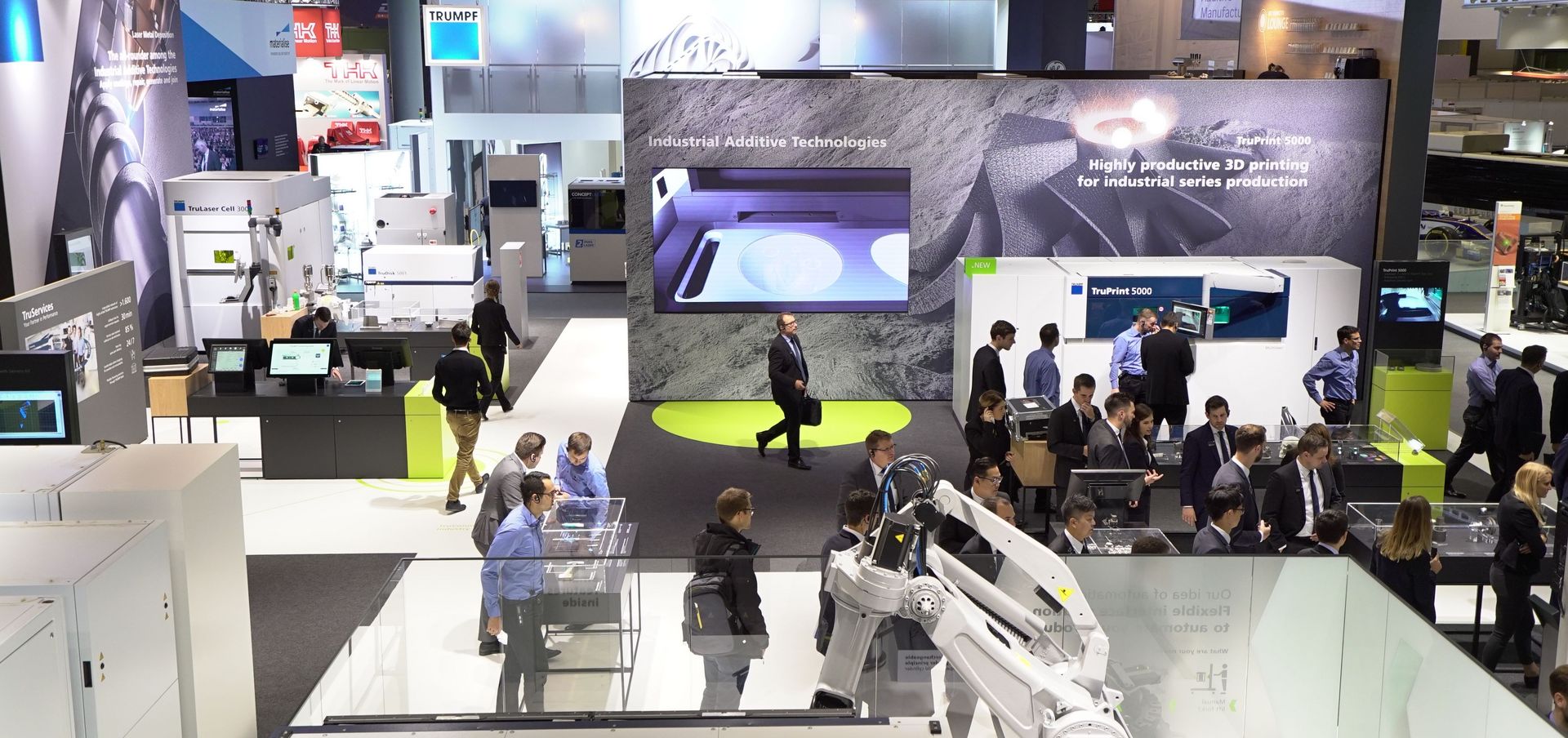

The trade show Formnext enters the third round: Launched in 2015, the trade fair has become the leading trade fair for additive manufacturing in just three years. All large and small manufacturers are on site to present their latest achievements.

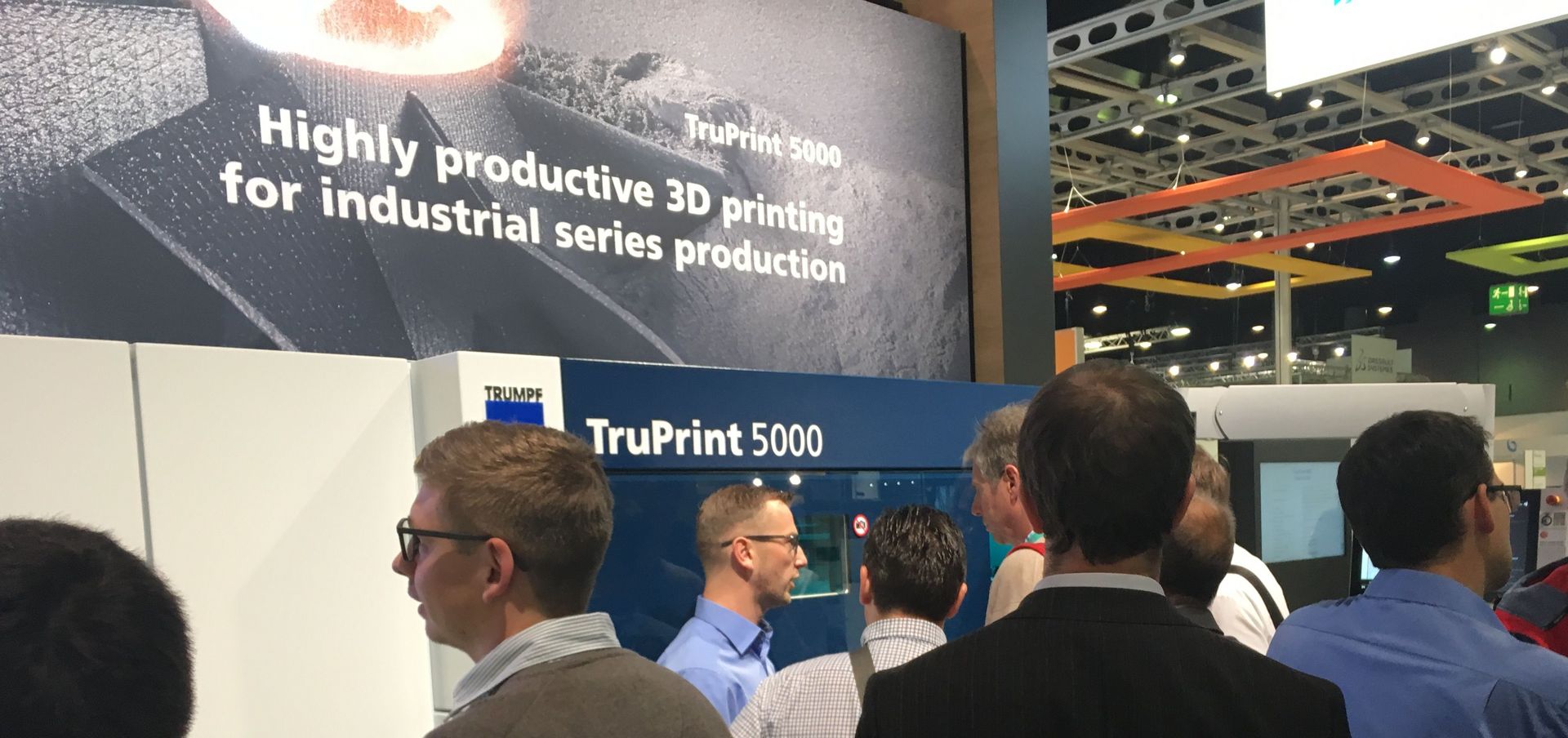

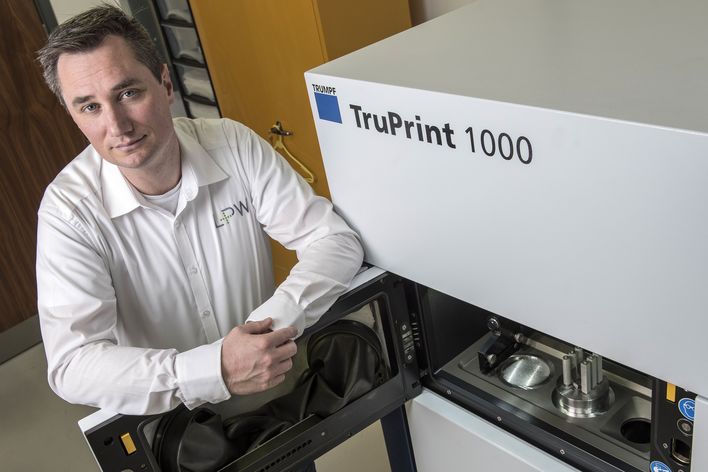

TRUMPF has exhibited its complete product and technology portfolio for additive manufacturing over more than 400 square meters. On board: The TruPrint 5000 - one, if not the fastest, 3D printing system in the world.

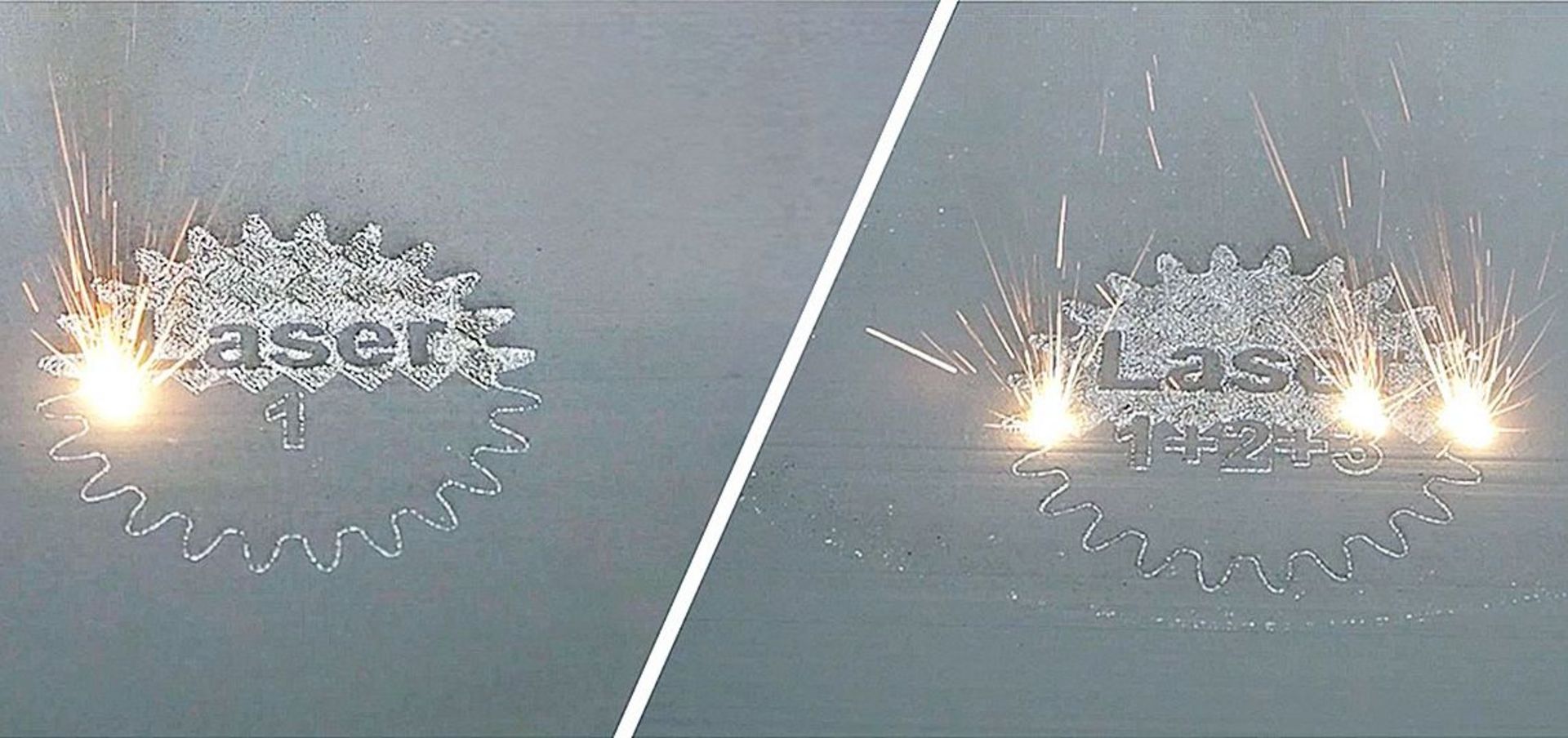

The TruPrint 5000 has not just one but three 500-watt fiber lasers that dance around in the process chamber on the powder bed and generate one or more components. In the professional world, this is called a multi-laser principle.

Not only the number but also the choreography of the three lasers are decisive for the high productivity of the system: they can illuminate every corner of the construction chamber independently of each other and independently of one another, thus producing components much faster and more efficiently. This is not the case with other multilaser concepts.

Add to this the high degree of automation of the system: It starts the production process at the touch of a button, all components calibrate independently - this reduces the effort for the operator and at the same time increases the productivity of the 3D printer.

If all process parameters are set optimally, the TruPrint 5000 - compared to 3D printers with one laser - only needs one third of the exposure time per job.

A small downer: The TruPrint 5000 is expected to be launched at the end of 2018.

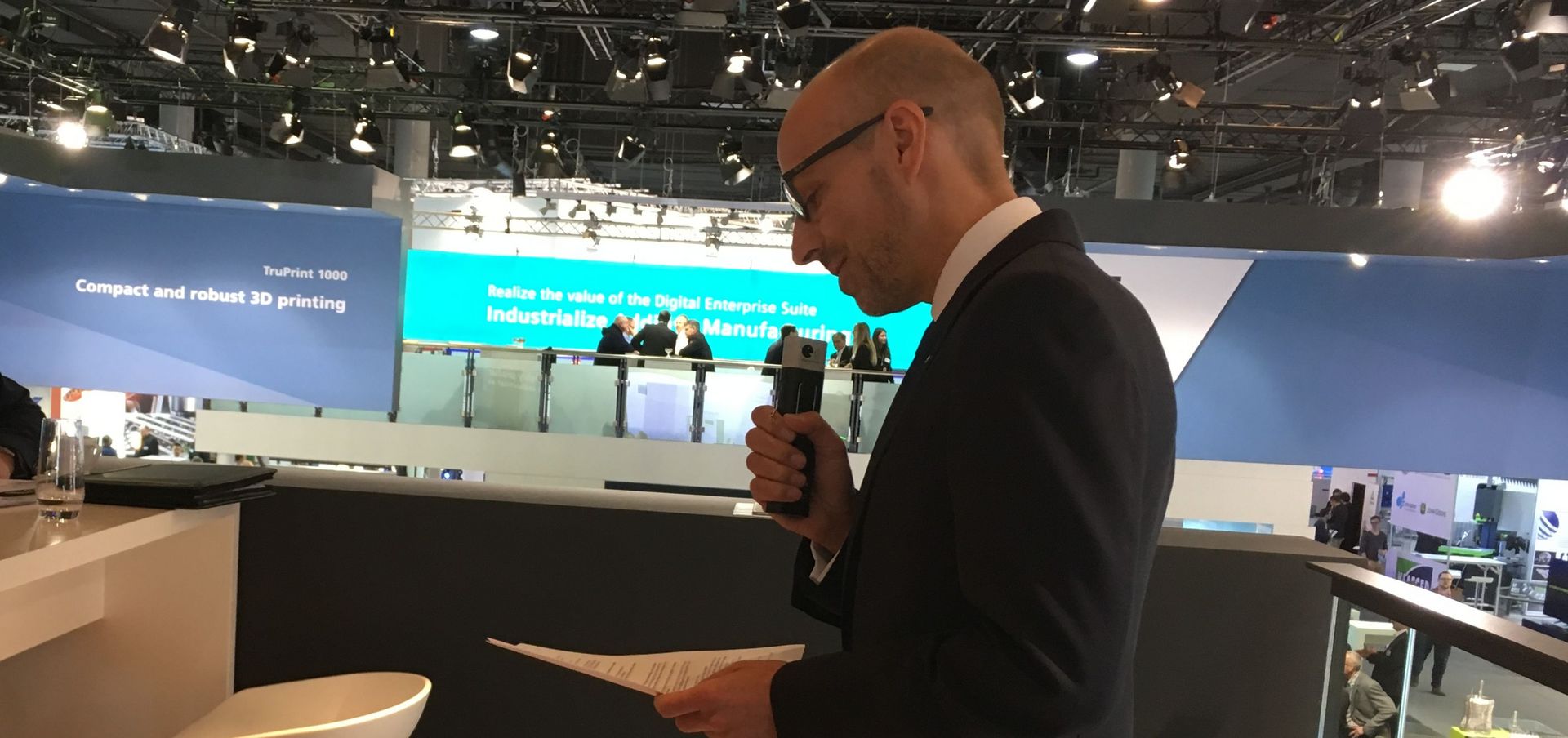

TRUMPF sees sales increase of half a billion euros

At a press conference, Peter Leibinger, CTO of TRUMPF, underlined his company's Additive Manufacturing goals: "If the market for 3D printers continues to develop in line with current indications, then we see an opportunity for our company to achieve additional revenues of half a billion euros in a timescale of five to seven years. We want to gain a leading role in the market and secure a market share of around 20 percent in the medium terms," says Leibinger.