TruMatic 5000 boosts productivity and part quality while reducing energy consumption // Fully automated material flow thanks to new SheetMaster

Blechexpo 2023: TRUMPF set to launch fully automated punch-laser machine for connected manufacturing

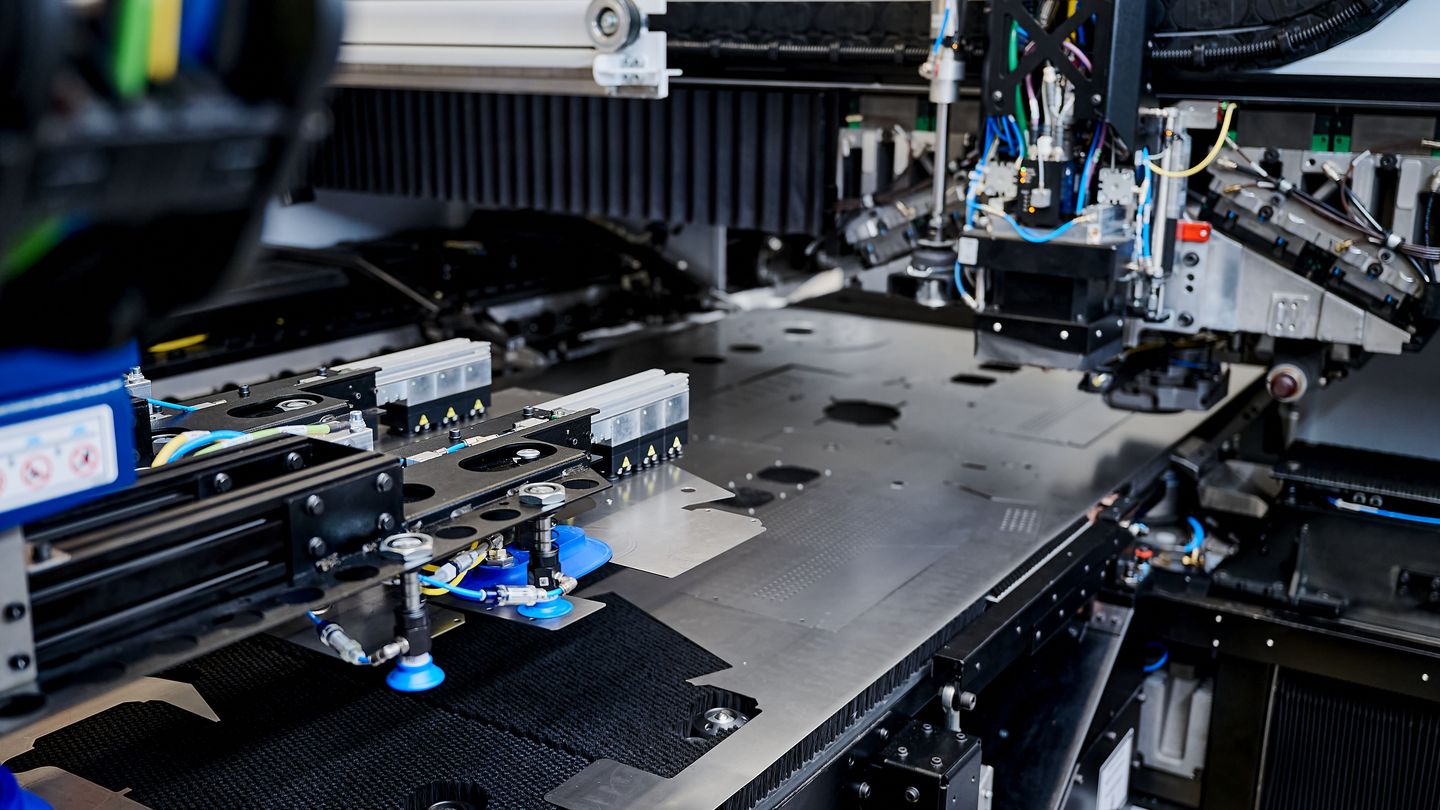

Ditzingen, Germany, October 17, 2023 – TRUMPF is poised to launch its TruMatic 5000 manufacturing cell with the new SheetMaster at Blechexpo in Stuttgart. Users of the new system will benefit from fully automated laser-cutting, punching and forming capabilities. The new SheetMaster enables a fully automated flow of materials within the manufacturing cell – from loading and unloading the machine to removing finished parts. “The TruMatic 5000 is yet another example of TRUMPF’s market-leading position in the field of connected manufacturing. This solution is designed to be seamlessly integrated in a self-contained smart factory, giving users efficiency gains along the entire process chain,” says TRUMPF product manager Steffen Wagner. TRUMPF’s new machine is equipped with a six-kilowatt fiber laser to maximize productivity. As well as saving energy, this laser also does an impressively fast job of cutting sheet-metal parts. The system comes with a descending die that prevents parts from being scratched during the punching process. The TruMatic 5000 punching head also comes with a patented TRUMPF electric drive known as the DeltaDrive, which uses around 30 percent less energy.

SheetMaster enables fully automated material flow

TRUMPF has fully automated the material flow in the TruMatic 5000. This improvement was made possible by the new SheetMaster technology, which uses grippers to handle parts in the manufacturing cell. The suction cups on the new SheetMaster’s grippers are monitored by sensors and can be activated individually. This makes gripper operation even more flexible, speeding up workpiece handling and saving valuable time, especially for smaller batches. In addition, the SheetMaster can be connected to an automated STOPA storage system which automatically supplies the manufacturing cell with raw material. The system also palletizes and sorts parts without human intervention. Further benefits of the new SheetMaster include its ability to eject cut and punched parts from the manufacturing cell. Parts can then be transported directly to the next stage of the process, such as bending, deburring or grinding. This reduces non-productive time and increases efficiency on the shop floor.

Maximum productivity for small batch sizes

The TruMatic 5000’s automation technology also includes the ToolMaster, a tool changer with up to 90 different tool cartridges that can automatically switch between multiple punching and forming tools. The ToolMaster enables users to produce small, high-mix batches of parts without having to manually retool the machine. Also included is an automatic nozzle changer with a nozzle inspection function. This prevents unscheduled stoppages during the night, for example due to a damaged nozzle. Blechexpo 2023 marks the commercial launch of the new punch-laser machine, which promises particular benefits for businesses that are keen to take their productivity to the next level through automation. It is suitable for companies that have already introduced connectivity to their shop floor, as well as those that are currently planning to do so. Typical areas of application include industrial kitchens, control-cabinet manufacturing and the furniture industry.

Digital photographs in print-ready resolution are available to illustrate this press release. They may only be used for editorial purposes. Use is free of charge when credit is given as “Photo: TRUMPF”. Graphic editing – except for cropping out the main motif – is prohibited. Additional photos can be accessed at the TRUMPF Media Pool.

連絡人