Lasers, optics, and sensor technology for the production of complex components // Increased efficiency from the very first component // Integrated quality control // Solution suitable for all industries

LASER trade fair: New TRUMPF solution boosts welding quality and efficiency

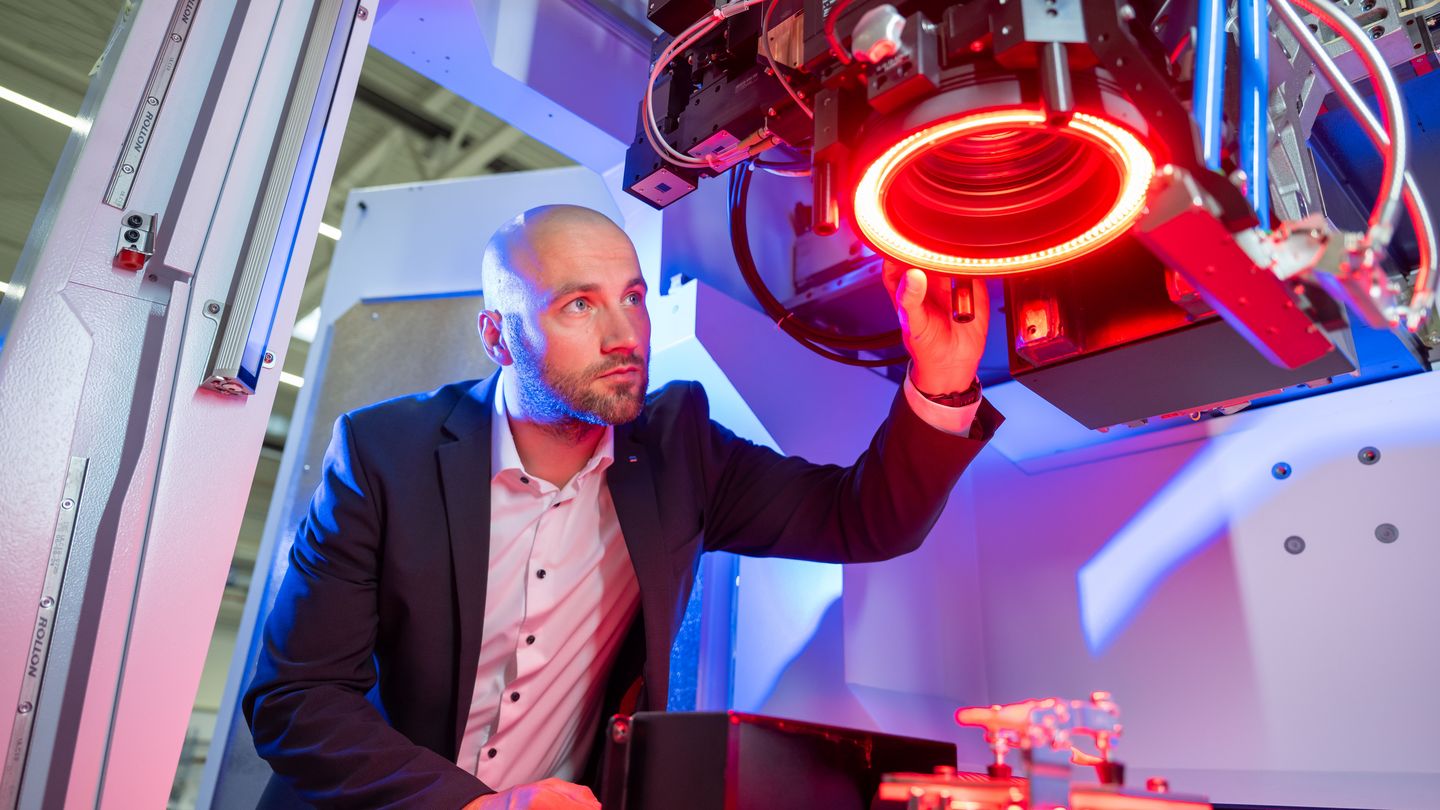

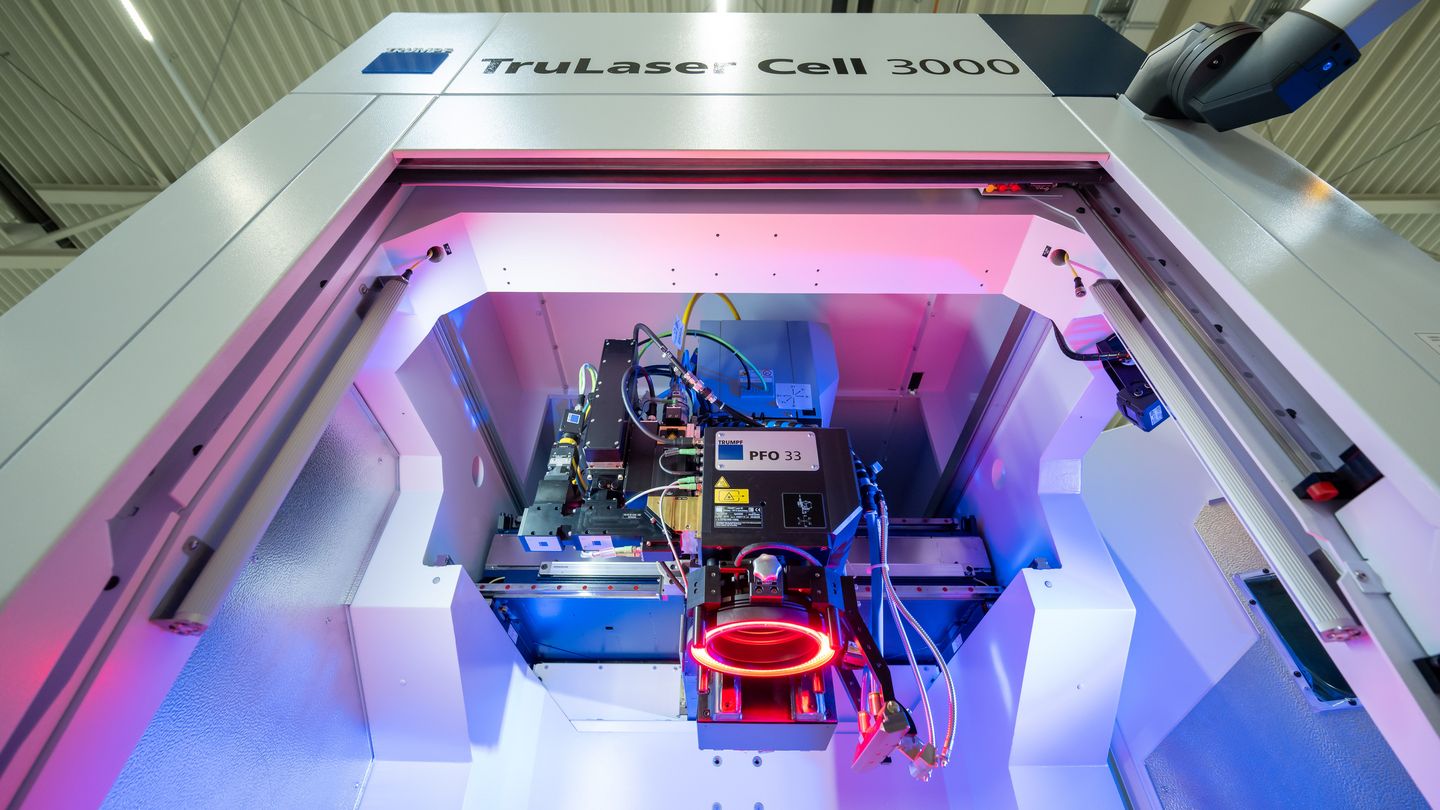

Ditzingen/Munich,24 June 2025 – High-tech company TRUMPF has developed a new system solution that enables users to increase the quality and efficiency of their welding processes. The solution combines several sensors that monitor all process steps during laser welding. An integrated AI quality control system checks the weld seams, for example, and OCT (optical coherence tomography) monitors the welding depth of the laser. "Our solution is unique on the market. TRUMPF offers all components, such as the beam source, sensors, and optics, from a single source. We also take care of installation, service, and programming of the system, which is tailored to the user. Our customers don't need any additional interfaces and don't have to coordinate with different suppliers," says Martin Stambke, Product Manager at TRUMPF. The high-tech company is showcasing the system solution at the world's leading trade fair, LASER – World of Photonics, in Munich.

Cost-efficient and powerful

The solution enables users to weld precision components that must be free of defects, such as batteries for electric cars or hairpins for electric motors. To ensure flawless weld seams, the user must set the optimum working distance between the various components and the laser. This is made possible by the programmable PFO 33 focusing optics, which can adjust the focus position of the laser independently. "This so-called 2.5D mode is more cost-effective in many applications than 3D mode, in which the PFO can still move up and down during the welding process. This is because less complex controls and programming, as well as fewer moving axes, reduce acquisition, operating, and maintenance costs for the user. In addition, it is faster for the optics to adjust the focus position themselves than to move the entire optics up and down in the laser cell. Our solution is therefore cost-efficient, yet powerful," says Stambke.

Better weld seam quality from the very first component

With integrated optical coherence tomography (OCT), users can not only monitor the welding depth of the laser, but also check the distance between the laser and the component. “This ensures the focus position of the laser and prevents welding errors,” says Stambke.

Moreover, VisionLine Inspect is used to check the quality of the manufactured components. A camera takes a picture of the weld seam and the system uses artificial intelligence (AI) to detect any potential errors. By combining AI preprocessing and conventional algorithms, TRUMPF creates traceability and transparency.

本新聞稿提供有數位版圖像,且其解析度適合列印。 該圖像的用途僅限於新聞編輯。如注明「圖片來源: TRUMPF」, 則可免費使用。不得對圖像進行任何改動,但裁剪主要場景除外。 如需更多圖片可造訪 TRUMPF Media Pool。

連絡人