Mit dem Fullfield Multilaser (2 x 700 W) können alle Laser im gesamten Bauraum belichten. Das Ergebnis: Steigerung der Produktivität, kürzere Fertigungszeiten pro Bauteil und Senkung der Teilekosten. Um eine noch höhere Präzision zu erreichen, werden die Multilaser Scanfelder automatisch zueinander kalibriert. Dadurch erzielen Sie eine sehr hohe Oberflächenqualität - ganz ohne Nahtstellen. Die Option Fullfield Multilaser erhalten Sie mit zwei leistungsstarken TRUMPF Faserlasern, die über einen Strahldurchmesser von 80 µm verfügen.

Flexible Lösung für die industrielle additive Fertigung

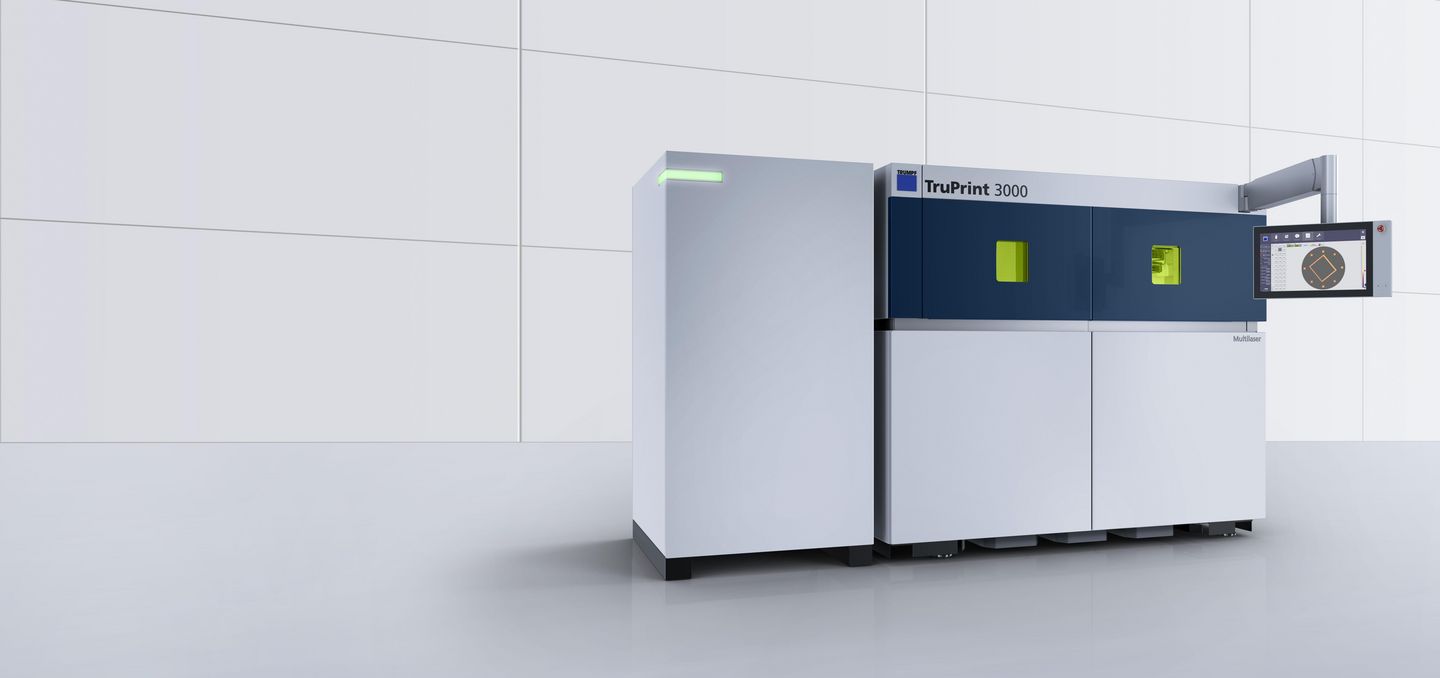

Die TruPrint 3000 ist eine universelle Mittelformat-Maschine (LMF / PBF / LPBF) mit industriellem Teile- und Pulvermanagement. Ab sofort profitieren Sie von noch mehr Flexibilität, Qualität und Produktivität für Ihre additive Serienproduktion: Denn den Metall 3D-Drucker TruPrint 3000 erhalten Sie jetzt auch mit Fullfield Multilaser Option mit zwei 500 Watt oder zwei 700 Watt Lasern von TRUMPF.

Die Produktivität wird unabhängig von der Bauteilgeometrie nahezu verdoppelt und die Teilekosten deutlich gesenkt. Die automatische Überwachung und Kalibrierung der Multilaser während des laufenden Baujobs ermöglicht eine optimale Qualität bei gedruckten Multilaserbauteilen. Neueste Entwicklungen an der Schutzgasführung steigern zusätzlich die Bauteilqualität und Reproduzierbarkeit der Teile. Dokumentiert wird dies parallel zum Baujob mittels Melt Pool Monitoring. Nachweispflichten wie z.B. im medizinischen Bereich können so erfüllt werden.

Hochflexibel passt sich die TruPrint 3000 den individuellen Anforderungen unserer Kunden an. Mit einem Bauvolumen von 300 mm Durchmesser und 400 mm Höhe findet sie ihren Einsatz in unterschiedlichsten Branchen. Je nach Bauteilgröße und -komplexität, Ihrer Präferenz im Workflow und den Produktionsvolumina können Sie flexibel zwischen internem oder externem Entpacken wählen - alles unter Schutzgas. Bei Zweiterem minimieren Sie zudem die Stillstandzeiten des 3D-Druckers durch hauptzeitparalleles Arbeiten.

Gleichbleibende Bauteilqualität durch neu entwickelte Schutzgasströmung

Zeitgleiche Belichtung im gesamten Bauraum für maximale Produktivitätssteigerung

Durch verschiedene Maschinen- und Peripheriekonfigurationen für das Teile- und Pulvermanagement

Sicherstellung hoher Qualitätsstandards während des Baujobs durch Melt Pool Monitoring

Einfaches Teile- und Pulverhandling unter Schutzgas für gleichbleibende Pulver- und Bauteilqualität

Absorberkühler

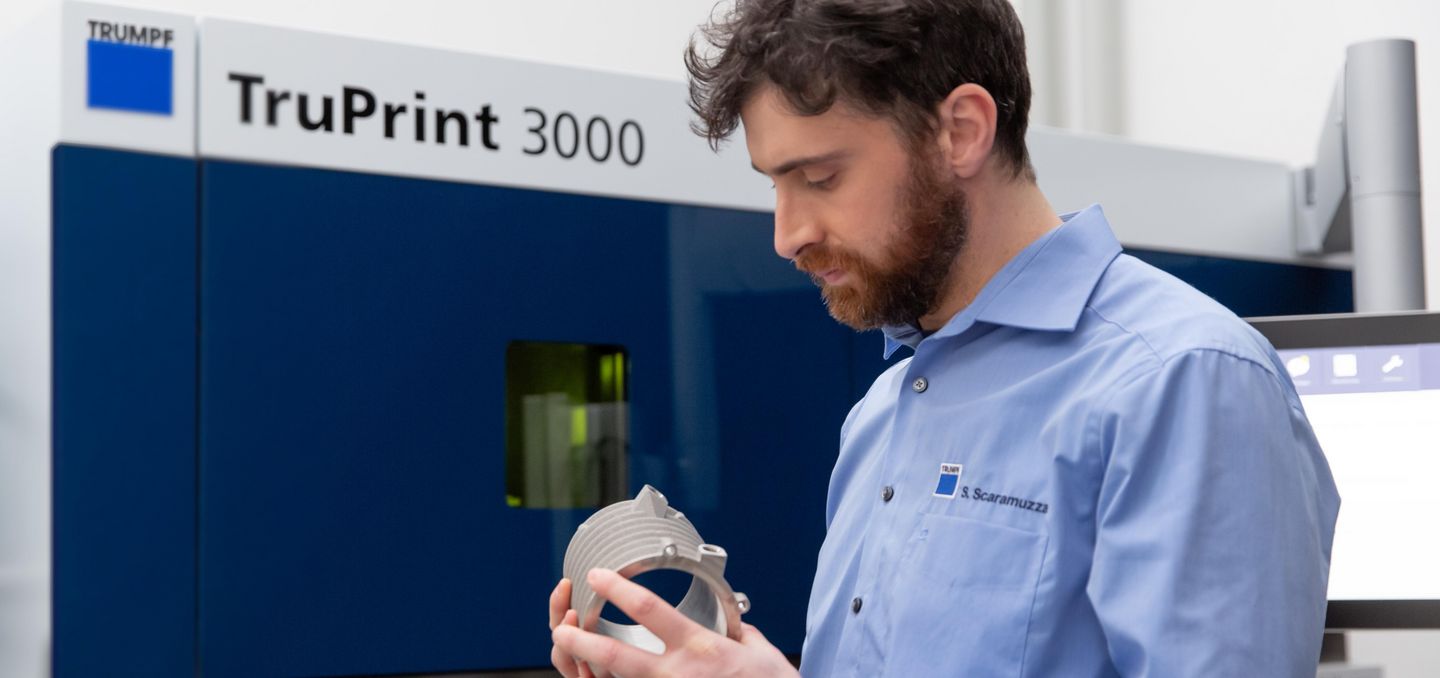

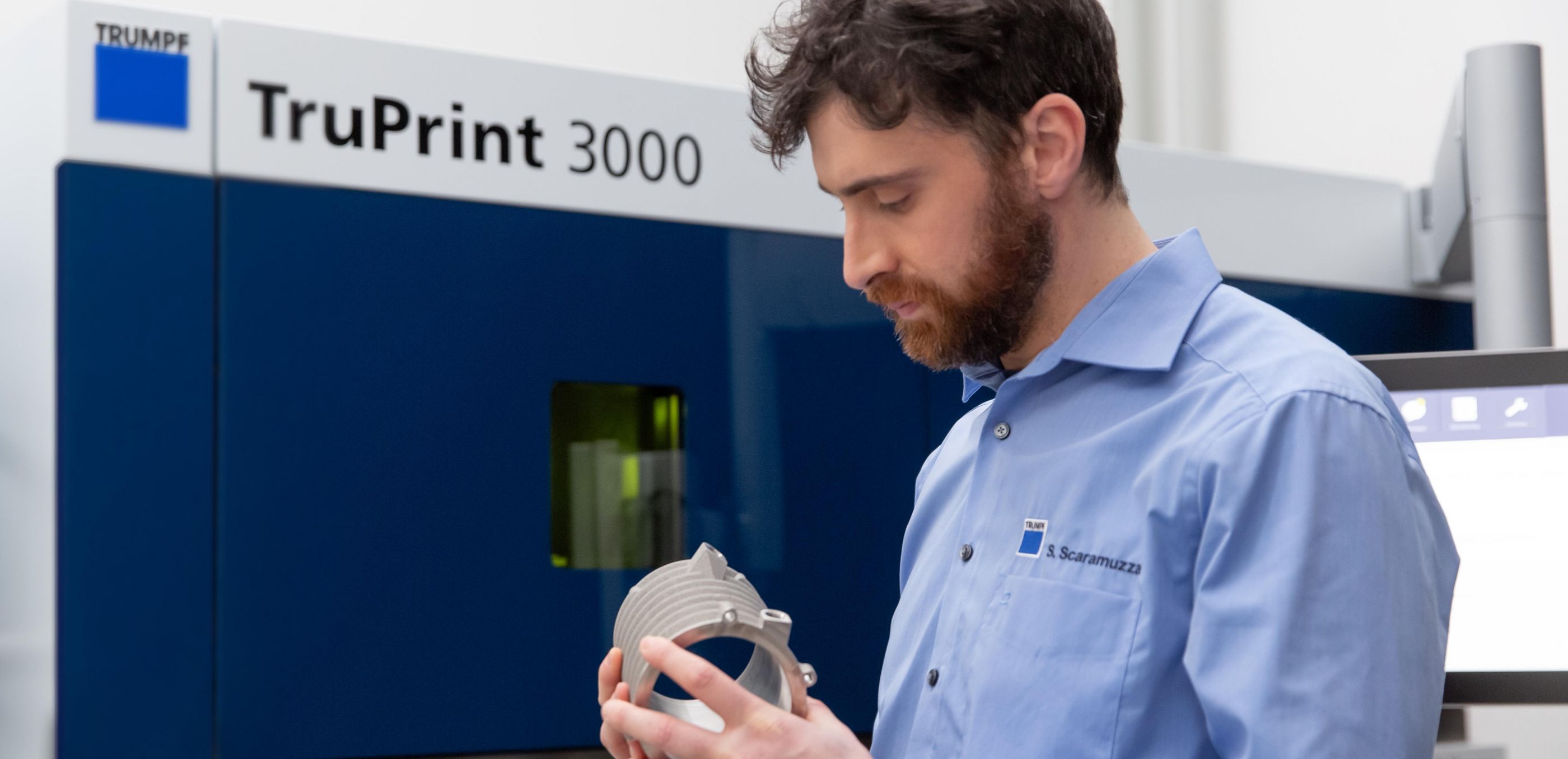

Ein additiv gefertigter Absorberkühler für eine Laserquelle von TRUMPF besteht lediglich aus zwei Bauteilen. So erübrigt sich im Vergleich zum konventionellen Teil die Montage der Baugruppe aus 27 Einzelteilen. Das gedruckte Bauteil überzeugt durch 90 % weniger Leckagestellen und einer Kühlung, die konturnah und durchflussoptimiert ist.

Vielfältige Anwendungsmöglichkeiten

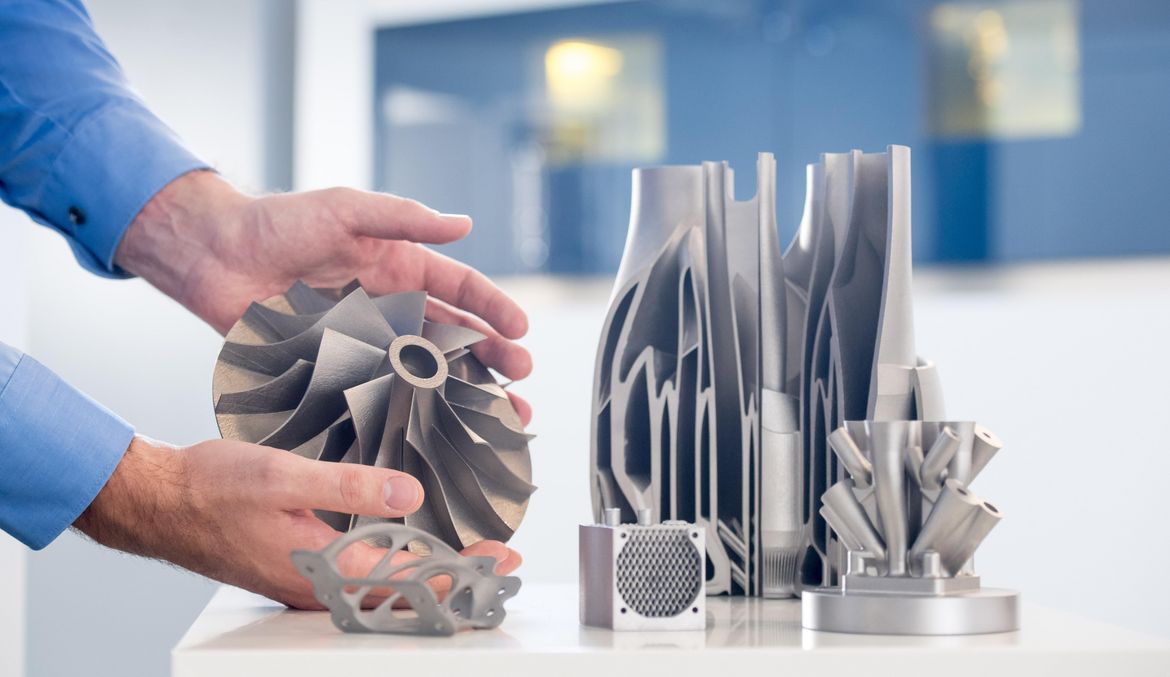

Die TruPrint 3000 ist eine flexible 3D-Druckmaschine für eine Vielzahl von Anwendungen aus unterschiedlichsten Branchen. Nutzen Sie die Laser Metal Fusion (LMF) Technologie und deren Vorteile wie Designfreiheit, Funktionsintegration und -optimierung.

Serienproduktion mit der TruPrint 3000

Im großen Bauraum der TruPrint 3000 lassen sich Bauteile flexibel anordnen, das eignet sich perfekt für die Anforderungen von Job Shops.

General Industry

Viele General Industry Applikationen können mittels Laser Metal Fusion (LMF) optimert werden. Mit Hilfe des 3D-Drucks konnte dieses Turboradialgebläse endkonturnah hergestellt werden, was die Nachbearbeitung reduziert. Außerdem führt die Ausarbeitung des Hohlkörpers zu einer Gewichtsreduktion von bis zu 25 %. Das geringere Gewicht ermöglicht höhere Drehzahlen.

Energie & Turbine

Laser Metal Fusion ermöglicht es selbst komplexe Innenraumstrukturen zu generieren. Der Laser schmilzt die gewünschte Teilekontur schichtweise im Pulverbett auf, wodurch jede Geometrie möglich ist.

|

TruPrint 3000

|

|

|---|---|

| Bauvolumen (Zylinder) | Durchmesser 300 mm x 400 mm Höhe |

| Verarbeitbare Werkstoffe | Schweißbare Metalle in Pulverform, wie z.B.: Edelstähle, Werkzeugstähle, Aluminium-, Nickelbasis-, oder Titan-Legierungen. Aktuelle Werkstoff- und Parameterverfügbarkeit auf Anfrage. |

| Vorheizung (Standard) | Bis zu 200 °C |

| Maximale Laserleistung am Werkstück (TRUMPF Faserlaser) | 700 W |

| Strahldurchmesser (Standard) | 80 μm |

| Schichtdicke (individuell einstellbar) | 20 - 150 μm |

| Aufbaurate | 5 - 120 cm³/h |

| Anschluss und Verbrauch | |

| Elektrischer Anschluss (Spannung) | 400/460 V |

| Elektrischer Anschluss (Stromstärke) | 32 A |

| Elektrischer Anschluss (Frequenz) | 50/60 Hz |

| Schutzgas | Stickstoff, Argon |

| Bauform | |

| Abmessungen (inkl. Filter) (B x H x T) | 3385 mm x 1750 mm x 2070 mm |

| Gewicht (inkl. Pulver) | 4300 kg |

Die technischen Daten aller Produktvarianten als Download.

TruTops Print

Mit TruTops Print bietet TRUMPF die passende Software-Lösung, um das Beste aus den TruPrint-Maschinen herauszuholen. Die moderne Benutzeroberfläche fasst alle Funktionalitäten übersichtlich zusammen und ermöglicht einen schnellen Zugriff auf alle Funktionen. Durch die hohe Flexibilität und die individuellen Möglichkeiten zur Datenvorbereitung, wie beispielsweise die z-Segmentierung, sowie das intuitive und übersichtliche Parametermanagement mit vollständig zugänglichen Parametern, werden höchste Effizienz und Produktivität bei bester Druckqualität und Reproduzierbarkeit sowie supportreduzierte Überhangbaubarkeit gewährleistet. Die hohe Güte der erstellten Vektordaten im WZA-Format kann mit dem integrierten BuildJob Viewer verifiziert werden.

Datenvorbereitung passend zu Ihrem Workflow

Für einen nahtlosen Datenvorbereitungs-Workflow ist TruTops Print bereits an zahlreiche CAD/CAM-Systeme angebunden. Dies bietet Ihnen die größtmögliche Flexibilität bei der Auswahl der Datenaufbereitungssoftware. Entscheiden Sie selbst, welche Lösung perfekt zu Ihrem Workflow passt.

Steigern Sie Ihre Produktivität mit der Option Multilaser: Zwei TRUMPF Faserlaser mit je 500 W und 80 µm Strahldurchmesser belichten zeitgleich im Bauraum und generieren so flexibel bis zu 80 % mehr Teile in gleicher Zeit. Auf diese Weise erzielen Sie eine schnellere Teileverfügbarkeit sowie höchste Flexibilität bei Kundenaufträgen. Da zudem jede Kontur von einem Laser belichtet wird, entstehen keinerlei "Nahtstellen". Sie arbeiten mit dem Fullfield Multilaser mit 100 % Überlapp. Durch die Option Automatic Multilaser Alignment findet automatisch während des laufenden Baujobs eine Überwachung und Kalibrierung der Multilaser Scanfelder zueinander statt - für eine optimale Qualität bei Multilaserbauteilen.

Die Option Integrierter Pulverförderer ist die Alternative zum externen Entpacken, denn Sie befreien das fertige Bauteil nach dem Bauprozess innerhalb der Prozesskammer unter Schutzgas vom Pulver. Bis zu 400 mm hohe Bauteile können intern entpackt werden.

Über eine integrierte Kamera in der TruPrint Baukammer und die automatische Bildverarbeitung können Sie das Pulverbett automatisch überwachen. Auf diese Weise erhalten Sie jederzeit eine Übersicht über den Bauteilezustand und können die Qualitätsparameter schichtweise analysieren. Fehlendes Pulver wird mittels der Option automatisches Nachbeschichten detektiert und die betroffene Schicht automatisch durch eine neue Pulverbeschichtung korrigiert.

Abweichungen im Laserschmelzprozess lassen sich mittels Sensoren frühzeitig erkennen und kritische Bereiche am Bauteil visualisieren. Außerdem können Sie alle Schmelzbäder parallel überwachen – besonders hilfreich mit der Option Fullfield Multilaser.

Für Ihre TruPrint stehen verschiedene Optionen zur Verfügung, um der Nachweispflicht nachzukommen: Laserleistungskalibrierung - auch für Multilaser, Fokuslagenmessung und Scanfeldkalibrierung - so können Sie messen, bei Bedarf rekalibrieren und Ihre Messergebnisse dokumentieren.

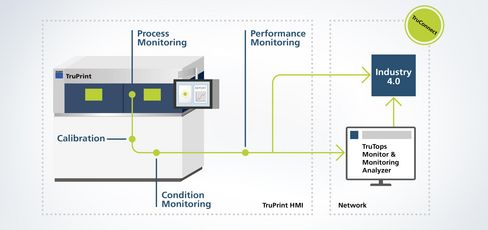

Monitoring TruPrint

Mit den intelligenten Monitoringlösungen von TRUMPF können Sie den Bauprozess der TruPrint Maschinen einfach überwachen, analysieren und kalibrieren - damit fertigen Sie noch effizienter und erzielen eine höhere Bauteilqualität. Das professionelle Monitoring ermöglicht die Darstellung und Auswertung von sensorgestützten Daten. Das Angebot umfasst Lösungen für Process, Condition sowie Performance Monitoring. Die Ergebnisse des Monitorings können direkt an der HMI der TruPrint Maschine eingesehen oder offline mittels Monitoring Analyzer ausgewertet werden. Mit TruTops Monitor erhalten Sie neben der Transparenz die Möglichkeit eines Fernzugriffs via PC oder Tablet. Das OPC UA Interface bietet Ihnen zudem volle Flexibilität mit der Anbindung in eine eigene Softwarelösung. Mit den zusätzlich verfügbaren Calibration Funktionen überprüfen Sie vor Baujobbeginn die prozessrelevanten Kenngrößen für eine optimale Produktionsbedingung.

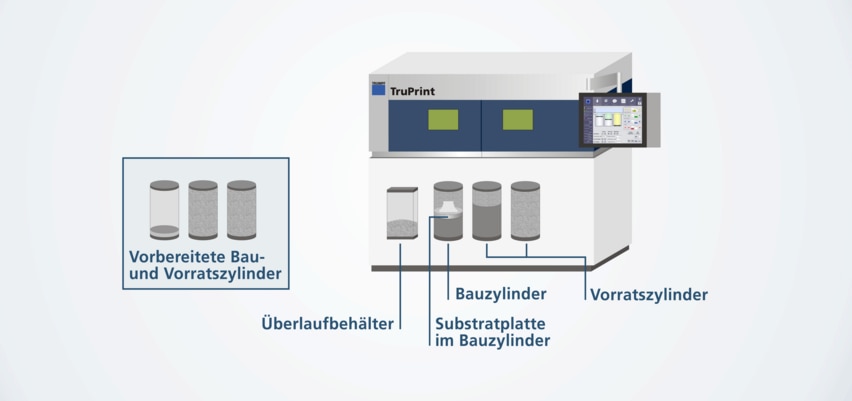

Entscheidend für eine industriereife Serienfertigung ist das optimale Handling des Pulvers und der Bauteile. Das industrielle Teile- und Pulvermanagement von TRUMPF ermöglicht hauptzeitparalleles Rüsten und Entpacken einer oder mehrerer Maschinen – das erhöht die Produktivität und Wirtschaftlichkeit für unsere Kunden. Standardschnittstellen und eine breite Palette unterschiedlicher Entpackmöglichkeiten, Sieblösungen und Lagermöglichkeiten ermöglichen höchste Flexibilität bei der Gestaltung Ihrer Anlage.

Pulver und Parameter

Hochwertige Metallpulver sind die Grundlage für zuverlässige Prozessbedingungen bei der additiven Fertigung. Die Kombination von empfohlenen Pulvern und den richtigen Parametern führt zu hochwertigen Materialeigenschaften bei 3D-gedruckten Bauteilen.

Je nach Land sind Abweichungen von diesem Produktsortiment und von diesen Angaben möglich. Änderungen in Technik, Ausstattung, Preis und Zubehörangebot sind vorbehalten. Bitte setzen Sie sich mit Ihrem Ansprechpartner vor Ort in Verbindung, um zu erfahren, ob das Produkt in Ihrem Land verfügbar ist.