Mr. Schüle, what is the problem with producing bevels?

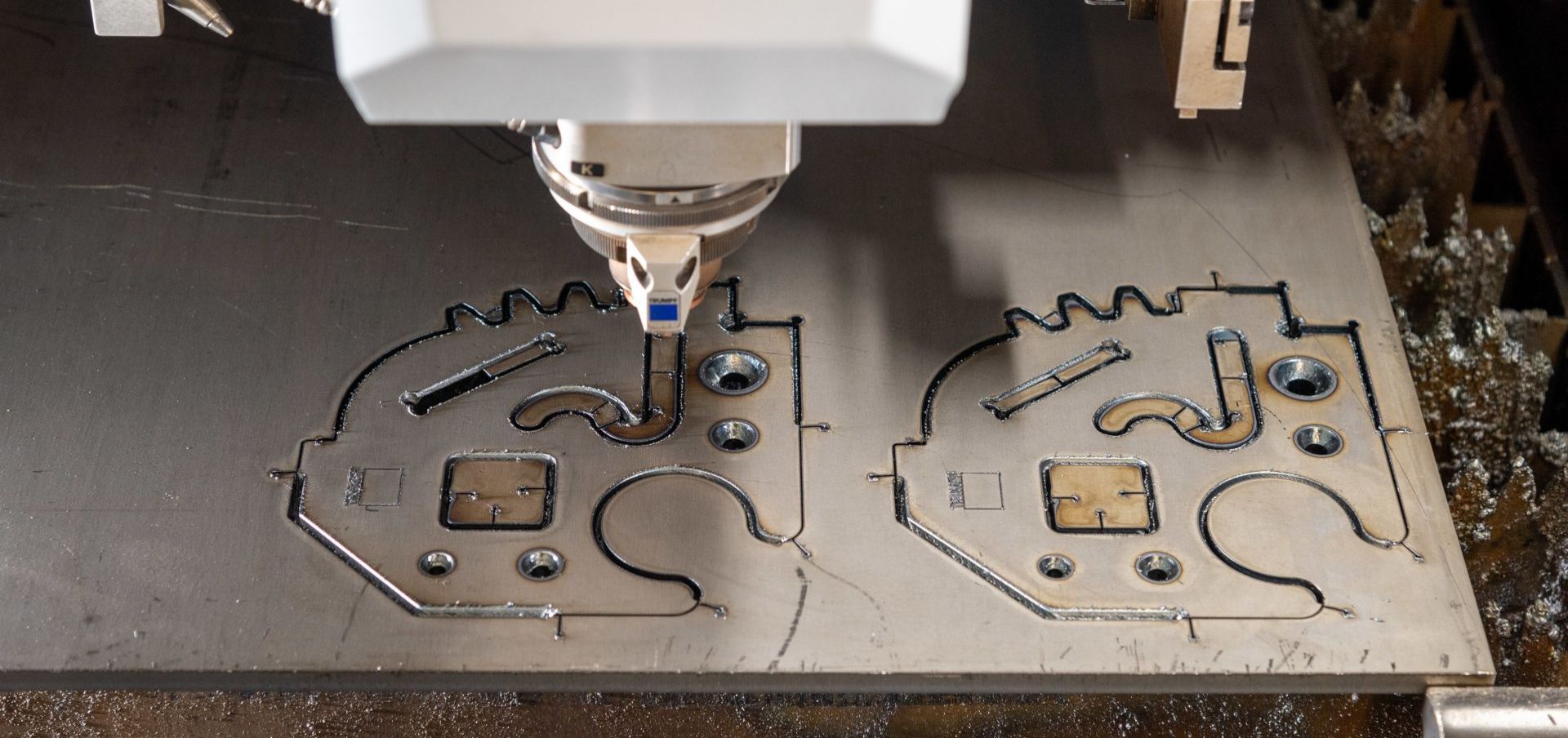

Until now, many companies have had to produce bevels manually on their parts. To do this, people work on parts with, among other things, angle grinders, milling machines or edge formers. This work step is laborious and takes a lot of time. What’s more, due to the shortage of skilled workers, there is not always someone available who can do this. It is also possible to produce chamfers automatically. For this, however, users need a technologically sophisticated machine with a special 3D cutting head. Smaller companies in particular seldom have these kinds of machines on hand.

How does EdgeLine Bevel remedy this situation?

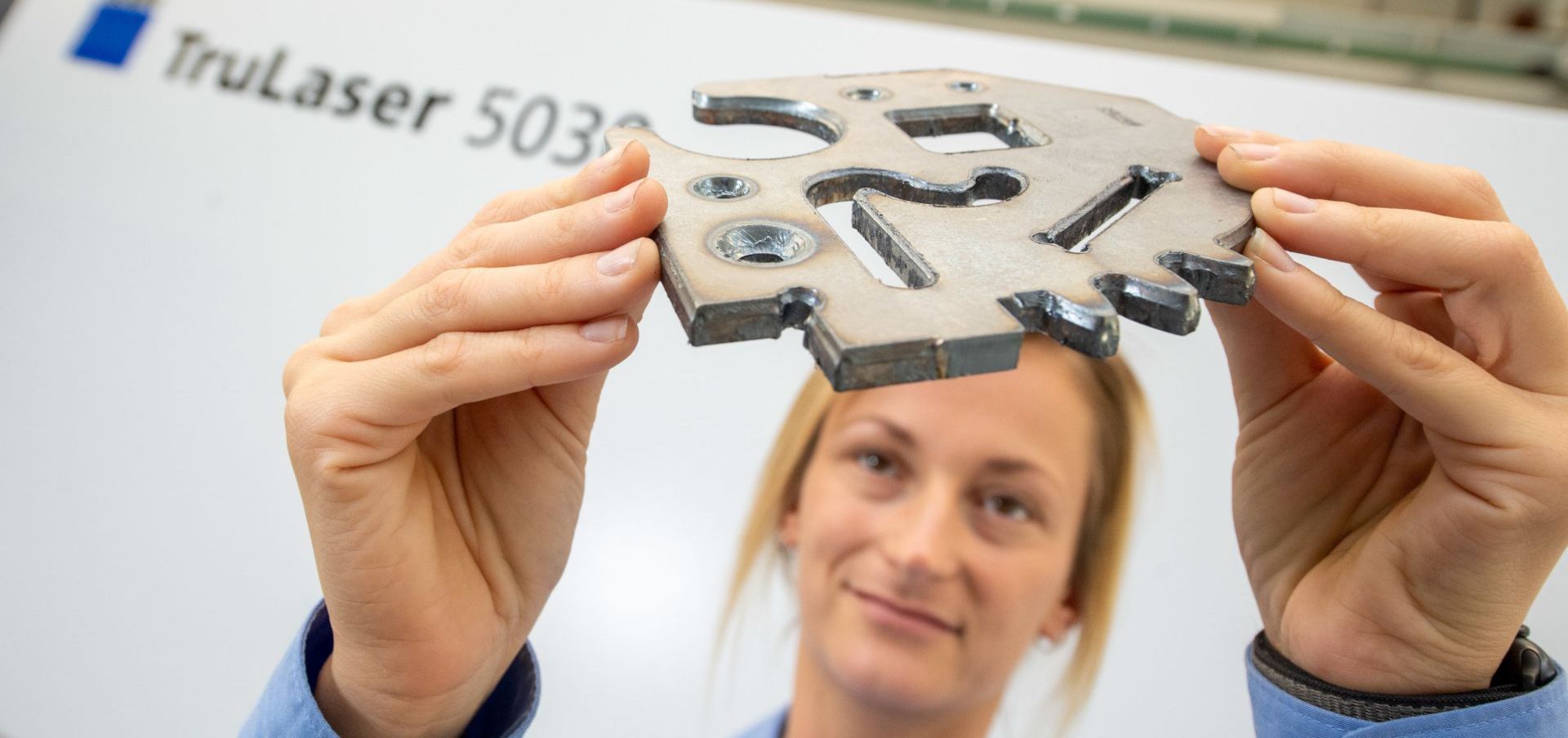

With this technology, users are able for the first time to produce bevels directly on a standard machine for laser cutting – automatically, at the push of a button. This eliminates the need for complex downstream processes and separate machines. This saves time and, of course, costs. In addition, EdgeLine Bevel reaches places in the part that the worker with an angle grinder cannot reach at all or only with difficulty. This increases processing quality. Incidentally, not only bevels but also countersinks can be generated automatically. This saves us another manual work step.

What parts is the technology particularly suitable for?

In principle, EdgeLine Bevel is suitable for all components that have to be beveled before welding or require countersinks for screw connections. The range of applications is extremely broad, as the technology is suitable for all companies that manufacture assemblies.

Can EdgeLine Bevel also be retrofitted?

Yes, companies that already have a standard TRUMPF machine for laser cutting will be able to retrofit it starting in the spring of 2022. Since EdgeLine Bevel is a software-based process, we can also retrofit the technology to customers' latest generation of laser cutting machines with a software update.

How is the solution being received by users?

The interest of our customers is huge. The video on YouTube alone has already been viewed almost 800,000 times in the first four weeks after its release, and we receive inquiries every day. This shows us that our technology is in tune with the times and that we always have the entire process chain in view in our solutions.

Patrick Schüle, Product Manager at TRUMPF: "With EdgeLine Bevel, TRUMPF shows that we have the entire sheet metal process chain in view."