Mario Papac is young, dynamic and superbly qualified – the textbook example of an ideal manager. Although he was born and raised in Germany, he never forgot his Croatian roots. Eventually, the business administrator decided to give up his career in Germany to join KFK in Croatia. The path taken by company founder Marko Rašic had motivated and inspired him, and Papac was determined to make his own mark in the land of his forefathers.

Rašic established KFK in 1997, just two years after the end of the Croatian War of Independence. Prior to founding his company, Raši´c had spent ten years working for facade construction companies in Germany and Austria, picking up a wealth of expertise along the way. But he longed to return to his Croatian homeland and help shape the country’s future. With the war not long over, the economy was still in bad shape, and sheet metal fabricators were few and far between. None of that stood in the way of Raši´c founding KFK, however, and his combination of hard work, entrepreneurial vision and practical experience soon transformed the small company into a global player. KFK now specializes in modular facades consisting of multiple parts that fit together like Lego bricks. Every project KFK works on is unique because every facade is different. That’s what makes this industry so challenging – and so exciting.

Facade fabricator by vocation

A lot has happened over the past 20 years. The six employees that were hired by the Zagreb-based facade fabricator when it was founded are still there, but now they have been joined by another 360 colleagues, including Mario Papac, Managing Director of KFK International GmbH. Founded in 2012, this subsidiary mainly handles large-scale projects in German-speaking regions and the UK. Thirty-six-year-old Papac knows exactly how tough things were for KFK founder Rašic when he first started out: “There were no specialists back then; employees would be responsible for a range of different jobs. Rašic still spends every day in the factory giving people useful tips and working on new solutions and products. He’s quite simply passionate about building facades – it’s not just a job for him, it’s his vocation.”

With EU funding, KFK can grow and further develop the country

KFK has always re-invested the lion’s share of its profits in new Machines and technologies. “A few years ago we decided to take another new approach that would enable us to carry out even bigger projects. That’s what led us to the EU funding programs,” says Mario Papac. The European Union supports cutting-edge ideas, technologies and machine purchases by providing companies with financial support. With the EU’s help, the company has contributed to the creation of a number of impressive buildings in Croatia, including the roof and facade design for Dubrovnik Airport. “Obviously you have to clear a whole set of hurdles to get the funding, but all those strict checks and controls are there for a good reason,” Papac adds. “For example, the EU ensures that we only buy approved machines from outstanding manufacturers. That’s not always easy, but it’s definitely worth it.”

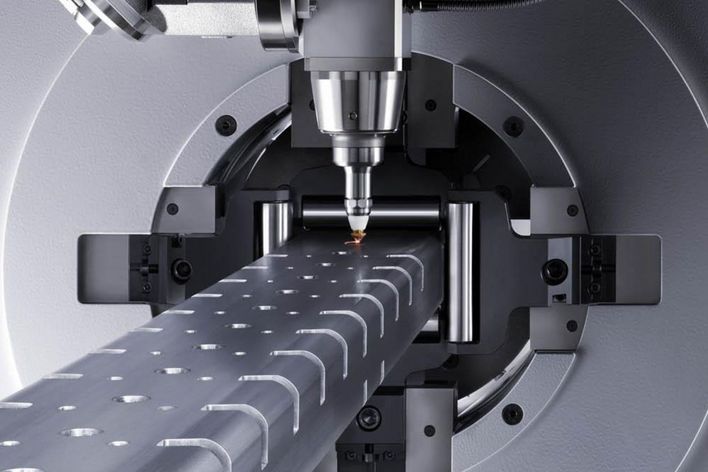

This financial support has always been a kind of bonus for KFK, propelling it into turbo speed and enabling it to grow faster while simultaneously helping to develop its home country: “The great thing is that it enables us to push ahead with projects both in Croatia and worldwide, as well as investing in new machines,” says Papac. A good example is KFK’s laser tube cutting machine TruLaser Tube 7000 from TRUMPF. This is one of the machines that has helped the company create entirely new facade designs based on tubular structures.

KFK used to focus predominantly on customers from Croatia, but today the company is involved in projects all over the world. “Right now we’re focusing on the UK, which is currently experiencing a boom in construction. All the world’s big cities are constantly striving to make buildings that are taller, more sophisticated and even better quality, and London is no exception,” says Papac. He is particularly proud of the biggest project KFK is working on at the moment: “It’s a residential building in London, the tallest structure of its kind currently under construction anywhere in Europe. With 76 floors and at 233 meters tall, it’s a project that obviously requires the production of lots and lots of facade modules.” It takes several years to complete projects on this scale – three and a half years in this case.

Croatian products, German quality

KFK is perfectly equipped for these kinds of demanding jobs. A year and a half ago, the Croats began making their own glass products. What makes them really stand out from the competition is their cutting-edge glass production line measuring approximately 360 meters. “It was a step that we had been considering for some time. Receiving the EU funding made the decision a lot easier, so we were able to put our plans into action,” says Papac. Now they can perform all the facade fabrication processes in-house, including all the glass processing steps. KFK even has its own test laboratory to maintain high quality standards at all times. “Obviously our facades are tested by external inspectors, too, but having a test lab of our own is extremely beneficial,” explains Papac.

Despite its technological advances and farsighted ideas, KFK has always been a company that makes decisions quickly. Papac considers this to be one of the company’s biggest strengths, along with its emphasis on producing perfect products: “Our founder Marko Rašic is a Croat through and through, but he always insists that our facades meet German standards of quality,” says Papac with a wink. This combination of German and Croatian traits definitely seems to work, proving that international understanding can sometimes be a surprisingly simple business.