Every laser and optical system used in production processes gives rise to thousands of measurements concerning states and events: actual laser output, delay, average pulse energy, cooling water pressure, and so on. In the past, this data often led a useless existence, as it was not systematically evaluated, depriving operators of a golden opportunity to learn from past experience and predict future developments. Car manufacturers wanting to exploit the potential of this data trove joined forces with TRUMPF in a project to design an architecture for the Internet of Things that benefits both partners and supports their business ambitions. The TRUMPF Condition Monitoring system detects problems before they cause damage.

Systematic observation and trend analysis

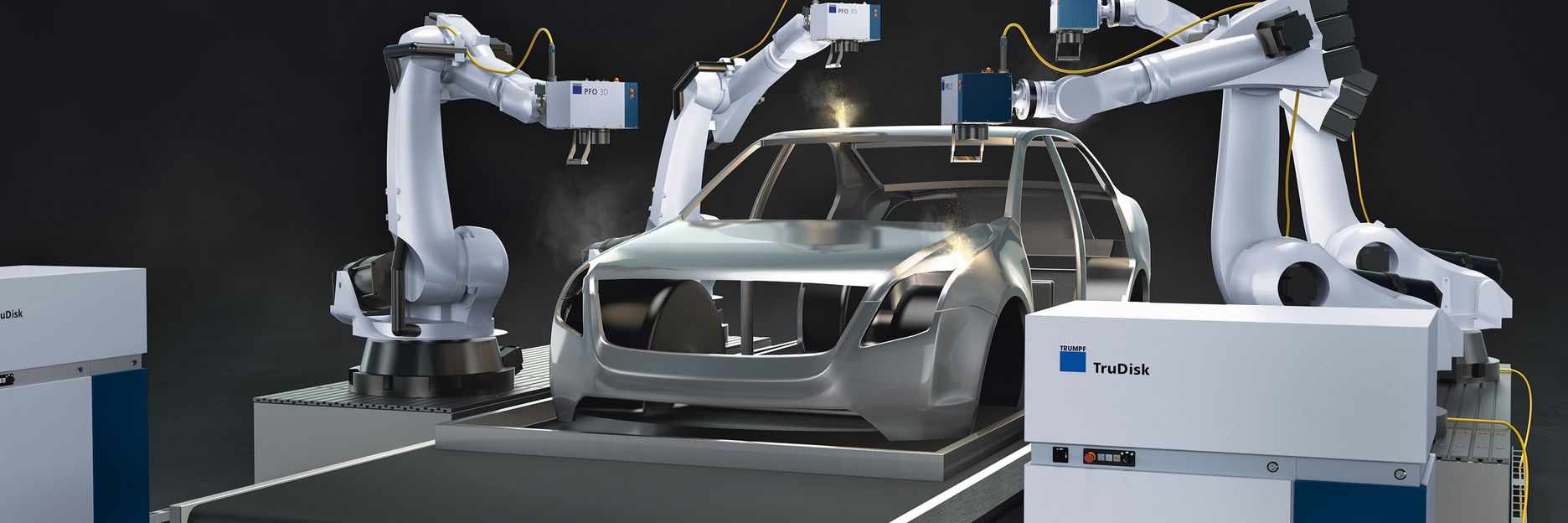

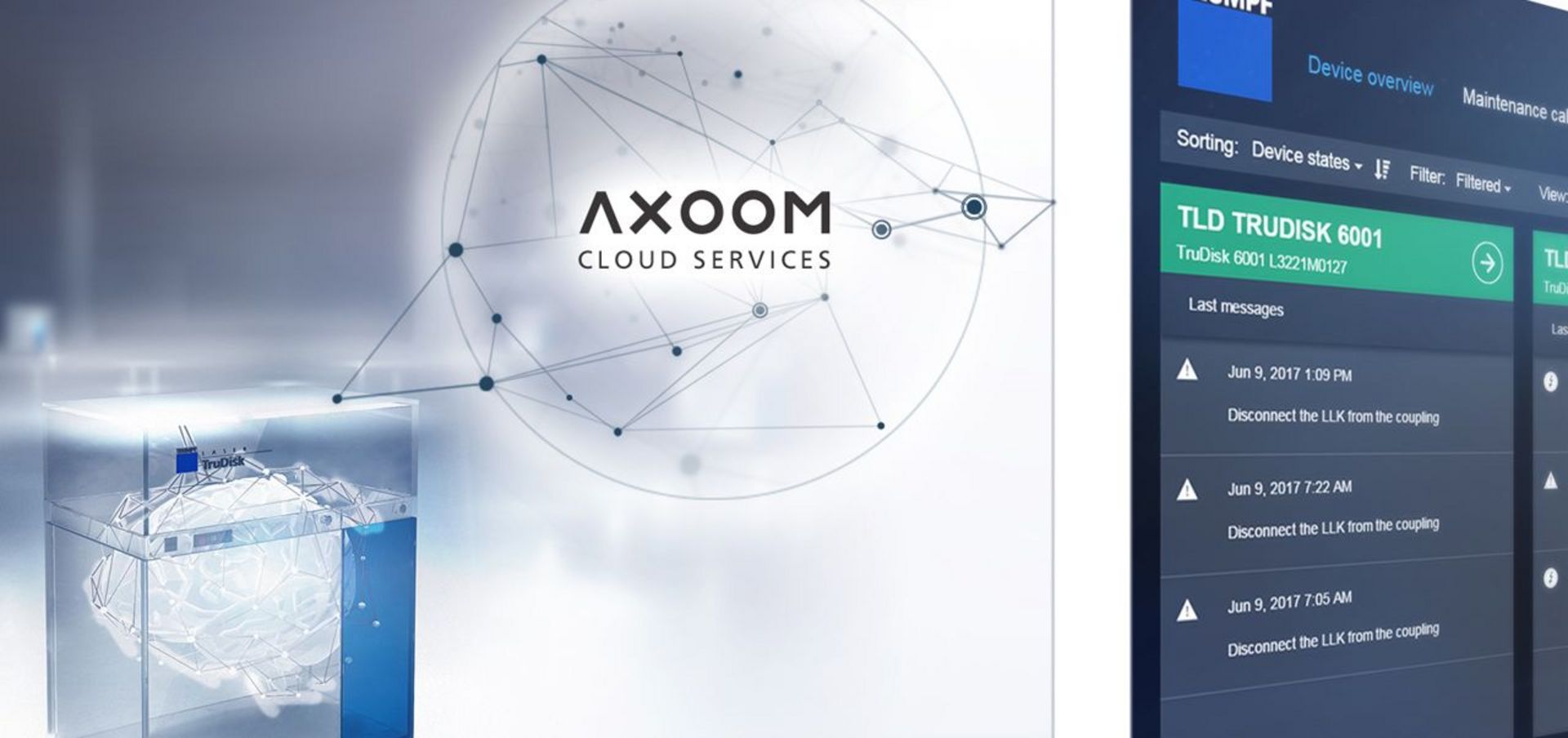

Laser welding is an everyday activity in the Mercedes-Benz plant in Sindelfingen, Germany: groups of robots equipped with I-PFO intelligent scanner optics weld the doors and tailgates of the E-Class vehicles, powered by a network of TruDisk disk lasers. The data derived from the lasers, processing optics and process sensor are sent to other stations on a kind of in-house data highway. Some of the data is uploaded to the AXOOM Cloud via the Internet. Algorithms and real TRUMPF experts then set to work transforming the data into trend analyses. The aim is to avoid failure events and identify ways to improve efficiency.

This has had successful results. For example, the team in Sindelfingen noticed that measured values for laser beam reflection were changing as time went by. It wasn’t immediately possible to determine what had caused this change, but it was obvious that something wasn’t quite right. The TRUMPF service technicians got in touch with the relevant system specialists at Mercedes-Benz, who were able to trace the problem to a focusing angle that had been misadjusted by the self-teaching algorithm. It was immediately corrected, and there have been no further problems.

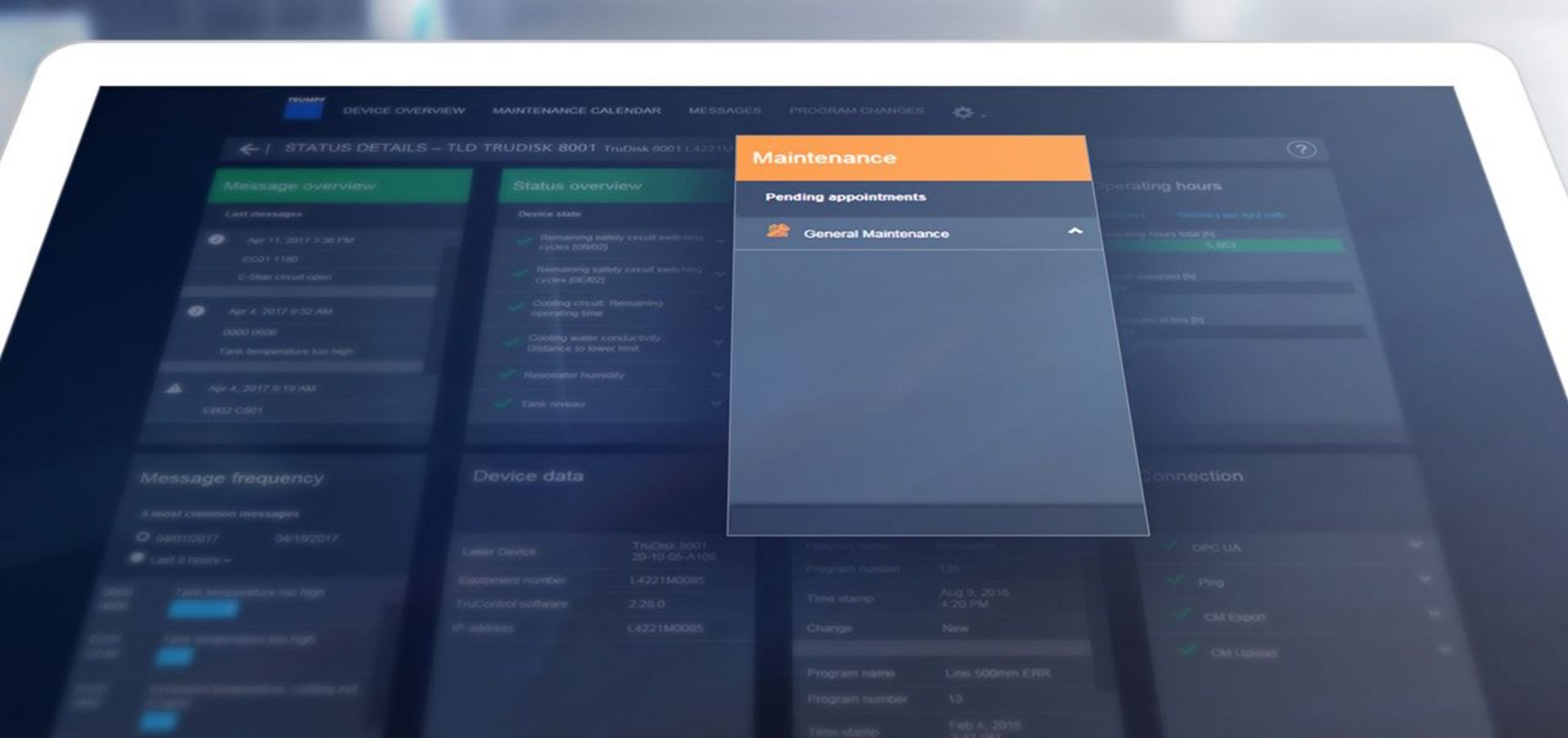

To supplement the expert knowledge of TRUMPF’s employees, Smart View Services have been introduced. These enable Daimler employees to detect and resolve many minor anomalies on their own, thanks to the user-friendly live overviews provided in the central customer portal. Anyone with access to a PC or smartphone can check the status of the plant, at any time and from anywhere in the world. As a result, the availability of the laser welding machines has increased significantly.

Trust and IT-Security

All data forwarded from the laser systems is reported to Daimler using encrypted data connections. Data logistics and secure IT connections to TRUMPF were designed in a joint process based on mutual trust. Both partners expressed their willingness to learn so that they might profit from the benefits of digitalization. TRUMPF received the 2017 Daimler Supplier Award for this outstanding show of collaboration.