Profitieren Sie von einer direkten und homogenen Wärmebehandlung großer Zielbereiche sowie von einer hohen Toleranz gegen Rückreflexionen. Dank der hohen Leistungsdichte von über 100 W/cm² erzielen die TruHeat VCSEL Systeme hohe Prozessgeschwindigkeiten.

Industrielle TruHeat VCSEL Systeme

Laserquellen auf Basis von VCSEL-Arrays sind in der Lage große Flächen mit gerichteter wellenlängenselektiver Infrarotstrahlung zu erwärmen. Die TruHeat VCSEL Systeme werden in zahlreichen industriellen Heizprozessen eingesetzt. Durch die direkte Bestrahlung der Behandlungsfläche können ohne teure Optiken oder Scannersysteme erhebliche Kostenvorteile gegenüber konventionellen Lasersystemen realisiert werden. Einzigartig an den Systemen ist, dass neben der präzisen Steuerung und der schnellen Umschaltung der Infrarotleistung auch das räumliche Heizprofil durch unabhängige Steuerung kleiner Segmente der Lasermodule beliebig programmiert werden kann. Die Heizmuster können sich während des Betriebs sogar dynamisch ändern. Dies ermöglicht eine beispiellose Prozessflexibilität.

Profitieren Sie von einer skalierbaren Ausgangsleistung im kW-Bereich.

Erzielen Sie eine hohe Prozessgeschwindigkeit durch eine Leistungsdichte von 100 W/cm².

Individuelle Emissionszonen der VCSEL Strahlquelle können unabhängig voneinander gesteuert werden.

Die robusten und kompakten Lasermodule können einfach in industrielle Anlagen und Produktionsprozesse integriert werden.

E-Mobility: Trocknen von Batteriefolien

Nach dem Beschichtungsprozess muss das Aktivmaterial auf den Elektrodenfolien getrocknet werden. Industrielle VCSEL-Heizsysteme können diesen Schritt übernehmen, denn Laserquellen auf Basis von VCSEL-Arrays sind in der Lage, große Flächen mit gerichteter wellenlängenselektiver Infrarotstrahlung zu erwärmen.

E-Mobility: Siegeln von Pouchzellen

Der Einsatz von TruHeat VCSEL Systemen zum Siegeln von Pouchzellen erhöht die Qualität der Siegelergebnisse. Außerdem wird durch die VCSEL-Heizsysteme die Prozesszeit reduziert, der Prozess ist im Vergleich bis zu dreimal schneller.

Lokale Entfestigung von Karosseriestahl in der Automobilindustrie

Mit TruHeat VCSEL Systemen ist es einfach und schnell möglich hochfeste Stahlteile selektiv zu enthärten. Dies hat besonders in der Automobilfertigung zahlreiche Vorteile.

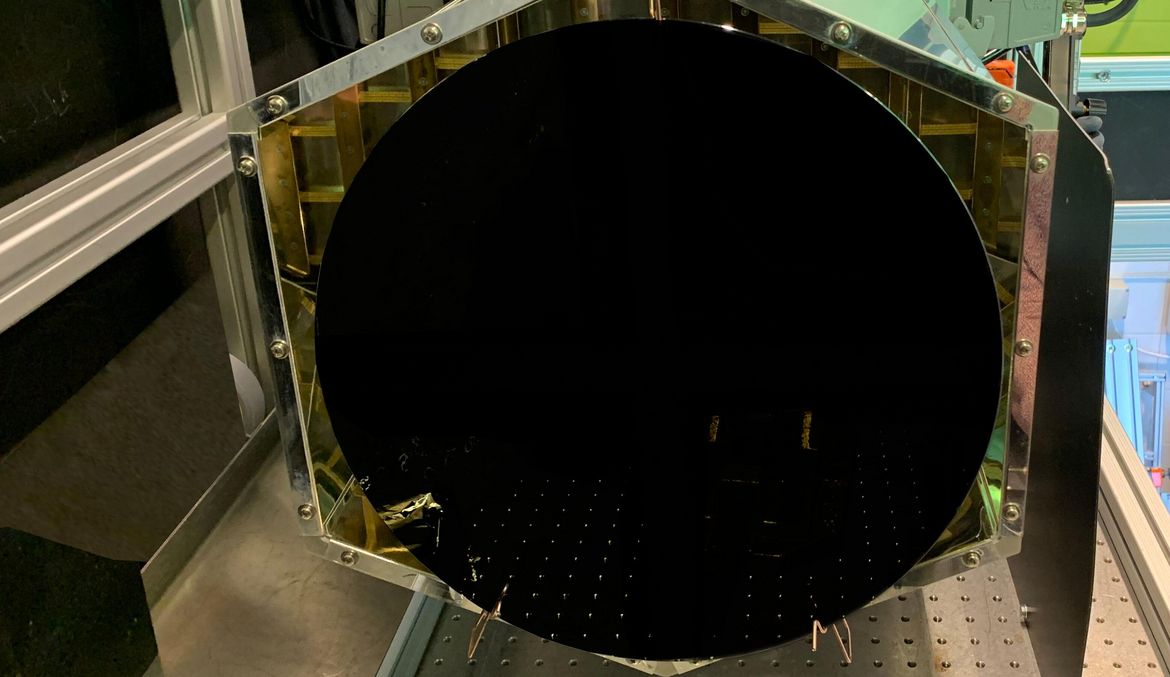

Wafer Heating

VCSEL-Laser können in der Halbleiter-Industrie für die Erwärmung der Wafer für Rapid Thermal Processing (RTP) zum Einsatz kommen. TruHeat VCSEL Systeme ermöglichen eine schnelle und homogene Erwärmung der Wafer, da sich die einzelnen Heizzonen hervorragend steuern lassen. Es können Temperaturanstiege von einigen hundert Grad Celsius pro Sekunde erreicht werden.

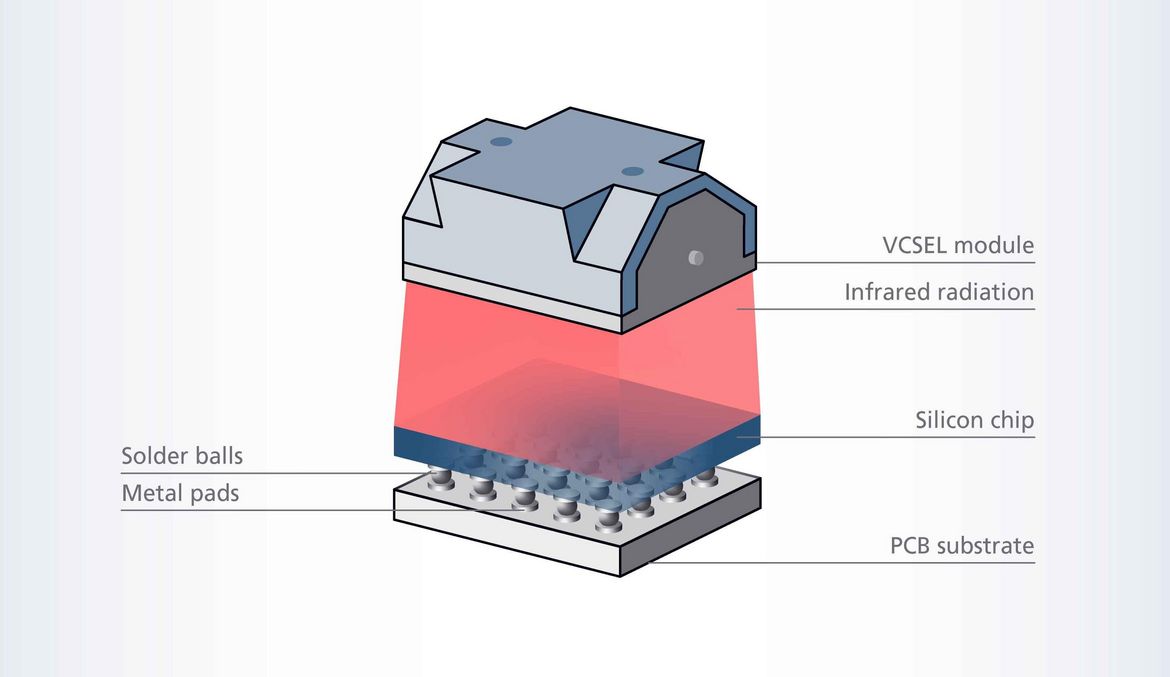

Halbleiterproduktion: Laser Assisted Bonding (LAB)

Beim Laser Assisted Bonding (LAB) wird ein Flip-Chip mit Hilfe von Lötkugeln als Verbindungselement auf eine Leiterplatte platziert. Ein TruHeat VCSEL System bestrahlt den Chip von oben, die Laserenergie wird durch einen Siliziumchip übertragen, um so die Lötkugeln zwischen Chip und Leiterplatte zu schmelzen. VCSEL-basierte Heizsysteme bieten im Vergleich zu anderen Lösungen größere Heizflächen mit höheren Leistungsoptionen.

Halbleiterproduktion: Laser Assisted Soldering (LAS)

Beim Laser Assisted Soldering (LAS) werden die Lötkugeln mittels VCSEL-Infrarot-Wärmebehandlung direkt mit den Lötpads auf der Leiterplatte verbunden. Dies ist besonders interessant, wenn kleinere Lötkugeln und Pitches zum Einsatz kommen. Die VCSEL-Heizsystemtechnologie bietet eine hochpräzise Erwärmung und höchste Qualität der Lötstellen. Der LAS Prozess trägt auch dazu bei, die Lebensdauer von Leiterplatten zu erhöhen.

Additive Fertigung mit Kunststoffen

Beim sogenannten selektiven Lasersintern (SLS) schmilzt ein fokussierter Laserstrahl Kunststoffpulver lokal auf und generiert so das Bauteil. Dies wird ermöglicht durch ein hochinnovatives TruHeat VCSEL System von TRUMPF, das über 3.000 individuell ansteuerbare Laser (VCSEL-Arrays) enthält. Die Produktionsgeschwindigkeit wird damit um etwa einen Faktor 10 gesteigert, im Vergleich zu konventionellen 3D-Druckmaschinen, bei denen ein oder zwei Laser das Baufeld scannen. Vor allem Anwendungen im Kunststoff-Spritzguss können mit dieser Technologie hoch produktiv umgesetzt werden.

Additive Fertigung mit Metallen (Vorheizung)

Bei 3D-gedruckten volumenstarken Bauteilen aus Metall, wirken sich thermische Gradienten oft negativ auf die gesinterten Teile aus. Spannungen können durch VCSEL basierte Laserwärme von oben minimiert werden. Denn die Laserwärme reduziert thermische Spannungen und Verzug am gedruckten Teil erheblich. Dies sorgt für verbesserte mechanische Eigenschaften des Bauteils.

Schnelles Fügen großer Kunststoffteile in der Möbelplattenfertigung

Profitieren Sie von einem zügigen Schweißen großer Kunststoffteile dank der hohen Leistungsdichte in der homogen bestrahlten Heizzone. Die Integration gestaltet sich aufgrund der geringen Abmessungen des Moduls sehr einfach.

Photovoltaik: Laser-Powered Co-Firing Process, ultrafast Regeneration und Light Soaking Prozess

Die TruHeat VCSEL Systeme bringen in der Solarzellenproduktion zahlreiche Vorteile. Beispielsweise bei dem Prozess des gezielten Einbrennens der Kontakte auf der Solarzelle. Daneben auch in Regenerationsprozessen: durch die intensive Bestrahlung der Zelle, werden Defekte vermindert, Energiebarrieren abgebaut und damit die Effizienz gesteigert.

|

TruHeat VCSEL 3010 (2.4 kW)

Produkt vergleichen

|

TruHeat VCSEL 3010 (9.6 kW)

Produkt vergleichen

|

TruHeat VCSEL 3010 (19.2 kW)

Produkt vergleichen

|

TruHeat VCSEL 3015

Produkt vergleichen

|

TruHeat VCSEL 3012

Produkt vergleichen

|

|

|---|---|---|---|---|---|

| Laserparameter | |||||

| Wellenlänge | 980 nm | 980 nm | 980 nm | 980 nm | 980 nm |

| Laser Leistung | 2,4 kW | 9,6 kW | 19,2 kW | 6,4 kW | 6 kW |

| Abstrahlwinkel | typisch 10° (bei 95 % Leistung) | typisch 10° (bei 95 % Leistung) | typisch 10° (bei 95 % Leistung) | typisch 10° (bei 95 % Leistung) | typisch 10° (bei 95 % Leistung) |

| Anzahl an Zonen | 12 Stück | 48 Stück | 96 Stück | 96 Stück | 30 Stück |

| Emissionsbereich | 40 x 52 mm2 | 40 x 208 mm2 | 417.5 x 38 mm2 | 199.1 x 38 mm2 | 521.6 x 25.3 mm2 |

| Leistungsdichte | typisch 115 W/cm2 | typisch 115 W/cm2 | typisch 115 W/cm2 | typisch 115 W/cm2 | typisch 115 W/cm2 |

| Laser Klasse | 4 | 4 | 4 | 4 | 4 |

| Optik | |||||

| Optisches Element | optional mit Fokussier- oder Streuoptik | optional mit Fokussier- oder Streuoptik | optional mit Fokussier- oder Streuoptik | optional mit Fokussier- oder Streuoptik | optional mit Fokussier- oder Streuoptik |

| Schutzglas |

Doppelte Schutzscheibe, antireflexbeschichtet |

Doppelte Schutzscheibe, antireflexbeschichtet |

Doppelte Schutzscheibe, antireflexbeschichtet |

Doppelte Schutzscheibe, antireflexbeschichtet |

Doppelte Schutzscheibe, antireflexbeschichtet |

| Größe | |||||

| Abmessung Breite | 87 mm | 87 mm | 112,7 mm | 93 mm | 133,5 mm |

| Abmessung Höhe | 48 mm | 48 mm | 113 mm | 100 mm | 87 mm |

| Abmessung Tiefe | 108 mm | 264 mm | 563 mm | 319 mm | 652 mm |

| Treibereinheit | |||||

| Anzahl Treibereinheiten | 1 Stück | 4 Stück | 1 Stück | 1 Stück | 1 Stück |

| Lasersteuerung | typisch 10 ms Zeitkonstante; individuelle Steuerung der Laseremissionszonen; integrierte Laserüberwachung | typisch 10 ms Zeitkonstante; individuelle Steuerung der Laseremissionszonen; integrierte Laserüberwachung | typisch 10 ms Zeitkonstante; individuelle Steuerung der Laseremissionszonen; integrierte Laserüberwachung | typisch 10 ms Zeitkonstante; individuelle Steuerung der Laseremissionszonen; integrierte Laserüberwachung | typisch 10 ms Zeitkonstante; individuelle Steuerung der Laseremissionszonen; integrierte Laserüberwachung |

| Maschinen-Schnittstelle | Ethernet-basiert (EtherCAT® Protokoll) | Ethernet-basiert (EtherCAT® Protokoll) | Ethernet-basiert (EtherCAT® Protokoll) | Ethernet-basiert (EtherCAT® Protokoll) | Ethernet-basiert (EtherCAT® Protokoll) |

| Stromversorgung | 3 Phasen400 V (±10%), 47-63 Hz | 3 Phasen 400 V (±10 %), 47-63 Hz | 3 Phasen400 V (±10%), 47-63 Hz | 3 Phasen400 V (±10%), 47-63 Hz | 3 Phasen400 V (±10%), 47-63 Hz |

| Installation | |||||

| Umgebungstemperatur | 5 - 40 °C | 5 - 40 °C | 5 - 40 °C | 5 - 40 °C | 5 - 40 °C |

| Luftfeuchtigkeit (max) | nicht kondensierend für Kühlwassertemperatur von 20 °C | nicht kondensierend für Kühlwassertemperatur von 20 °C | nicht kondensierend für Kühlwassertemperatur von 20 °C | nicht kondensierend für Kühlwassertemperatur von 20 °C | nicht kondensierend für Kühlwassertemperatur von 20 °C |

| Kühlgerät | Kühleinheit mit Waser/Wasser oder Wasser/Luft Wärmetauscher notwendig | Kühleinheit mit Waser/Wasser oder Wasser/Luft Wärmetauscher notwendig | Kühleinheit mit Waser/Wasser oder Wasser/Luft Wärmetauscher notwendig | Kühleinheit mit Waser/Wasser oder Wasser/Luft Wärmetauscher notwendig | Kühleinheit mit Waser/Wasser oder Wasser/Luft Wärmetauscher notwendig |

|

TruHeat VCSEL 3010 (2.4 kW)

|

TruHeat VCSEL 3010 (9.6 kW)

|

TruHeat VCSEL 3010 (19.2 kW)

|

TruHeat VCSEL 3015

|

TruHeat VCSEL 3012

|

|

|---|---|---|---|---|---|

| Laserparameter | |||||

| Wellenlänge | 980 nm | 980 nm | 980 nm | 980 nm | 980 nm |

| Laser Leistung | 2,4 kW | 9,6 kW | 19,2 kW | 6,4 kW | 6 kW |

| Abstrahlwinkel | typisch 10° (bei 95 % Leistung) | typisch 10° (bei 95 % Leistung) | typisch 10° (bei 95 % Leistung) | typisch 10° (bei 95 % Leistung) | typisch 10° (bei 95 % Leistung) |

| Anzahl an Zonen | 12 Stück | 48 Stück | 96 Stück | 96 Stück | 30 Stück |

| Emissionsbereich | 40 x 52 mm2 | 40 x 208 mm2 | 417.5 x 38 mm2 | 199.1 x 38 mm2 | 521.6 x 25.3 mm2 |

| Leistungsdichte | typisch 115 W/cm2 | typisch 115 W/cm2 | typisch 115 W/cm2 | typisch 115 W/cm2 | typisch 115 W/cm2 |

| Laser Klasse | 4 | 4 | 4 | 4 | 4 |

| Optik | |||||

| Optisches Element | optional mit Fokussier- oder Streuoptik | optional mit Fokussier- oder Streuoptik | optional mit Fokussier- oder Streuoptik | optional mit Fokussier- oder Streuoptik | optional mit Fokussier- oder Streuoptik |

| Schutzglas |

Doppelte Schutzscheibe, antireflexbeschichtet |

Doppelte Schutzscheibe, antireflexbeschichtet |

Doppelte Schutzscheibe, antireflexbeschichtet |

Doppelte Schutzscheibe, antireflexbeschichtet |

Doppelte Schutzscheibe, antireflexbeschichtet |

| Größe | |||||

| Abmessung Breite | 87 mm | 87 mm | 112,7 mm | 93 mm | 133,5 mm |

| Abmessung Höhe | 48 mm | 48 mm | 113 mm | 100 mm | 87 mm |

| Abmessung Tiefe | 108 mm | 264 mm | 563 mm | 319 mm | 652 mm |

| Treibereinheit | |||||

| Anzahl Treibereinheiten | 1 Stück | 4 Stück | 1 Stück | 1 Stück | 1 Stück |

| Lasersteuerung | typisch 10 ms Zeitkonstante; individuelle Steuerung der Laseremissionszonen; integrierte Laserüberwachung | typisch 10 ms Zeitkonstante; individuelle Steuerung der Laseremissionszonen; integrierte Laserüberwachung | typisch 10 ms Zeitkonstante; individuelle Steuerung der Laseremissionszonen; integrierte Laserüberwachung | typisch 10 ms Zeitkonstante; individuelle Steuerung der Laseremissionszonen; integrierte Laserüberwachung | typisch 10 ms Zeitkonstante; individuelle Steuerung der Laseremissionszonen; integrierte Laserüberwachung |

| Maschinen-Schnittstelle | Ethernet-basiert (EtherCAT® Protokoll) | Ethernet-basiert (EtherCAT® Protokoll) | Ethernet-basiert (EtherCAT® Protokoll) | Ethernet-basiert (EtherCAT® Protokoll) | Ethernet-basiert (EtherCAT® Protokoll) |

| Stromversorgung | 3 Phasen400 V (±10%), 47-63 Hz | 3 Phasen 400 V (±10 %), 47-63 Hz | 3 Phasen400 V (±10%), 47-63 Hz | 3 Phasen400 V (±10%), 47-63 Hz | 3 Phasen400 V (±10%), 47-63 Hz |

| Installation | |||||

| Umgebungstemperatur | 5 - 40 °C | 5 - 40 °C | 5 - 40 °C | 5 - 40 °C | 5 - 40 °C |

| Luftfeuchtigkeit (max) | nicht kondensierend für Kühlwassertemperatur von 20 °C | nicht kondensierend für Kühlwassertemperatur von 20 °C | nicht kondensierend für Kühlwassertemperatur von 20 °C | nicht kondensierend für Kühlwassertemperatur von 20 °C | nicht kondensierend für Kühlwassertemperatur von 20 °C |

| Kühlgerät | Kühleinheit mit Waser/Wasser oder Wasser/Luft Wärmetauscher notwendig | Kühleinheit mit Waser/Wasser oder Wasser/Luft Wärmetauscher notwendig | Kühleinheit mit Waser/Wasser oder Wasser/Luft Wärmetauscher notwendig | Kühleinheit mit Waser/Wasser oder Wasser/Luft Wärmetauscher notwendig | Kühleinheit mit Waser/Wasser oder Wasser/Luft Wärmetauscher notwendig |

Die technischen Daten aller Produktvarianten als Download.

TruHeat VCSEL Serie 3000

Die Standardmodule der TruHeat VCSEL Serie 3000 sind verfügbar in den Varianten 2.4 kW, 4.8 kW, 9.6 kW und 19.2 kW. Die Standardmodule kommen für gerichtete, großflächige Heizanwendungen zum Einsatz. Der jeweilige Anwendungsbereich wird direkt angestrahlt, ohne den zusätzlichen Einsatz einer Optik oder eines Scannersystems.

TruHeat VCSEL 3012

Das TruHeat VCSEL 3012 System verfügt über eine relativ geringe Leistungsdichte, bei einer großen Breite. Daher eignet es sich besonders für das Trocknen von Batteriefolien. Es können mehrere Module hintereinander angeordnet werden, um eine längere Trockenstrecke zu erreichen.

Sonderlösungen

Die VCSEL-Heizsysteme sind flexibel und können an kundenspezifische Anforderungen angepasst werden. Je nach Kundenanwendung wird gemeinsam die richtige Konfiguration des VCSEL-Heizsystems ermittelt.

Das Bild zeigt ein kompaktes Lasermodul mit 32 VCSEL-Arrays und Fokussieroptiken für den Einsatz im 3D-Druck von Kunststoffen oder das Markieren von Verpackungsmaterial. Jedes VCSEL-Array lässt sich dabei individuell ansteuern, mit einer Ausgangsleistung von 2 W.

Steuerungssoftware für TruHeat VCSEL Systeme

Basic Driver Control Software

Die Basisversion der Steuerungssoftware bietet die Funktionalität die Laserkanäle des TruHeat VCSEL Systems manuell zu steuern und die Leistung einzustellen.

Advanced Driver Control Software

Die erweiterte Version der Steuerungssoftware baut auf der Basisversion auf und bietet zusätzliche Funktionalitäten wie die Temperaturregelung oder das Pulsen. Zudem können Zeit- und Leistungsprofile erstellt werden. Damit lässt sich die Leistung des TruHeat VCSEL Systems während der Bearbeitungszeit variieren.

Mit zusätzlichen Linsen kann die Wärmedichte der TruHeat VCSEL Systeme beeinflusst werden. Mit positiven Linsen kann die Leistungsdichte der VCSEL-Heizmodule erhöht werden. Der Einsatz von negativen Linsen verringert die Leistungsdichte der Module.

Um Spritzer und Dämpfe vom Schutzglas des Lasersystems fernzuhalten, kann das Air Knife eingesetzt werden. Es erzeugt einen schützenden Luftstrom vor dem Laser.

Montagewinkel vereinfachen die technische Montage eines TruHeat VCSEL Systems.

Für Anwendungen, bei denen eine geringere Leistungsdichte erforderlich ist, kann ein TruHeat VCSEL System mit weniger dicht gepackten Emittern und einer Defokussierungslinse eingesetzt werden.

Je nach Land sind Abweichungen von diesem Produktsortiment und von diesen Angaben möglich. Änderungen in Technik, Ausstattung, Preis und Zubehörangebot sind vorbehalten. Bitte setzen Sie sich mit Ihrem Ansprechpartner vor Ort in Verbindung, um zu erfahren, ob das Produkt in Ihrem Land verfügbar ist.