Rainer Bodendoerfer is not afraid of change – quite the contrary. In the past two years, he has made a number of changes at WECUBEX Rohrtechnik. This was rather difficult in the beginning – it involved introducing a change of culture at the company and convincing uncertain and partially skeptical employees of the Smart Factory idea. In so doing, Bodendoerfer did everything right. It all began at TRUMPF's in-house exhibition, INTECH 2016. According to Bodendoerfer: "When I saw the effects digitalization could have on sheet metal processing, I was so amazed that I immediately booked a Smart Factory check."

High Flexibility for small lot sizes

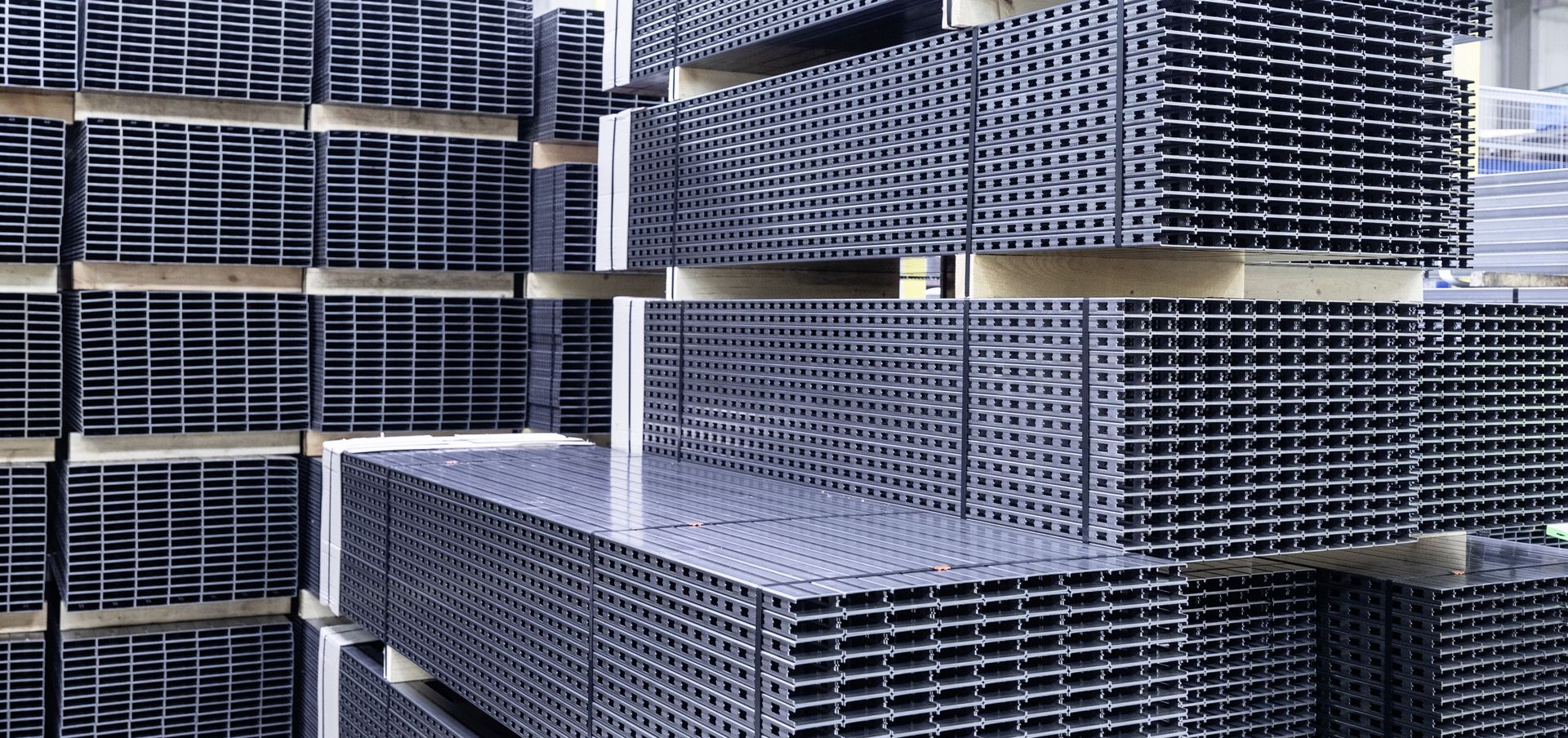

WECUBEX Rohrtechnik is based in Burgbernheim, Bavaria, and together with three additional sites in Germany, Austria, and the Czech Republic, is part of the WECUBEX Group. At the Burgbernheim site, the focus is on producing perforated, welded, and powder-coated sheet metal and tube components made of steel and stainless steel for shop fittings, the food and packaging industry, medical technology, and vehicle construction. The big challenge here is the small lot sizes, which require utmost flexibility during production.

Adrenalin through analysis

In the first step to the new start, the TRUMPF networked production consultants determined the current status at WECUBEX. The analysis focused on indirect processes from customer requests to order processing – including programming – all the way to logistics and invoicing. "The results of this analysis were so exciting that we scrutinized our production processes right the next day," says Bodendoerfer. The consultants inspected the typical workflow based on a mass produced product. Using value stream mapping, the information and material flow, as well as the time lapse between the individual work steps, were determined.

Have a conversation!

Together with his six-member Smart Factory core team and TRUMPF, Bodendoerfer first set about optimizing his shop floor management. He explains: "We now communicate across all levels. Regular cross-departmental exchange between workers, team leaders, heads of production, the sales department, all the way to management, ensures that we can identify and quickly rectify issues together.

That being said, it is not just people that are part of the conversation at WECUBEX. The consultants recommended that a total of ten machines which are important for production at WECUBEX be connected, as the basis for shop floor management. These included machines from TRUMPF as well as other vendors. The networked machines now deliver key figures such as capacity utilization, machine statuses, and reasons for disruptions to a cell phone, in real time. Bodendoerfer: "Capturing machine data is an important foundation of our shop floor management. Both of these together have brought us an increase in productivity of approximately 10 percent in 2017."

Pull instead of push

An additional large and important update was the fundamental transformation of the production strategy at WECUBEX – the change from push production to pull production. In the traditional push principle, production and material flow are controlled by a central unit. This ensures that materials, parts, and products are "pushed" through the production chain as part of a pre-set plan. This works as long as there are no disruptions at any point in the chain, for example as a result of a capacity bottleneck at a processing station. Bodendoerfer: "Up until now we were focusing on machine utilization rate. This meant that often the laser flatbed machines were cutting faster than the employees working at the bending machines could bend. The result was large numbers of half-finished and finished parts, as well as a high throughput time." Jams of this type are eliminated in pull production. Orders are produced in a just-in-time manner. This way, the processing stations downstream only demand the amount of material from upstream stations (via a decentralized control unit) that the order actually requires. Materials, parts, and products are "pulled" through the production chain. Bodendoerfer: "The parts are now flowing noticeably faster through the production process – throughput time has been reduced by 43 percent."

Get lean – cut setup time in half

In addition to traditional lean manufacturing measures such as process-optimized machine arrangement, reduced setup times also made these improvements possible. "Smaller lot sizes mean a higher setup time," explains Bodendoerfer. "But this can be clearly reduced by keeping a couple of things in mind." Workers and team leaders learned about these approaches at a 2-day setup workshop. The current setup process was analyzed and optimized in the context of lean manufacturing management. The employees who underwent this training were able to reduce setup time for the most important production systems by 50 percent.

Success is addictive

Even previous skeptics in the company have now come around to the concept of a Smart Factory – this is important because Rainer Bodendoerfer has plans to continue. Once a month he and his core team revise the plan of measures (which includes approximately 100 points) and determine the next steps together. In order to accommodate small lot sizes with even more flexibility in the future, Rainer Bodendoerfer has decided on a planning system recommended by TRUMPF. This further reduces throughput times and stock numbers, thereby increasing delivery reliability. According to Bodendoerfer: "The recently implemented measures allowed us to improve our delivery reliability by 18 percent compared to the end of 2016. There must be more where that came from."

Rainer Bodendoerfer and his team are undertaking a great deal to bring WECUBEX closer to its goal of being an industry benchmark. He is being supported by the WECUBEX Group. "I keep my colleagues from the other three sites updated on everything that is happening. We at Burgbernheim are the forerunners and make the benefits of a Smart Factory tangible. I am certain that all of us at the WECUBEX Group will take away certain aspects to implement. I recently showed our Smart Factory solutions to about 50 key clients, and they were very impressed. This motivates us to continue and to take the next steps towards our Smart Factory."