Ten billion is a big number, and it seems even bigger when you put it in context: ten billion transistors on a single computer chip. Back in the early 1960s, microchips only had space for a few dozen transistors, yet just ten years later this figure had already climbed into the thousands. By 2011, the number of transistors per chip had rocketed to almost three billion – and now we’re at ten billion and counting. Yet we still need many more – twice as many in fact - and within two years at the latest.

That’s because the future is all about connectivity. Autonomous electric vehicles communicating with cities’ parking and energy management systems and processing huge amounts of data from their surroundings in just a fraction of a second; smart glasses offering up real-time information on the person sitting across from us on the train; intelligent machines talking to each other to confirm how to divide up work on a part; and factory floor robots equipped with innovative camera systems that help them see toppling containers and avoid collisions.

These may seem like the stuff of tomorrow’s world, but they’re not as far off as you might think – and they’ll need plenty of computing power. That means the microchips at the heart of our digital world need to get even more powerful. They need to handle even more data in less time while offering ever more functionality and consuming less and less energy. And we can only achieve that by making their circuits even smaller. With this in mind, people often quote the words of Gordon Moore, the co-founder of Intel, one of the world’s leading manufacturers of semiconductor chips.

Moore predicted back in 1965 that the number of transistors in an integrated circuit would double every 12 to 18 months. Ever since then, Moore’s law has essentially shaped the industry’s evolution. Taking Moore’s law as a roadmap, companies have battled to populate every square millimeter of a chip ever more densely, with billions of dollars at stake. But to pack more and more transistors on the semiconductors inside chipsets, we quite simply need to harness ever-shorter wavelengths of light.

Like patterns on a sheet of paper

Every chip starts out in a lithography system. It projects the image of a photomask onto a silicon wafer and exposes the layer of photoresist on the wafer to light. Photolithography follows the fundamental principle of Abbe’s diffraction limit, which defines the minimum distance that must lie between two structures in order to identify them as separate structures. The upshot of this diffraction limit is that a light source cannot image features smaller than its wavelength. In simple terms, it’s a bit like trying to draw patterns on a sheet of paper with a soft pencil: The lines can only be as thin as the tip of the pencil itself.

Nevertheless, engineers have come up with a clever ruse to overcome this physical limitation. Sticking with the example of a pencil, their method lies in replacing the soft pencil with an extremely hard one, enabling them to draw thinner “lines” to create space for more circuits on a wafer. A wafer is a silicon disk with a diameter of 300 millimeters that holds hundreds of microchips, in some cases as many as a thousand. Conventional lithography systems operate at a wavelength of 193 nanometers – equivalent to 193 millionths of a millimeter. By way of comparison, a single human hair is around 30,000 nanometers, or 0.03 millimeters, wide. Using the “hard pencil” can make features even smaller, shrinking them by a factor of ten to a size of around 20 nanometers. That already goes beyond Abbe’s diffraction limit, yet the march of miniaturization continues. It has to continue, but we’ve reached the limits of what is technically feasible, and conventional wafer fabrication methods have run out of steam. So does Moore’s law still have a future?

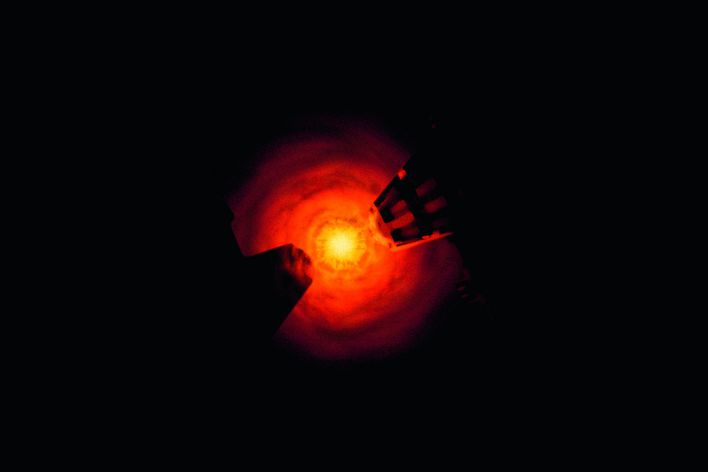

What now? Scientists and researchers have essentially known the answer to that question for the past 20 years. To continue on the same trajectory, we need light with an incredibly small wavelength – 13.5 nanometers to be precise. On that scale, we could reduce feature size to less than ten nanometers, creating enough space to fit over ten billion transistors on a single chip. That’s plenty of computing power to realize our digital ambitions – and the key to achieving it is a specially designed laser from TRUMPF.

Form a research project to a viable manufacturing method

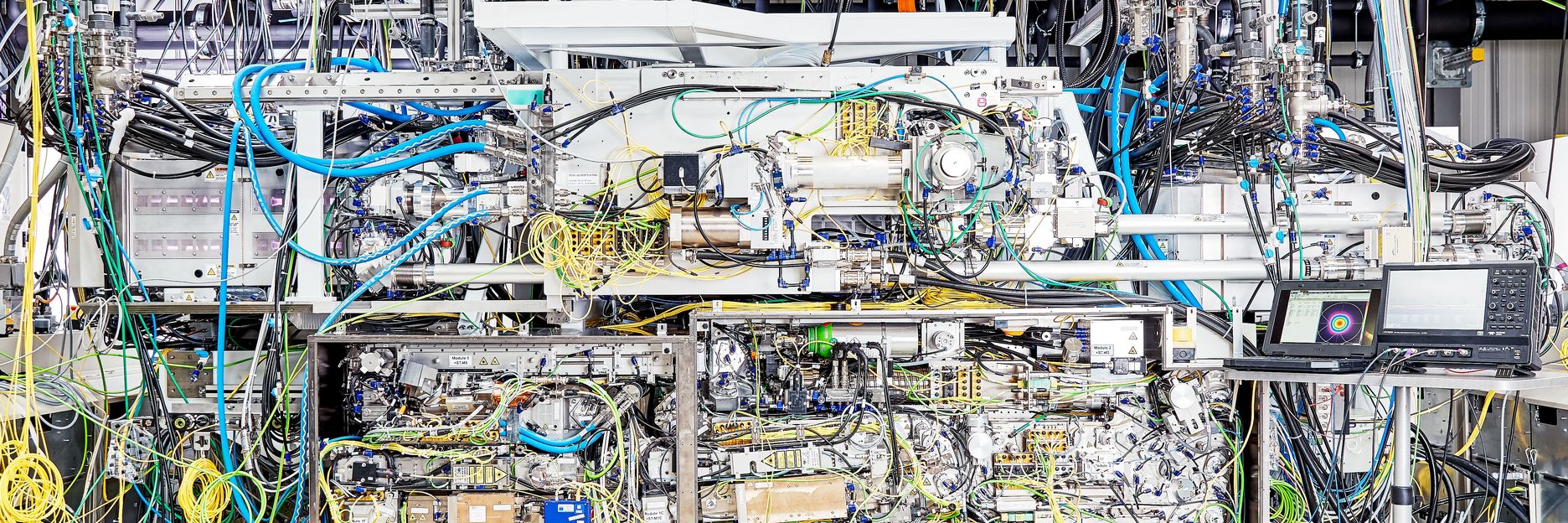

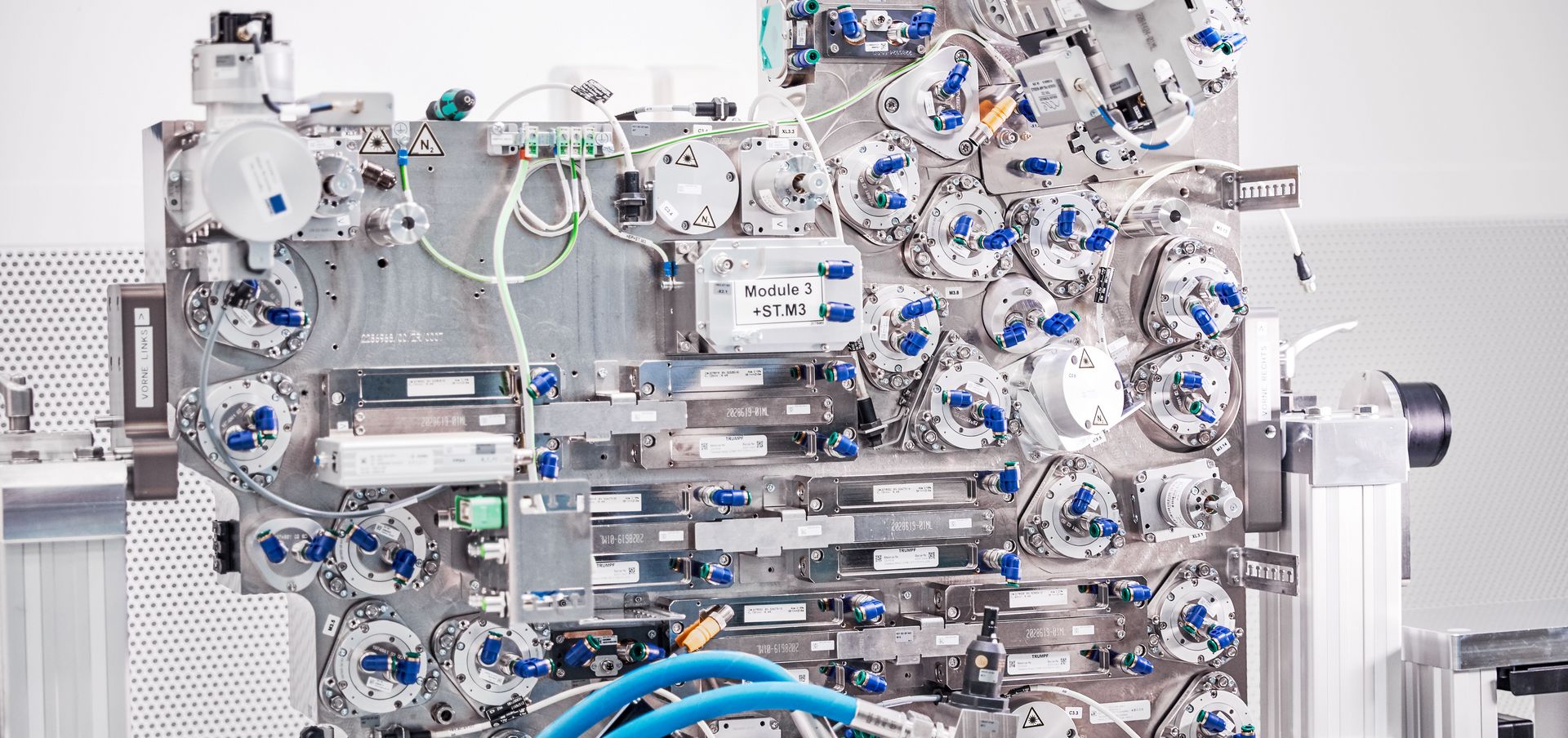

It may seem like a simple number, but obtaining light with a wavelength of 13.5 nanometers is a highly complex business. At 13.5 nanometers we find ourselves firmly in the extreme ultraviolet (EUV) spectrum of light, close to the atomic level. That presents us with some unexpected challenges. To equip lithography systems with EUV light, we need to push the limits of what is technically feasible in multiple areas of technology. Even the smallest faults, deviations or impurities can have a major impact on process performance. In fact, the problems facing EUV lithography developers are so varied and so new that they cannot be solved by a single company working alone without partners. Mastering this highly complex technology and bringing the process to fruition requires an entire network of researchers and developers with different specialized skills.

At the heart of this network are three companies: TRUMPF, ASML – the world’s leading manufacturer of lithography systems – and optics specialist ZEISS. These three partners have spent many years working closely together to make EUV technology industry-ready. What started out as a simple research project has grown into something much bigger: TRUMPF has now established a separate business unit in Ditzingen with over 500 employees specifically dedicated to developing and producing the EUV laser. EUV lithography is here to stay – and it is now regarded as the future of chip fabrication on an industrial scale.

First EUV-exposed chips come off the production line

The key to the technology’s breakthrough has always been its productivity. Throughput of 125 wafers per hour is regarded as the magic break-even point for the chip industry. This was achieved in late 2017 thanks to a newly designed component from TRUMPF that keeps the performance of the overall system stable.

So everything is now on course for the digital future. Over 30 EUV systems are already in use at chip fabs around the world, and more orders are in the pipeline. We have clearly reached the point of no return, with chipmakers moving en masse to EUV lithography. In other words, most of the smartphones that come to market in 2019 will be equipped with EUV-exposed chips. However simplistic it sounds, the fact of the matter is that, without TRUMPF, Moore’s law would have come to an end.