TRUMPF adds new features to its TruMark Series 6000 // TruMark 6030 offers outstanding productivity // Marking laser offers new features including 3D marking and an innovative image processing solution

TruMark Series 6000: Taking laser marking to a new dimension

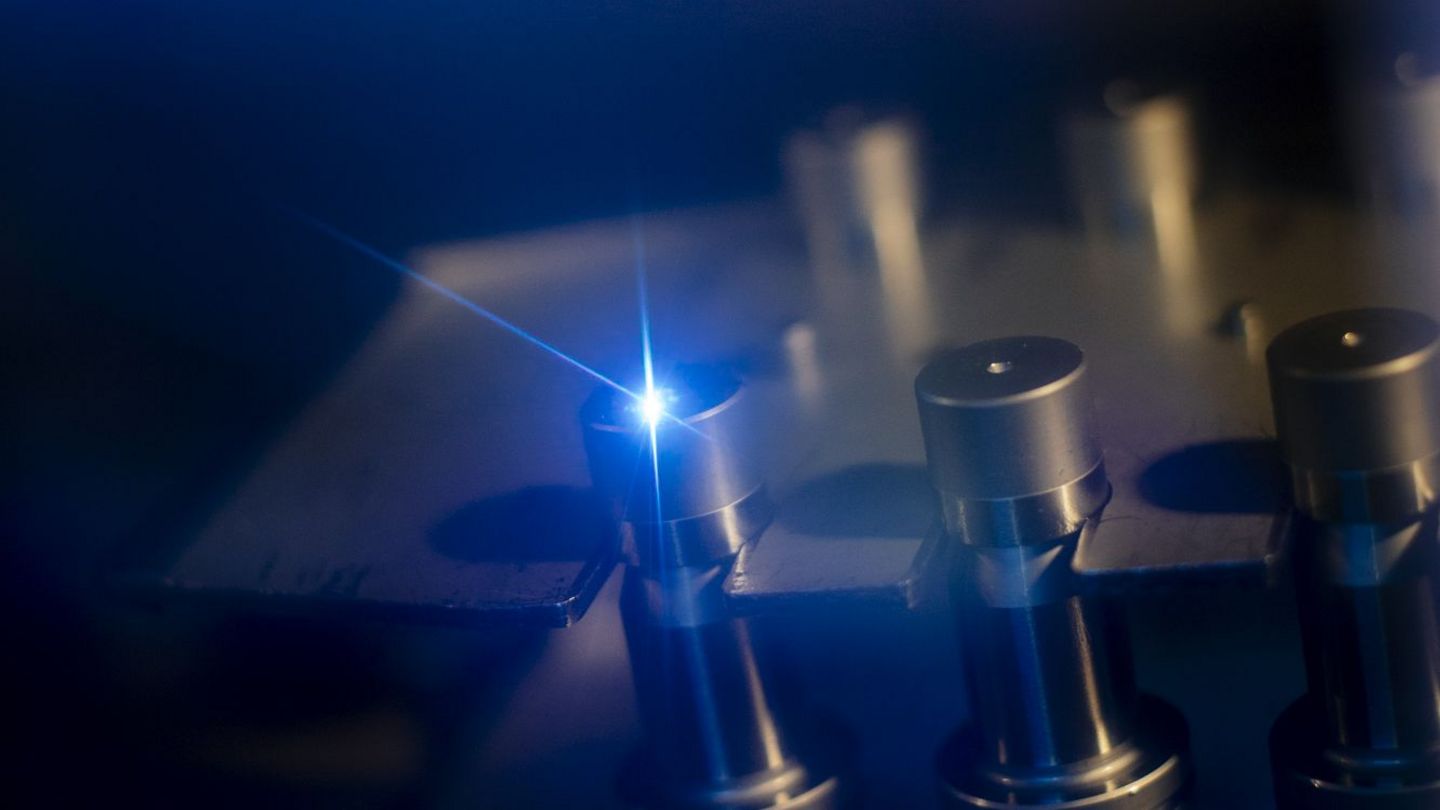

Munich / Ditzingen, June 26, 2017 – One of the most impressive features of the new TruMark 6030 is its ability to shorten process times by up to 25 percent. To achieve this, the TRUMPF engineers boosted the available pulse energy and increased the average power on the workpiece to 25 watts. They also equipped the marking laser with a new Yb beam source for the very first time. This offers outstanding beam quality and high power densities, enabling the laser to achieve clean ablation and high-contrast marking.

Better marking thanks to efficient scaling

The output of the TruMark 6030 can be precisely scaled across its entire operational range without varying the laser properties. The intelligent system measures the pump and laser output inside the laser, and a power controller ensures that the marking laser is always operated at the desired output. The fact that every marking laser has the same performance curves makes it easy for users to add a second production line, safe in the knowledge that the marking results will be completely identical right from the start and will remain constant even after producing several million parts.

A new dimension

Marking 3D parts previously required the use of indirect methods. But the new TruTops Mark 3.0 marking software makes life much easier for users. Based on the fully-featured 3D CAD marking system, the new TruMark 6030 is now perfectly capable of dealing with 3D surfaces on complex parts, all thanks to its ability to shift the focus point along the z-axis by up to 50 millimeters. Power densities remain just as high during this process, with no change in the laser parameters. As well as full 3D support, the new marking software also offers intuitive operation and a modular configuration.

The perfect perspective on the process

Thanks to the VisionLine image processing software, the system can look through the lens directly at the marking process, enabling even greater precision. It identifies the actual location of the part based on defined contours and automatically keeps the marking content in the correct position. It can also detect the workpiece surface and set the correct working distance using the autofocus function. VisionLine can scan Data Matrix codes, assess their quality, and document the results.

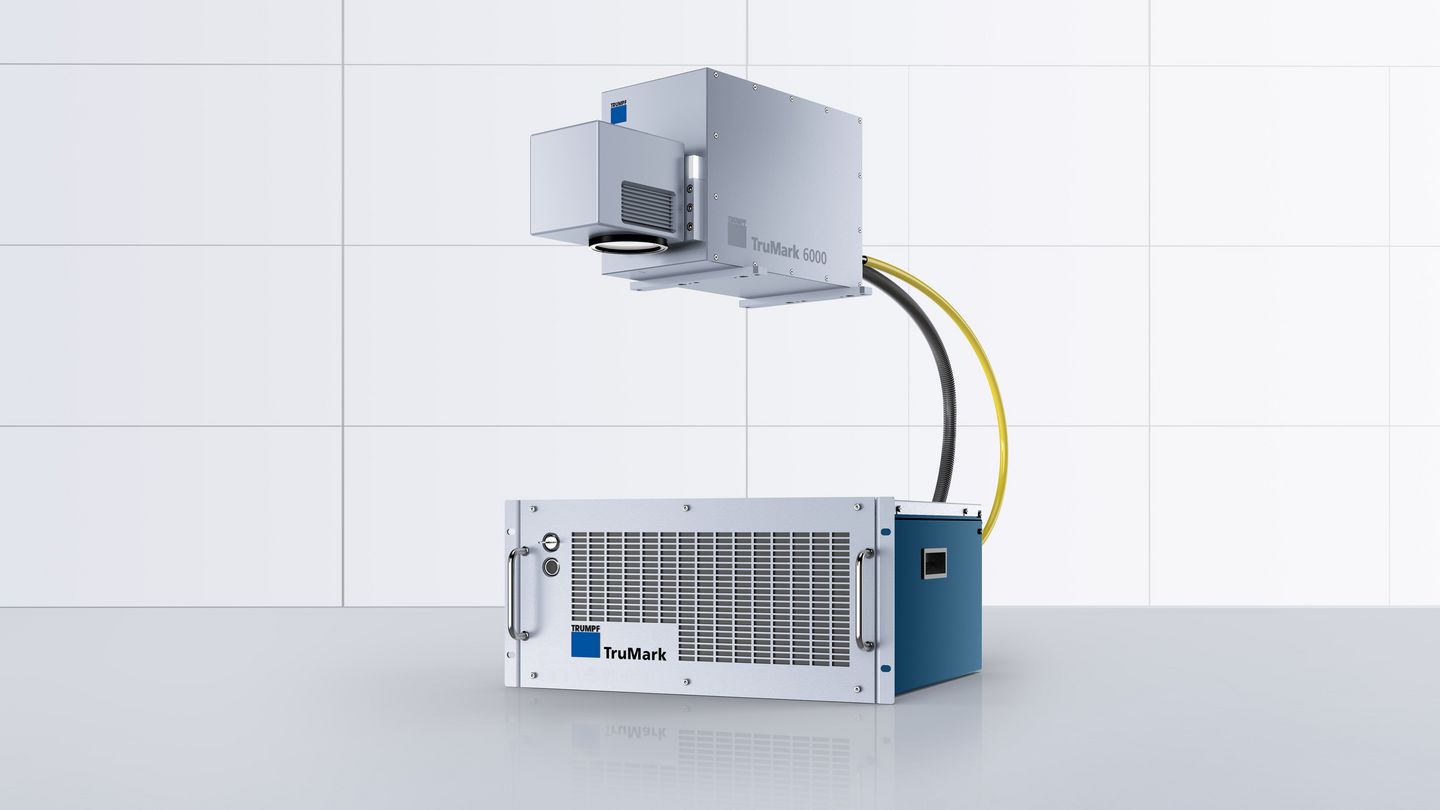

Get started immediately with “plug-and-produce”

It couldn’t be simpler to integrate this next-generation marking laser. The compact supply unit has the standard dimensions of a 19-inch rack so it fits easily in any cabinet. The connection cables are six meters long, providing plenty of leeway for installation. At the same time, the removable plug connectors on the laser head offer the welcome simplicity of “plug-and-produce”, making it easy for users to integrate the laser, get it up and running fast, and start processing materials.

Integration is made even simpler thanks to a range of interfaces such as I/Os and a plethora of fieldbus protocols such as Profibus and EtherNet/IP. Once again, the software provides comprehensive support to users, ensuring that the integration process runs smoothly and quickly. With its special sensor system and interfaces such as OPC/UA, this new marking laser can also supply process and laser data, making it the perfect choice to handle future Industry 4.0 requirements. The TruMark 6030 is compliant with Performance Level “e”, which means it meets the highest machinery safety standards. That makes it a robust addition to any process chain in which reliability is paramount.

A robust system that offers high availability

Based on cutting-edge production engineering, the new TruMark Series 6000 offer users a truly robust marking system that can comfortably accelerate the processing head up to 2g. In combination with the other high-performance optical components of the laser, such as the pump diodes, this new system ensures high availability, making it an economical choice for a wide range of different tasks.

Digital photographs in print-ready resolution are available to illustrate this press release. They may only be used for editorial purposes. Use is free of charge when credit is given as “Photo: TRUMPF”. Graphic editing – except for dropping out the main motive – is prohibited.

Persoană de contact