TRUMPF integrates an additional process step in its tube-cutting machines // The TruLaser Tube 5000 adapts to the individual production material flow

The new TruLaser Tube 5000 now also creates threads in tubes

Ditzingen/Düsseldorf, April 16, 2018 - Two in one: the new TruLaser Tube 5000 integrates the tube and thread cutting processes in one machine, saving time and logistical effort in production. The configuration of the new machine is as versatile as its applications and can be individually tailored to the production material flow.

Cutting threads in thin- and thick-walled tubes

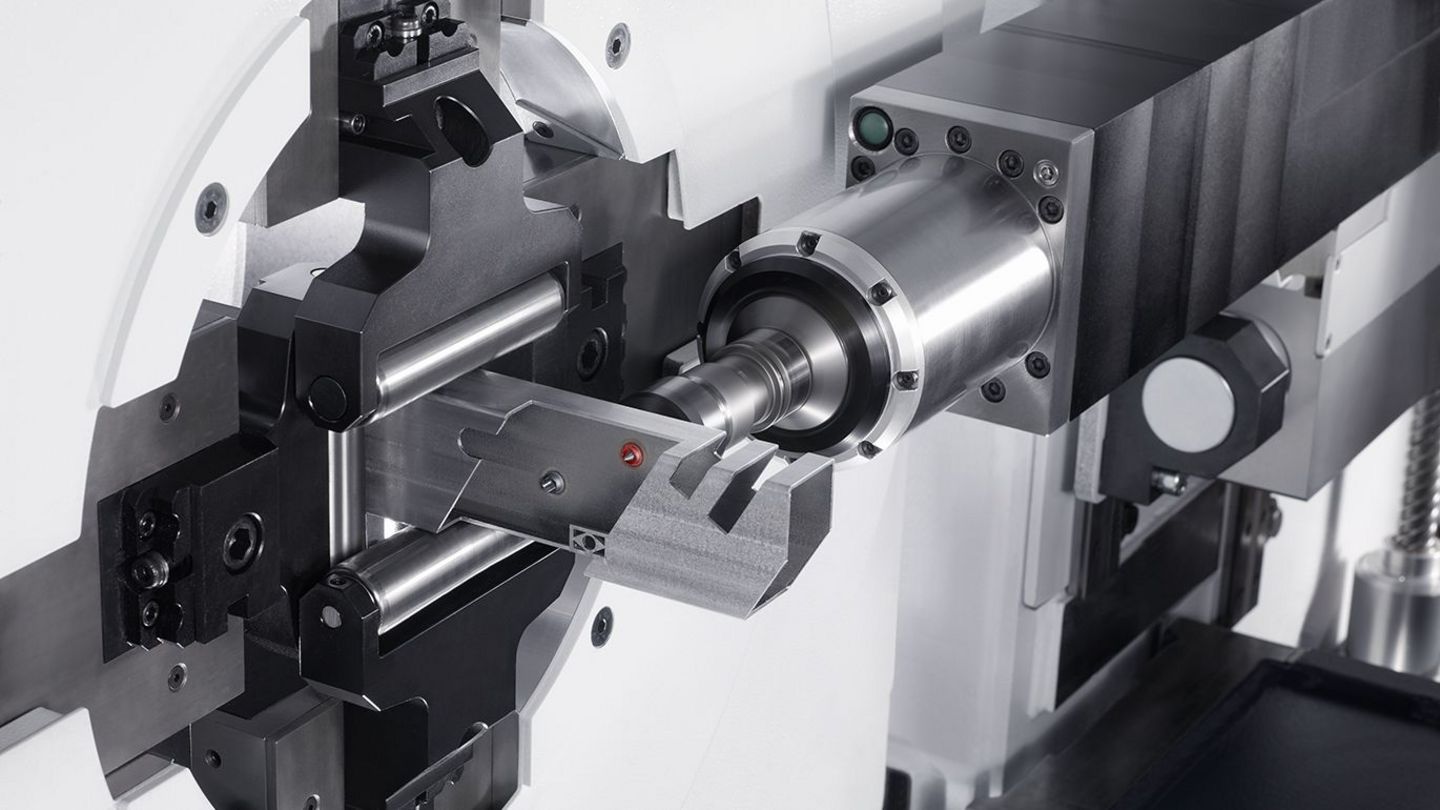

Laser tube processing has long since replaced conventional methods such as drilling, sawing and milling. But whereas threads were previously cut in the tubes at a separate processing station, TRUMPF has equipped the new TruLaser Tube 5000 with a four-position tool changer and a spindle that allows the machine to produce threads in thin- and thick-walled tubes. Since thin-walled tubes often do not have enough substance material, threads are not only cut and formed, but also produced by flow drilling. This technique is particularly suitable for tubes with wall thicknesses of one to three millimeters. In the first machining step, the flow drill produces an extrusion in which, in the second step, a heavy-duty thread is cut. Integrating this process step in the machines ensures that the threads are cut in the right place. In addition, it minimizes logistical effort for the company and significantly reduces throughput time. Sensors monitor the process and alert the operator when a tool breaks, for example. And the physical strain on operators is reduced particularly when working with heavy tubes, as they no longer have to carry the tubes to a separate processing station.

Flexible machine configuration

Material flow varies from one production to the next. The TruLaser Tube 5000 takes this into account. For instance, users can feed in material directly from the warehouse: the optional LoadMaster Tube automated loading system can be equipped with an extended conveyor path that supports such alternative loading routes. The unloading side offers the same flexibility, eliminating the need for conveyor tables to transport parts out of the machine, since the machine can unload parts directly into wire mesh boxes.

Powerful laser and user-friendly design

The TruLaser Tube 5000 cuts tubes measuring up to 152 millimeters in diameter with wall thicknesses of up to ten millimeters. Its new clamping range automatically adapts to different profile and pipe geometries with no tooling required. The machine is equipped with TRUMPF's own TruFlow laser with 2.0, 2.7 or 3.2 kilowatts of laser power. This CO2 laser produces high-quality edges even in thick-walled pipes, and a large viewing window ensures that operators have a clear view of the machining process. Access to the loading and unloading sides of the machine is barrier-free, simplifying manual loading for the occasional production of single parts, for instance. A large, swiveling 17-inch touchscreen makes it easy to operate the machine, and users can quickly call up information on the user-friendly control panel specially developed by TRUMPF for laser tube cutting machines.

Contato