Family-run metal fabricator UEKI Steel Material Company Ltd. will soon be celebrating its 60th anniversary. Located at Kawadamachi Street 804 in the Japanese city of Utsunomiya, the company embarked on a process of reinvention in 2020. “We’ve always worked with a wide variety of customers. Some work in the steel construction and sheet-metal fabrication industries, while others are in the auto and aviation sectors,” says CEO Yuko Ueki. Their customers have all sorts of different requirements when it comes to geometries and materials – but one thing they all have in common is a steadily growing demand for top-notch precision. “This was the backdrop to our reinvention. The question was: how could we use our infrastructure and the expertise of our workforce to expand our product range?” says Ueki.

An impressive tool

The first step toward creating new products came with the purchase of a new laser-cutting machine in 2018. Ueki was determined that it should be easy to use and maintain. “We wanted a machine that offered superior reliability and precision in steel processing, sheet-metal fabrication and tube cutting – and that’s why we opted for the TruLaser 3030 fiber from TRUMPF. It sets the standard in the market,” says Ueki.

Government subsidies reduced the initial costs by providing loan financing to cover not only the cost of the machine, but also new facilities on the company’s premises – and the investment soon paid off. The machine arrived from TRUMPF Japan within six months, and TRUMPF technicians were on hand to help get it up and running. The 35 production workers were immediately impressed by the versatility, accuracy, and sheer power of the laser as a tool.

Intricate ironwork

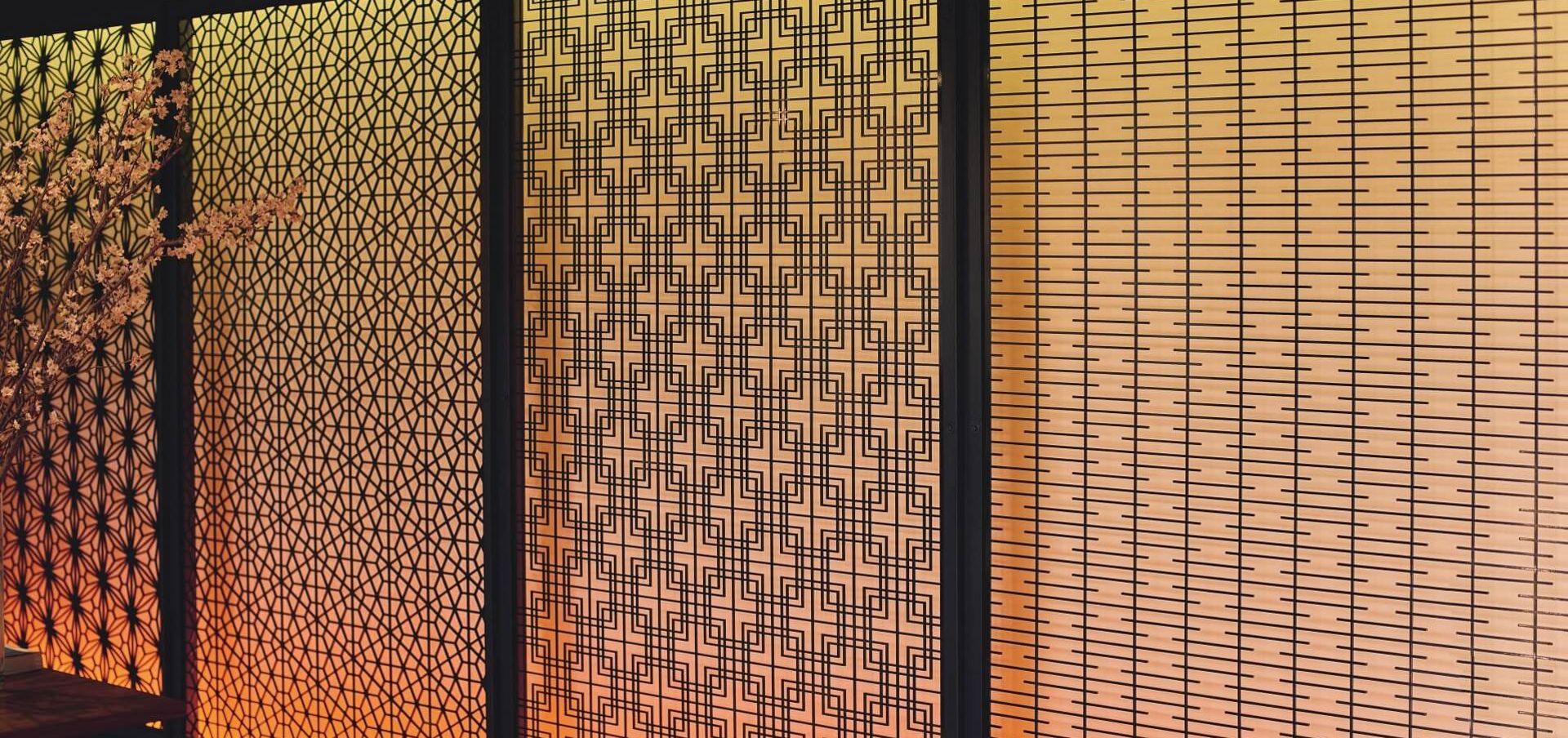

Determined to find an additional line of business, Ueki turned her attention to the traditional Japanese art form of Kanuma Kumiko. The skill of interconnecting delicate pieces of cedar and cypress wood into complex and ornate patterns is over a thousand years old. Its fame has spread far beyond Tochigi Prefecture to make it an integral part of modern Japanese architecture and home design. “One of our inspirations was the chain of Ritz-Carlton hotels in Japan,” says Hideo Nakamura, director of business development at UEKI Steel Material. The interior design of many of the hotels is based on Kumiko elements reinforced with aluminum.

The path toward sustainability

Producing aluminum is an energy-intensive process, however. This wasn’t a good fit with Ueki’s sustainability goals, so the decision was made to use regionally produced Japanese iron instead. The production process requires significantly less energy, and the resulting iron can easily be maintained in good condition and stored for an almost indefinite period. The journey from the initial business idea to the first respectable prototype of a Kumiko component took more than a year. But the superior quality of the results was well worth the wait. “The inspiration of traditional Kanuma Kumiko techniques is clearly visible. And our ability to successfully produce so many different geometries ultimately comes down to the outstanding precision of the TRUMPF laser system. The machine has brought us very close to meeting our goal of absolute symmetry,” says Nakamura.

Papercutting and costume jewelry

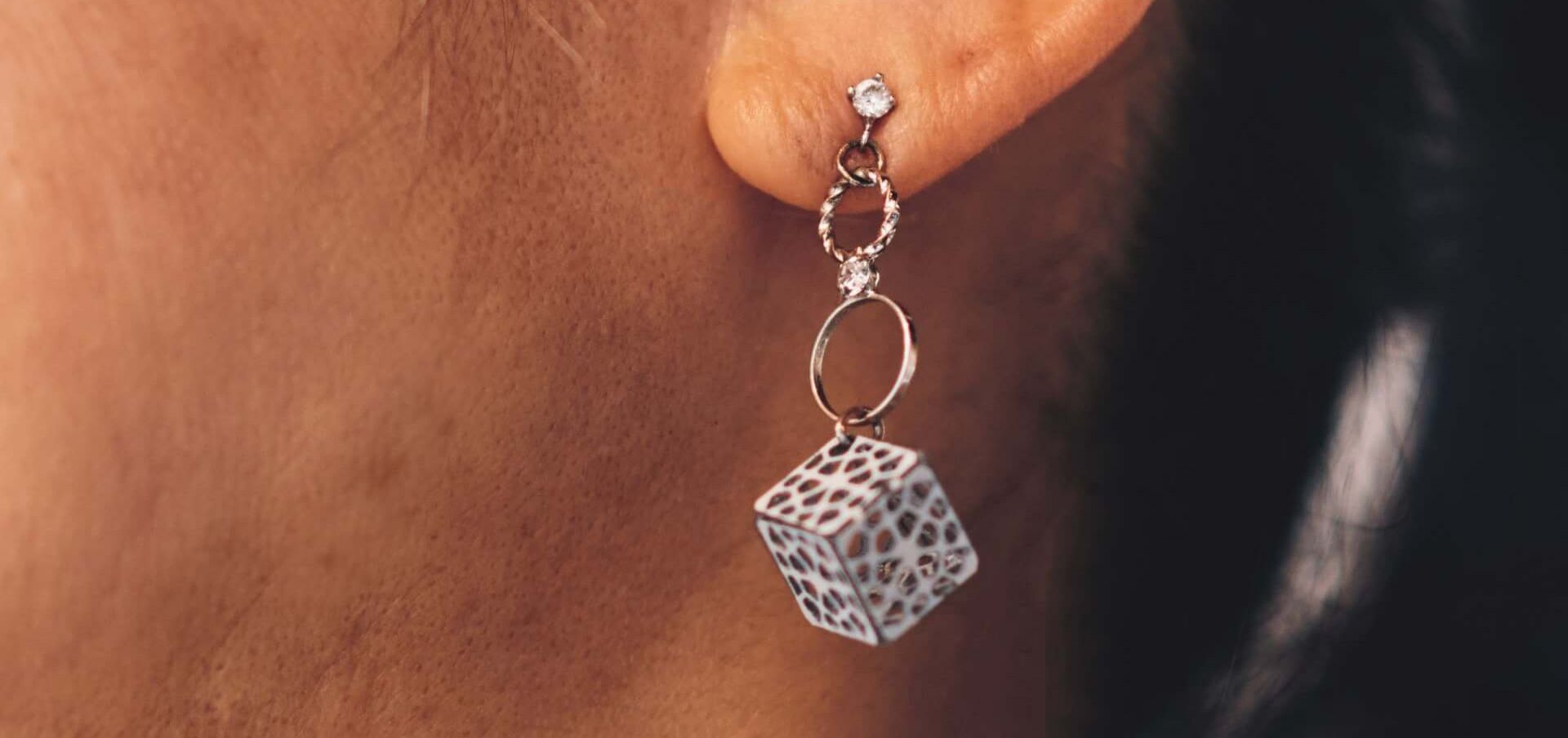

UEKI Steel Material markets its innovative accessories under its very own “maasa” brand. Two of the family-run company’s most successful products are candle stands made from steel plates and decorative light shades made from tubes. Each one is completely unique, and customers are happy to pay a premium price when they know their purchase is genuinely one of a kind. The “maasa“ brand continues to move from strength to strength, and the team constantly finds new inspiration for its unusual interior creations thanks to its collaboration with renowned papercutting artists from the local area. “For example, we used 0.35-millimeter strips of iron to produce a completely innovative design of ornate candle holders,” says Ueki proudly. Their range of products also includes elegant costume jewelry such as necklaces and earrings, all fabricated on the TRUMPF laser-cutting machine.

On a growth path

Currently, UEKI’s maasa products are exclusively available in Japan. But plans are already underway to tap into additional markets, and the company plans to start developing an online store in spring 2023. “We would like to market our products to private customers as well as gain a foothold in the B2B sector and build maasa’s reputation among architects and designers,” says Ueki. Ultimately, she hopes to turn maasa into an international brand and to start selling their one-of-a-kind creations in other countries. The team already has plans to expand their portfolio with elements and motifs of Japanese calligraphy.

“We’re looking at different options to boost our manufacturing capacity. Either we’ll collaborate with a long-standing customer who also uses TRUMPF machinery, or we’ll simply invest in another laser-cutting machine ourselves,” says Ueki. Whatever option they choose, TRUMPF technology looks set to play an important role in the company’s ongoing expansion.