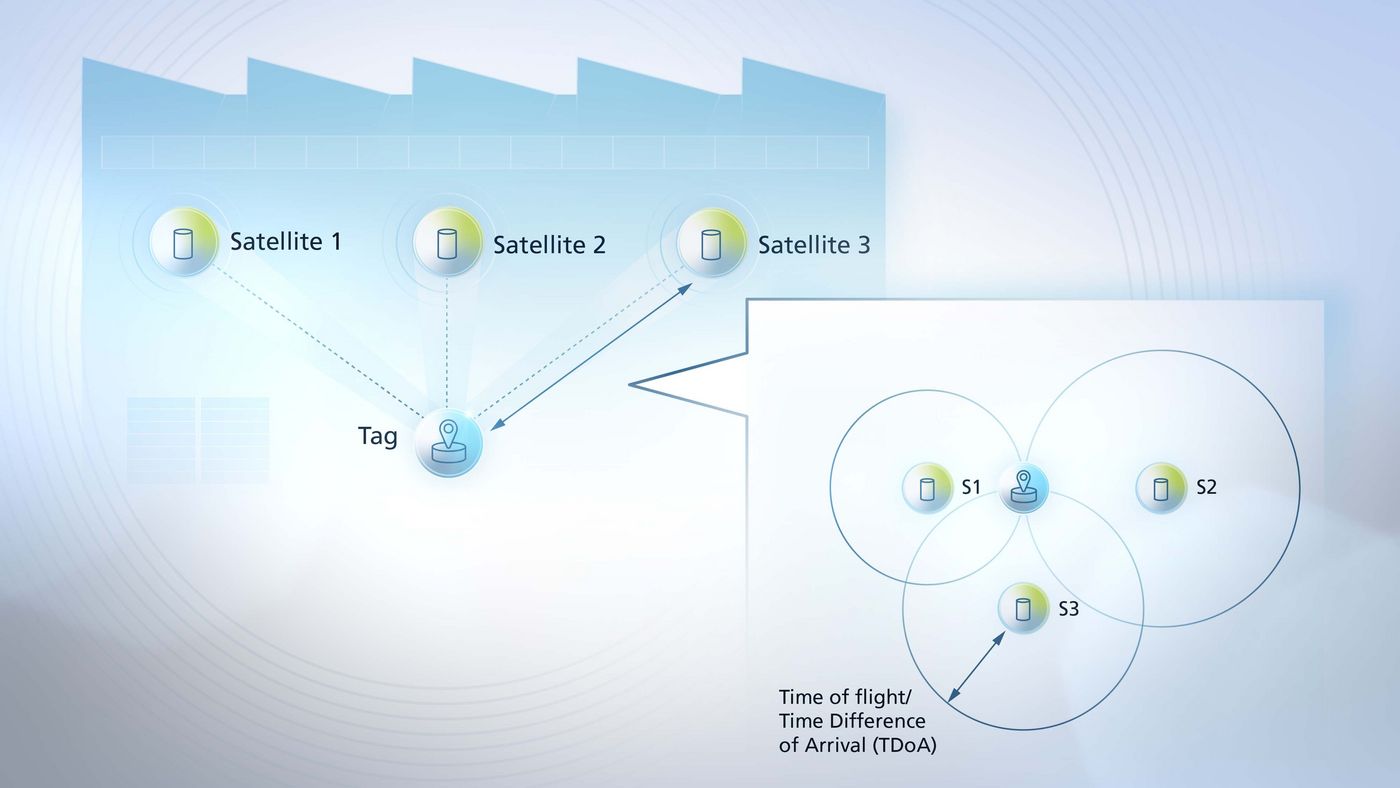

"Real Time Locating Systems" (RTLS) ermöglichen die Echtzeitverfolgung von Gegenständen und neuen Anwendungen wie das aufwandsfreie Verbuchen von Lagerorten oder der rüstfreie Einsatz fahrerloser Transportsysteme. Kernkomponenten eines RTLS sind fest installierte Satelliten, flexible Tags, eine Lokalisierungssoftware zur Bestimmung der Ortungsdaten und Applikationen, die auf diese Daten zugreifen, um verschiedene Use Cases, wie das Tracking von Gegenständen, zu ermöglichen. Dabei kommen verschiedene Technologien zum Einsatz. TRUMPF setzt auf Echtzeitortung mit UWB (Ultrabreitband) und den offenen Industriestandard omlox, um interoperable Lösungen anzubieten. Die Ortung erfolgt über Laufzeitmessung der Signale (Time-of-Flight).

Transparenz mit RTLS (Real-Time-Locating-System)

Entdecken Sie unsere Lösungen für Echtzeitortung

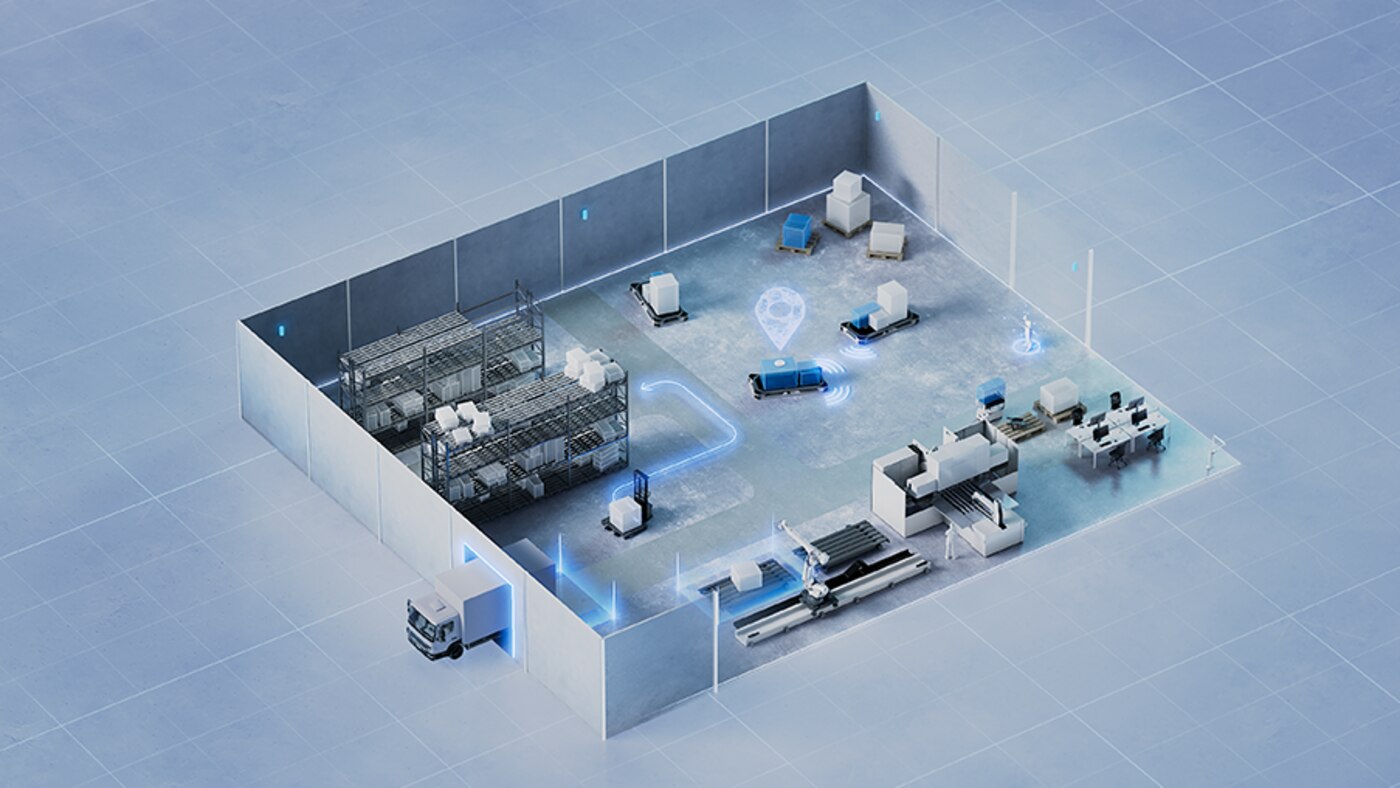

Komplexe innerbetriebliche Prozesse, schwankende Auftragsvolumina, immer kleinere Stückzahlen und unterschiedliche Teile – die gesamte Logistikbranche steht vor immer größeren Herausforderungen. Hinzu kommen aktuell weltweite Störungen in Lieferketten und ein zunehmender Mangel an Personal. Nahezu jede Branche ist betroffen: Von der fertigenden Industrie über das Gesundheits- und Transportwesen bis zum Retail Sektor. Ein zentraler Hebel, diese Prozesse zu optimieren, bildet die Transparenz, die sich nicht nur auf einzelne Gebäude beschränkt, sondern die gesamte Supply Chain umfasst: Wo sind Stillstandszeiten? Wie hoch sind die Suchzeiten und wo fallen diese an? Wie lässt sich das Miteinander zwischen AGV/AMR und Mitarbeitern so sicher wie möglich gestalten, sodass es zu keinen Kollisionen kommt? Antworten auf diese Fragen liefern Ortungsdaten, die mithilfe von „Real Time Locating Systems“ (RTLS) generiert werden.

Was ist ein RTLS?

Was ist alles mit einem RTLS möglich?

Ortungsdaten ermöglichen verschiedene Use Cases im Fertigungs- und Logistikumfeld. In diesen Anwendungen spielt die UWB-Funktechnik dank präziser Ortungsdaten, hoher zeitlichen Auflösung und robuster Signalübertragung ihre Stärken aus:

- Asset Tracking

- Automated Booking

- Machine Navigation (AGV)

- Human Navigation (VR)

- Automated Documentation

- Movement Analysis

Erfahren Sie mehr zu den Anwendungen von RTLS

Treten Sie mit unseren Experten in Kontakt!

Sie möchten mehr darüber wissen, wie Sie omlox-fähige Komponenten integrieren, um offene und flexible RTLS-Lösungen zu schaffen? Kontaktieren Sie uns!