I still remember a bearded physics teacher drawing a ray of light and a mirror on the board and saying: "The angle of incidence is equal to the angle of reflection." Later on, we would discover that the whole light thing was a lot more complicated, but this seventh-grade perspective on optics has proved to be sufficient for laser material processing for decades: light is a ray, and a focus is a point at which converging rays unite. Frankly, that wasn't such a bad thing. In most applications - and for the purpose of designing optics - geometrical, or ray, optics gives you plenty of information, at least for the rectilinear propagation of light in a medium, reflection, refraction, shadow formation, and the path light follows in optical devices, such as focusing optics. If you are interested only in focusing light energy on a particular spot, then ray optics is a useful model.

Crossing the threshold

But there's a lot more you can do with light, so it's worth taking things a few more steps. Even in well-established laser machining processes such as cutting steel with conventional optics, engineers often strive to optimize the focal point, which essentially means acknowledging that the focus is not actually a spot, but rather a spatial distribution of intensities. In order to calculate and optimize these intensity distributions, we need to picture light as a wave; we thus enter the domain of wave optics. Here, a focus is not a point, but rather an intensity distribution that extends in the x, y and z directions. That opens up a wealth of additional information about the focus. And, more importantly, it means it can finally be manipulated. In a big way!

A thousand times more efficient

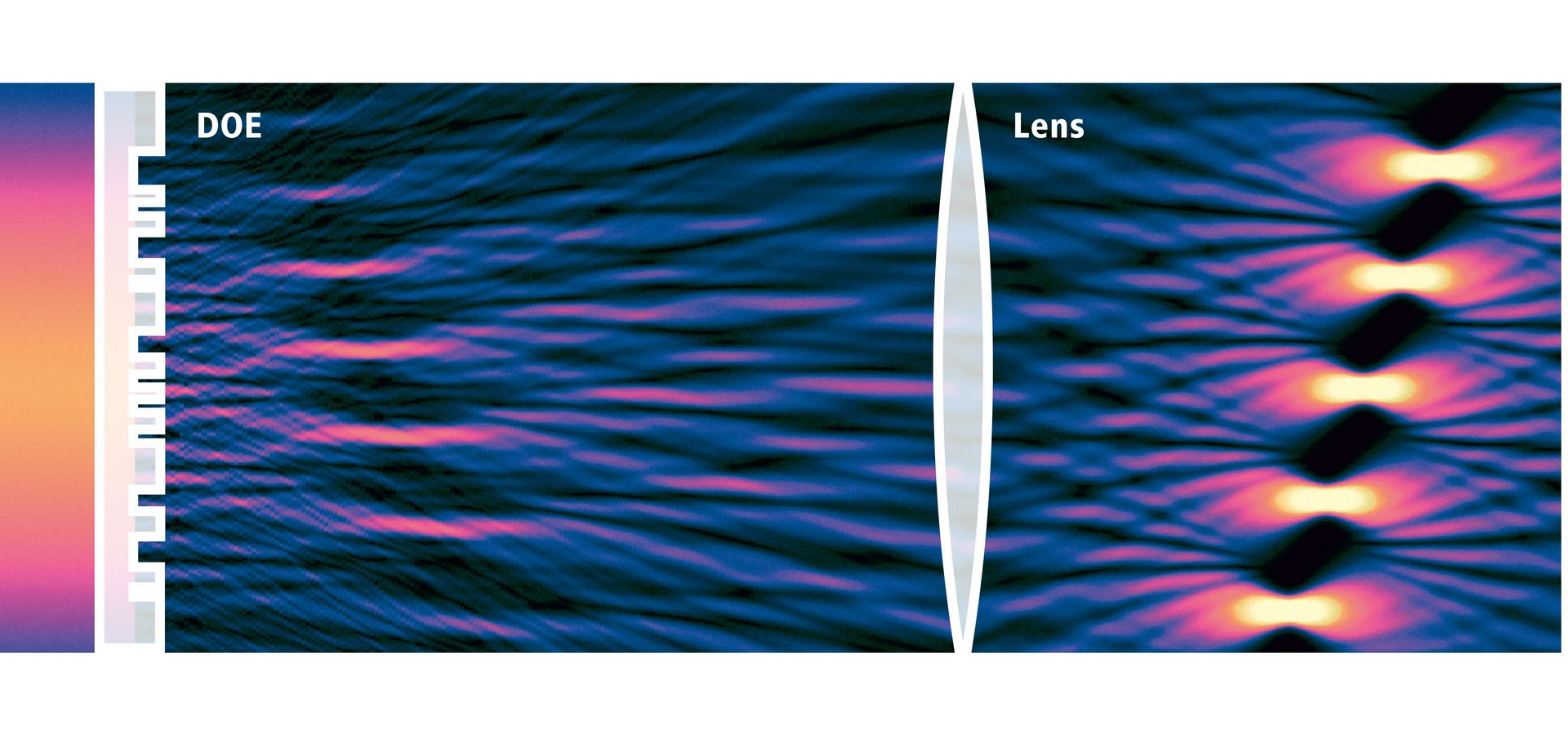

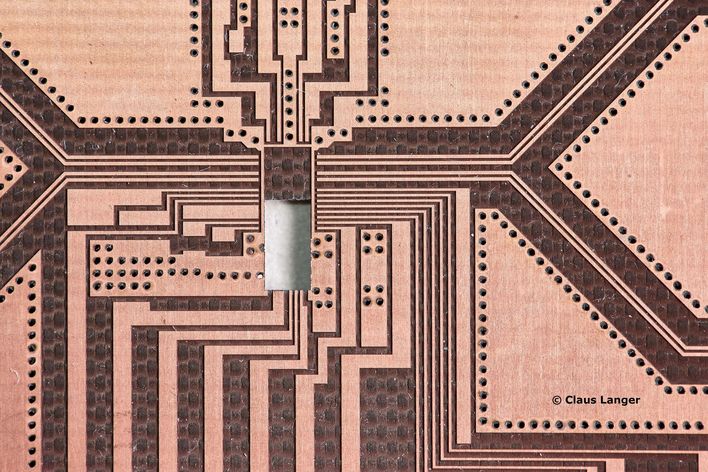

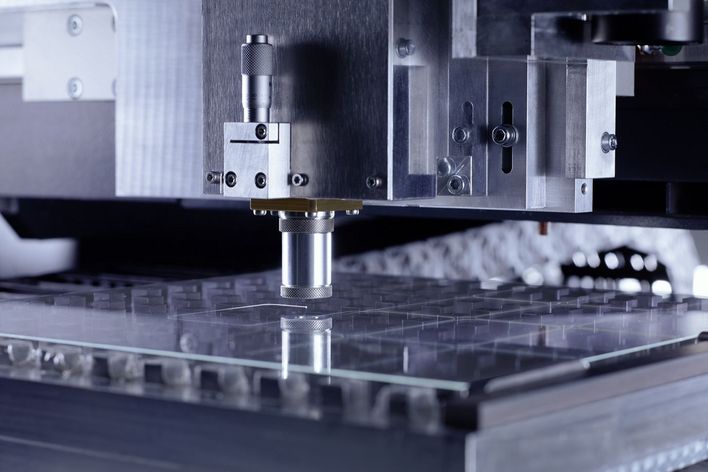

Targeted aberration of the laser beam enables us to tailor the focus to the requirements of a particular application. In glass cutting, for example, we can extend the focus along the direction of propagation in order to simultaneously change the structure of the material throughout the entire volume of the glass. Another option is to use diffractive optical elements (DOEs) to accelerate light. This method causes the focus to bend at a certain angle, so it looks like the letter C, for example. Laser beams with a C-shaped focus can then be used during cutting to give display glass the curved edges it needs without any reworking. Other DOEs split the focus and distribute it freely in space within a given volume. In TRUMPF's advanced engineering department, we have already split a laser beam into 133 foci and freely distributed them in a different form within a volume of one cubic millimeter. This has enabled us to tap into new opportunities and efficiencies in the microprocessing realm.

On this basis, it is perfectly conceivable that we could distribute them in other volumes, too, with the number of foci ascending to the hundreds of thousands. Metalworking applications could benefit from rectangular functions (flat-top distribution), which generate homogeneous intensity over a certain width, while the intensity outside the rectangle is simply zero. Instead of producing surface structures pulse by pulse, a focus with flat-top distribution can ablate the material in a single shot. The efficiency gains are huge: depending on the laser you're using, diffractive beam splitting can divide each focal point of the beam into between 50 and 1,000 foci without any loss of power, thereby increasing the processing throughput by a factor of 50 or 1,000, respectively.

High computing effort

As we can see, wave optics offers all sorts of new opportunities. But it's not just about shifting how we think about things; it also involves a lot of hard work! That's because switching from ray optics to wave optics means leaving behind a mathematically simple model and switching to a much more complex one. This transition affects not only mathematical modeling, but also computer simulations and the analysis of lab results. In the TRUMPF advanced engineering department, we have performed pioneering work in all these fields. As a result, we can describe light in terms of wave optics along its complete path from the beam source to the workpiece. This also involves not only modeling the coherence of light waves from the light source, but also considering issues such as resonator modes in order to understand the field distribution within the focusing optics. It is not uncommon to be dealing ith a billion pieces of information for a single laser beam within this kind of four-dimensional matrix (three spatial dimensions and one time dimension). That requires correspondingly high computing and simulation capacities. What's more, the wave-optics model is different for each laser. For example, there is a huge difference between cw, short-pulse, disk and fiber lasers in terms of their wave optics.

Dr Daniel Flamm works in the TRUMPF advanced engineering department. This group of young researchers investigates fundamental aspects of laser optics. Among other areas, they are currently examining the potential of wave optics for laser material processing.

Gateway to a new world

Wave optics are currently ushering us through the gateway to a new world of laser material processing. In the coming years, we will be operating with applications and achieving efficiency gains that will almost seem like witchcraft to users of geometrical optics! Yet the next threshold is already in sight. If we think of ray optics as a crutch, and wave optics as a pair of running shoes, then quantum electrodynamic (QED) optics may well seem like a racing car 30 years from now. But, for the moment, QED optics is difficult to calculate for macroscopic applications and yields far too much information, which we are incapable of using for optics design. Of course, that was also true of wave optics until recently.