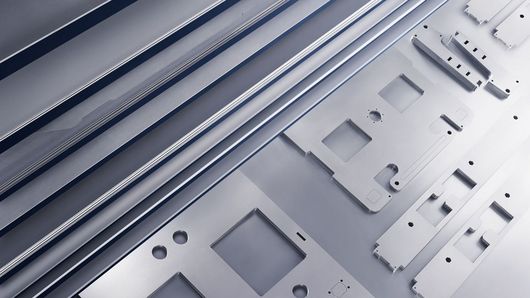

Safe loading for all 2D laser machines

The universal loading unit, LoadMaster, will automatically supply unprocessed sheets to your machine. A suction cup moves the sheets from the loading station to the pallet changer and sets them down there. Finished sheets can be easily unloaded by hand. The LoadMaster stands for process reliability and high productivity at low costs – for all 2D laser machines and with any sheet thickness.

Automatic loading without additional equipment takes the strain off operators and increases occupational safety.

Faster order processing through automated loading with unprocessed material.

As an option, thin unprocessed sheets can also be reliably separated.

|

LoadMaster large format3x1.5

Compare product

|

LoadMaster max format 4x2

Compare product

|

LoadMaster oversize format 6x2

Compare product

|

LoadMaster oversize format 6x2.5

Compare product

|

|

|---|---|---|---|---|

| Loading | ||||

| Maximum sheet size | 3000 mm x 1500 mm | 4000 mm x 2000 mm | 6000 mm x 2000 mm | 6000 mm x 2500 mm |

| Minimum sheet size | 1000 mm x 1000 mm | 1000 mm x 1000 mm | 1000 mm x 1000 mm | 1000 mm x 1000 mm |

| Maximum sheet thickness | 25 mm | 25 mm | 25 mm | 20 mm |

| Maximum sheet weight | 900 kg | 1600 kg | 2400 kg | 2400 kg |

|

LoadMaster large format3x1.5

|

LoadMaster max format 4x2

|

LoadMaster oversize format 6x2

|

LoadMaster oversize format 6x2.5

|

|

|---|---|---|---|---|

| Loading | ||||

| Maximum sheet size | 3000 mm x 1500 mm | 4000 mm x 2000 mm | 6000 mm x 2000 mm | 6000 mm x 2500 mm |

| Minimum sheet size | 1000 mm x 1000 mm | 1000 mm x 1000 mm | 1000 mm x 1000 mm | 1000 mm x 1000 mm |

| Maximum sheet thickness | 25 mm | 25 mm | 25 mm | 20 mm |

| Maximum sheet weight | 900 kg | 1600 kg | 2400 kg | 2400 kg |

The technical data of all product versions as a download.

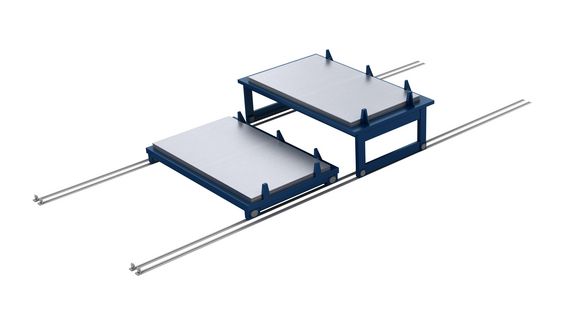

To ensure the fastest possible supply of materials, you can connect your machine to your materials store. In this context, you can expand your LoadMaster with TRUMPF cart systems in accordance with your individual needs. They automatically provide raw sheets where needed.

With the modular design, you can tailor the TruStore Series 1000 to suit your company's needs. As your requirements grow, you can upgrade your system to the TruStore Series 3000 at any time.

The loading station is equipped with fanning magnets for the separation of ferromagnetic unprocessed sheets.

With individual and dual cart systems for loading and unloading, you can integrate the LiftMaster into your materials warehouse.

The LoadMaster loads a TruLaser 3030

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price, and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.