VCSEL lasers are used as a tool for surface heating in many industrial processes. As a high-intensity infrared heat source, precisely directed diode laser heat treatment with selective wavelength radiation is both scalable as well asenergy-efficient. VCSEL laser arrays support drying, welding, sealing, soldering, and heating. They also demonstrate many advantages in the additive manufacturing of plastic, alloy and steel components. The narrow-band radiation is also suitable for plastic welding or laser melting of surfaces. In principle, they are designed to be optimal for all processes in which precise surface and temperature control is crucial. In addition, VCSEL heating systems use IR cameras or pyrometers to support temperature measurement during heat treatment. Laser heat treatment modules are very well-suited for flexible large-area heating applications requiring high precision. Compared to conventional heating methods, users benefit from significantly more flexibility, precision and cost savings.

Laser heat treatment with VCSEL

VCSEL lasers are used for the heat treatment of various surfaces and raw materials. They optimize processes such as drying, welding, sealing, soldering or heating.

VCSEL laser heat treatment for drying, welding, sealing, and heating

How does heat treatment with VCSEL lasers work?

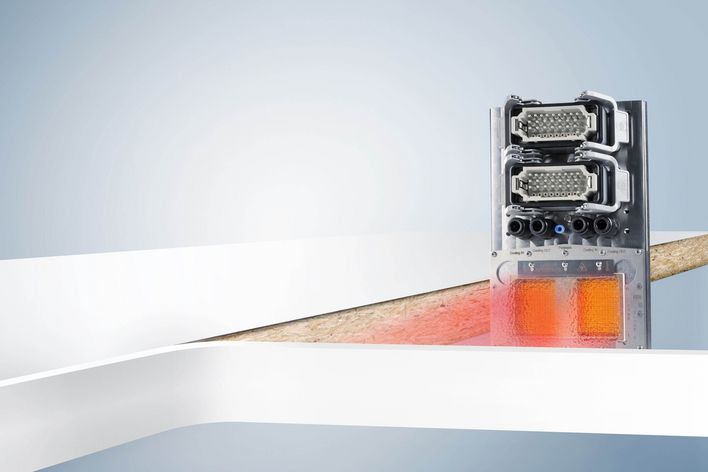

Thousands of micro-lasers (VCSEL) are installed on a single chip. 56 of these chips are attached to each emitter and multiple emitters are assembled on a module. The rectangular radiation area can contain millions of micro-lasers and emit several kW of infrared laser power. VCSEL modules generate near-infrared radiation with 100 W/cm² of irradiance in a directed and large-area rectangular beam cross-section. In this way, precise, local heat treatment can be achieved without additional, expensive laser optics or scanner systems.

What is the benefit of local laser heat treatment in industrial production processes?

Advantages of diode lasers (VCSEL) for industrial heat treatment

VCSEL laser technology offers many advantages over conventional technologies such as heating with reflow ovens and hot bars, hot stamping or lasers with zoom optics.

Selectable wavelengths and local emission zones enable precise configuration of the intensity and area, as well as excellent process results.

Align the module size according to your needs: change the number of mounted emitters or customize the housing.

At 100 W/cm², the irradiance of the VCSEL heating system is significantly higher than the power of infrared or halogen lamps.

Adjust the heat density and laser radiation to individual production needs by selecting the number of VCSEL emitters or adding lens functions.

TRUMPF offers user support for customers worldwide.

Where are VCSEL lasers used for heat treatment?

Many production and industrial processes benefit from heating by VCSEL laser arrays. This includes the welding, soldering, sealing and softening of plastic, alloy and steel components in production and assembly lines.

VCSEL heating systems join or connect raw materials together, weld plastics and process multi-material layers for strip installation. The result: excellent strength and low distortion.

The heat generated by VCSEL heating systems creates a tight connection between different surfaces.

Laser heat treatment of wet coating materials effectively speeds up drying processes.

For example, heat treatment with VCSEL lasers softens materials or increases throughput.

VCSEL systems provide localized heat to the areas to be soldered and limit the soldering time. This results in higher quality and higher throughput.

VCSEL heat treatment reduces thermal stresses in 3D printing of metal components. A VCSEL system can also melt plastics and thus create a 3D-printed component.

Welding

VCSEL heating systems can be used for many applications. This includes welding plastic parts, joining the edges of furniture panels, or heating adhesive tape for the production of composite materials.

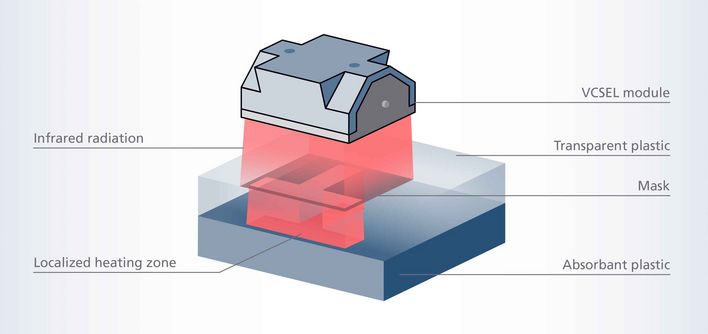

Plastics can be welded with the use of laser irradiation. In this process, two thermoplastics are joined using a laser beam. This penetrates the transparent surface layer of the component and heats the radiation-absorbing part underneath. The absorbent plastic base material melts and thereby fuses the transparent joining area. VCSEL heating systems can simultaneously weld and heat the application area of the workpiece in a single pass.

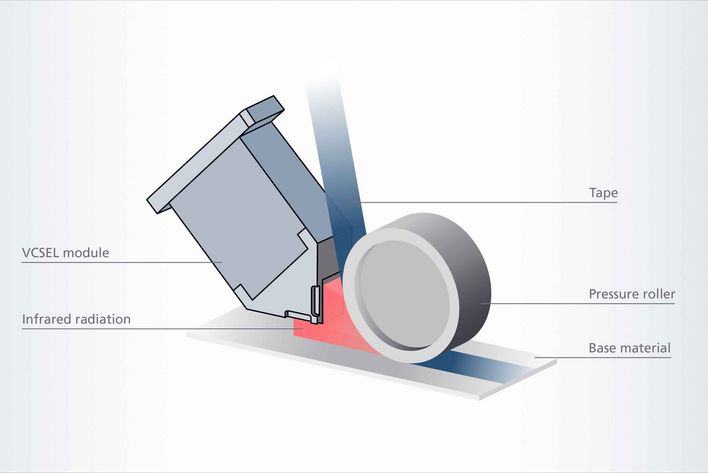

VCSEL systems offer customized high-performance laser solutions for fiber placement and tape-laying processes. Thanks to VCSEL laser heat treatment, composites can be produced in a more scalable and flexible manner.

VCSEL arrays are suitable for the industrial manufacture of furniture panels. You achieve seamless edge and surface welds and thus excellent product results. A compact and reliable VCSEL heat treatment source delivers targeted and precisely controllable infrared laser power; it particularly excels in high-throughput production applications.

Sealing

The VCSEL technology enables very precise, high-speed seals. This can significantly improve the efficiency of battery production, for example.

VCSEL systems can triple the speed of sealing pouch cells. They do this by applying heat for welding inside the pouch film, near the welding area. Heat treatment also provides a very precise seal. This extends the service life of the battery cells since it prevents the formation of wrinkles in the film. This process increases the quality and homogeneity of the pouch cells.

Drying

VCSEL heating systems are versatile in applications with variable scale, e.g. the drying of battery foils.

After coating, battery foils are dried to remove any solvents from their active materials. Industrial VCSEL systems are optimally suited for large-scale heat treatment processes such as the drying of foils. In particular, heat treatment with VCSEL laser arrays is very flexible in terms of both scalability and power irradiance. Large surface areas can be heated with highly precise, local control of wavelength-selective infrared heat.

Heating

VCSEL heating systems can be used to precisely treat areas to be heated when processing specific materials such as steel and silicon wafers.

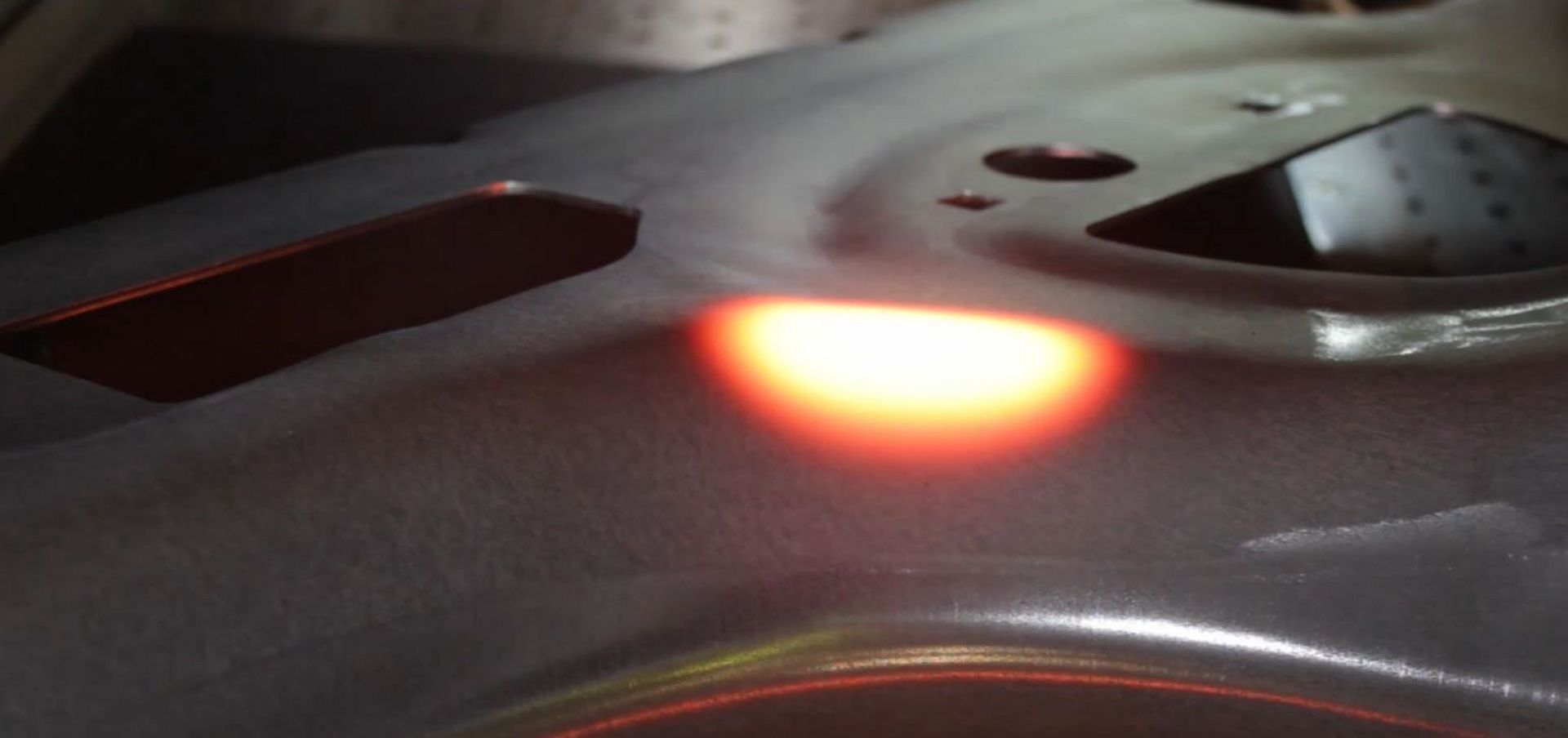

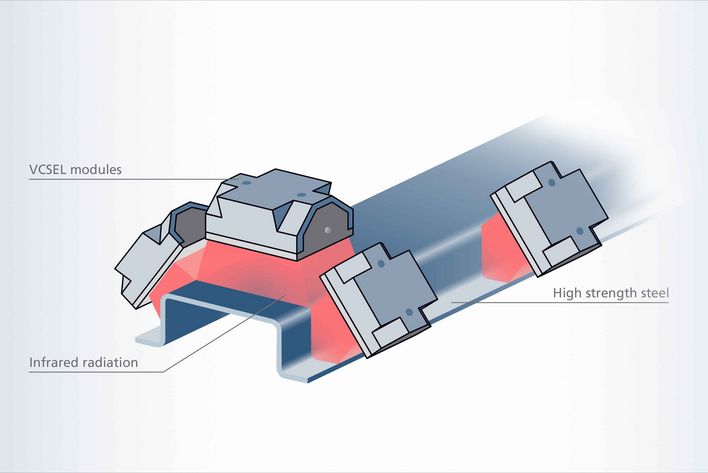

Localized softening of body steel parts in the automotive industry is ideally suited for targeted heat treatment of certain areas. This includes components such as B pillars. VCSEL solutions offer a quick and easy way to selectively soften high-tensile steel parts.

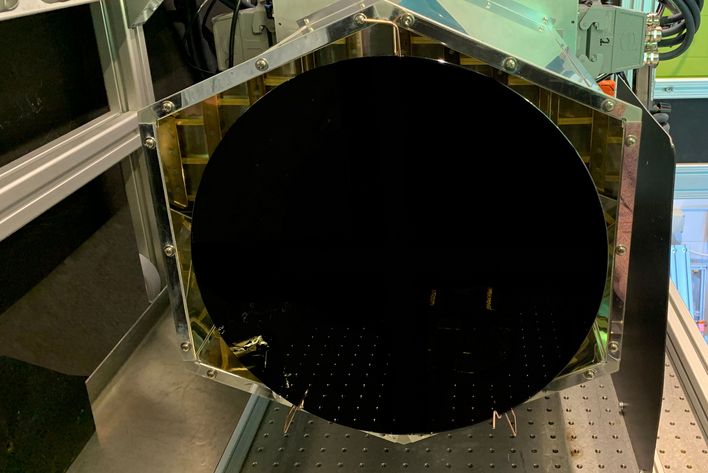

VCSEL arrays enable homogeneous heating of silicon wafers. Due to their highly uniform and rapid heating, they are ideal for rapid thermal processing (RPT) in wafer production. Individual heating zones can be controlled with a high level of precision. Laser heat enables very rapid temperature increases of several hundred degrees Celsius per second. VCSELs increase wafer quality by means of excellent localized control via temperature profiles.

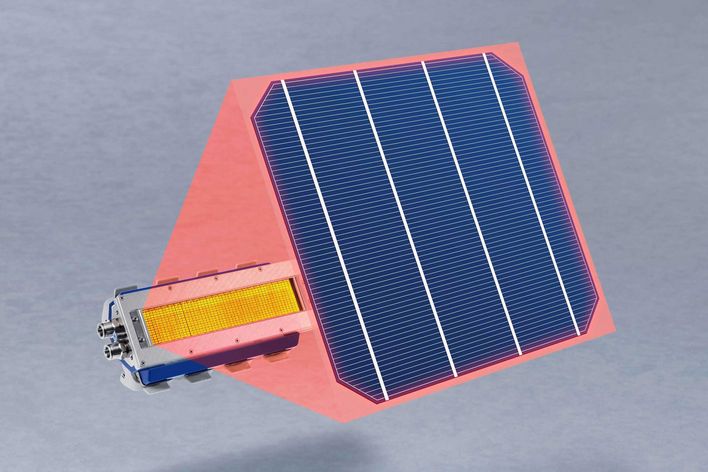

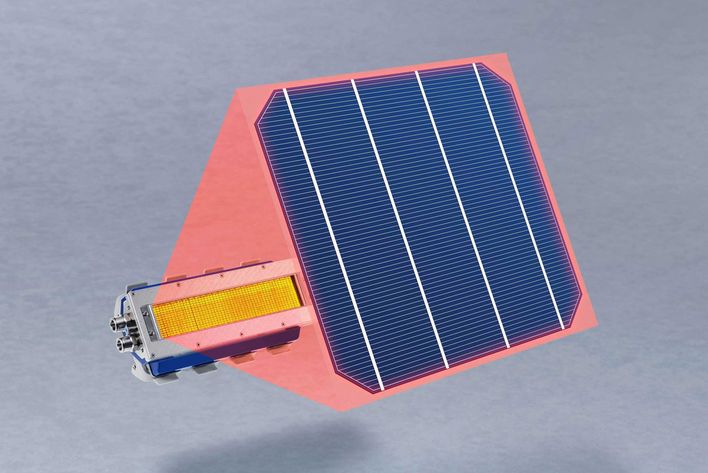

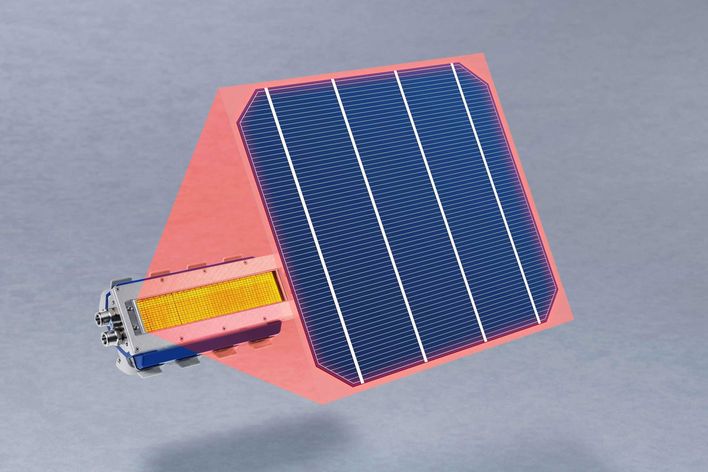

VCSEL laser arrays make the production of solar cells more efficient. The process of burning in the contacts made up of silver particles on the surface of the solar cells is called "firing". Using VCSEL systems for this process offers a number of advantages. During fast firing with laser beams, only the solar cells are heated, while the rest of the furnace area remains largely cool. Laser beams as a heat source increase energy efficiency and cost efficiency. Furthermore, less space is required for the furnace and the service life is extended. These properties of diode laser heating systems can significantly reduce production costs.

VCSEL arrays can increase the efficiency of solar cells. With ultrafast regeneration in a matter of seconds, high-performance VCSEL laser modules for irradiating monocrystalline Si solar cells sustainably prevent reactive boron-oxygen formation. The result: significantly increased cell efficiency. This process is both efficient and highly localized in terms of intensity and target area. Ultrafast cell regeneration significantly increases the efficiency of high-performance solar cells.

With ultrafast light soaking, energy barriers are broken down during production by the intense radiation and high temperatures generated by the VCSEL heating systems. This process reduces the interior resistance of the solar cell, enabling it to work more efficiently. As a result, VCSEL systems can increase the efficiency of solar cells.

Soldering

VCSEL lasers are highly effective at soldering small contact points on circuit boards, delivering higher output power than traditional technologies when needed.

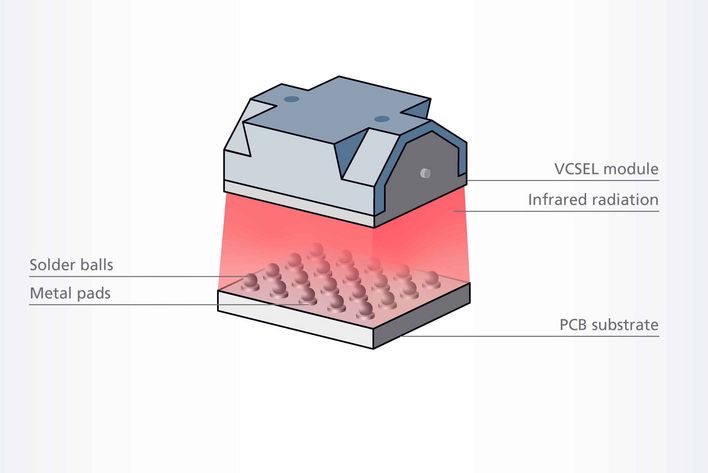

With LAS, solder balls are soldered directly onto printed circuit boards using VCSEL laser infrared heat treatment, which is particularly advantageous for smaller ball and pitch scenarios. With LAS, VCSEL lasers ensure high-precision local heat treatment and the highest quality of the solder joints. As an added benefit, laser heat treatment increases the lifespan of the printed circuit boards.

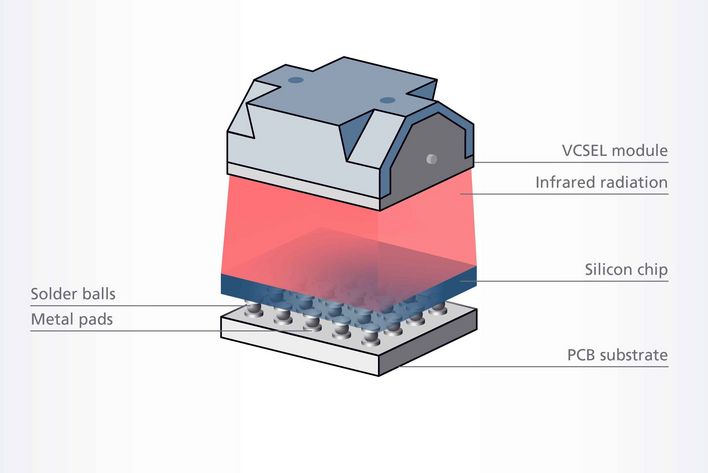

The LAB process uses a flip chip on a printed circuit board and solder balls for connections. The VCSEL system heats the chip from above, and laser energy transmitted through a silicon plate melts the solder balls between the chip and the printed circuit board. This enables heating of larger areas of a complete board with multiple chips – with higher output power than other solutions.

Additive manufacturing

VCSEL arrays offer unique advantages for 3D printing of metals and plastics.

When 3D-printing large-volume metal parts, thermal gradients often adversely affect the sintered parts. With VCSEL-based heating systems, stress can be minimized from above. This is because the heat from the laser significantly reduces thermal stress and distortion on the printed part. This improves the mechanical properties of the component.

Thousands of individually addressable VCSEL lasers with focusing optics can be used as the light source for selective laser sintering (SLS). This provides enormous advantages compared to conventional SLS printers that only work with one or two scanning lasers. With special VCSEL heating systems , a high resolution (250 dpi) can be achieved in combination with an unsurpassed production speed. This is about 10 times faster than the best conventional plastic 3D printers.

VCSEL heating systems for heat treatment in action

Find out more about the diverse applications and technology of laser heat treatment with VCSEL heating systems.

The local heat treatment option allows selected surfaces to be directly treated with irradiation. The emission zones of TruHeat VCSEL systems can be individually controlled with precision.

With VCSEL arrays, the intensity profiles can be individually adjusted for precise control of emission zones and power process parameters.

How are TRUMPF VCSEL heating systems manufactured and how are they used?

Learn more: Download our white paper!

The white paper shows the application results of processing a Ø 300 mm silicon wafer with a special 9.6 kW VCSEL heating system. In addition to the application results, VCSEL heating systems demonstrate advantages for large-area, homogeneous heat treatment in rapid thermal processing (RTP) of Si wafers.

Contact us!

Get in touch with our laser heat treatment experts to explore and solve your specific needs.