Whether it is metal, plastic or other materials: you can mark many materials and contents with the laser. Even large areas and points which are hard to access can be processed. In addition, elaborate steps for component preparation, such as cleaning with chemicals or polishing surfaces, are omitted. The laser does it in one process step.

Laser marking

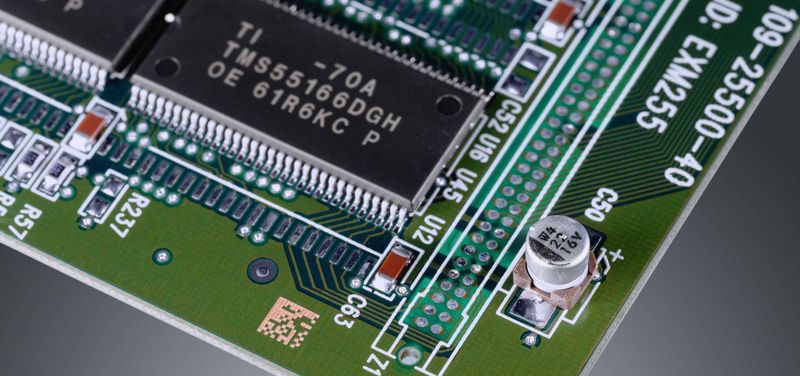

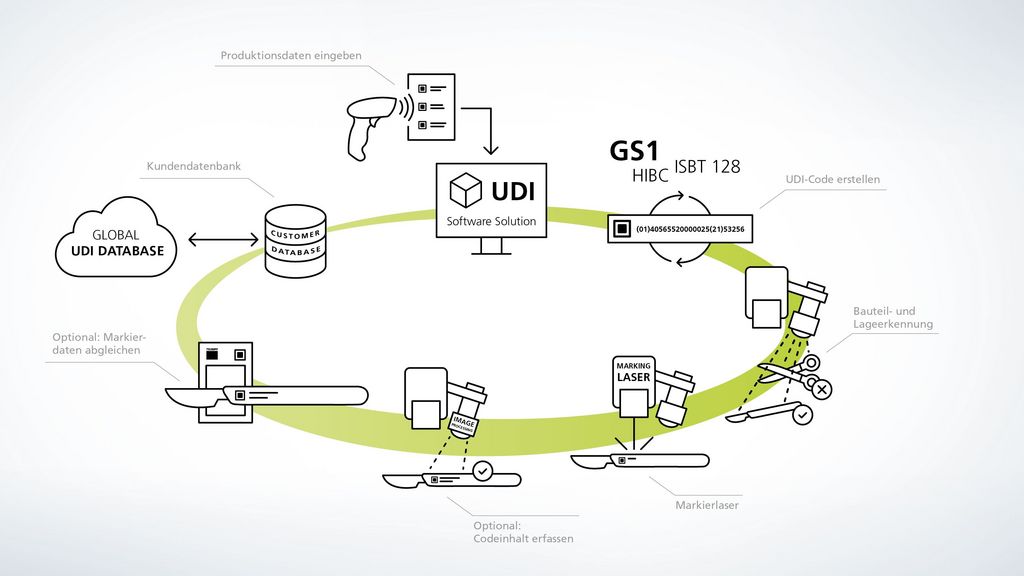

Whether it is for data matrix code identification marking of a component, for function-related markings on speedometers and shower heads or for customization of utility objects such as ID cards or cosmetic articles, their versatility is what distinguishes laser marking procedures above everything else.

If that was not enough. Laser marking meets the more stringent demands on traceability and raw materials, for forgery protection and customized products. Laser marking can even satisfy the request to make a component its own storage medium for the Smart Factory.

How does laser marking work?

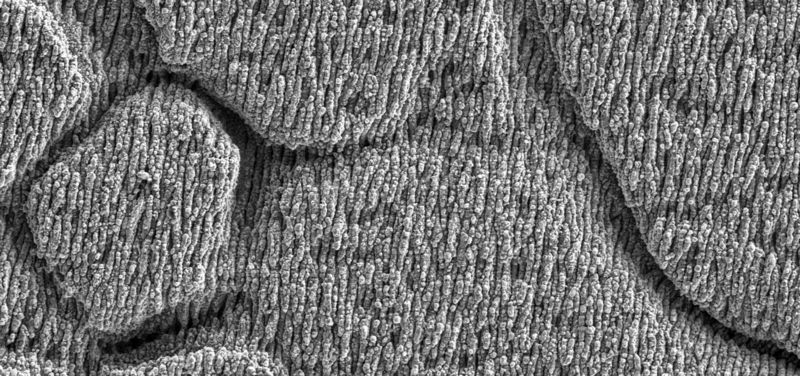

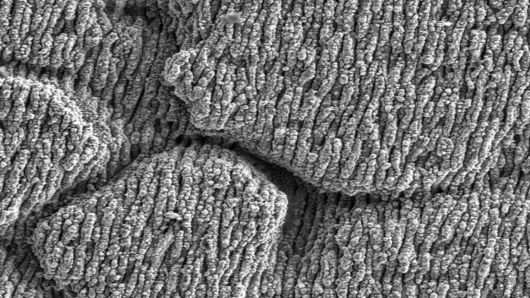

In laser marking, the marking is applied directly onto the surface using an intensive pulsed laser beam. The interaction of the focused beam with the surface leads to a change in the material – for example, discoloration, structuring, engraving or material removal.

The way the material changes depends largely on the wavelength of the laser, the pulse duration and the irradiance of the laser beam.

Procedures in laser marking

Laser marking is a collective term for several procedures: annealing, engraving, black marking, color change and foaming. But which procedure is most suitable? That depends mainly on the material and the quality requirements of the product in question. This means, for example, that a completely different procedure is suitable for laser marking on metal than for marking plastic.

Find out more about the different laser marking procedures:

Find your perfect marking laser.

Find out which marking laser is best suited to you - just start the TruMark product finder!

The comparison: laser marking vs. alternative marking procedures

With its many benefits, the laser as a non-contact tool scores highly compared to conventional marking procedures which are based either on paint, chemical reactions or mechanical pressure:

Laser markings are environmentally friendly: lasers do not need expensive and environmentally damaging consumables such as ink or chemicals when marking, unlike etching, inkjet or screen printing procedures.

Compared to some other procedures, laser marking is gentle on the material: there is practically no tool or material wear with laser marking.

Laser markings are long-lasting and high-contrast: compared to many conventional marking procedures, markings with lasers are always easily legible as well as chemically and thermally resistant.

Modern marking lasers consume less energy than a commercial hair dryer which means that they can be operated at very low cost.

What are the advantages of laser marking?

Marking in the industry – that increasingly means marking with lasers. Because the list of the advantages of laser marking is long.