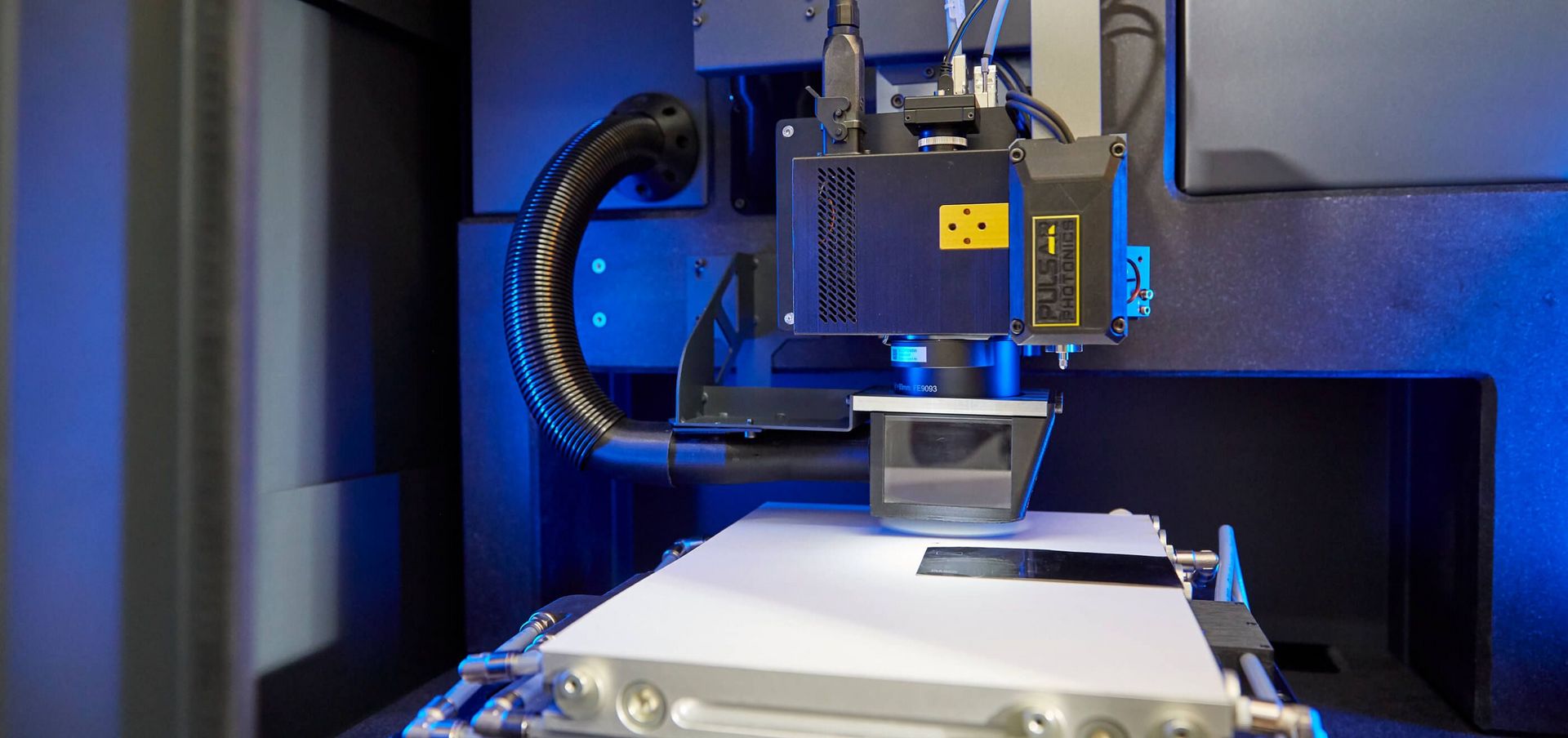

The machine operator carefully positions a blank approx. 20 x 30 cm in size in the working area of the RDX 500 microprocessing machine, and the vacuum chuck applies gentle suction to fix the blank in place. The machine’s motorized axis system can position parts with an accuracy of 300 nm and repetition accuracy of ±100 nanometers, and it aligns the blank so that the built-in camera system can see its top-left corner.

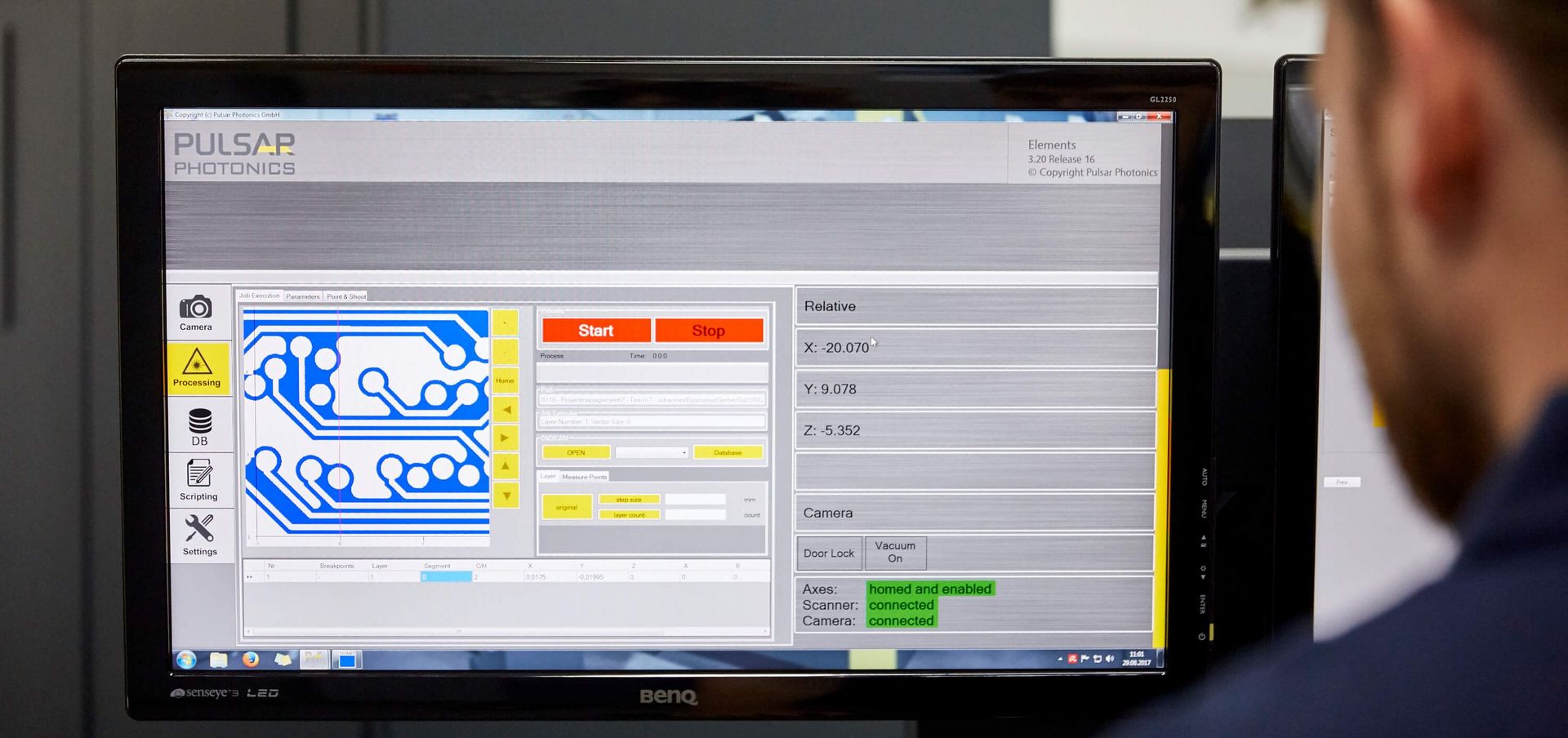

Next, the operator launches the software assistant and hands control over to the program. The software scans the blank’s registration marks to determine its precise alignment and ensures it is in exactly the right position, because even the tiniest deviations can have major repercussions on a micrometer scale. The software assistant carries out whatever adjustments are required without any input from the operator – and the TruMicro 2030 ultrashort pulsed laser from TRUMPF starts doing its job.

Reducing complexity

The user-friendly software assistant was developed by Pulsar Photonics GmbH, which was founded in 2013 as a spin-off from the Fraunhofer Institute for Laser Technology ILT. The company specializes in building systems for laser micromachining, focusing in particular on ultrashort pulsed lasers. It develops suitable systems technology for each customer, and offers tailored application development and contract manufacturing services. Founders and managing directors Joachim Ryll, Stephan Eifel and Jens Holtkamp knew right from the start that ultrashort pulsed laser technology would never gain widespread acceptance unless they could get simplify matters.

So, when a request came in from a manufacturer of high-power electronic systems, they seized the opportunity to show how even the most complex manufacturing methods can be simplified if you know enough about the processes involved. Ryll explains: “When it comes to producing components for high-power electronic systems, you might have a machine operator who specializes in each individual stage of component production, but we can’t expect them to be an expert in every machine in the entire process.”

The customer wanted a compact machine system with a fast, high-precision processing technique to facilitate the laser machining of printed circuit boards (PCBs). One of the key requirements was that the process needed to be user-friendly – something of a challenge when you are performing micro drilling, laser ablation and precision cutting in a single operation on both the front and back of the PCB!

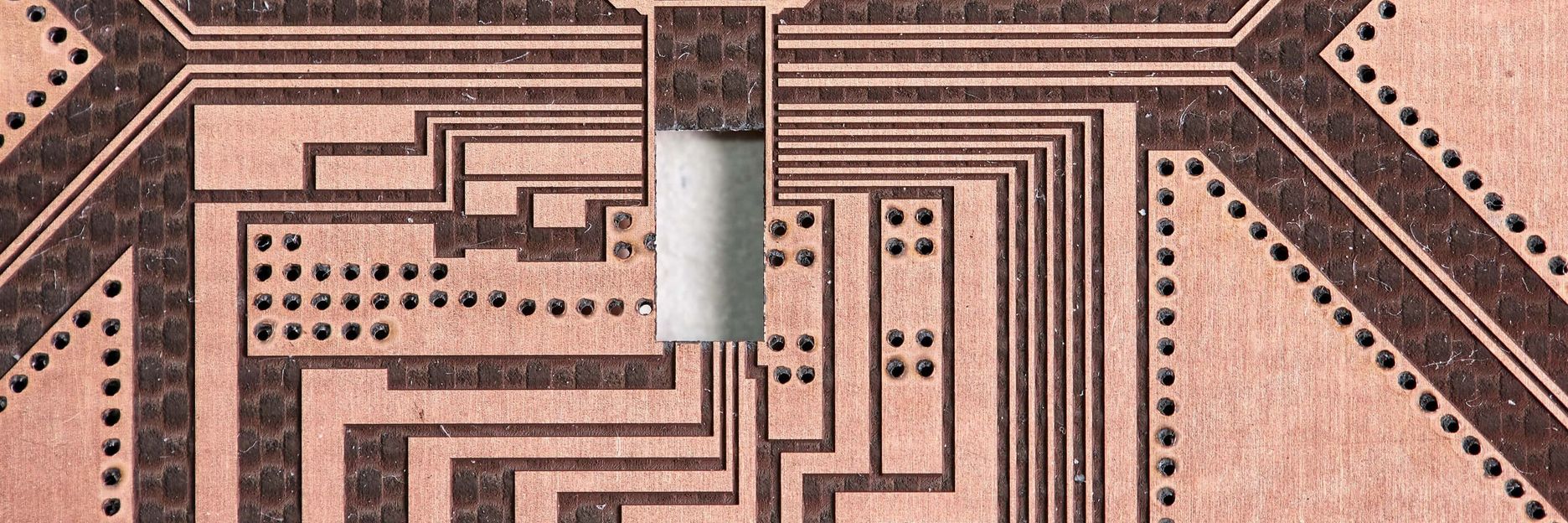

The blank used to make the PCB consists of a copper-plastic-copper composite. One example of the specified machining processes involves turning the blank into 50 PCBs for high-frequency electronic systems known as interposers. Each interposer measures five by five millimeters and is subsequently used to adapt the tiny conductive tracks of an integrated circuit to PCB fabrication technology.

In the first step, a TruMicro 2030 with a pulse duration of 900 femtoseconds drills plated-through holes, or “via holes,” in the blank. These holes act as interlayer connections, enabling the conductor paths to extend in three dimensions across multiple layers. At the same time, they serve as a means of fixing the integrated circuit in place on the PCB.

In the next step, the laser uses ablation to create fine conductive tracks in the copper. The USP laser takes advantage of a technique known as cold ablation to ensure that the inner plastic layer of the blank is not damaged in this process. The laser also offers the required level of precision. This is important because failing to properly ablate the gaps between the conductive tracks could result in a flow of electricity that would impair the entire unit. Finally, the component is flipped onto its back. The camera detects the registration marks and the system once again automatically aligns the component to enable the laser to machine the other side of the blank.

At the end of this process, the TruMicro 2030 cuts the individual circuit boards out of the base plate. Conventional methods of manufacturing printed circuit boards generally employ longer pulsed nanosecond lasers. “That wasn’t an option for our customer because it didn’t meet the requirement for high resolution. The only way to reliably produce conductive tracks up to 50-100 µm wide is by using a USP laser,” says Ryll.

Thinking in layers

The software specialists from Pulsar Photonics started by getting to grips with the Gerber format, the standard file format for PCB fabrication. The Gerber format is used by CAD systems to output PCB fabrication data, which is then transferred into the CAM system to generate the parameters for each individual step in the process. Just like the PCB itself, a CAM file consists of multiple layers. From drilling and ablation to plated-through holes, each step in the process has its own layer with specific process parameters. “We had to start by acquiring the necessary expertise on the Gerber format, because it is specific to the electronics fabrication industry, and that was uncharted territory for us,” says Ryll.

And there were more challenges ahead for the software and process experts at Pulsar Photonics. The next task was to meet the customer’s requirement that the highly complex application should be simple enough to be used by virtually any machine operator who has experience in CNC machining – and the solution they came up with was quite remarkable. The software system guides the operator through the manufacturing process with just a few prompts for confirmation. There is no longer any need for the operator to enter any laser parameters because these are already integrated into the software and can simply be obtained like the ingredients for a meal. “We tried it out with some students and all of them learned how to use it within 15 minutes,” says Ryll with understandable satisfaction.

Perfectly integrated

Pulsar Photonics was able to supply exactly the right machine for the job in the form of the RDX 500. This compact, modular system has been specifically designed to tackle the challenges of laser micromachining. Its precise axis systems facilitate highly accurate component loading, while a camera system and sophisticated sensor system make sure the process runs smoothly and reliably. When it came to finding the right laser, the TruMicro 2030 from TRUMPF was the obvious choice. “Lasers are one of the bought-in parts of our systems, and the choice of manufacturer depends on the application in each case. On this occasion our top priorities were the stability of the laser and how easily it could be integrated into the system,” says Ryll. He was particularly impressed by the process speed of the TruMicro 2030 on a visit to the TRUMPF Application Center: “It makes our system much faster than with the picosecond laser we tested previously.”

In late August, the RDX 500 was delivered to the customer, marking the end of a development process that had taken some 26 weeks. The machine is now busy fabricating PCBs in small and medium-sized batches ranging from just ten pieces to several thousand for end customers from sectors including broadband communication, aerospace and the auto industry. The team of USP laser experts at Pulsar Photonics met all the customer’s requirements, plus they demonstrated once again how you can make this complex technology remarkably user-friendly by choosing the best ways to connect and control the individual components and combining them with intelligent software.