wide range of possible input formats. You can use the convenient and powerful CAD functions in every processing step with the fully integrated CAD platform. You can also train new programmers very quickly thanks to the intuitive operating concept.

Quick and uncomplicated: your software for 3D laser processing

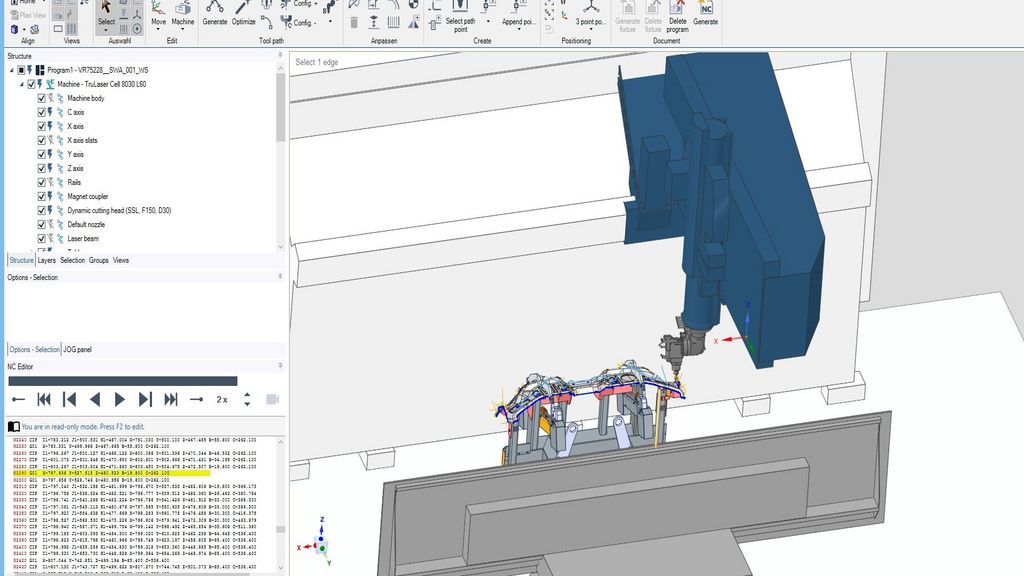

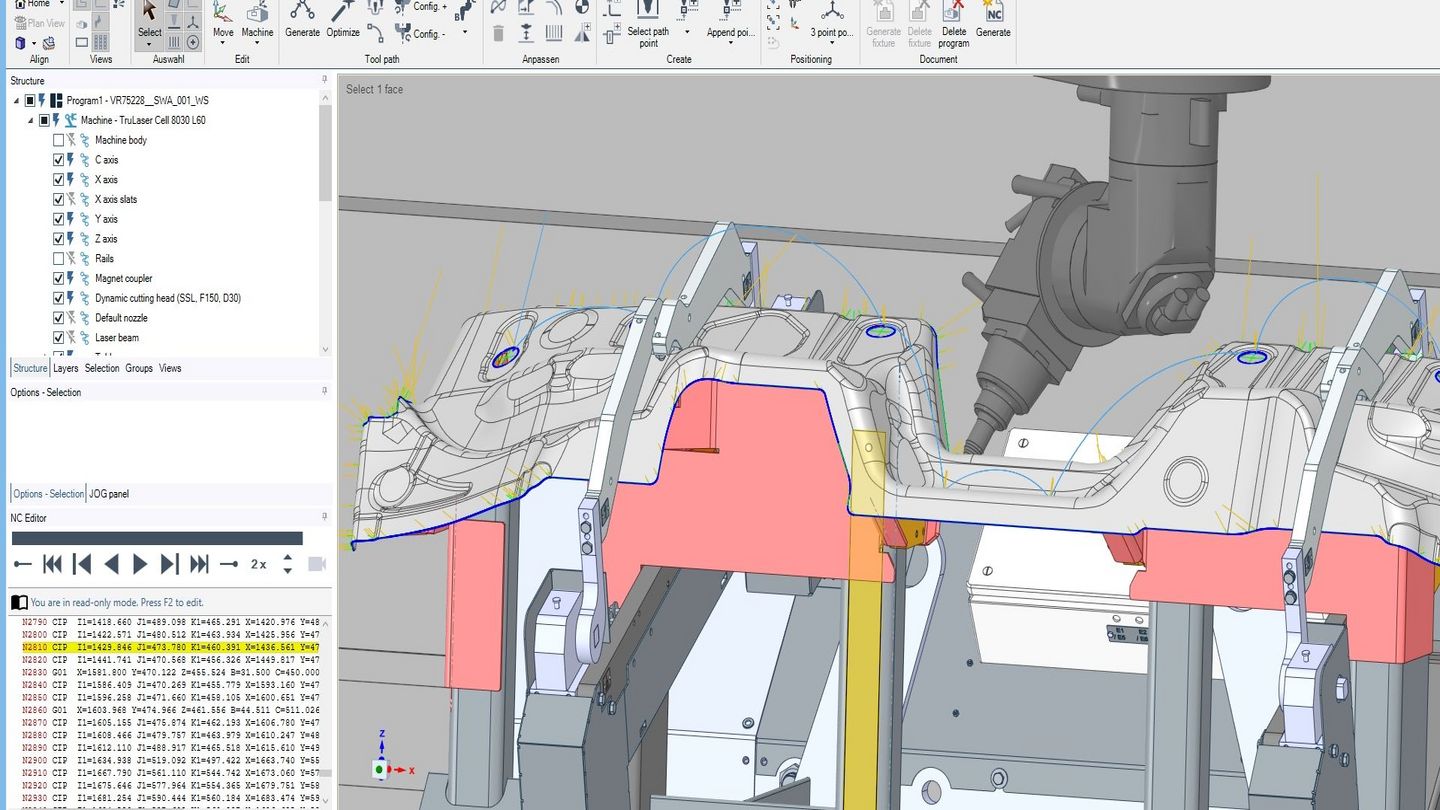

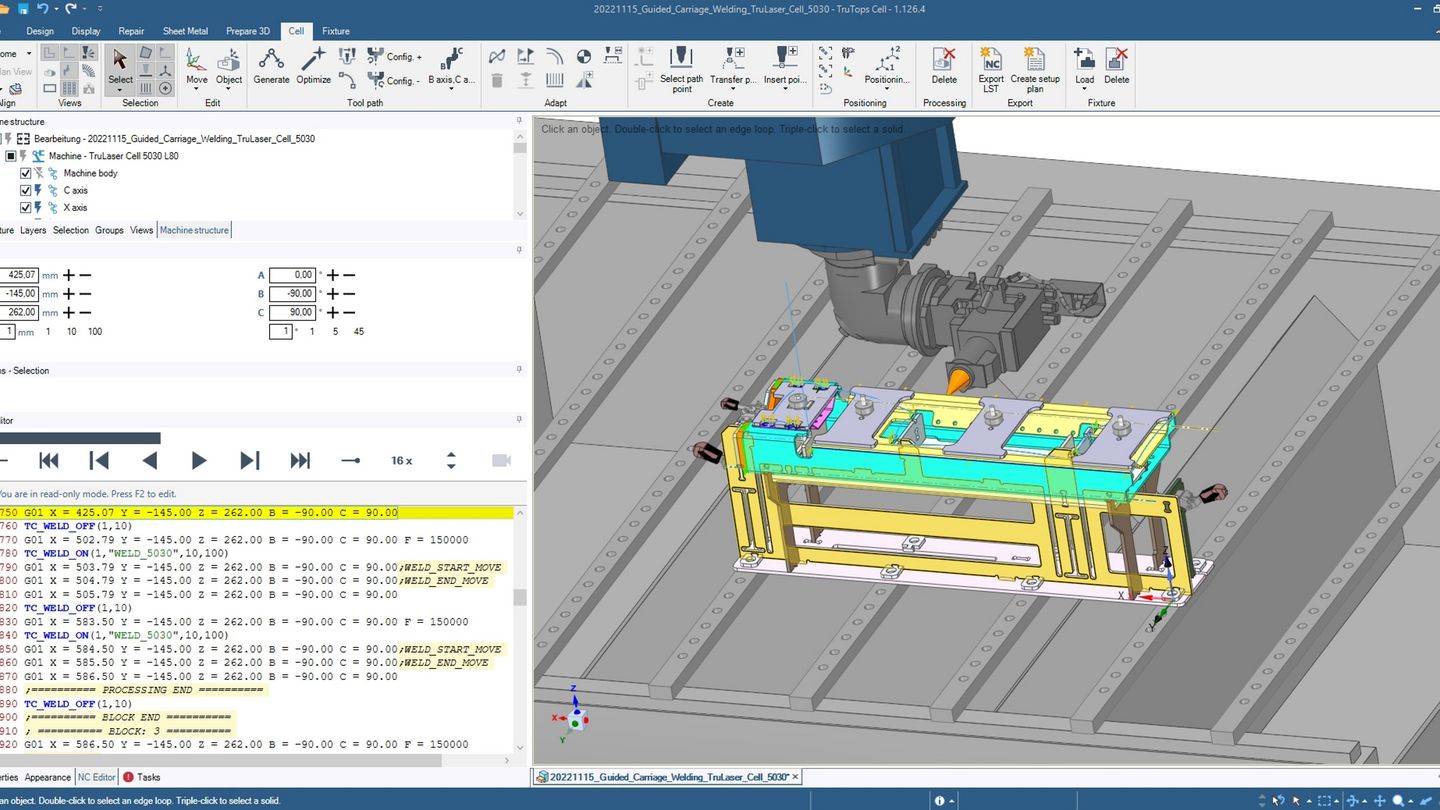

Proven strengths and new advantages – the next generation of the 3D programming expert is launched with the new TruTops Cell. From loading the first CAD model and programming the application and fixture to reading back the NC program for further program optimisation, TruTops Cell supports your entire 3D laser processing process. Thanks to implemented TRUMPF technologies and predefined standard parameters, the software guarantees the best possible operation of your TruLaser Cell systems.

The program quickly guides the user through the most important work steps to the finished NC program with step-by-step programming sequences and numerous automatisms.

Maximum flexibility for importing CAD data and in the modification of CAD models.

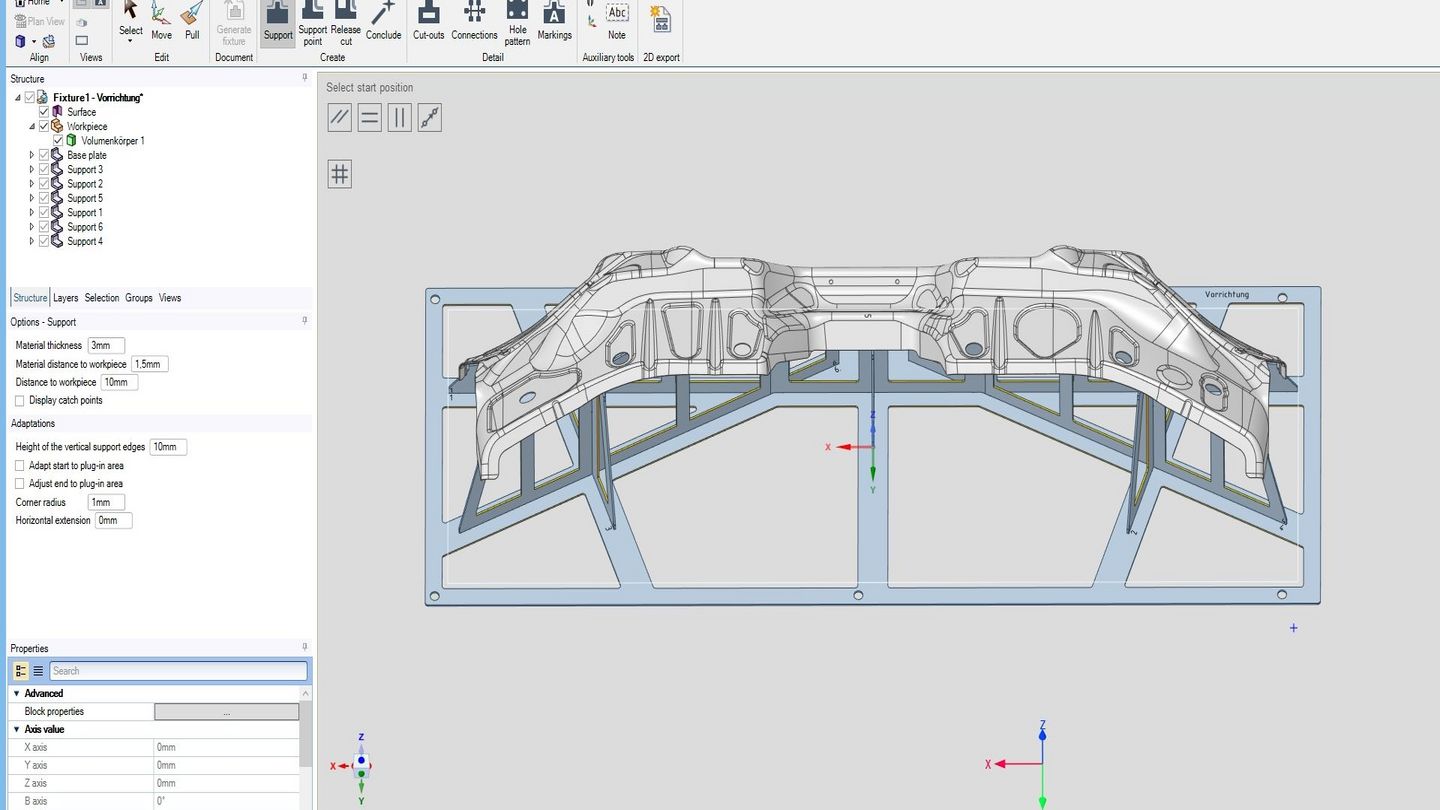

The integrated tool for the construction of layering devices sets new standards in terms of speed and flexibility.

Numerous optimisation tools and standard parameters make it possible for you to get the most out of the technologies and functions of your TRUMPF 3D laser systems.