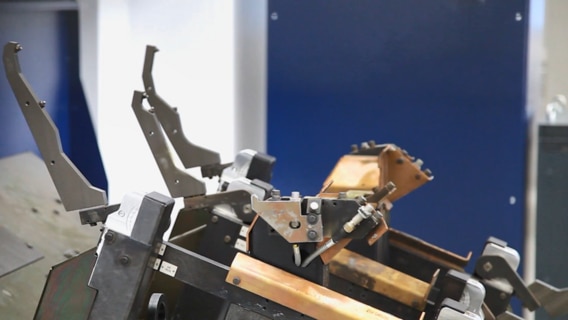

Der Aufbau der TruLaser Cell 8030 ist nicht nur kompakt, sondern auch äußerst bedienerfreundlich und ergonomisch. Der Rotationswechsler ist sowohl von vorn als auch von den Seiten gut zugänglich. Dabei kann das Layout der Maschine flexibel konfiguriert werden, um das Hallenlayout gemäß Ihren Anforderungen zu planen.

Ihre High-End-Laserschneidanlage für warmumgeformte Bauteile

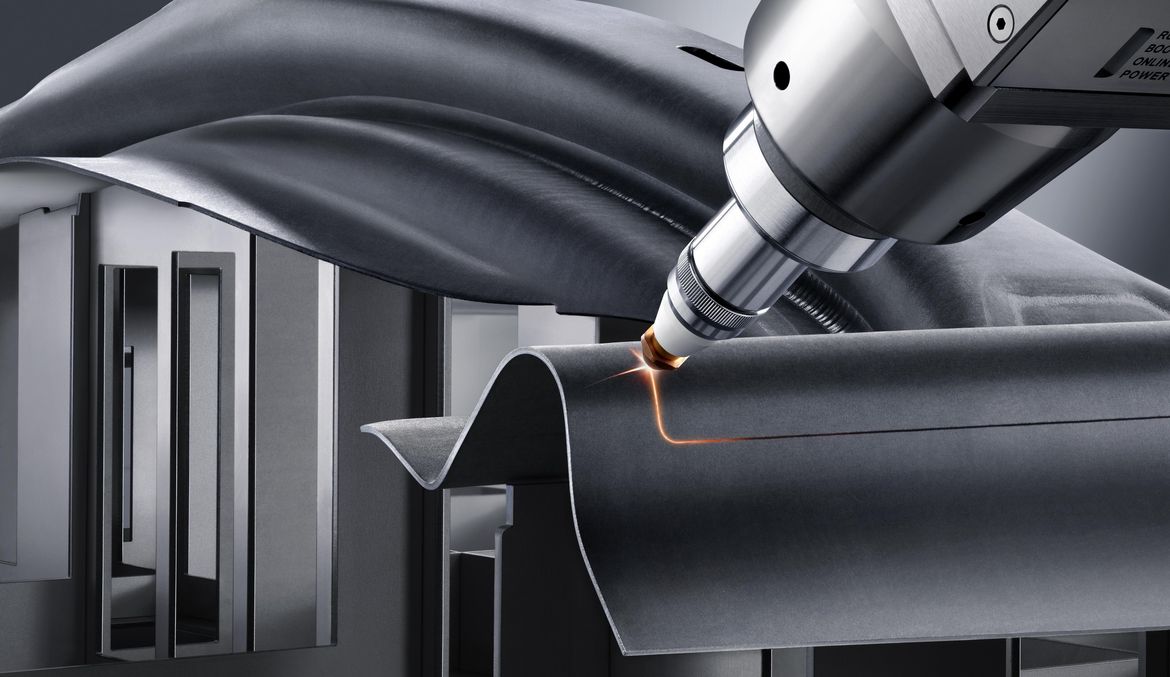

3D-Laserschneiden

Die TruLaser Cell 8030 setzt den Standard für das 3D-Schneiden warmumgeformter Bauteile und lässt sich flexibel für Ihre Anforderung konfigurieren. So können Sie zwischen der großen Variante zum Schneidern von Doorrings und kompletter Seitenteile oder der kleineren Variante zur Fertigung von Einzelteilen und Segmenten der Rohkarosse wählen. Dank neuer Entwicklungen und optimierter Details bietet sie eine noch größere Produktionssicherheit verbunden mit der wohl höchsten Produktivität am Markt. Dank Optionen wie z. B. dem Smart Approach oder dem Dynamic Level 3 steigern Sie Ihre Wirtschaftlichkeit.

Im Vergleich zum Vorgängermodell profitieren Sie jetzt von einer noch höheren Beschleunigung und Dynamic Level 3.

Der optimierte Rotationswechsler ist der schnellste am Markt. Mit der um 20 % kürzeren Drehzeit von 1,8 Sekunden erhöht sich so die Gesamtperformance mit jedem Bauteil.

Die neue Maschine basiert auf den Erfahrungen der größten installierten Basis von 3D-Maschinen im Bereich Hotforming

Optimale Produktionsprozesse dank Funktionen wie X-Blast Technology oder ObserveLine Comfort & Professional

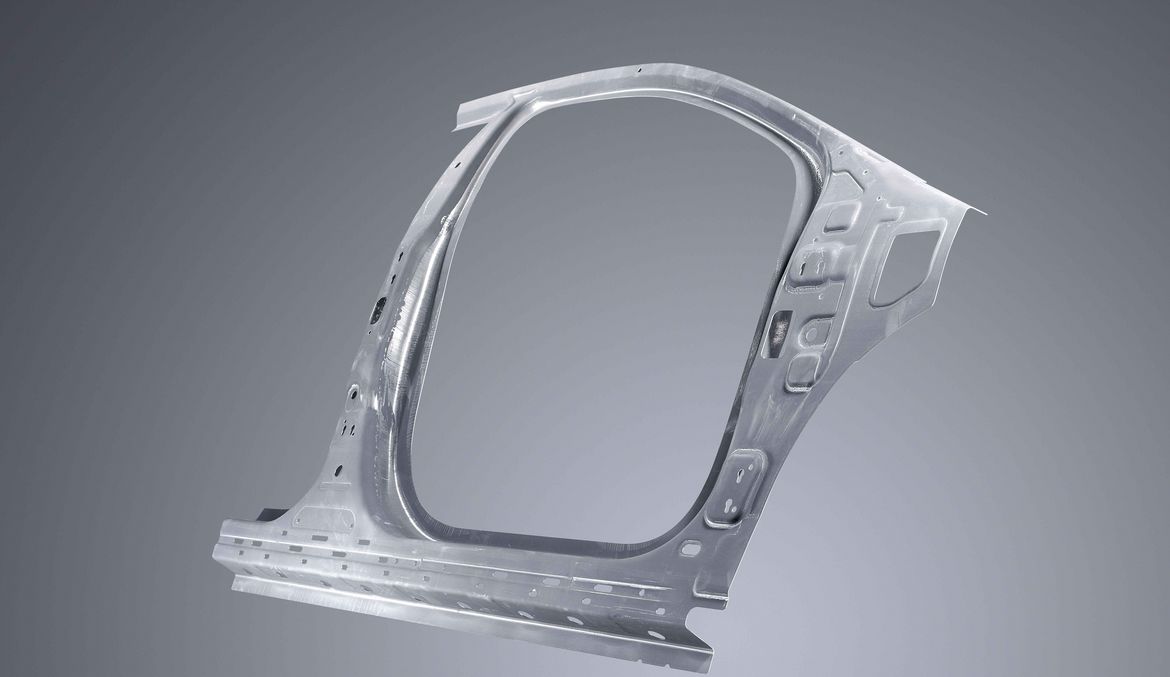

Laserschneiden eines Doorrings

Mit der TruLaser Cell 8030 schneiden Sie die großen Abmaße eines warmumgeformten KFZ-Seitenteils nicht nur sehr schnell, sondern auch in bewährt hoher Qualität dank TruDisk Laser und X-Blast Technologie.

Laserschneiden eines Querträgers

Im Vergleich zum Vorgängermodell schneidet die TruLaser Cell 8030 den warmumgeformten KFZ-Querträger mit rund 10 % höherer Maschinendynamik, 10 % geringeren Nebenzeiten und einer 30% schnelleren Butzenkontrolle. Der TruDisk Laser und die X-Blast Technologie garantieren Ihnen dabei eine konstant hohe Schneidqualität.

Warmumgeformte und lasergeschnittene Rahmenstirnwand

Großserienteile bearbeiten Sie auf der TruLaser Cell 8030 besonders wirtschaftlich. Darüber hinaus bietet Ihnen die NC-Programmierung maximale Flexibilität bei der Geometrie Ihrer Bauteile.

Lasergeschnittene B-Säule

Die TruLaser Cell 8030 schneidet verlässlich 3D-Bauteile wie B-Säulen für Automobile. Die Bearbeitung warmumgeformter Bauteile mit dem Laser ist dabei deutlich wirtschaftlicher als mit herkömmlichen Verfahren. Zusätzlich können Bauteile dank des flexiblen Werkzeugs Laser einfach an neue Anforderungen angepasst werden – auch zu einem späteren Zeitpunkt.

|

TruLaser Cell 8030 (Standardvariante)

|

TruLaser Cell 8030 (Große Variante)

|

|

|---|---|---|

| Achsverfahrbereich | ||

| Max. Anzahl Achsen | 5 | 5 |

| Achsverfahrbereich X-Achse | 3000 mm | 3000 mm |

| Achsverfahrbereich Y-Achse | 1300 mm | 2100 mm |

| Achsverfahrbereich Z-Achse | 600 mm | 650 mm |

| Achsverfahrbereich B-Achse | ± 135 ° | ± 135 ° |

| Achsverfahrbereich C-Achse | n x 360 ° | n x 360 ° |

| Achsverfahrbereich Dynamische Schneidoptik | ± 10 mm | ± 10 mm |

| Max. Werkstückgröße | ||

| Max. Werkstückgröße in X | 2540 mm | 2540 mm |

| Max. Werkstückgröße in Y | 840 mm | 1640 mm |

| Max. Werkstückgröße in Z | 370 mm | 420 mm |

| Max. Achsgeschwindigkeiten | ||

| Max. Achsgeschwindigkeit achsparallel in X | 100 m/min | 100 m/min |

| Max. Achsgeschwindigkeit achsparallel in Y | 100 m/min | 100 m/min |

| Max. Achsgeschwindigkeit achsparallel in Z | 100 m/min | 100 m/min |

| Max. Achsgeschwindigkeit simultan | 173 m/min | 173 m/min |

| Max. Achsgeschwindigkeit B–Achse | 90 1/min | 90 1/min |

| Max. Achsgeschwindigkeit C–Achse | 90 1/min | 90 1/min |

| Max. Achsbeschleunigungen | ||

| Max. Achsbeschleunigung achsparallel in X | 11 m/s2 | 10 m/s2 |

| Max. Achsbeschleunigung achsparallel in Y | 11 m/s2 | 10 m/s2 |

| Max. Achsbeschleunigung achsparallel in Z | 11 m/s2 | 10 m/s2 |

| Max. Achsbeschleunigung simultan | 19,1 m/s2 | 17,3 m/s2 |

| Max. Achsbeschleunigung B–Achse | 200 rad/s2 | 200 rad/s2 |

| Max. Achsbeschleunigung C–Achse | 100 rad/s2 | 100 rad/s2 |

| Max. Achsbeschleunigung Dynamische Schneidoptik | 40 m/s2 | 40 m/s2 |

| Positioniergenauigkeit | ||

| Positioniergenauigkeit Linearachsen (X, Y, Z) | 0,08 mm | 0,08 mm |

| Positioniergenauigkeit Rotationsachsen (B) | 0,015 ° | 0,015 ° |

| Laser | ||

| Max. Laserleistung | 3000 W - 4000 W | 3000 W - 4000 W |

| Verfügbare Laser | TruDisk | TruDisk |

| Automatisierung Rotationswechsler | ||

| Max. Beladung je Seite | 300 kg | 750 kg |

| Arbeitsstationen | 2 | 2 |

| Typ. gesamte Nebenzeit | 3,7 s | 4,9 s |

| Typ. Rotationszeit | 1,8 s | 3,0 s |

| Durchmesser Drehteller | 4000 mm | 5000 mm |

| Arbeitshöhe | 700 mm | 700 mm |

Die technischen Daten aller Produktvarianten als Download.

TruTops Cell

TruTops Cell bringt alles mit, was Sie für eine bequeme Programmierung Ihrer 3D-Laserbearbeitungsprozesse brauchen – egal ob es um die Programmierung von Laserschneid-, Laserschweiß- oder Laserauftragsschweißprogrammen geht. Sie liest 3D-CAD-Daten über zahlreiche Schnittstellen ein und korrigiert sie im Bedarfsfall. Das System erstellt automatisch Schneidvorschläge in allen drei Dimensionen. Außerdem errechnet es automatisch Vorschläge für Vorrichtungen.

Software

Von der Kundenanfrage bis zur Auslieferung des gefertigten Teils – das Software-Portfolio von TRUMPF optimiert Ihren kompletten Fertigungsprozess. TRUMPF kombiniert dabei die Software intelligent mit Maschinen und Services zu maßgeschneiderten Industrie 4.0-Lösungen für Ihre Smart Factory.

Je nach Anwendung wählen Sie den richtigen Festkörperlaser für Ihre Applikation aus, welchen Sie dann optimal mit der TruLaser Cell 8030 kombinieren können.

Verbessern Sie die Dynamik, Wirtschaftlichkeit und Produktivität Ihrer TruLaser Cell 8030 mit einer Vielzahl an innovativen Optionen.

Maximale Produktivität bei minimaler Fläche – das ist Ihre Herausforderung. BrightLine Speed führt zu einer Erhöhung der Schnittgeschwindigkeit um bis zu 60 % und reduziert den Gasverbrauch gleichzeitig um bis zu 50 %. Das steigert Ihre persönliche Wettbewerbsfähigkeit deutlich – und das bei verbessertem CO2 Fußabdruck.

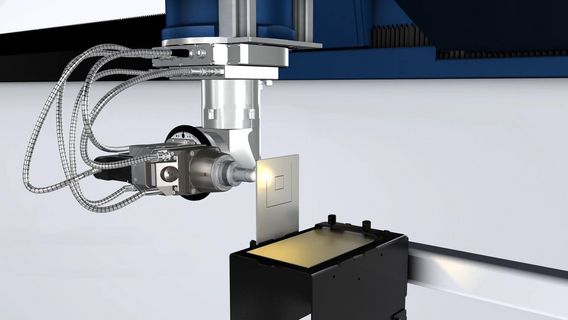

Unterschiedlichste Gründe können dazu führen, dass ein Schneidbutzen im Fertigteil hängen bleibt. Mit dem optischen Messverfahren ObserveLine Comfort erkennen Sie diesen Fehler schnell, da die Option jede Kontur auf einen vollständigen Beschnitt überprüft - und das doppelt so schnell als mit vergleichbaren Systemen am Markt. Gegenüber der Messung mit Abstandsregelung hat ObserveLine Comfort dabei mehrere Vorteile. So verkürzt das Verfahren die Messzeit und selbst kleinere Lochdurchmesser sowie schräg stehende Butzen sind messbar.

Leichte Düsenkollisionen können zu einer minimalen, für den Bediener unsichtbaren Fehlpositionierung der Schneidoptik führen. Es kommt zu erhöhter Ausschussproduktion und damit verbunden Kosten. Das optische Messverfahren ObserveLine Professional überprüft in regelmäßigen, frei definierbaren Abständen die Positionsgenauigkeit der Maschine ganz ohne Umrüsten und nahezu ohne Auswirkungen auf die Taktzeit. Fehlpositionen werden erkannt und der Ausschuss wird reduziert.

Bei dem Smart Optics Setup handelt es sich um eine an den Maschinengrundkörper angebaute Vorrichtung zum Schneiden von Testblechen und zur Rejustage der Maschine. Durch standardisierte Makros wird die Umsetzung noch einfacher. Das spart Zeit und Geld.

Die Funktion Smart Approach optimiert und verbessert das Anfahrverhalten der Maschine beim Einstechen an der Bauteilkante. Dieses patentierte Verfahren senkt bei maximaler Prozesssicherheit die Zykluszeit um bis zu 9 %.

FocusLine ermöglicht eine programmgesteuerte Einstellung der Fokuslage in Abhängigkeit von Materialart und Materialdicke. Die Verstellung der Lage erfolgt durch einen mit Luftdruck beaufschlagten Spiegel, dessen Oberflächenkrümmung beeinflusst wird.

FastLine verbessert und optimiert das Anfahrverhalten der Maschine beim Einstechen zum Schneiden der Kontur. Abhängig von Materialart und -dicke sowie der Anzahl der zu bearbeitenden Konturen können Sie die Produktivität Ihrer Anlage um bis zu 60 % steigern.

Neue Vorrichtungen integrieren Sie einfach und kostengünstig über die pneumatische und elektrische Schnittstelle in die Maschinensteuerung.

Mit TruTops Cell Basic lassen sich Programme einfacher, schneller und sicherer direkt an der Maschine anpassen. Die Navigation innerhalb des NC-Codes wird hiermit spielend einfach, da die zu ändernde Kontur mit dem entsprechenden NC-Text mittels eines Mausklicks ausgewählt wird. Alle durchgeführten Änderungen werden sofort visualisiert und machen damit das Arbeiten im Programm sicher wie nie.

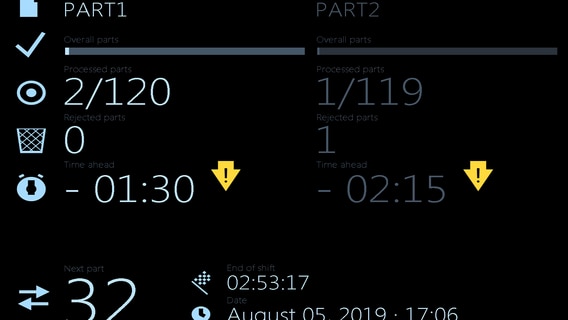

Mit Restlaufanzeige Comfort sind Sie jederzeit bestens informiert. Sie zeigt die verbleibende Bearbeitungszeit des aktuell bearbeiteten Bauteils an und liefert zusätzliche Informationen über den momentanen Status des aktuellen Fertigungsauftrags.

Die nahtlose Integration vieler Maschinen von TRUMPF in die eigene Softwarewelt ist problemlos und einfach. Sei es eine Integration in Oseon oder eine Anbindung an Monitoring und Analyse Tools - für jede Kombination stellen wir die passende Lösung bereit. Auch eine Anbindung an Software Systeme von Drittanbietern ist mit unseren Schnittstellen basierend auf dem OPC UA Standard möglich.

Je nach Land sind Abweichungen von diesem Produktsortiment und von diesen Angaben möglich. Änderungen in Technik, Ausstattung, Preis und Zubehörangebot sind vorbehalten. Bitte setzen Sie sich mit Ihrem Ansprechpartner vor Ort in Verbindung, um zu erfahren, ob das Produkt in Ihrem Land verfügbar ist.