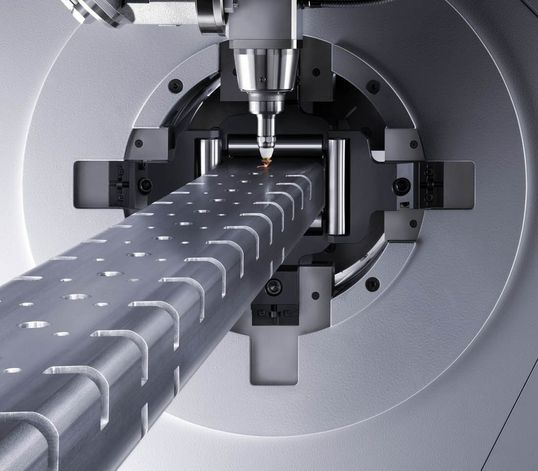

A convertible with an open top is automatically associated with freedom. The unique open machine concept of TruLaser Tube machines is very similar. Thanks to its ease of access, loading and unloading is possible from practically all sides. Enjoy your newfound freedom!

Choosing the right partner has never been so easy: laser tube cutting with TRUMPF

As an experienced specialist, you know what is important when it comes to laser tube cutting: you need robust, sophisticated technology, perfectly matched components and a service network that is always close to hand. It goes without saying that the machine, laser, software and all automation components should be internal to the company. Benefit from tested technology data and cutting data and advice on part design. Use TRUMPF's expertise, decades of experience and process know-how to always remain one step ahead of the competition.

What our customers say

"With the tapping unit, we can integrate an additional subsequent process into the machine. This has already allowed us to reduce costs for tube laser parts with friction threads by 20%."

"We rarely produce standard series, but handle a lot of project business. That means up to 100 different production orders every day. We mainly need the machine for contour cuts that ensure an optimum welding connection."

"When purchasing, the decisive factors for us were the machine's high level of automation and the fact that TRUMPF has an outstanding local service team right here in Taiwan."

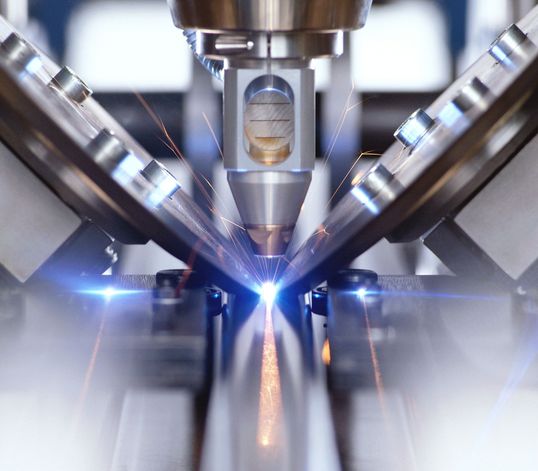

From turbo-charged cutting to a sense of freedom – tube processing taken one step further

Curious? Find out more about intelligent functions that make your work easier!

Get comprehensive advice from our product experts. As a market and technology leader in laser technology and the machine tool industry, we are the trendsetter in the market – and are therefore your perfect partner when it comes to laser tube cutting.

The origin of TruLaser Tube machines

The Swabian Jura in Germany is where everything comes together. It is a vacation region that is affectionately sometimes also called the "Blue Belt". TRUMPF's impressive scope of manufacturing is tangible here. This is because all components needed to build a laser tube cutting machine undergo final assembly here. In this hustle and bustle, trucks deliver parts from surrounding sites, day in, day out. These parts are needed to finally deliver the finished machine.

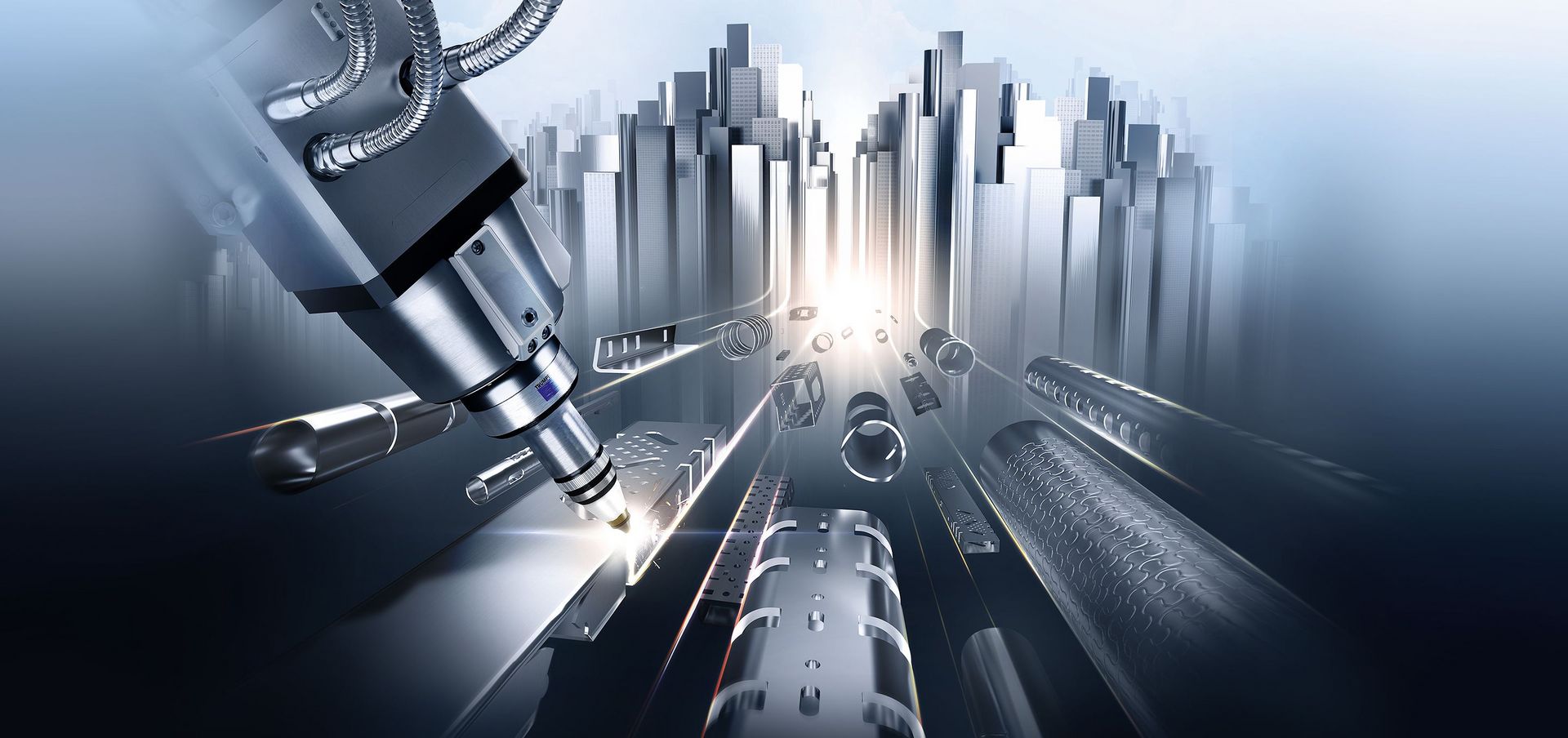

Allow us to introduce... your future tools for laser tube cutting

Comprehensive advice – get the complete package from TRUMPF

We will accompany you on your path into networked production

Real success stories. Real people. Real tubes.

Enough about theory. Are you curious how our machines perform in daily practice? We anticipate that many of your competitors in the market are already using numerous options, such as RapidCut, bevel cutting, and tapping units to stay one step ahead in the future, too. Because things can always be done a little faster, more precisely and often more easily.

Whether it's small villages or big cities, tubes are used everywhere. Designs made from tubes and profiles are ubiquitous

Tubes are a fixture of our everyday lives: From robust frame constructions for buses and agricultural machinery, delicate designer furniture and lamps to complex systems made from tubes in machine and systems engineering – laser-processed tube designs are found everywhere. No wonder – because few tools can be used with such flexibility and offer so much contour freedom. Innovative products made from laser-cut tubes are already being used successfully: in the furniture industry, construction industry, automotive industry, commercial vehicles and transport, machine and systems engineering, the agricultural sector, the fitness industry, and air-conditioning and energy technology.

Tubes prefer TRUMPF – for your successful work with tubes

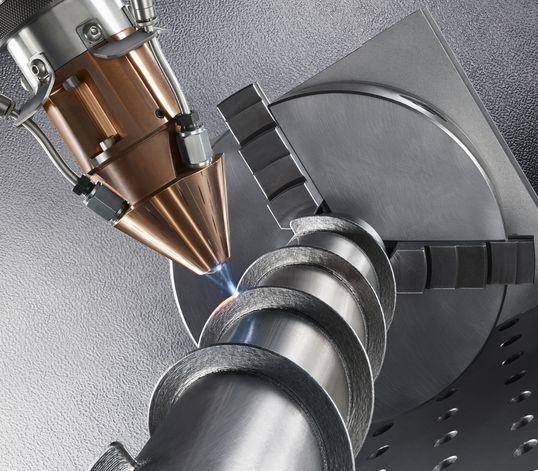

Use our decades of expertise in tube processing for your success. As your partner, we will support you in all upstream and downstream processes.

Contact

Get in touch with us! Our experts are by your side as strong and knowledgeable partners.