In sheet metal processing, punching refers to a slitting process in which a sheet is cut through in a single stroke. Single strokes, which can occur in extremely rapid succession, create round holes in the sheet, for example. Outer contours can also be created with punching machines.

Punching sheet metal

Punching

Punched shapes are geometrically perfect: a punched hole is absolutely round. A punching machine functions like a hole punch for paper. The punch presses the paper against the hole support and then into a round opening. This cuts out a circular hole. The punched out offcuts are gathered in the punch container. Punching metal works in the exact same way: the sheet lies between the punch and the die. The punch moves down and dips into the die. The edges of the punch and die move past each other in parallel, cutting the sheet. This is why punching belongs to the shear cutting process group.

Perfectly punched metal in four steps

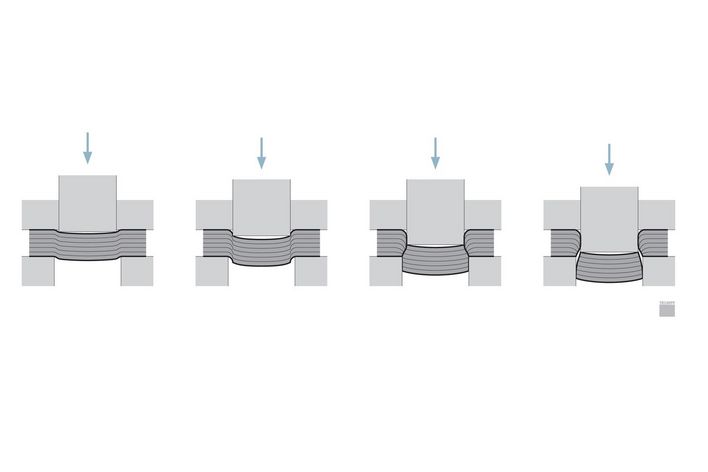

To put it precisely, punching takes place in four phases. When the punch meets the sheet metal, the sheet initially becomes deformed. Then it is cut. Eventually, the tension within the material is so great that the sheet breaks along the cut contour. The punched piece of sheet metal – known as the punching slug – is ejected downward. When the punch moves back up, it may drag the sheet along with it. In this case, the stripper detaches the sheet from the punch. The larger the cutting part on the sheet edge, the better the edge quality. For precision fits, for example, the tool is first prepunched and then punched again with the final diameter using a slightly larger tool. The cut proportion of this kind of edge is then up to 100%.

Even more flexibility: combining punching and laser cutting

Punching is perfect for repeating shapes. For complex geometries where the punching tools must be changed frequently or which do not often occur consecutively, another tool comes into play: the laser. Depending on the application, with a punch laser machine you can use the quick punching tool with a high repetition speed or the slower, yet completely unrestricted in contouring, laser head. Find out how in this film.

Mit geeigneten Stanzwerkzeugen kann eine Stanzmaschine aber nicht nur "lochen", sondern auch kleinere Biegungen und Umformungen im Blech durchführen. Auch das Entgraten, Signieren, Senken, Rollen oder Gewinde formen ist möglich. Mit einer Maschine, die stanzen kann, ist deshalb häufig die komplette Bearbeitung eines Werkstücks möglich – ohne dass weitere Maschinen oder Geräte genutzt werden müssen.

Nibbeln

Beim Nibbeln werden die Stanzlöcher so aneinander gesetzt, dass sie sich überschneiden. Auf diese Weise lassen sich Durchbrüche und Konturen mit beliebigen Formen erzeugen. Genibbelt wird beispielsweise bei größeren Radien oder bei unregelmäßigen Formen. Die Ansatzstellen der einzelnen Hübe bleiben an der genibbelten Kante sichtbar. Fährt man mit dem Finger an der Kante entlang, kann man die Stellen auch ertasten. Je mehr sich die Löcher überlappen, desto glatter wird die Kante. Doch dafür muss die Stanzmaschine auch mehr Hübe entlang einer Nibbelstrecke ausführen.