USA, 1964: Chandra Kumar Naranbhai Patel, an electrical engineer and physicist, develops the first CO2 laser with continuous output power in his laboratory. Three years later, the US-based company Coherent Radiation Inc. launches the first laser that can cut metal. Trade journals worldwide praise this new ‘miracle tool’ to the skies.

Laser leaves Leibinger no rest

Ten thousand meters above the Atlantic, Berthold Leibinger checks through his travel documents one last time. It’s February 1978, and he has arranged to visit various laser manufacturers in the US. But this long-haul flight is doing little to recharge his batteries for the days ahead. Far from relaxing, his mind is racing with thoughts about lasers. Ten years earlier, the laser had been little more than a nifty gadget. Its grotesquely huge resonators made it far too awkward and impractical, so it was mostly confined to test laboratories. But now lasers had become smaller, more manageable and sturdy enough to put to good use. Some people in the US were already cutting metal sheets with lasers and talking excitedly about installing lasers in machine tools. Leibinger was determined to see all this with his own eyes. After all, cutting free-form contours in metal sheets was the domain of nibbling machines – and the press had branded him the Nibbler King for good reason! Leibinger fidgeted around in his airplane seat. What if the laser was just as good as a nibbler at cutting metal – or even better? And what if the laser was faster? His mind whirred with all the possible implications.

First encounter with the future

Safe on the ground in Hartford, Connecticut, Leibinger pulls his coat tighter around him. It’s the middle of a bitterly cold winter on the East Coast. Leibinger’s first port of call is United Technologies. There he meets a Mr. Carstens, who waxes lyrical about the wonders of lasers. Leibinger is impatient to see the laser in action. Eventually, Carstens takes a cigar box out of the drawer and empties some samples onto the table. He can’t help smiling, and is barely able to conceal his pride in his new tool. Leibinger can’t take his eyes off the laser-cut samples in front of him. He picks one up and runs his fingers over the contours. The cut edges are rough and have a noticeable burr, and there are bits of weld stuck to the bottom. Carstens talks enthusiastically about how effortlessly and silently the laser works, but Leibinger isn’t really listening; he’s still too busy inspecting the samples. They are nowhere near ready for industrial application and would clearly need significant rework before they could be put to use. Nevertheless, a vision starts to form in Leibinger’s head: what if the cut edges could be made smooth enough? What then?

Leibinger trusts his intuition

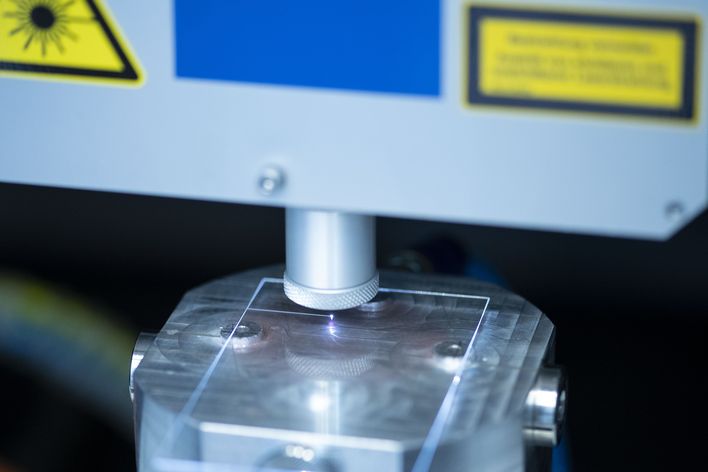

The scene shifts to Carstens’ factory floor. They are standing in front of the laser. A flick of a switch, and an invisible light dances across the metal sheet. A few sparks fly, and the part is cut from the sheet – job done! Leibinger is thinking about his copy nibbler, picturing the mechanical sensor moving along a template and the machine nibbling its way through the metal. He glances at the laser; it is clearly an elegant and innovative solution, even if it needs some perfecting. Leibinger can’t shake off the sudden feeling that his punching press is clunky and antiquated. Meanwhile, the vision in his head continues to take shape.

His visit to United Technologies over, Leibinger flies to California and meets other laser manufacturers. The weather improves as he moves from east to west – and so do the lasers. On the airplane back to Germany, he stares at the samples on the folding tray table in front of him, lost in thought. Gradually his mouth curls into a smile. Leibinger has an intuition – a crystal clear vision – and right there and then he makes a decision: as soon as he gets home, he will be sending an order to the US. It’s time to buy a laser.

The future begins at EMO 1979

Germany, 1979: at the EMO exhibition, rumors have been flying of a new machine tool with a combined processing head, and everyone is eagerly awaiting the live demonstration. The machine operator launches the program and the punching tool kicks off by punching a start hole. Then the laser fires up, dancing across the metal and cutting complex contours in the sheet. The Nibbler King has successfully showcased his first combination punch laser machine! The production of copy nibblers ceased just a few years later, with the laser taking over their role entirely.

This story is based on real events, including Leibinger’s journey to the US in the winter of 1978, his visits to laser manufacturers and the world premiere at the EMO trade fair. The rest is fiction, including our description of Leibinger’s thoughts and feelings.

Berthold Leibinger was a senior figure and partner at TRUMPF who spent his whole life working as an entrepreneur and philanthropist. After studying engineering in Stuttgart and spending two years in the US, he joined TRUMPF in 1961 when the company was still a fledgling machine maker. He fueled the company’s growth with numerous inventions, for which he received remuneration in the form of shares. He thus became a partner in the company in 1966 in addition to his role as CEO. Under his stewardship, TRUMPF evolved into one of the world’s leading machine toolmakers. Leibinger is now regarded as one of the pioneers in the industrial application of lasers. He died on October 16, 2018, aged 87.