The right optics for your application

Regardless of whether you are welding, cutting, ablating, heat treating, or drilling, you can count on high-quality process results with robust focusing optics from TRUMPF. The optics can be used flexibly with the TRUMPF solid-state lasers and optimally adapted to the lasers. Through the modular toolkit from TRUMPF, the fixed optics can be adapted individually to your requirements.

TRUMPF focusing optics will impress you with their long service life and reliability.

A large number of options guarantees you the right solution for any task.

Various optic designs ensure system-specific adaptation to the work situation and environment.

The sophisticated technology means that customized seams can be created with an excellent seam quality.

Important work parameters can be set simply and specifically for the application.

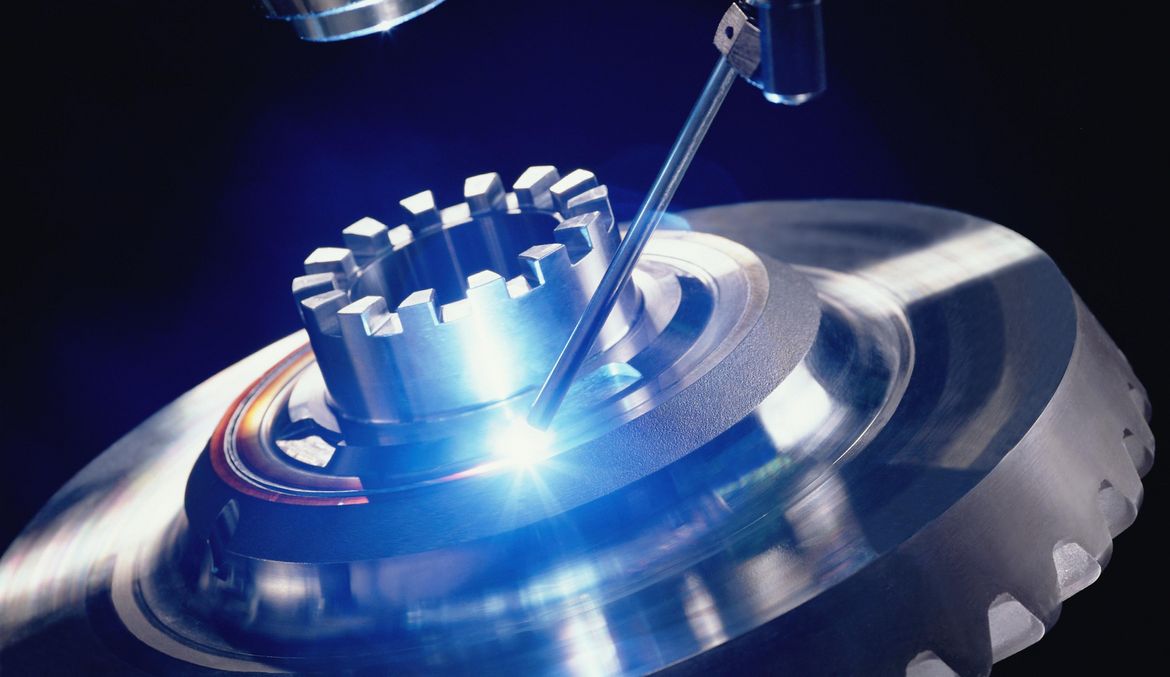

Transmission components

The optics help you focus the laser beam precisely on the weld. The simultaneously supplied shielding gas ensures an even higher quality welding result and thereby reduces time-consuming reworking of the weld seam.

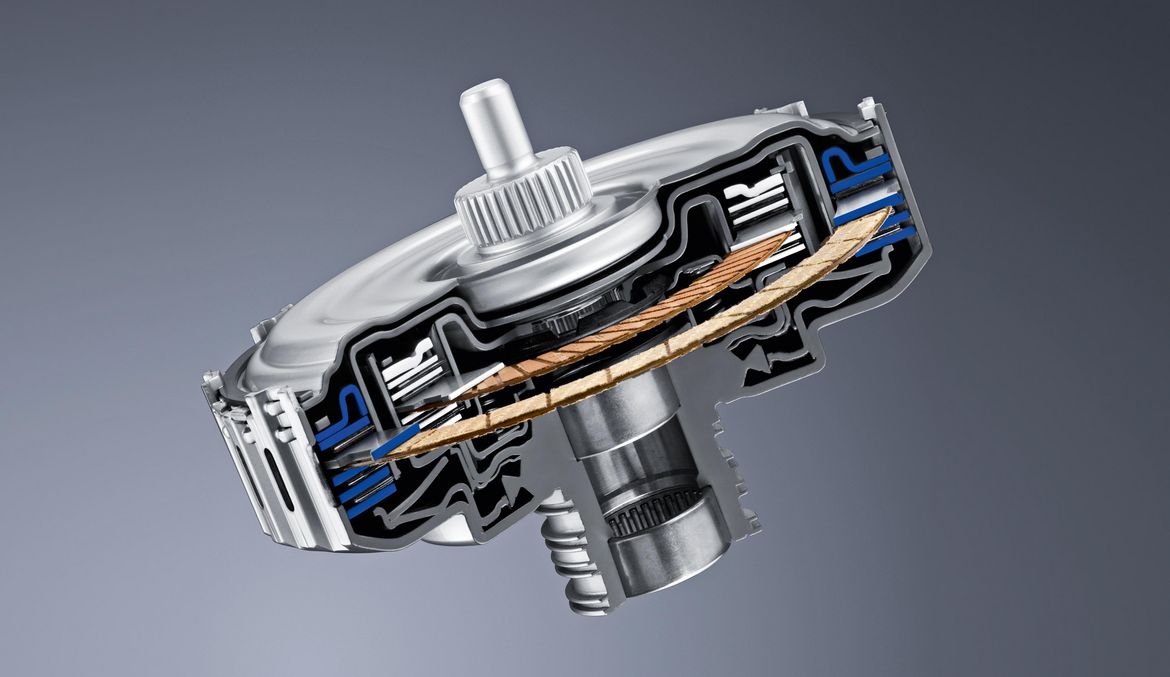

Dual clutch unit

TRUMPF processing optics deliver the best performance in 24/7 operation, resulting in consistent quality welds long term.

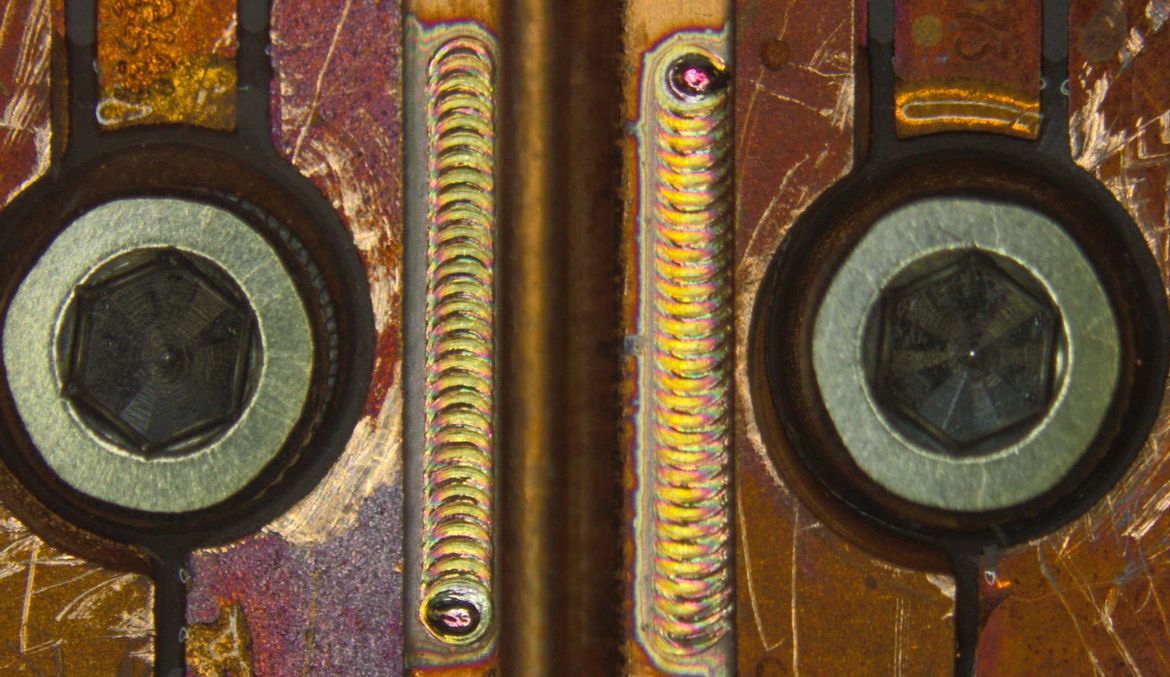

Center differential

Precisely focusing the laser light is especially important when welding a butt joint or overlapping joint. TRUMPF focusing optics bring their strengths to bear in this field, and can be used, for example, to weld a center differential with an overlapping joint of outstanding quality.

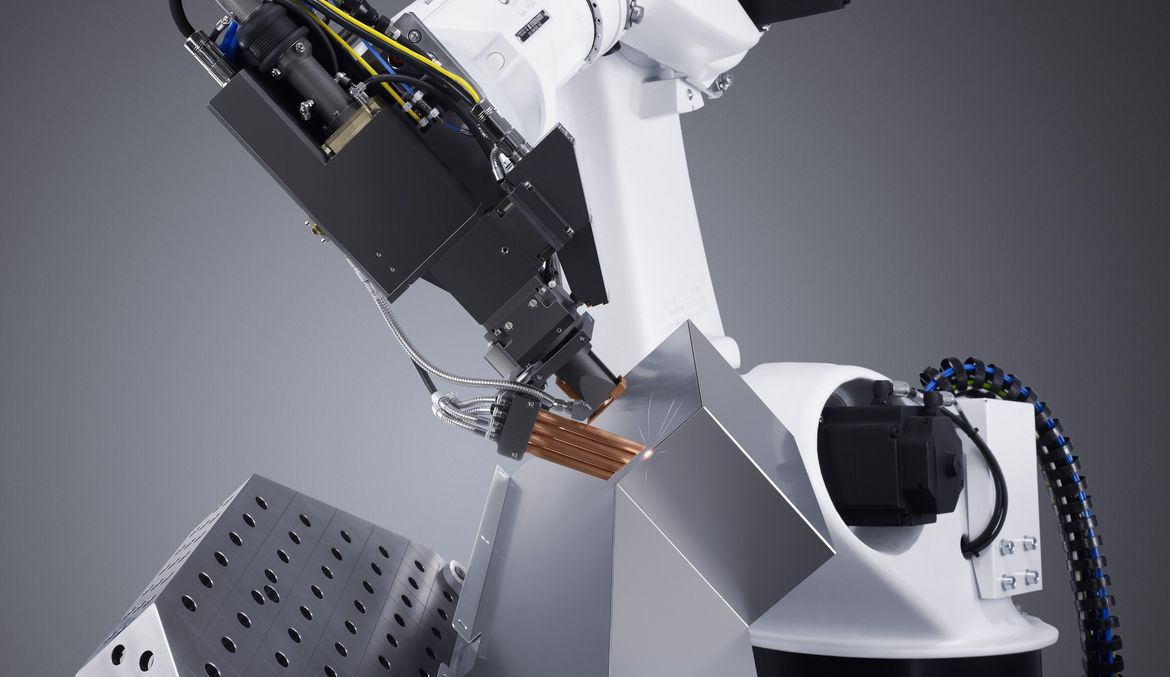

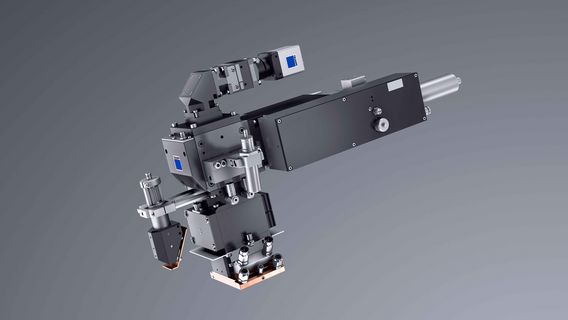

Robotic welding

With the combination of TRUMPF focusing optics, such as motorized focusing optics, and a robot, you can substantially increase the size of the work area of your optics and use their excellent focusing properties.

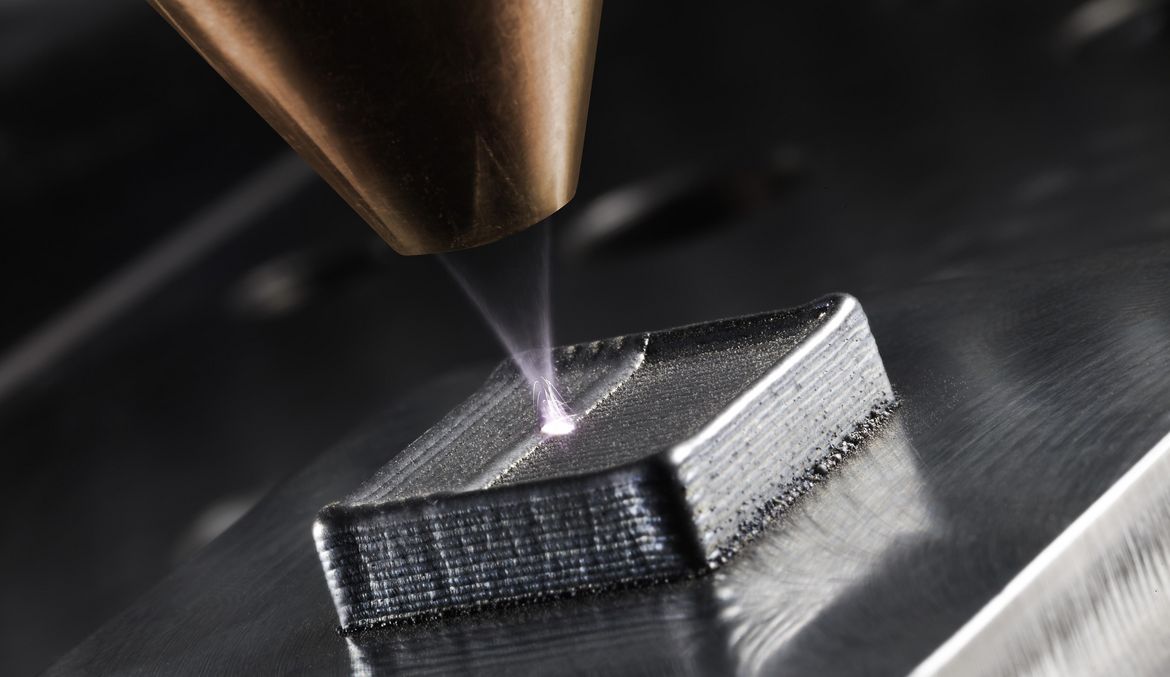

Laser metal deposition

Generative laser metal deposition with TRUMPF focusing optics.

Copper welding

You can also process copper using TRUMPF focusing optics. This means you can weld contacts on printed circuit boards, for example.

|

BEO D25

Compare product

|

BEO D35

Compare product

|

BEO D50

Compare product

|

BEO D70-2

Compare product

|

RFO

Compare product

|

CFO

Compare product

|

|

|---|---|---|---|---|---|---|

| Laser parameters | ||||||

| Wavelength | - | - | - | - | - | - |

| Power | up to 150 W (cw) | up to 4000 W (cw) | up to 8000 W (cw) | up to 8000 W (cw) | from 16000 W (cw) | up to 8000 W (cw) |

| Numerical aperture | typ. 0.11 / max. 0.12 | typ. 0.11 / max. 0.12 | typ. 0.11 / max. 0.12 | typ. 0.11 / max. 0.12 | typ. 0.11 / max. 0.12 | typ. 0.11 / max. 0.12 |

| Laser light cable type | LLK-A | LLK-Q, LLK-D, LLK-B, LLK-A, PIPA-Q | LLK-D, LLK-B, LLK-A, PIPA-Q | LLK-D, LLK-X, LLK-B | LLK-D | LLK-D, LLK-B |

| Optics configuration 2 | ||||||

| Collimation | 90 mm | 35 / 80 / 100 mm | 35 / 100 / 125 / 150 / 200 mm | 150 / 175 / 200 mm | - | 200 mm |

| Focal length | 48 / 60 / 90 / 135 mm | 70 / 100 / 140 / 200 / 300 mm | 150 / 200 / 250 / 300 mm | 200 / 300 / 400 / 600 mm | 600 mm | 100 / 150 / 200 / 300 / 400 / 600 mm |

| Structural design | ||||||

| Dimensions (W x H x D) | 25 mm x 198 mm x 25 mm (configuration example) | 166 mm x 313 mm x 62 mm (configuration example with camera monitoring and crossjet) | 128 mm x 407 mm x 100 mm (configuration example with camera monitoring and crossjet) | 172 mm x 510 mm x 78 mm (configuration example with camera monitoring and crossjet) | 123 mm x 446 mm x 176 mm (configuration example with camera monitoring and crossjet) | 163 mm x 519 mm x 114 mm (configuration example with camera monitoring and crossjet) |

| Weight | 0.3 kg (configuration example) | 2.5 kg (configuration example with camera monitoring and crossjet) | 3.5 kg (configuration example with camera monitoring and crossjet) | 6 kg (configuration example with camera monitoring and crossjet) | 6.5 kg (configuration example with camera monitoring and crossjet) | 8.5 kg (configuration example with camera monitoring and crossjet) |

| Compatibility | ||||||

| Available lasers | TruPulse | TruDiode, TruDisk, TruFiber, TruPulse | TruDiode, TruDisk, TruFiber, TruPulse | TruDisk, TruPulse, TruFiber Multi Mode | TruDisk | TruDiode, TruDisk, TruPulse |

| Available sensor system | - | - | VisionLine, CalibrationLine Power | VisionLine Cam/Basic/Detect/Project, CalibrationLine Power | - | VisionLine, CalibrationLine Power |

| Options | ||||||

| Available options | 90° version, bifocal module, camera monitoring, sensor interface, 15 g version | 90° version, crossjet, shielding gas supply, bifocal module, camera monitoring, sensor interface, lighting, cartridge module, 15 g version | 90° version, crossjet, MVE nozzle, shielding gas supply, bifocal module, camera monitoring, sensor interface, lighting, cartridge module | 0°, 90° und 2x90° Version, Crossjet, MDE-Düse, Schutzgasversorgung, Sensoraufnahme, Koaxialbeleuchtung, Seitliche Beleuchtung, Bifokalmodul und Multifokuselement, Einstellbarer Linienlaser, Schutzglasverschmutzungsüberwachung, LLK-Streulicht- und Kühlwassertemperaturüberwachung, Programmierbare Motorische Fokussierung (PMF) | Crossjet, camera monitoring, cartridge module, protective glass monitoring unit | 90° version, crossjet, MVE nozzle, shielding gas supply, bifocal module, camera monitoring, sensor interface, lighting, cartridge module, protective glass monitoring unit, power measuring cartridge, pilot laser, compensation cartridge |

|

BEO D25

|

BEO D35

|

BEO D50

|

BEO D70-2

|

RFO

|

CFO

|

|

|---|---|---|---|---|---|---|

| Laser parameters | ||||||

| Wavelength | - | - | - | - | - | - |

| Power | up to 150 W (cw) | up to 4000 W (cw) | up to 8000 W (cw) | up to 8000 W (cw) | from 16000 W (cw) | up to 8000 W (cw) |

| Numerical aperture | typ. 0.11 / max. 0.12 | typ. 0.11 / max. 0.12 | typ. 0.11 / max. 0.12 | typ. 0.11 / max. 0.12 | typ. 0.11 / max. 0.12 | typ. 0.11 / max. 0.12 |

| Laser light cable type | LLK-A | LLK-Q, LLK-D, LLK-B, LLK-A, PIPA-Q | LLK-D, LLK-B, LLK-A, PIPA-Q | LLK-D, LLK-X, LLK-B | LLK-D | LLK-D, LLK-B |

| Optics configuration 2 | ||||||

| Collimation | 90 mm | 35 / 80 / 100 mm | 35 / 100 / 125 / 150 / 200 mm | 150 / 175 / 200 mm | - | 200 mm |

| Focal length | 48 / 60 / 90 / 135 mm | 70 / 100 / 140 / 200 / 300 mm | 150 / 200 / 250 / 300 mm | 200 / 300 / 400 / 600 mm | 600 mm | 100 / 150 / 200 / 300 / 400 / 600 mm |

| Structural design | ||||||

| Dimensions (W x H x D) | 25 mm x 198 mm x 25 mm (configuration example) | 166 mm x 313 mm x 62 mm (configuration example with camera monitoring and crossjet) | 128 mm x 407 mm x 100 mm (configuration example with camera monitoring and crossjet) | 172 mm x 510 mm x 78 mm (configuration example with camera monitoring and crossjet) | 123 mm x 446 mm x 176 mm (configuration example with camera monitoring and crossjet) | 163 mm x 519 mm x 114 mm (configuration example with camera monitoring and crossjet) |

| Weight | 0.3 kg (configuration example) | 2.5 kg (configuration example with camera monitoring and crossjet) | 3.5 kg (configuration example with camera monitoring and crossjet) | 6 kg (configuration example with camera monitoring and crossjet) | 6.5 kg (configuration example with camera monitoring and crossjet) | 8.5 kg (configuration example with camera monitoring and crossjet) |

| Compatibility | ||||||

| Available lasers | TruPulse | TruDiode, TruDisk, TruFiber, TruPulse | TruDiode, TruDisk, TruFiber, TruPulse | TruDisk, TruPulse, TruFiber Multi Mode | TruDisk | TruDiode, TruDisk, TruPulse |

| Available sensor system | - | - | VisionLine, CalibrationLine Power | VisionLine Cam/Basic/Detect/Project, CalibrationLine Power | - | VisionLine, CalibrationLine Power |

| Options | ||||||

| Available options | 90° version, bifocal module, camera monitoring, sensor interface, 15 g version | 90° version, crossjet, shielding gas supply, bifocal module, camera monitoring, sensor interface, lighting, cartridge module, 15 g version | 90° version, crossjet, MVE nozzle, shielding gas supply, bifocal module, camera monitoring, sensor interface, lighting, cartridge module | 0°, 90° und 2x90° Version, Crossjet, MDE-Düse, Schutzgasversorgung, Sensoraufnahme, Koaxialbeleuchtung, Seitliche Beleuchtung, Bifokalmodul und Multifokuselement, Einstellbarer Linienlaser, Schutzglasverschmutzungsüberwachung, LLK-Streulicht- und Kühlwassertemperaturüberwachung, Programmierbare Motorische Fokussierung (PMF) | Crossjet, camera monitoring, cartridge module, protective glass monitoring unit | 90° version, crossjet, MVE nozzle, shielding gas supply, bifocal module, camera monitoring, sensor interface, lighting, cartridge module, protective glass monitoring unit, power measuring cartridge, pilot laser, compensation cartridge |

The technical data of all product versions as a download.

BEO D25

BEO D25 are the smallest optics in the range and are best suited for laser welding applications with pulsed lasers. The robust design allows accelerations up to 15g.

Lasers: TruPulse

Laser power: max. 200 W

BEO D35

BEO D35 focusing optics are used for welding and cutting with pulsed or CW solid-state lasers (fiber and disk lasers) up to the kilowatt range.

Lasers: TruDisk, TruPulse, TruFiber

Laser power: max. 4 kW

BEO D50

With the new BEO D50 processing optics, TRUMPF has developed robust and compact optics which can be used up to a power of 8 kW. The crossjet function has been optimized and expanded to include new functions such as monitoring for gas, water flow, and temperature.

Lasers: TruDisk, TruPulse, TruFiber, TruDiode

Laser power: max. 8 kW

BEO D70

The robust, second generation BEO D70 focusing optics show their strengths during laser welding involving large working distances and small focal diameters. Gas-tight weld seams are possible thanks to the additional optional multifocus element for the optics. The smart monitoring functions further increase the safety and process stability.

Laser: TruDisk, TruFiber Multimode, TruPulse

Laser power: max. 24kW

BEO D70 swivel optics

The swivel optics consist of the focusing optics BEO D70 and the swivel module. The swivel optics are OEM-compatible thanks to a customer-provided, connectable drive and linking of the swivel module with your machine system. Depending on the design of the focusing optics, the swivel optics can be used for welding for 2D and 3D processing.

Lasers: TruDisk (1030nm), TruFiber, TruDiode, TruPulse

Laser power: up to 8 kW

CFO

With the controlled focusing optics of the CFO line, parameters which are relevant to the process, such as water temperature and shielding gas flow, are recorded at all points during processing. Complete with protective glass monitoring, these processing optics are particularly suitable for automated processes. There are numerous options available, for example: Crossjet, MVE nozzle (metal vapor effect), shielding gas supply, protective glass monitoring unit, power measuring cartridge or compensation cartridge.

Lasers: TruDisk, TruDiode, TruFiber, TruPulse

Laser power: max. 8 kW

RFO

The RFO high-performance mirror optics are optics for the lowest thermal shifts. They allow for consistent, reproducible application results, even with a high laser power.

Laser: TruDisk

Laser power: up to 16 kW

BEO ring optics

The focusing optics for simultaneous welding of plastics with ring focus is optimally suited for highly productive systems. The ring diameter is calculated by means of an assembly in the BEO modular system, in a customer-specific manner. This allows radial or axial weld seams to be achieved without moving the component or the laser beam.

Lasers: TruDiode

Laser power: < 1 kW

In addition to a range of processing optics, TRUMPF also offers you the right machines and beam sources. This allows you to find exactly the right combination for your application and requirements – all from a single source. When it comes to beam sources, TRUMPF offers all relevant lasers for the industry. You can rely on our experts, trust us to always have the best solution in mind for your production tasks, and know that we will advise you independently of any preferred technologies.

You can adapt your focusing optics to any job using the large number of options. You can also receive special optics for laser metal deposition with powder feed, or for linear laser spots.

The multifocus option for BEO D70 optics in combination with BrightLine Weld provides the innovative solution for media-tight weld seams. The laser beam is divided into four individual beam points on the workpiece. The result is a robust and stable welding process with improved weld quality thanks to fewer pores, spatter and crack formation. At the same time, you can make use of greater welding depth.

Laser: TruDisk

Laser power: up to 16 kW

The motor positioning of the collimator lens means that the focus point can be conveniently set in the Z direction. Modifications can be entered either directly by way of the laser control system TruControl or by way of an external machine control. Applications for which the focal position must be frequently changed can therefore be performed without additional effort.

The CCD camera monitors the process at the processing point, and enables convenient setup of the laser process. It is the basis for process monitoring.

Crossjet is a compressed air flow that runs orthogonally to the laser beam. It diverts contamination and spatter, extending the protective glass service life. The optics are more robust and the laser process is more reliable.

To make your welding process more efficient, you can add, in addition to the crossjet, the airflow from the metal vapor effect nozzle (MDE nozzle). The airflow keeps the metal vapor torch that arises while welding constant and therefore the energy brought into the material. This stabilizes the welding depth for precise laser processing. You also reduce your costs through a longer service life for your protective glass.

For high-quality welding results, a separate nozzle supplies shielding gas. This results in less oxidation of the weld seam. You can choose from various nozzles: aerator nozzle or linear nozzle.

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price, and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.

Footnotes-

Other wavelengths are available on request.

-

Other optics configurations are available on request.