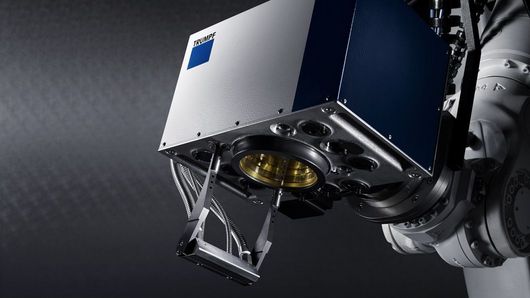

Sensor system

The TRUMPF sensor system monitors the quality of your processes. It supplies you with data continuously and controls the process in accordance with your requirements. The intelligent process sensor system helps you to save money during production by making it quicker to set up processes or enabling the feed rate to be increased during processing. You also avoid production rejects and unnecessary laser-power surpluses. The TRUMPF sensor system is ideal for integration in optics, lasers, and systems – and as TRUMPF is a complete system provider, you can obtain everything from a single source.

Contact

Services