In automated welding, every part looks exactly the same. The quality does not fluctuate because the operator needs a break. And reproducible quality is becoming more and more important as the demands of the market increase. In manual welding, this often leads to unscheduled post-processing or dissatisfied customers and complaints.

Welding systems for high quality

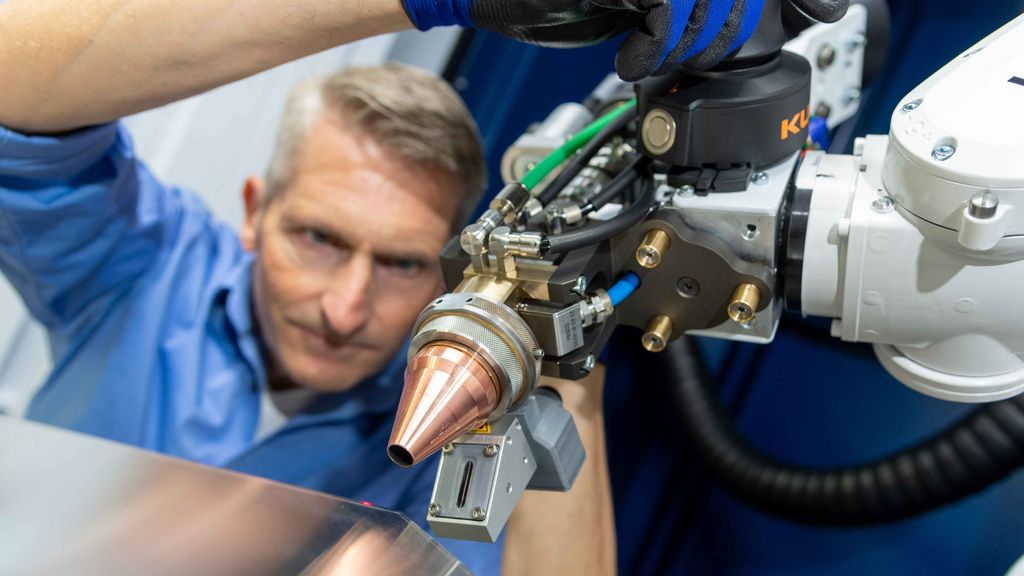

Imagine always welding to a consistently high quality standard, saving tedious post-processing. Sound good? Compared to manual welding, automated arc welding with the cobot and laser welding offer you an enormous quality advantage. By the way, operation is much easier than you might think. Your skilled welding professionals will become programmers thanks to e-learning. Making everyone a professional right from the beginning.

Welding presents your company with great challenges

If the robot welds the standard parts, the specialist has more time for tricky tasks.

The automated welding cell does not get tired – which makes your quality predictable.

Working on a robot is fun, especially when programming is so easy.

You weld consistent seams with automated processes. The laser saves a great deal of post-processing.

Looking at weld seams in practice

We understand the challenges you face

Welcome to the WeldGuide

Whether part design, fixture technology or components calculation: we share our expertise in laser welding in sheet metal processing with you in the WeldGuide. For example, for the best welding results, you need the suitable component drawings – you will find information on this in the WeldGuide. Your engineers can use this service for free with a MyTRUMPF account.

Consultation

As your partner, you are there for you – so that you not only achieve perfect weld seams every time, but also a successful transition into your prosperous future.