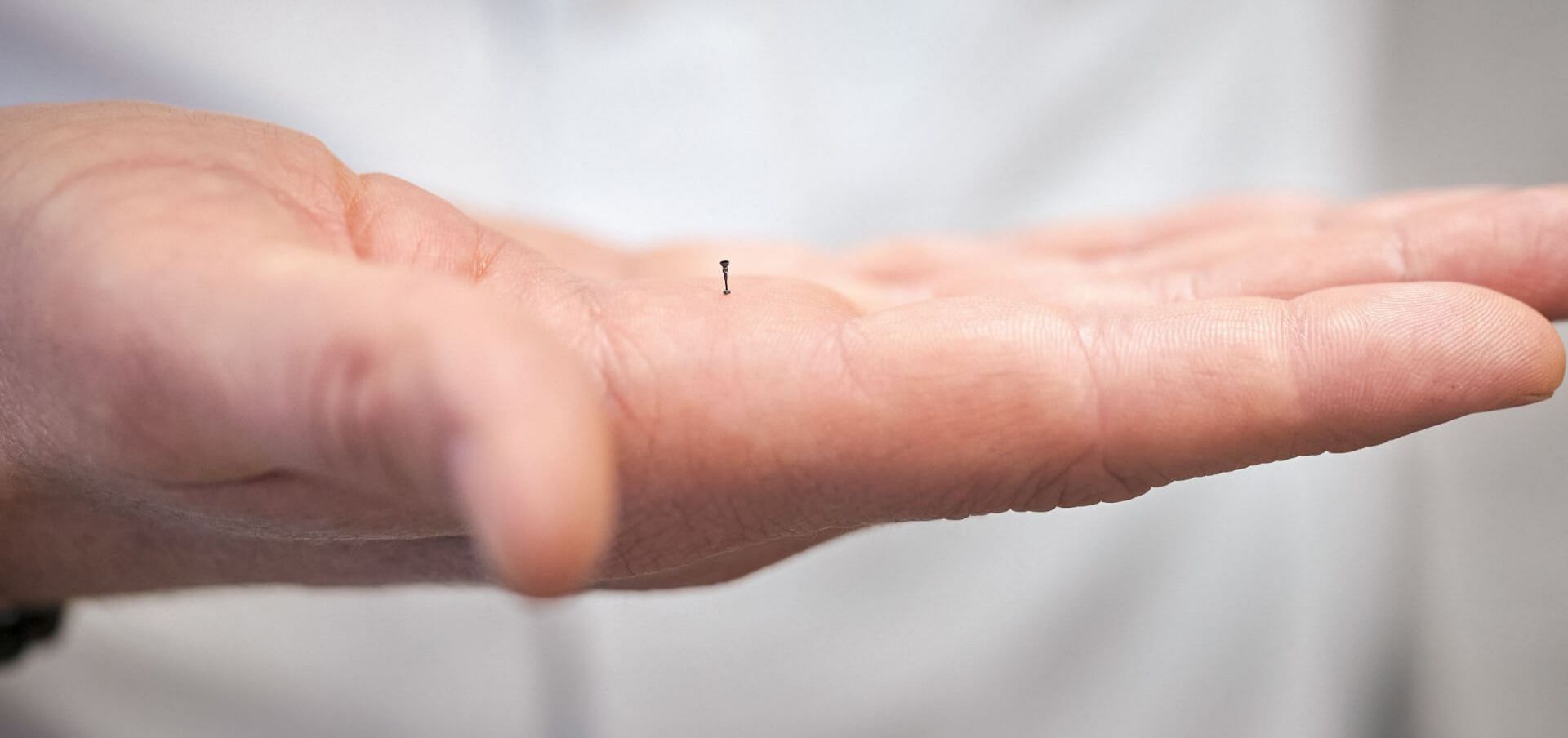

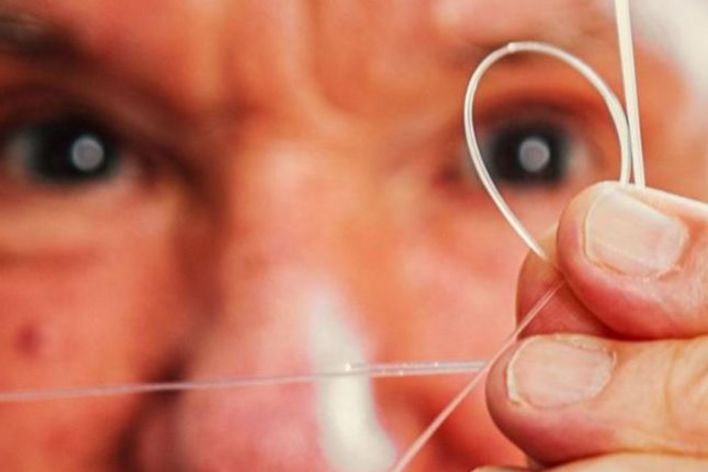

During turning, the workpiece rotates – and a chisel moves across its outline, cutting away material. The force exerted upon the component is known as “cutting force.” And this is what Lendner is interested in. GFH machines are not used to manufacture finger-sized valves or thick pistons. GFH builds microprocessing machines – and cutting forces have no place in the world of microprocessing. His customers want to produce tiny medical forceps that are just a few micrometers thick, stylish mini watch hands, or exceptionally fine electronic modules. If he were to start applying brutal cutting force, there would be a constant risk of rejects due to deformation. GFH machines therefore use lasers in place of mechanical machining tools for processes such as drilling, milling and surface finishing. But lasers aren’t suitable for turning. This gives rise to the age-old problem of mechanical tools in the microprocessing sector: “When the turning chisels become ever finer, they wear out very quickly, meaning that tools have to be constantly replaced,” explains Lendner. “What’s more, even the tiniest turning chisels eventually reach their physical limits.”

Therefore, Lendner and his team do exactly what they have been doing for the past 20 years: they think about how they can replace a mechanical tool with ultrashort pulse lasers (USPs). They have already achieved this feat in terms of texturing, cutting and drilling at micro level. But that’s not all: GFH brings together all three USP laser machining processes in a combined machine, meaning that the workpiece doesn’t even need to be re-clamped. Lendner is proud, but then a customer from the medical technology sector comes along and suddenly also wants laser turning.

A Second Wind

“The USP laser is a universal tool. Its light doesn’t touch the workpiece or heat it up. At micrometer precision, it removes precisely the material that we want to remove. So there shouldn’t be any reason why laser pulses can’t also be used for turning,” remarks Lendner.

But the reality proved to be harder than envisaged. Even the initial attempts performed on sample parts required the entire expertise and combined frustration tolerance of his team. Lendner: “I reached the point where I wondered whether all the hard work was even worth it. We therefore published the initial results in order to see whether anyone was even interested in laser turning.” The response was huge – and went well beyond the field of medical technology. “We saw that the demand was there and that we could really make a splash!” This energized the GFH team, who were given a second wind.

It Takes Two to Turn!

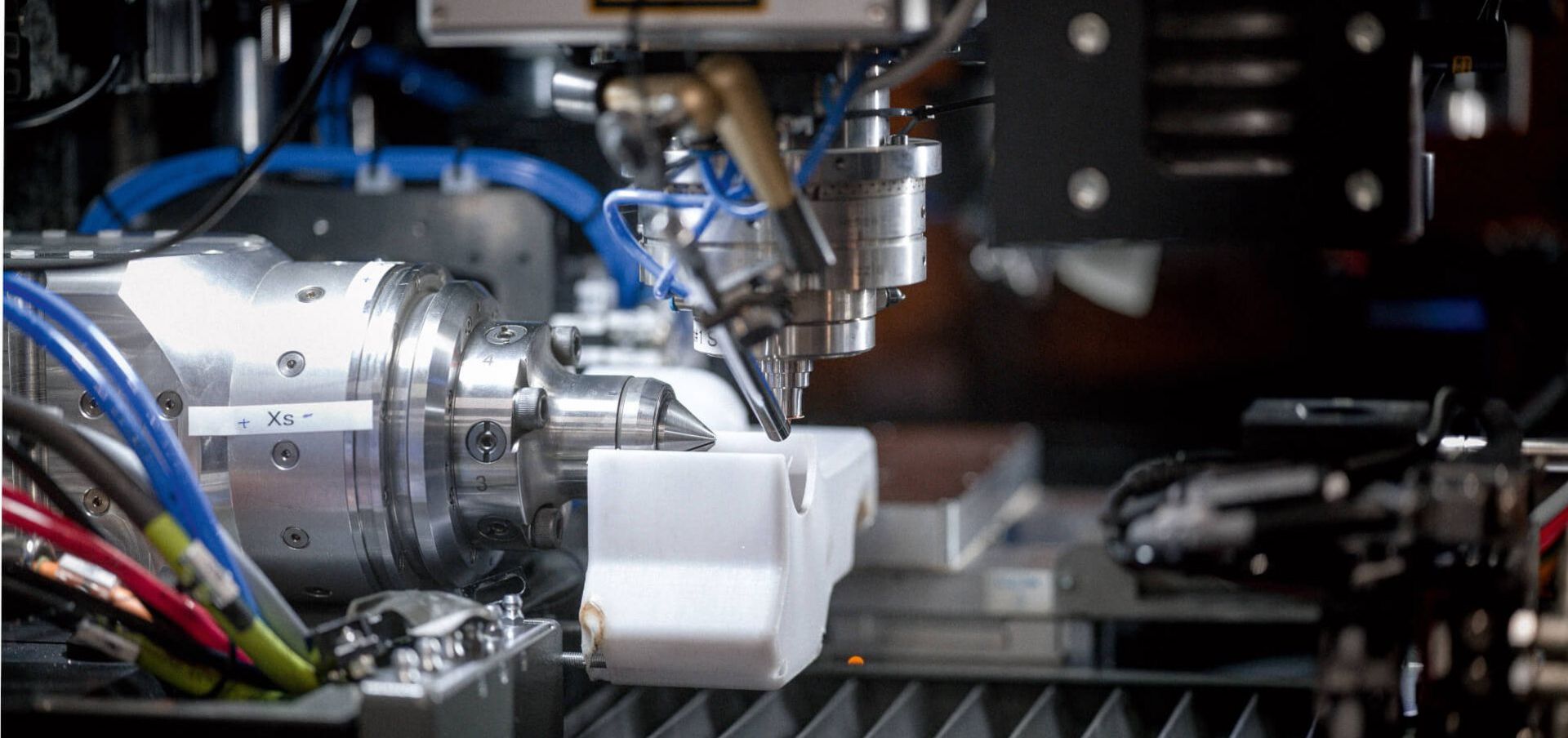

They needed this energy, as they still had many years of development ahead of them. The main problem was the processing speed. “When you have a rotating part, the laser only ever processes a narrow strip of the surface, i.e. the strip that is currently turned toward the optical element. Therefore, the key factor is how quickly the machine can rotate new, unprocessed sections of the surface into the light.” Thanks to a high-precision air-bearing rotation axis, the workpiece can reach up to 3,500 rotations per minute. Although this looks incredibly fast to the naked eye, it feels like tortuous slow motion to a laser that pulses at a rate of picoseconds. The laser can cut a line, drink one or two cups of coffee, read a book, take a lunch break, watch the director’s cut of the Star Wars trilogy and then see whether it’s needed again. “At this rate, material abrasion is quite simply too slow to be cost-effective.”

But the team then had a light-bulb moment: although all kinds of physical constraints apply to a rotating piece of metal, there are no such constraints on incorporeal light. With this in mind, the developers then started rotating the laser beam at lightning speed. When the beam is applied to the rotating workpiece, the processing speed is increased dramatically by means of contrarotation.

This fresh idea brings with it a third wind. The GFH engineers now utilize a trepanning optic that they had actually developed for a different project. At the heart of the trepanning optical unit are rotating cylindrical lenses, enclosed in an extremely finely balanced precision spindle. This unit allows the focus to circle the workpiece at up to 30,000 times a minute, firing off a lightning-fast salvo of ultrashort pulses. In the first step – rough machining – the light vaporizes as much material as possible, with considerable energy input. In the subsequent fine-machining stage (“finishing”), less energy is used and the final surface finish achieved. Mission “laser turning” has been accomplished.

Yet Another Triumph

The trepanning optic has even more up its sleeve. If a beam can come into contact with the surface from a variety of angles and circle the workpiece, it is also more effective at cutting and drilling at micro level. “We can now precisely determine the wall angles of cuts and boreholes – and even produce holes that dilate downward,” explains Lendner. “Try doing that with a mechanical drill!”

And the team’s euphoria hits new heights when it becomes clear that they – as secretly hoped – are able to process sapphire glass, ceramic and diamonds in next to no time. These are materials that have always offered stiff resistance to any mechanical ablation process – and that have finished off one tool after another. Lendner puts it in more matter-of-fact terms: “This demonstrates a key advantage of laser technology compared to conventional manufacturing processes: no strain on the workpiece, no wear and tear on the tool. This is what makes the technology so cost-effective.”

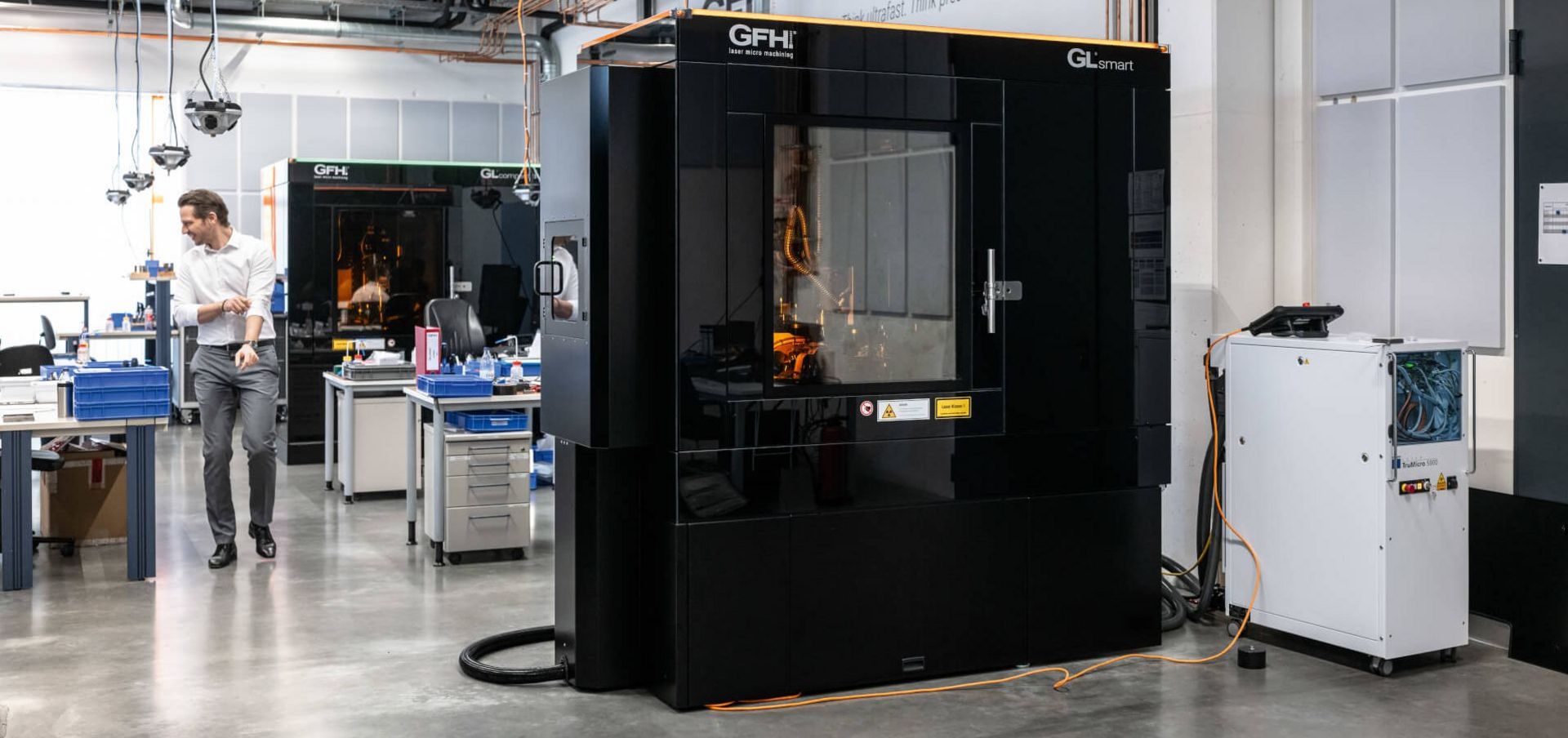

Since 2020, the GL.smart microprocessing machine has been in use at the sites of several customers, including in the medical technology sector (where the idea originated). It is the first laser system that combines all four machining processes at micro level: drilling, texturing, cutting – and now turning. “Well, you can’t really refer to it as ‘machining’ when you use ultrashort pulse lasers, but rather ‘vaporizing’ – but everyone knows what you mean,” says Lendner, with a beaming smile.