Nichts geht über individuelle Erfahrungswerte mit einem Laser direkt in Ihrer Anlage! Gerne beraten wir Sie zu Ihren Applikationsanforderungen und überlegen gemeinsam wie ein Testlaser Ihnen dabei helfen kann. Wir ermöglichen es Ihnen einen passenden TRUMPF Laser an Ihrem Standort und in Ihrer Anlage zu testen – bis zu 30 Tage lang.

Vielseitigkeit für ein breites Spektrum an Anwendungen

Unsere gepulsten Faserlaser TruPulse nano mit GTWave- und PulseTune-Technologie zählen zu den vielseitigsten Industrielasern im TRUMPF Portfolio. Diese Laser arbeiten im Nanosekunden-Pulsdauerbereich und werden in einer Vielzahl industrieller Anwendungen eingesetzt. Sie bieten Anwendern eine unübertroffene Flexibilität. Da sie zudem komplett wartungsfrei sind können Sie sich auf das Ergebnis konzentrieren, anstatt auf zeitaufwändige und kostspielige Wartungspläne.

Erstellen Sie dauerhafte Markierungen mit einem berührungslosen Verfahren bei hoher Geschwindigkeit und hoher Präzision. Lasermarkierungen erfordern zudem keine Verbrauchsmaterialien; sie werden computergeneriert und bieten daher größte Flexibilität.

Erklimmen Sie den Gipfel der gepulsten Nanosekunden-Technologie mit erweiterten Funktionen für die Mikrobearbeitung, die unsere PulseTune-fähigen Laser auf ein neues Niveau heben. Diese Laser bieten OEM-Integratoren eine hochflexible Steuerung der Impulsbreite und der Spitzenleistung. Die einzigartige PulseTune-Funktion ermöglicht marktführende Pulsfrequenzen bei gleichzeitiger Konstanthaltung der Spitzenleistung.

Wählen Sie aus bis zu 48 verfügbaren Wellenformen. Da sich zentrale Pulseigenschaften für einzelne Anwendungen perfekt optimieren lassen, erhöhen Sie Ihre Prozessqualität und Produktivität.

Die gepulsten Faserlaser arbeiten wartungsfrei. So können Sie sich jederzeit auf das Ergebnis konzentrieren – zeitaufwändige Wartungspläne sind passé.

Nanosekunden-Schweißen

Unabhängig von Material, Dicke oder der Kombination unterschiedlicher Metalle bieten unsere Laser Ihnen die Vielseitigkeit, um eine Vielzahl an Produkten zu schweißen – von Brennstoffzellen und Batterien bis hin zu feinen Drähten für die Herstellung medizinischer Geräte. Mit unserem patentierten Nanosekunden-Schweißverfahren können Sie nahezu jede Kombination dünner metallischer Bauteile verbinden. Dazu zählen auch hochreflektierende und leitfähige Metalle.

Bohren

Bei einer Laserbohrung wird ein Laserstrahl wiederholt auf einen bestimmten Bereich gepulst. Das zu bohrende Material wird dabei Schicht für Schicht verdampft und geschmolzen, bis Bohrlöcher entstehen. Das Bohren mit Lasern zeichnet sich durch eine hohe Präzision aus, die durch Überwachung der Strahlintensität und -dauer sorgfältig gesteuert werden kann.

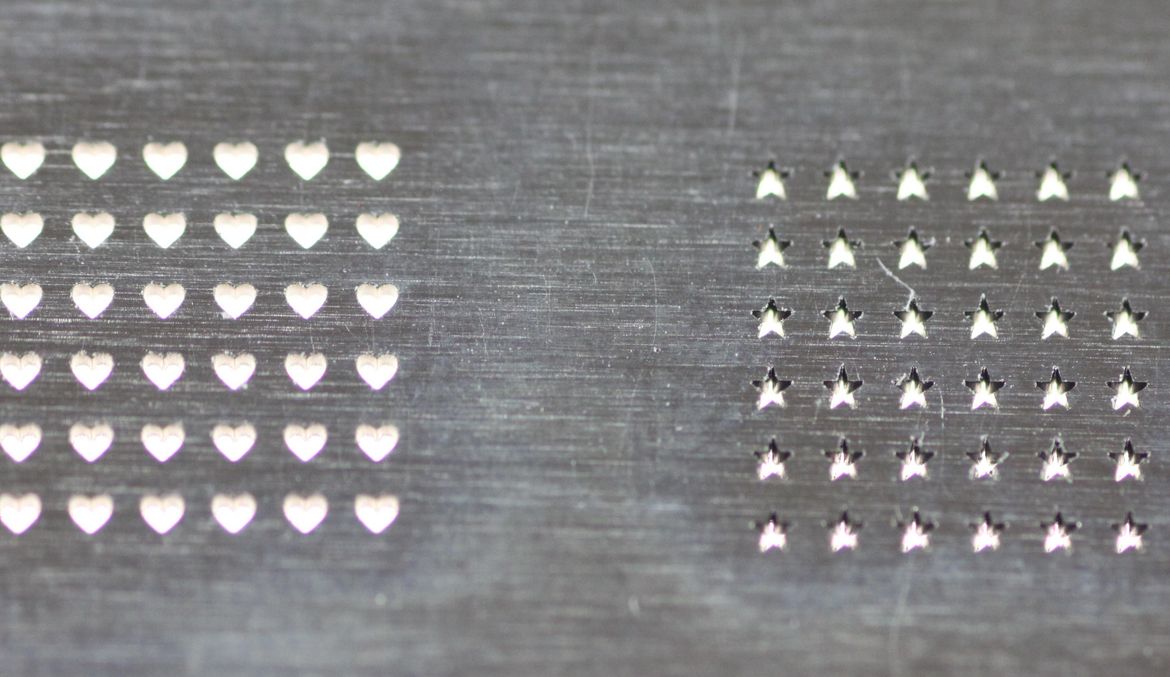

Schneiden

Der Laserstrahl lässt sich einfach so programmieren, dass er eine Vielzahl von Dicken und Materialien präzise schneiden kann. Dazu zählen Metalle, einschließlich reflektierender Metalle wie Kupfer, Silber und Aluminium, aber auch Messing, Wolfram, Stahl, Zinn und Titan. Auch Edelsteine wie Diamanten, oder Keramik, grafische Verbundwerkstoffe, Silizium und viele Arten von Kunststoffen können bearbeitet werden. Selbst sehr komplexe Formen können hochpräzise geschnitten werden, da der Anwender immer die volle Kontrolle über die Strahlintensität, -dauer und den Wärmeeintrag hat.

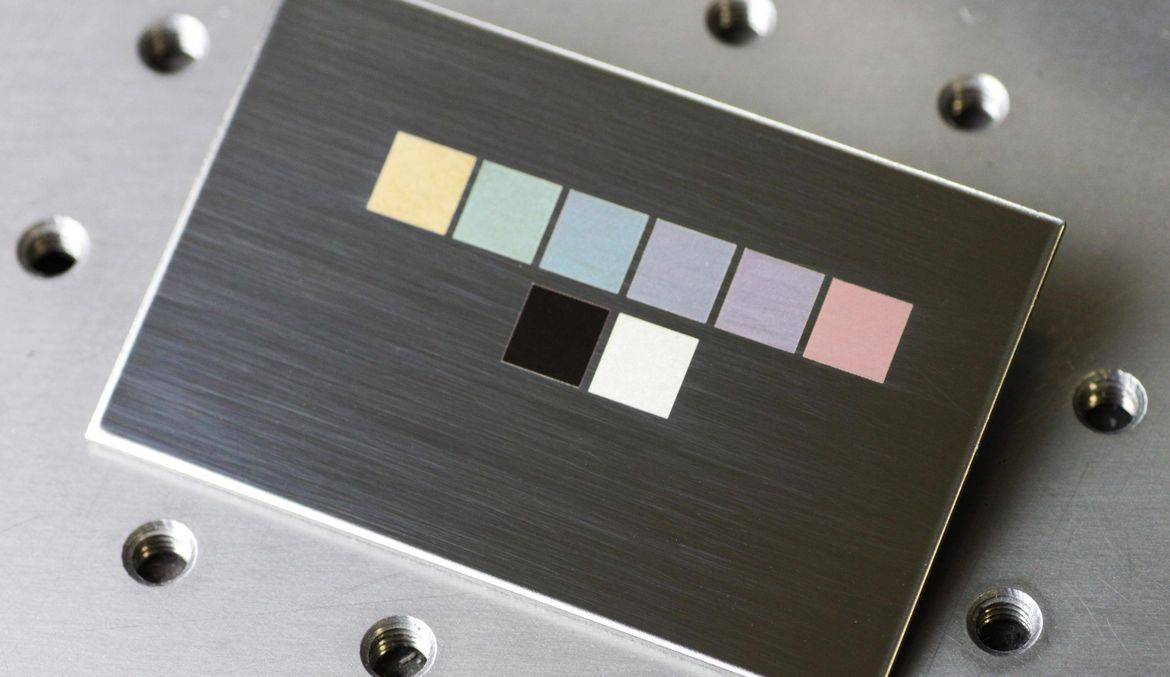

Markieren und Gravieren

Während eine Markierung nur auf die Oberfläche eines Werkstücks einwirkt, ist eine Gravur eine Markierung mit Tiefe. Nahezu jedes Material kann mit dem Laser in Schwarz oder bei einigen Materialien sogar farblich markiert werden. Lasermarkierungen kommen u.a. auf Keramik, Kunststoffen, Metallen, LEDs, Gummi und grafischen Verbundwerkstoffen zum Einsatz.

Schichtabtrag

Der Laser ermöglicht das präzise Entfernen von Schichten in Metallen oder industriellen Verbindungen, z.B. bei Halbleitern und Mikroprozessoren in elektronischen Produkten.

Reinigung

Zur Laserreinigung kommen typischerweise hohe Pulsfrequenzen und kurze Pulsdauern mit hohen Spitzenleistungen zum Einsatz – wie gemacht für gepulste Nanosekundenlaser. Ziel ist es, Oberflächenreste und kontaminierte Schichten zu entfernen, ohne dabei die Substratmaterialien zu beschädigen. Laserreinigung stellt eine kostengünstige und umweltschonende Anwendung dar, die weltweit in der Industrie etabliert ist.

|

TruPulse 1002 nano (FK10-EP)

Produkt vergleichen

|

TruPulse 1002 nano (FK10-HS)

Produkt vergleichen

|

TruPulse 1003 nano (FK10-HS)

Produkt vergleichen

|

TruPulse 1005 nano (FK10-HS)

Produkt vergleichen

|

TruPulse 1010 nano (FK10-EP)

Produkt vergleichen

|

TruPulse 2002 nano (FK10-EP)

Produkt vergleichen

|

TruPulse 2002 nano (FK10-RM)

Produkt vergleichen

|

TruPulse 2003 nano (FK10-RM)

Produkt vergleichen

|

TruPulse 2005 nano (FK10-EP)

Produkt vergleichen

|

TruPulse 2005 nano (FK10-RM)

Produkt vergleichen

|

TruPulse 2007 nano (FK10-EP)

Produkt vergleichen

|

TruPulse 2007 nano (FK10-RM)

Produkt vergleichen

|

TruPulse 2010 nano (FK10-EP)

Produkt vergleichen

|

TruPulse 2013 nano (FK10-EP)

Produkt vergleichen

|

TruPulse 2020 nano (FK10-EP)

Produkt vergleichen

|

TruPulse 2030 nano (FK10-EP)

Produkt vergleichen

|

TruPulse 3002 nano (FK10-EP)

Produkt vergleichen

|

TruPulse 3002 nano (FK10-HS)

Produkt vergleichen

|

TruPulse 4007 nano (FK10-HS)

Produkt vergleichen

|

TruPulse 5020 nano (FK10-EP)

Produkt vergleichen

|

TruPulse 2060 nano (FK10-EP)

Produkt vergleichen

|

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Laserparameter | |||||||||||||||||||||

| Mittlere Ausgangsleistung | 20 W | 20 W | 30 W | 50 W | 100 W | 20 W | 20 W | 30 W | 50 W | 50 W | 70 W | 70 W | 100 W | 130 W | 200 W | 300 W | 20 W | 20 W | 70 W | 200 W | 600 W |

| Max. Pulsspitzenleistung | > 7 kW | > 7 kW | > 7 kW | > 7 kW | > 7 kW | > 10 kW | > 10 kW | > 10 kW | > 10 kW | > 10 kW | > 10 kW | > 10 kW | > 10 kW | > 10 kW | > 10 kW | > 8 kW | > 12 kW | > 12 kW | > 20 kW | > 50 kW | > 10 kW |

| Strahlqualität (M²) | < 1,3 | < 1,3 | < 1,3 | < 1,3 | < 1,3 | < 1,6 | < 1,6 | < 1,6 | < 1,6 | < 1,6 | < 1,6 | < 1,6 | < 1,6 | < 1,6 | < 1,6 | < 1,6 | < 1,8 | 1,8 | 3 | < 5 | < 1,6 |

| Wellenlängenbereich | 1059 nm - 1065 nm | 1059 nm - 1065 nm | 1059 nm - 1065 nm | 1059 nm - 1065 nm | 1060 nm - 1070 nm | ||||||||||||||||

| Max. Pulsenergie | > 0,8 mJ | > 0,6 mJ | > 0,6 mJ | > 0,6 mJ | > 1 mJ | > 1 mJ | > 1 mJ | > 1 mJ | > 1 mJ | > 1 mJ | > 1 mJ | > 1 mJ | > 1,3 mJ | > 1,5 mJ | > 1,5 mJ | > 1,5 mJ | > 1 mJ | > 0,8 mJ | > 1,25 mJ | > 5 mJ | > 2,1 mJ |

| Pulsdauerbereich | 3 ns - 2000 ns | 10 ns - 240 ns | 10 ns - 240 ns | 11 ns - 220 ns | 4 ns - 2000 ns | 3 ns - 500 ns | 26 ns - 250 ns | 26 ns - 250 ns | 6 ns - 500 ns | 26 ns - 250 ns | 9 ns - 500 ns | 28 ns - 260 ns | 4 ns - 2000 ns | 3 ns - 2000 ns | 9 ns - 2000 ns | 12 ns - 1200 ns | 10 ns - 220 ns | 2 ns - 500 ns | 10 ns - 250 ns | 12 ns - 2000 ns | 20 ns - 800 ns |

| Pulsfolgefrequenz | 1 kHz - 4000 kHz | 1 kHz - 1000 kHz | 1 kHz - 1000 kHz | 1 kHz - 1000 kHz | 1 kHz - 4000 kHz | 1 kHz - 1000 kHz | 1 kHz - 500 kHz | 1 kHz - 500 kHz | 1 kHz - 1000 kHz | 1 kHz - 500 kHz | 1 kHz - 1000 kHz | 1 kHz - 500 kHz | 1 kHz - 4000 kHz | 1 kHz - 4000 kHz | 1 kHz - 4000 kHz | 1 kHz - 4000 kHz | 1 kHz - 1000 kHz | 1 kHz - 1000 kHz | 1 kHz - 1000 kHz | 1 kHz - 4000 kHz | Bis zu 4166 kHz |

| Wellenlänge | 1062 nm ± 3 nm | 1062 nm ± 3 nm | 1062 nm ± 3 nm | 1062 nm ± 3 nm | 1062 nm ± 3 nm | 1062 nm ± 3 nm | 1062 nm ± 3 nm | 1062 nm ± 3 nm | 1062 nm ± 3 nm | 1062 nm ± 3 nm | 1062 nm ± 3 nm | 1062 nm ± 3 nm | 1062 nm ± 3 nm | 1062 nm ± 3 nm | 1062 nm ± 3 nm | 1062 nm ± 3 nm | |||||

| Bauform | |||||||||||||||||||||

| Abmessungen (B x H x T) | 347 mm x 201 mm x 95 mm | 347 mm x 201 mm x 95 mm | 347 mm x 201 mm x 95 mm | 347 mm x 201 mm x 95 mm | 377 mm x 249 mm x 115 mm | 347 mm x 201 mm x 95 mm | 347 mm x 201 mm x 95 mm | 347 mm x 201 mm x 95 mm | 347 mm x 201 mm x 95 mm | 347 mm x 201 mm x 95 mm | 377 mm x 249 mm x 95 mm | 377 mm x 249 mm x 95 mm | 377 mm x 249 mm x 115 mm | 423 mm x 417 mm x 133 mm | 423 mm x 417 mm x 133 mm | 447 mm x 417 mm x 88 mm | 347 mm x 201 mm x 95 mm | 347 mm x 201 mm x 95 mm | 377 mm x 249 mm x 95 mm | 473 mm x 417 mm x 133 mm | 622 mm x 482 mm x 177 mm |

| Aufstellung | |||||||||||||||||||||

| Umgebungstemperatur | 0 °C - 45 °C | 0 °C - 45 °C | 0 °C - 45 °C | 0 °C - 42 °C | 5 °C - 40 °C | 0 °C - 45 °C | 0 °C - 45 °C | 0 °C - 45 °C | 0 °C - 40 °C | 0 °C - 40 °C | 0 °C - 40 °C | 0 °C - 40 °C | 0 °C - 40 °C | 10 °C - 45 °C | 10 °C - 40 °C | 15 °C - 38 °C | 0 °C - 45 °C | 0 °C - 45 °C | 0 °C - 40 °C | 10 °C - 40 °C | 15 °C - 40 °C |

|

TruPulse 1002 nano (FK10-EP)

|

TruPulse 1002 nano (FK10-HS)

|

TruPulse 1003 nano (FK10-HS)

|

TruPulse 1005 nano (FK10-HS)

|

TruPulse 1010 nano (FK10-EP)

|

TruPulse 2002 nano (FK10-EP)

|

TruPulse 2002 nano (FK10-RM)

|

TruPulse 2003 nano (FK10-RM)

|

TruPulse 2005 nano (FK10-EP)

|

TruPulse 2005 nano (FK10-RM)

|

TruPulse 2007 nano (FK10-EP)

|

TruPulse 2007 nano (FK10-RM)

|

TruPulse 2010 nano (FK10-EP)

|

TruPulse 2013 nano (FK10-EP)

|

TruPulse 2020 nano (FK10-EP)

|

TruPulse 2030 nano (FK10-EP)

|

TruPulse 3002 nano (FK10-EP)

|

TruPulse 3002 nano (FK10-HS)

|

TruPulse 4007 nano (FK10-HS)

|

TruPulse 5020 nano (FK10-EP)

|

TruPulse 2060 nano (FK10-EP)

|

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Laserparameter | |||||||||||||||||||||

| Mittlere Ausgangsleistung | 20 W | 20 W | 30 W | 50 W | 100 W | 20 W | 20 W | 30 W | 50 W | 50 W | 70 W | 70 W | 100 W | 130 W | 200 W | 300 W | 20 W | 20 W | 70 W | 200 W | 600 W |

| Max. Pulsspitzenleistung | > 7 kW | > 7 kW | > 7 kW | > 7 kW | > 7 kW | > 10 kW | > 10 kW | > 10 kW | > 10 kW | > 10 kW | > 10 kW | > 10 kW | > 10 kW | > 10 kW | > 10 kW | > 8 kW | > 12 kW | > 12 kW | > 20 kW | > 50 kW | > 10 kW |

| Strahlqualität (M²) | < 1,3 | < 1,3 | < 1,3 | < 1,3 | < 1,3 | < 1,6 | < 1,6 | < 1,6 | < 1,6 | < 1,6 | < 1,6 | < 1,6 | < 1,6 | < 1,6 | < 1,6 | < 1,6 | < 1,8 | 1,8 | 3 | < 5 | < 1,6 |

| Wellenlängenbereich | 1059 nm - 1065 nm | 1059 nm - 1065 nm | 1059 nm - 1065 nm | 1059 nm - 1065 nm | 1060 nm - 1070 nm | ||||||||||||||||

| Max. Pulsenergie | > 0,8 mJ | > 0,6 mJ | > 0,6 mJ | > 0,6 mJ | > 1 mJ | > 1 mJ | > 1 mJ | > 1 mJ | > 1 mJ | > 1 mJ | > 1 mJ | > 1 mJ | > 1,3 mJ | > 1,5 mJ | > 1,5 mJ | > 1,5 mJ | > 1 mJ | > 0,8 mJ | > 1,25 mJ | > 5 mJ | > 2,1 mJ |

| Pulsdauerbereich | 3 ns - 2000 ns | 10 ns - 240 ns | 10 ns - 240 ns | 11 ns - 220 ns | 4 ns - 2000 ns | 3 ns - 500 ns | 26 ns - 250 ns | 26 ns - 250 ns | 6 ns - 500 ns | 26 ns - 250 ns | 9 ns - 500 ns | 28 ns - 260 ns | 4 ns - 2000 ns | 3 ns - 2000 ns | 9 ns - 2000 ns | 12 ns - 1200 ns | 10 ns - 220 ns | 2 ns - 500 ns | 10 ns - 250 ns | 12 ns - 2000 ns | 20 ns - 800 ns |

| Pulsfolgefrequenz | 1 kHz - 4000 kHz | 1 kHz - 1000 kHz | 1 kHz - 1000 kHz | 1 kHz - 1000 kHz | 1 kHz - 4000 kHz | 1 kHz - 1000 kHz | 1 kHz - 500 kHz | 1 kHz - 500 kHz | 1 kHz - 1000 kHz | 1 kHz - 500 kHz | 1 kHz - 1000 kHz | 1 kHz - 500 kHz | 1 kHz - 4000 kHz | 1 kHz - 4000 kHz | 1 kHz - 4000 kHz | 1 kHz - 4000 kHz | 1 kHz - 1000 kHz | 1 kHz - 1000 kHz | 1 kHz - 1000 kHz | 1 kHz - 4000 kHz | Bis zu 4166 kHz |

| Wellenlänge | 1062 nm ± 3 nm | 1062 nm ± 3 nm | 1062 nm ± 3 nm | 1062 nm ± 3 nm | 1062 nm ± 3 nm | 1062 nm ± 3 nm | 1062 nm ± 3 nm | 1062 nm ± 3 nm | 1062 nm ± 3 nm | 1062 nm ± 3 nm | 1062 nm ± 3 nm | 1062 nm ± 3 nm | 1062 nm ± 3 nm | 1062 nm ± 3 nm | 1062 nm ± 3 nm | 1062 nm ± 3 nm | |||||

| Bauform | |||||||||||||||||||||

| Abmessungen (B x H x T) | 347 mm x 201 mm x 95 mm | 347 mm x 201 mm x 95 mm | 347 mm x 201 mm x 95 mm | 347 mm x 201 mm x 95 mm | 377 mm x 249 mm x 115 mm | 347 mm x 201 mm x 95 mm | 347 mm x 201 mm x 95 mm | 347 mm x 201 mm x 95 mm | 347 mm x 201 mm x 95 mm | 347 mm x 201 mm x 95 mm | 377 mm x 249 mm x 95 mm | 377 mm x 249 mm x 95 mm | 377 mm x 249 mm x 115 mm | 423 mm x 417 mm x 133 mm | 423 mm x 417 mm x 133 mm | 447 mm x 417 mm x 88 mm | 347 mm x 201 mm x 95 mm | 347 mm x 201 mm x 95 mm | 377 mm x 249 mm x 95 mm | 473 mm x 417 mm x 133 mm | 622 mm x 482 mm x 177 mm |

| Aufstellung | |||||||||||||||||||||

| Umgebungstemperatur | 0 °C - 45 °C | 0 °C - 45 °C | 0 °C - 45 °C | 0 °C - 42 °C | 5 °C - 40 °C | 0 °C - 45 °C | 0 °C - 45 °C | 0 °C - 45 °C | 0 °C - 40 °C | 0 °C - 40 °C | 0 °C - 40 °C | 0 °C - 40 °C | 0 °C - 40 °C | 10 °C - 45 °C | 10 °C - 40 °C | 15 °C - 38 °C | 0 °C - 45 °C | 0 °C - 45 °C | 0 °C - 40 °C | 10 °C - 40 °C | 15 °C - 40 °C |

Die technischen Daten aller Produktvarianten als Download.

Keine Wartung erforderlich

TruPulse Nano-Faserlaser sind eine echte "Fit-and-Forget"-Technologie, die während ihrer gesamten Betriebsdauer keine Wartung erfordert. Weitere Betriebskosten sind daher nicht zu erwarten.

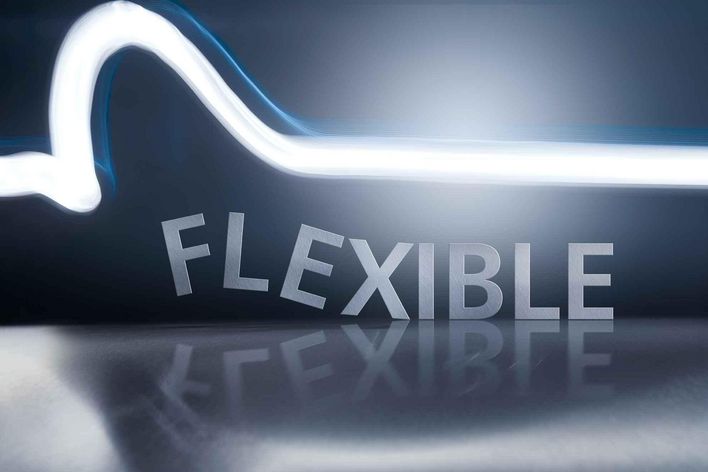

Mehr Flexibilität durch variable Pulskontrolle

Die TruPulse nano Serie profitiert von der PulseTune-Funktionalität. Dies bietet den Anwendern eine Auswahl an Pulsdauern von 3 ns bis 2 µs. Hierdurch wird eine unübertroffene Flexibilität bei der Prozessoptimierung, eine verbesserte Produktivität und eine Steigerung der Prozessqualität ermöglicht.

Hohe Zuverlässigkeit und 3 Jahre Garantie

Unsere Laser sind für den 24/7-Schichtetrieb ausgelegt und bieten branchenführende Zuverlässigkeit. Zudem bieten wir eine Standardgarantie von 3 Jahren. Das robuste Strahlführungskabel sowie alle weiteren Anschlusskomponenten bieten eine einfache Systemintegration.

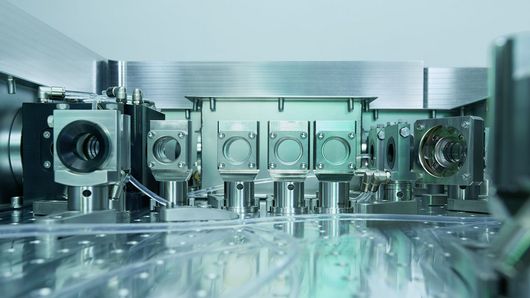

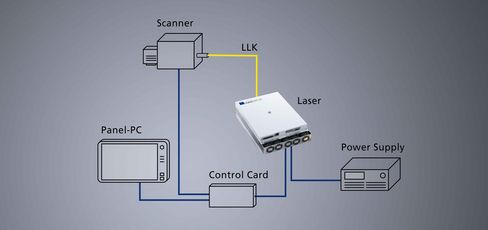

Einfache Integration

TruPulse nano Laser sind Integrationsmodule, die in der Regel mit Scanneroptiken und einer zugehörigen Steuerhardware und -software eingesetzt werden. Unsere Produkte verfügen über eine Industriestandardschnittstelle, die häufig in Drittanbieter Hard- und Software vorhanden ist.

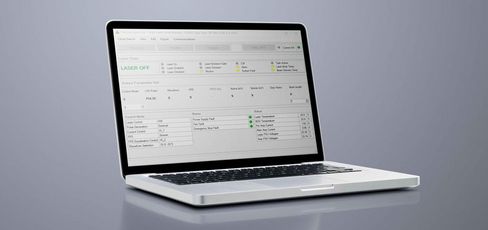

Benutzeroberfläche für Laserüberwachung und -diagnose

Für alle TruPulse nano Produkte steht eine grafische Benutzeroberfläche (GUI) zur Verfügung. Diese GUI bietet dem Benutzer vielfältige Funktionen und bietet zudem eine Überwachung des Lasers. Zudem wird die Software zur Unterstützung der Integration verwendet.

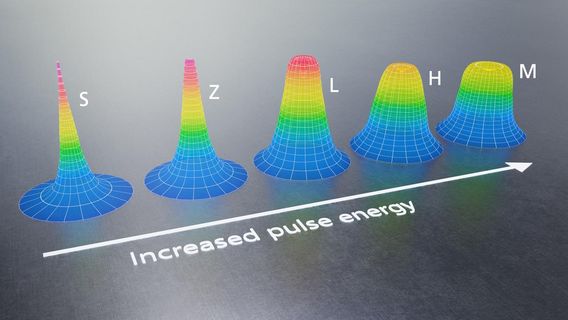

Serie 1000 | S-Typ (Single mode M2 <1,3): Erzeugt eine sehr feine Spotgröße (<20 Mikrometer) mit hoher Leistungsstabilität und großer Tiefenschärfe. Ideal für Anwendungen, die kleine Strukturgrößen erfordern.

Serie 2000 | Z-Typ (M2 <1,6): Bietet höhere Spitzenleistung und Pulsenergie bei nur geringfügiger Zunahme der Spotgröße und guter Tiefenschärfe.

Serie 3000 | L-Typ (Low Mode M2 1,6 - 2,0): Für allgemeine Markierungsanwendungen mit etwas größeren Spots und Merkmalen. Markierungen sind mit bloßem Auge erkennbar.

Serie 4000 | H-Typ (High Mode M2 2,5 - 3,5): Bietet hohe Pulsenergien, Spitzenleistungen und noch größere Spots, ideal für breite Linien, Anwendungen mit gefüllter Schrift und eine große Flächendeckung.

Serie 5000 | M-Type – Multimode (M2 4,0 - 6,0): Höchste Pulsenergien und längere Pulsdauern optimal zum Schweißen und Reinigen.

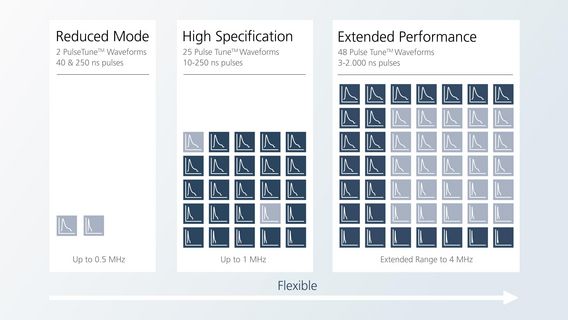

Je nach Anforderung haben Sie die Wahl zwischen mehreren Produkten im Rahmen unserer PulseTune Serie.

- Die Einstiegsprodukte im Reduced Mode (RM) verfügen über begrenzte Pulsoptionen sowie grundlegende Software- und Hardwareschnittstellen. Bei diesen Modellen können Sie zwei PulseTune-Wellenformen nutzen und arbeiten mit einer begrenzten Pulsfrequenz von bis zu 500 kHz.

- Mit den High Specification Modellen (HS) profitieren Sie von unserer PulseTune-Technologie und einer variabel wählbaren Pulsdauer mit 25 voreingestellten Wellenformen. Dank verbesserter Steuerung und modulierter CW-Funktionalität bearbeiten Sie noch präziser. Die Pulsfrequenz liegt bei bis zu 1 MHz.

- In der Extended Performance (EP) können Sie zwischen bis zu 48 optimierten PulseTune-Wellenformen wählen. Damit bieten wir Ihnen unsere vielseitigste Faserlaserquelle mit verbesserter Steuerung und modulierter CW-Funktionalität. Darüber hinaus sind die Pulsenergie und Spitzenleistung nochmals erhöht. Der Pulsdauerbereich liegt bei 3-2000 ns, die Pulsfrequenz bei bis zu 4 MHz.

Je nach Land sind Abweichungen von diesem Produktsortiment und von diesen Angaben möglich. Änderungen in Technik, Ausstattung, Preis und Zubehörangebot sind vorbehalten. Bitte setzen Sie sich mit Ihrem Ansprechpartner vor Ort in Verbindung, um zu erfahren, ob das Produkt in Ihrem Land verfügbar ist.

Sammeln Sie Ihre eigene Erfahrung: Jetzt Ihren Testlaser anfragen!