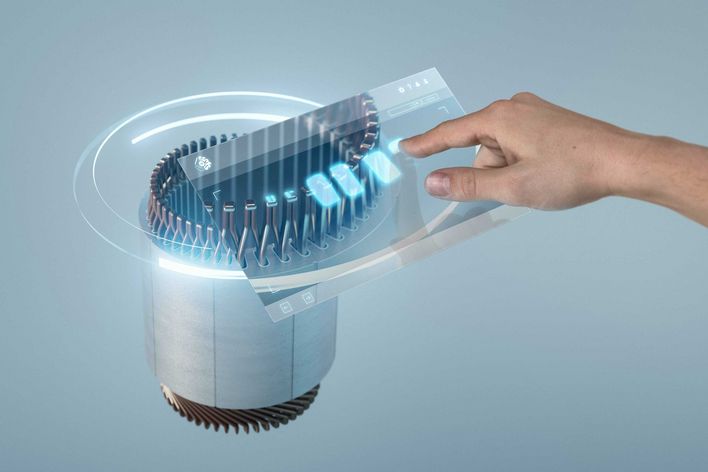

Erweitern Sie die Möglichkeiten von VisionLine Detect mit EasyModel AI. Die cloudbasierte AI-Trainings-Plattform ermöglicht es, ohne Programmierkenntnisse und mit wenigen Trainingsdaten bereits gute Ergebnisse zu erzielen. So können Sie bildbasierte KI-Modelle passgenau zu Ihren Anforderungen und Ihrem Bauteil trainieren. Mit der VisionLine Detect Option KI Filter verbessern Sie anschließend die Merkmalsdetektion und machen Ihren Prozess unabhängiger von äußeren Einflüssen, wie z. B. schwierigen Beleuchtungssituationen oder schwankenden Vorprozessen.

Total confidence with TRUMPF process sensors!

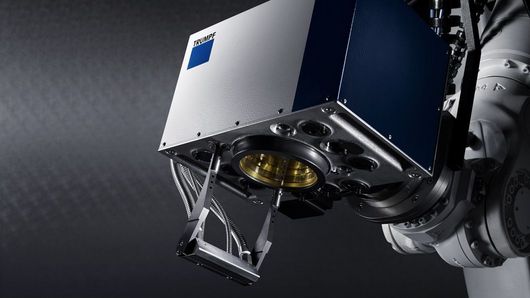

You can avoid defective parts with TRUMPF's image processing solution VisionLine. Camera-based image processing means you can keep an eye on everything for cutting and welding applications. VisionLine automatically detects the component position, forwards this information to the control, and ensures that the welding seam is always in the right place. With the Basic, Detect and Project options, you can choose between simple monitoring of the workpiece, characteristics recognition or a customer-specific extension. Image processing is available for lasers with optics as an integrator package as well as for the TruLaser Station and TruLaser Cell systems.

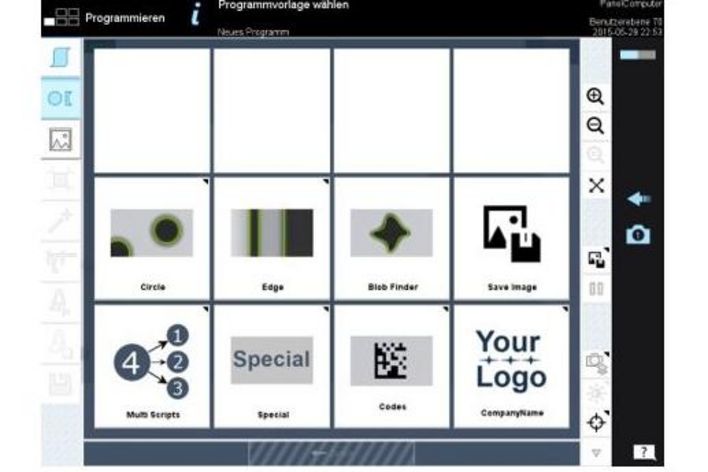

Thanks to the intuitive user interface and pre-defined attribute library, it is very easy to integrate VisionLine in the production process. After just a few work steps, the operator can start right away.

Enjoy the benefits of having TRUMPF as an entire system supplier – from the laser to the process sensor system and consulting.

Reduce your component positioning requirements without any loss of quality.

The attribute library supports the person doing the set-up work as they create their image processing tasks.

You can save image data at any time to guarantee traceability.

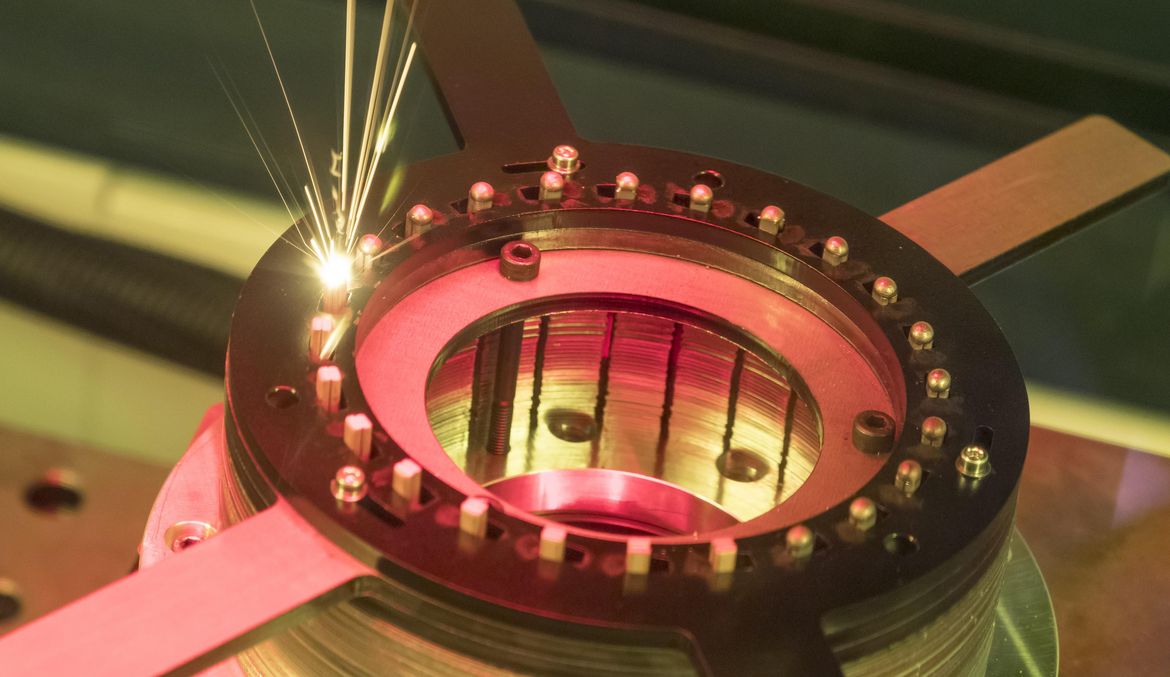

Hairpin welding with VisionLine image processing

A typical application for VisionLine image processing is

position recognition of hairpins in stators which are used in electric motors.

Welding of electronic components

The image processing system detects the pins that are to be welded, for example in electronic control units, sensors, and actuators.

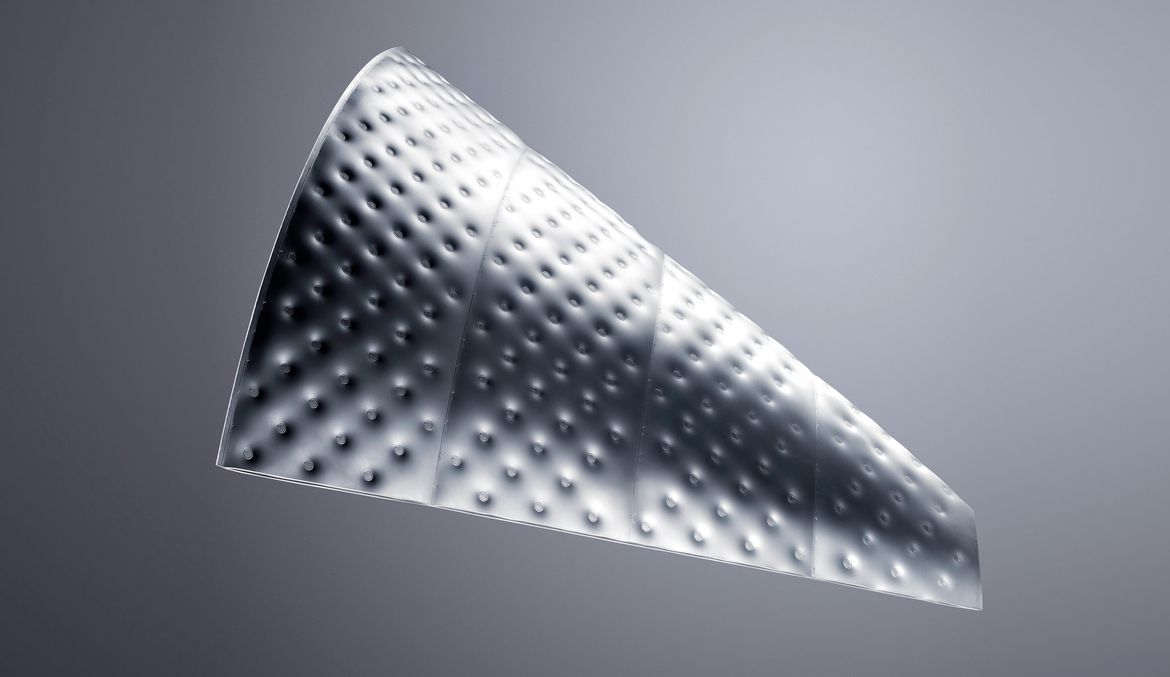

Welding of joint connections

Image processing enables you to detect seam points when welding heat exchangers or seat rails, indicating they are welded at the right location.

Marking of gear parts

When marking components, VisionLine supports quality control with the "distance measurement" function.

|

Image processing for cutting and welding applications

|

|

|---|---|

| Configuration | |

| Systems available | TruLaser Cell 3000 |

| Available lasers | TruDiode, TruDisk, TruFiber, TruPulse |

| Available options |

Basic, Detect, Project

Adjust (TruLaser Cell 3000) |

| Available focal lengths |

150 / 200 mm (FocusLine Professional)

150 / 200 / 250 mm (WeldLine Modular) 150 / 200 / 250 / 300 mm (BEO D50) 200 / 300 mm (BEO D70) 255 / 345 / 450 mm (PFO 33-2) 255 / 450 mm (PFO 3D-2) |

| Lighting | - |

| Parameters | |

| Typ. image processing time | 80 ms - 150 ms |

| Typ. precision of the working distance search | ± 50 μm with f = 150 mm (TruLaser Cell 3000) |

| Typ. precision of the position recognition | ± 20 μm in the image center |

The technical data of all product versions as a download.

VisionLine Basic

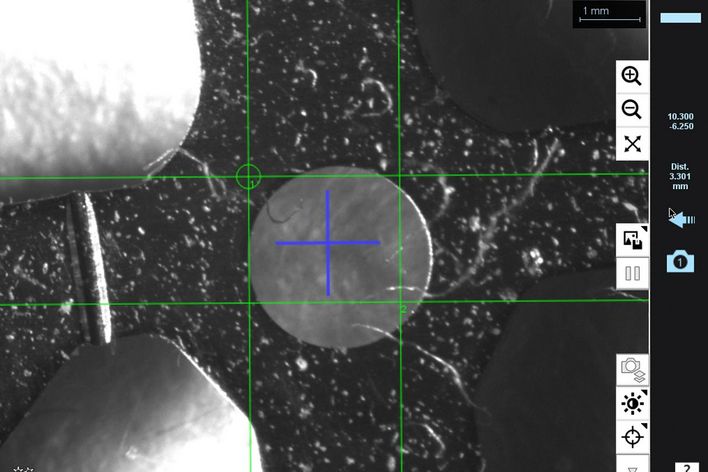

A digital camera image with cross-hairs in the laser focus helps with workpiece monitoring and teaching. Using the VisionLine Basic in combination with the TRUMPF scanner optics of the PFO series is particularly advantageous. In this case, the offset between the laser light and monitoring light outside of the center of the scan field is corrected so that the focus position shown in the image corresponds to the actual position of the laser focus.

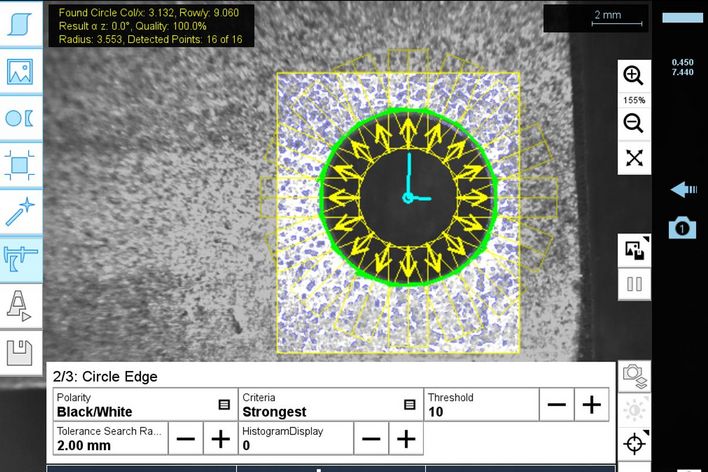

VisionLine Detect

Edge-detection offers the option of integrating simple characteristics recognition on the workpiece in the production process for position correction. The appropriate distinguishing features (for example, blots, circles, lines or intercept points) can be selected from a template library for many application scenarios.

VisionLine Project

With an additional service package, TRUMPF provides a complete solution for complex image processing tasks. Programming the process-stable image processing, including extensive documentation is performed, subject to a successful feasibility study.

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price, and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.

AI-Trainings-Plattform – EasyModel AI