The new BrightLine scan welding process enables you to robustly and flexibly weld small joint gaps, specifically adjust seam widths, and influence weld flaking. Elevate your laser welding work to a new level by adding new areas of application, such as thick sheet metal and aluminum, and reducing the amount of spatter.

One system, countless benefits

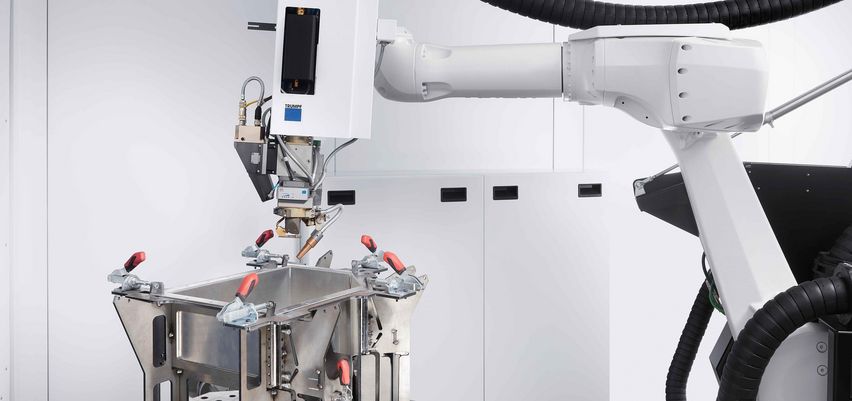

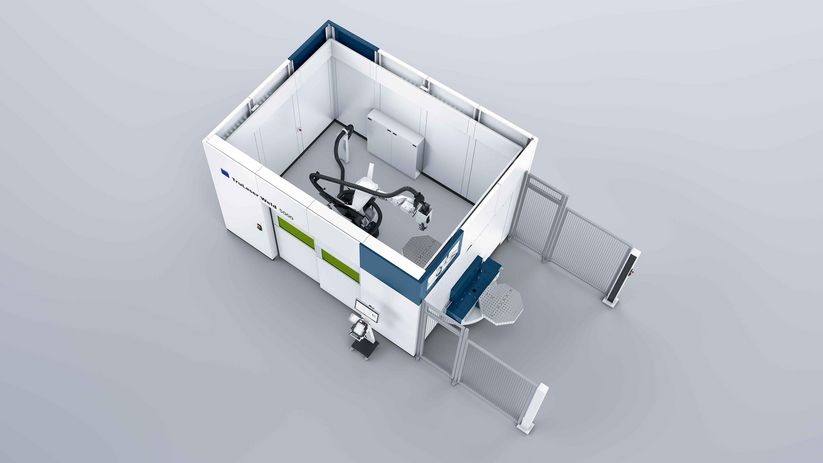

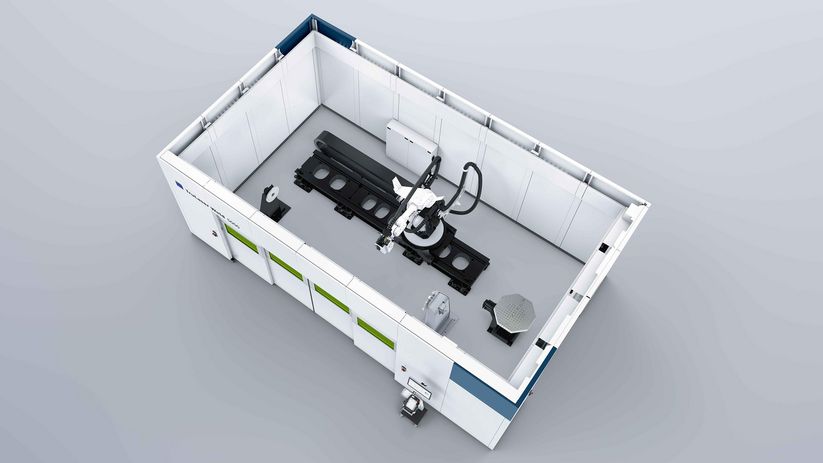

Robots, lasers, processing optics, enclosed protective housing, and positioners – TruLaser Weld 5000 is a turn-key system for automatic laser welding. You can flexibly weld deep and strong seams or nicely rounded, smooth seams using one system. FusionLine also enables you to connect components with gaps. The versatile system can be precisely tailored to meet your needs with different component positioners.

Heat conduction welding, deep penetration welding, or FusionLine – all on just one machine

Functions such as the rotatable control panel and the additional status monitor make your work easier.

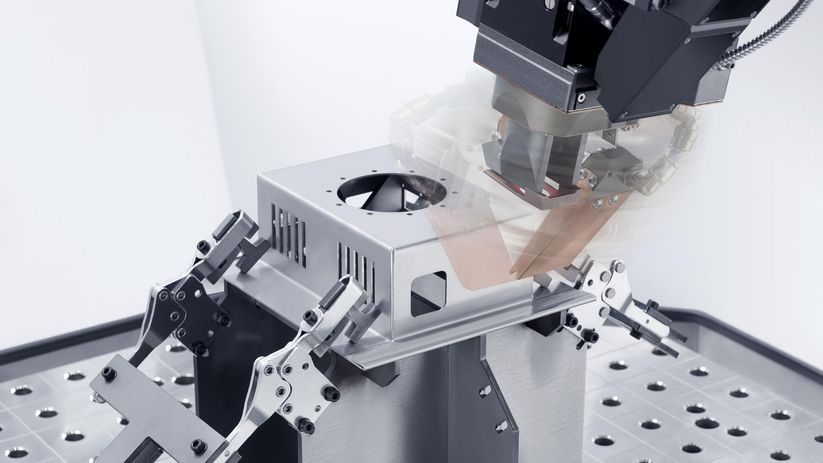

The rotary module for shield gas guidance provides excellent parts accessibility

Different component positioners are available depending on the desired loading option.

With the simple TruTops Weld offline programming system

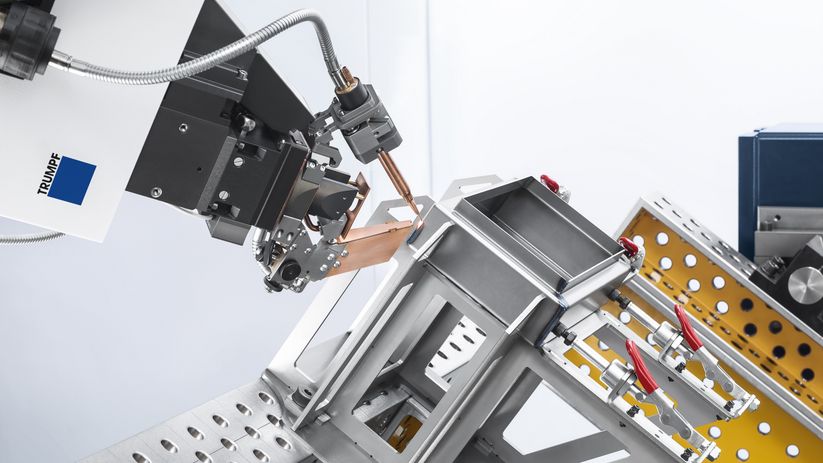

The TeachLine sensor system reliably detects the seam placement.

Welding with process reliability

BrightLine Scan allows you to weld corners, gaps and other tolerances with process reliability. This sample part made of mild steel shows a conventionally designed cover for a clamp.

High-quality welding results

BrightLine Scan's high frequencies achieve high-quality welding results with aluminum alloys. This aluminum sample part shows a battery tray element with a 135° corner.

Flexible welding

The water tank made of stainless steel shows different deep-welded seam geometries in sheet thicknesses of 0.06 in and 0.12 in.

Quick and reliable

You can create slim high-strength seams quickly with the deep welding process.

Almost invisible

The counter segment made of stainless steel shines as a result of heat conduction welding with particularly attractive visible seams.

For all common materials

The lower terminal box is made of mild steel, the middle one is made of stainless steel, and the upper one is made of aluminum. You can weld all material with the laser with flexibility.

As if it were a single piece

You can create nicely rounded seams with heat conduction welding, with barely any component distortion.

Hardly any rework required

Catering containers made of stainless steel can be produced with laser welding with hardly any post-processing required.

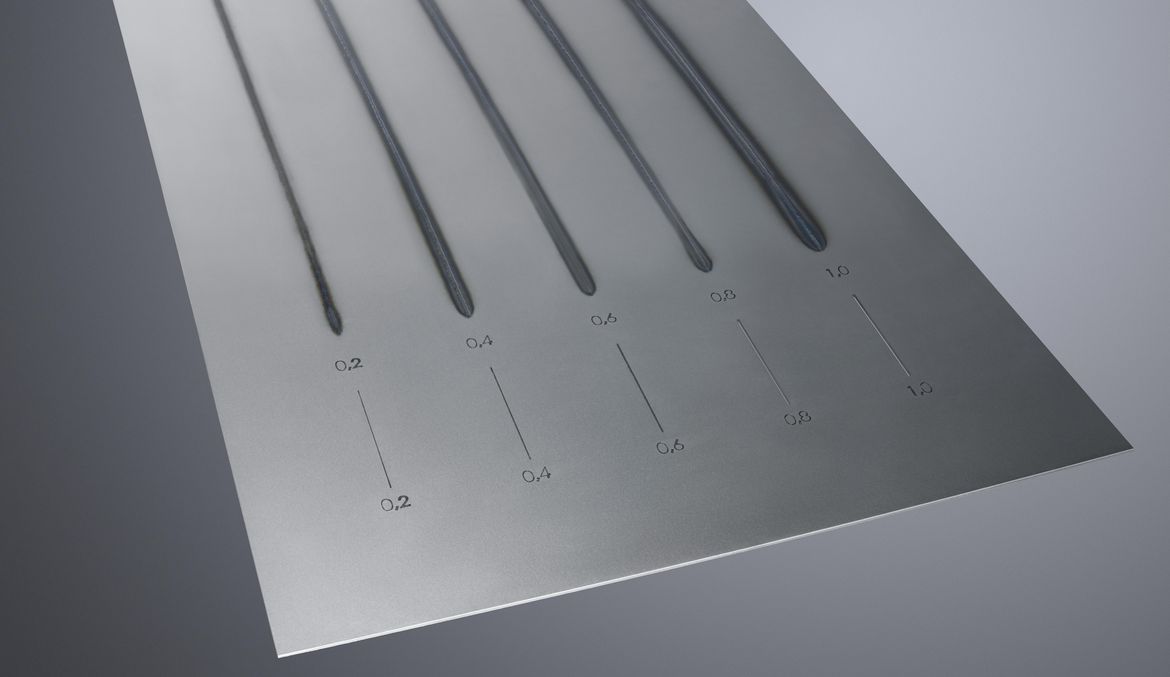

Tolerant laser welding

The new FusionLine bridges gaps up to a millimeter wide.

|

TruLaser Weld 5000

|

|

|---|---|

| Axis data | |

| Type | High accuracy robot |

| Number of axes | 6 |

| Nominal carrying capacity | 70 kg |

| Repeatability | +/- 0.05 mm |

| Laser-specific data | |

| Available lasers | TruDisk 4001 / 6001 / 8001 | TruFiber 3001 / 4001 / 6001 |

| Rotate and tilt positioner | |

| Maximum work area | 2000 mm x 1000 mm x 1200 mm |

| Maximum loading | 500 kg |

| Dual station table | |

| Max. Arbeitsraum | ⌀ 2350 mm x 1150 mm |

| Maximum loading (per side) | 250 kg |

| Rotary table | |

| Max. Arbeitsraum | ⌀ 1200 mm x 2600 mm |

| Maximum loading (per side) | 750 kg |

| Rotary table with turning axis | |

| Max. Arbeitsraum | ⌀ 1200 mm x 2600 mm |

| Maximum loading | 750 kg |

| Turnover positioner | |

| Max. Arbeitsraum | ⌀ 2000 mm x 4000 mm |

| Maximum loading | 1000 kg |

| Compact rotary table with 3D clamping plate | |

| Max. work area (⌀) | 3000 mm |

| Max. Arbeitsraum (Höhe) | 1250 mm |

| Maximum loading (per side) | 600 kg |

| Max. Lastmassenträgheitsmoment | 600 kg*m2 |

| Drehbereich Rotationswechsler | ± 180 ° |

| Drehzeit Rotationswechsler (für 180°) | 3.7 s |

| Einlegehöhe | 830 mm |

| Compact rotary table with vertical rotary axes | |

| Max. work area (⌀) | 3000 mm |

| Max. Arbeitsraum (Höhe) | 1250 mm |

| Maximum loading (per side) | 600 kg |

| Max. Lastmassenträgheitsmoment Ringrundschalttisch | 600 kg*m2 |

| Drehbereich Rotationswechsler | ± 180 ° |

| Drehzeit Rotationswechsler (für 180°) | 3.7 s |

| Drehbereich vertikale Drehachsen | ± 190 ° |

| Drehzeit vertikale Drehachsen (für 180°) | 2.5 s |

| Max. Lastmassenträgheitsmoment vertikale Drehachsen | 359 kg*m2 |

| Einlegehöhe | 885 mm |

| Dimensions, weights | |

| Possible cabin dimensions |

4800 mm x 3650 mm x 3215 mm

4800 mm x 4800 mm x 3215 mm 4800 mm x 5950 mm x 3215 mm 5950 mm x 4800 mm x 3215 mm 5950 mm x 5950 mm x 3215 mm 7100 mm x 4800 mm x 3215 mm 7100 mm x 5950 mm x 3215 mm 8250 mm x 4800 mm x 3215 mm 8250 mm x 5950 mm x 3215 mm 9400 mm x 4800 mm x 3215 mm 9400 mm x 5950 mm x 3215 mm |

The technical data of all product versions as a download.

With an NC rotary axis integrated into the robot control, the rotate and tilt positioner also makes it possible to weld components that are difficult to access in just one tool setup.

The rotary table enables you to set up outside the cell during the welding process, which increases the efficiency of your system.

Compact, productive, and low cost: With the automatic rotating work table you will double your throughput and can weld on the inside on one side of the table, while simultaneously setting up a new component on the outside.

Compact, flexible, and cost-effective: Increase your flexibility and access to the components by using the vertical rotary axis.

Fast, flexible, and solid: Benefit from the high carrying capacity, the large distance between centers, and fast rotation time. This is perfect for fast "round-the-clock" processing of high quantities and large components.

The TruLaser Weld 5000 robot travels along a linear axis, covering a large work area. In line with this, the system has a four-meter long turnover positioner.

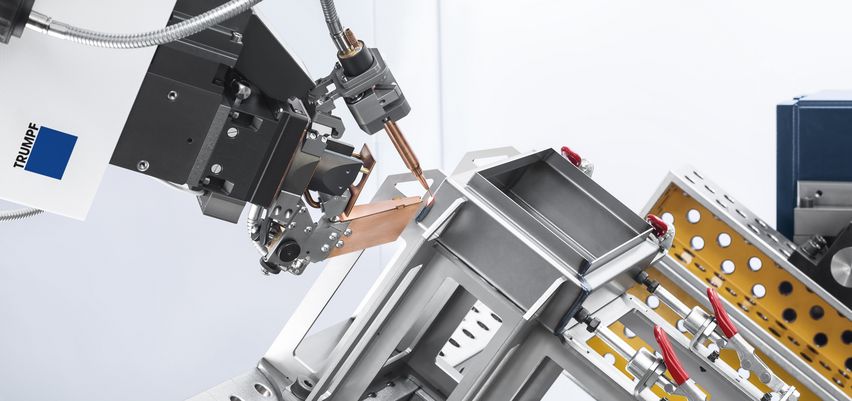

The shielding gas nozzle rotates continuously around the optics. The amount the robot needs to reorient itself is significantly reduced. This reduces expenditure on clamping systems and programming, makes your components more accessible, and you can weld much more quickly.

The TeachLine sensor system means that you can also weld components without time-consuming reteaching. The sensors detect the placement of the seam, even if its actual position deviates slightly from the required position.

FusionLine allows you to close gaps up to 1 mm wide and to laser-weld economically without optimizing your component portfolio for laser welding.

During this new welding process using beam oscillation, two programmable mirrors move the laser beam. Frequencies of up to 2000 Hz ensure that the welding process is particularly robust and flexible. Elevate your laser welding work to a new level.

You can attach fixtures quickly and precisely using the zero-point clamping system. It offers the right systems for rotate and tilt positioners and rotary tables.

Seamless integration of multiple TRUMPF machines into your own software environment is very easy. We have the right solution for every combination, whether it be integration into Oseon or a connection to monitoring and analysis tools. A connection to third-party software systems is also possible with our interfaces based on the OPC UA standard.

TruTops Weld

Create your welding program quickly and easily on the computer using the TruTops Weld offline programming system, thereby reducing non-productive time on your TruLaser Weld 5000.

Software

The software portfolio from TRUMPF optimizes your entire production process – from the customer query through to delivery of the finished part. TRUMPF combines the software intelligently with machines and services to create customized Industry 4.0 solutions for your Smart Factory.

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price, and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.