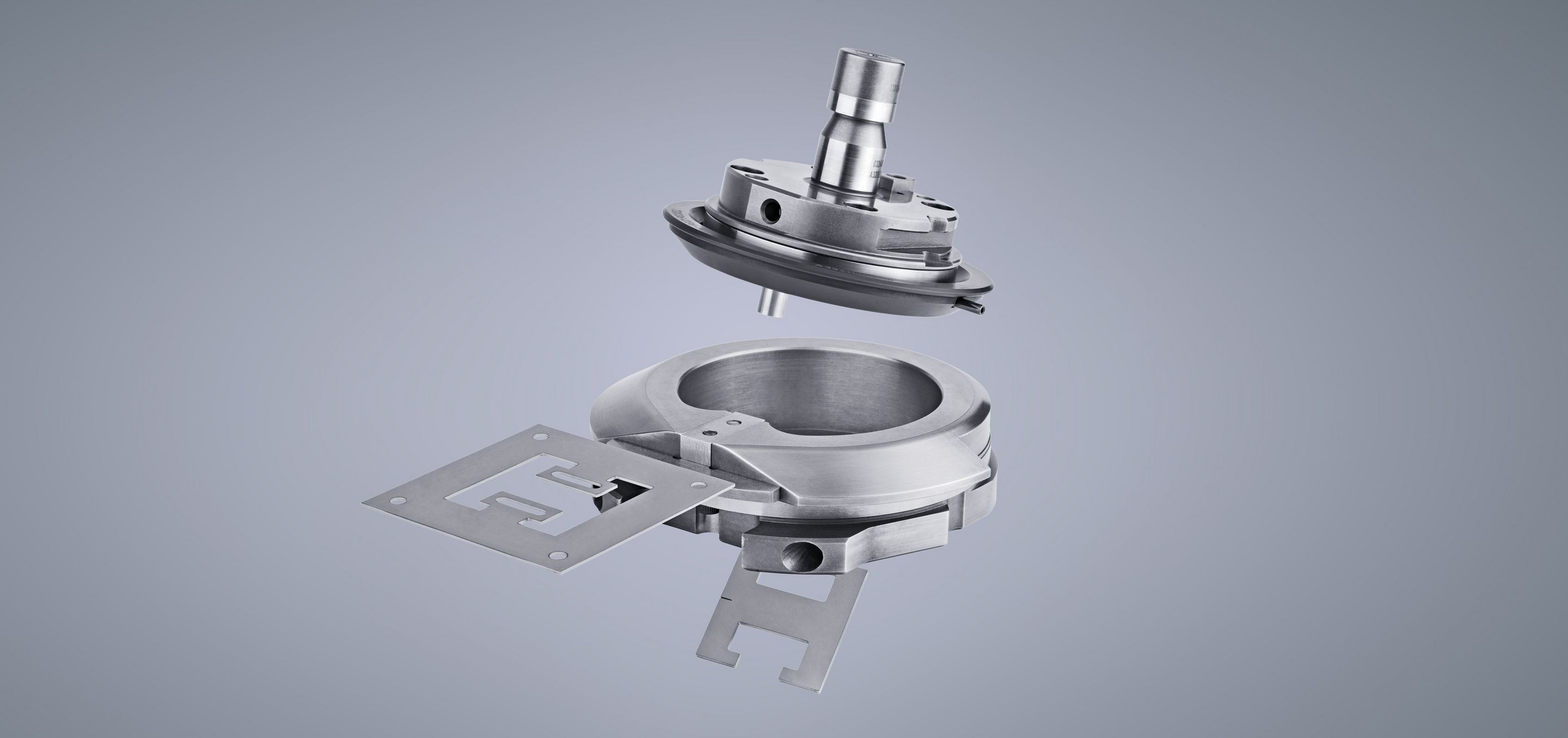

During removal, laser-cut small parts may tip, stick up, or tilt and then become stuck in the scrap skeleton. With the ejector tool for sorting, these problems become a thing of the past. You can eject even the most complex geometries in a process-reliable way. Together with the Delta Drive, the machine drive of the TruMatic 1000 fiber, you can sort finished and remaining parts in up to four different containers. Whilst the finished parts fall into the finished parts container via the part chute, the waste parts are transported to the chip container via the die. This also means scratches on the finished parts are minimized. If the size of the remaining parts is greater than the size of the die width, the remaining parts can alternatively be ejected via the part chute.

Process-reliable sorting and removal

The ejector tool for sorting removes finished parts separately from remaining parts through the part chute – quickly and reliably. This means you will never again have to collect finished parts from the chip container and you save valuable time.

Process-reliable removal

Remove even complex small parts quickly and safely in microjoint technology.

Considerable time savings

Separation of finished parts and remaining parts directly on the machine.

High flexibility

Also remove large parts with a large sheet thickness via the part chute with process reliability.

Tool options

Contact