Our best-in-class

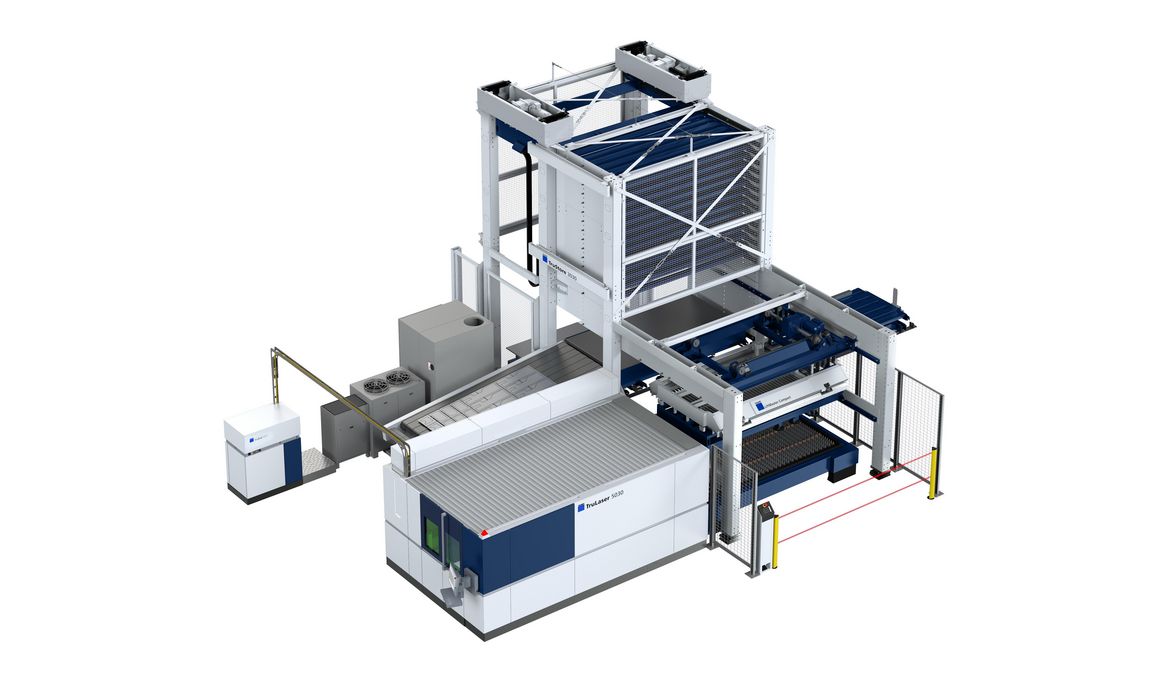

The LiftMaster Compact is the fastest and most compact loading and unloading unit in the TRUMPF portfolio. The dynamic and variable automation solution is particularly attractive for fast sheet processing times, regardless of whether with or without storage connection. It requires little space and saves time and money with its short cycle time of 90 seconds.

Even without supervision, the LiftMaster Compact will run 24/7 without compromising process reliability.

For a complete loading and unloading cycle, including pallet change, the LiftMaster Compact requires just 90 seconds.

With the synchronous loader, the LiftMaster Compact can load and unload workpieces simultaneously.

Expand your LiftMaster Compact into a complete processing cell with a TruStore or PartMaster sorting station.

|

LiftMaster Compact large format

|

LiftMaster Compact max format

|

|

|---|---|---|

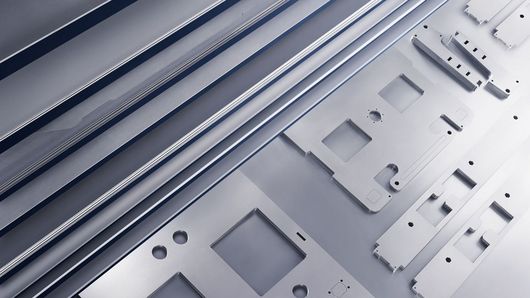

| Loading | ||

| Maximum sheet size | 3000 mm x 1500 mm | 4000 mm x 2000 mm |

| Minimum sheet size | 1000 mm x 1000 mm | 1000 mm x 1000 mm |

| Maximum sheet thickness | 25 mm | 20 mm |

| Maximum sheet weight | 900 kg | 1600 kg |

| Unloading | ||

| Maximum sheet size | 3000 mm x 1500 mm | 4000 mm x 2000 mm |

| Minimum sheet size | 150 mm x 150 mm | 150 mm x 150 mm |

| Maximum sheet thickness | 25 mm | 20 mm |

| Maximum sheet weight | 900 kg | 1260 kg |

The technical data of all product versions as a download.

With the PartMaster you can easily remove finished parts and scrap skeletons manually, without problems.

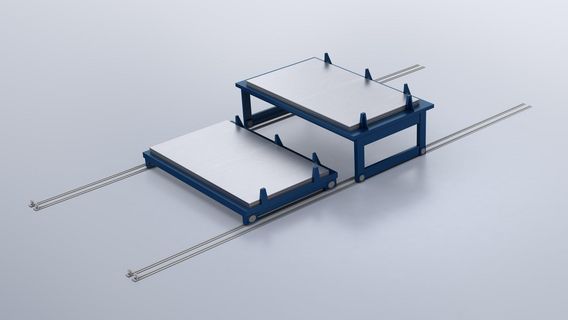

The synchronous loader has a suction frame that transports a finished part pallet, onto which the cut sheets are placed. It traverses horizontally between the unprocessed material table and the pallet changer.

Instead of the standard unprocessed material table you can use loading carts.

TruLaser 5030 fiber with LiftMaster Compact and TruStore 3030

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price, and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.