The Industry 4.0 provider AXOOM is covering an ever wider spectrum, with new offers especially for machine manufacturers. At the Euroblech 2016, the eponymous business platform opened the new AXOOM IoT business area, simultaneously presenting further solutions for manufacturing companies.

AXOOM is paving the way to the Internet of Things for machine manufacturers

Hanover / Karlsruhe, October 26, 2016 – AXOOM IoT is the direct route to the Internet of Things (IoT). Providers are given an easy way to connect with their machines, components and sensors – worldwide. This allows them to react quickly to problems, optimize production processes, actively initiate updates and maintenance work and significantly reduce operating costs. The products are easy to use, modular, scalable for real-time analysis of live data from the production environment – and can be used directly thanks to a Starter Kit.

“Machines from various manufacturers can be connected to our platform. On the one hand, this enables machine manufacturers to communicate with all devices in the field and thereby offer better services; on the other hand, users in a manufacturing company receive a complete digital representation of their production halls,” explains managing director Florian Weigmann. "We are connecting two worlds and optimizing information flows between machine manufacturers and the production industry.” With AXOOM, digital services and apps can be created in next to no time – and this opens up new business models. Machine digitization and connectivity give both the manufacturer and the end-user clear added value.

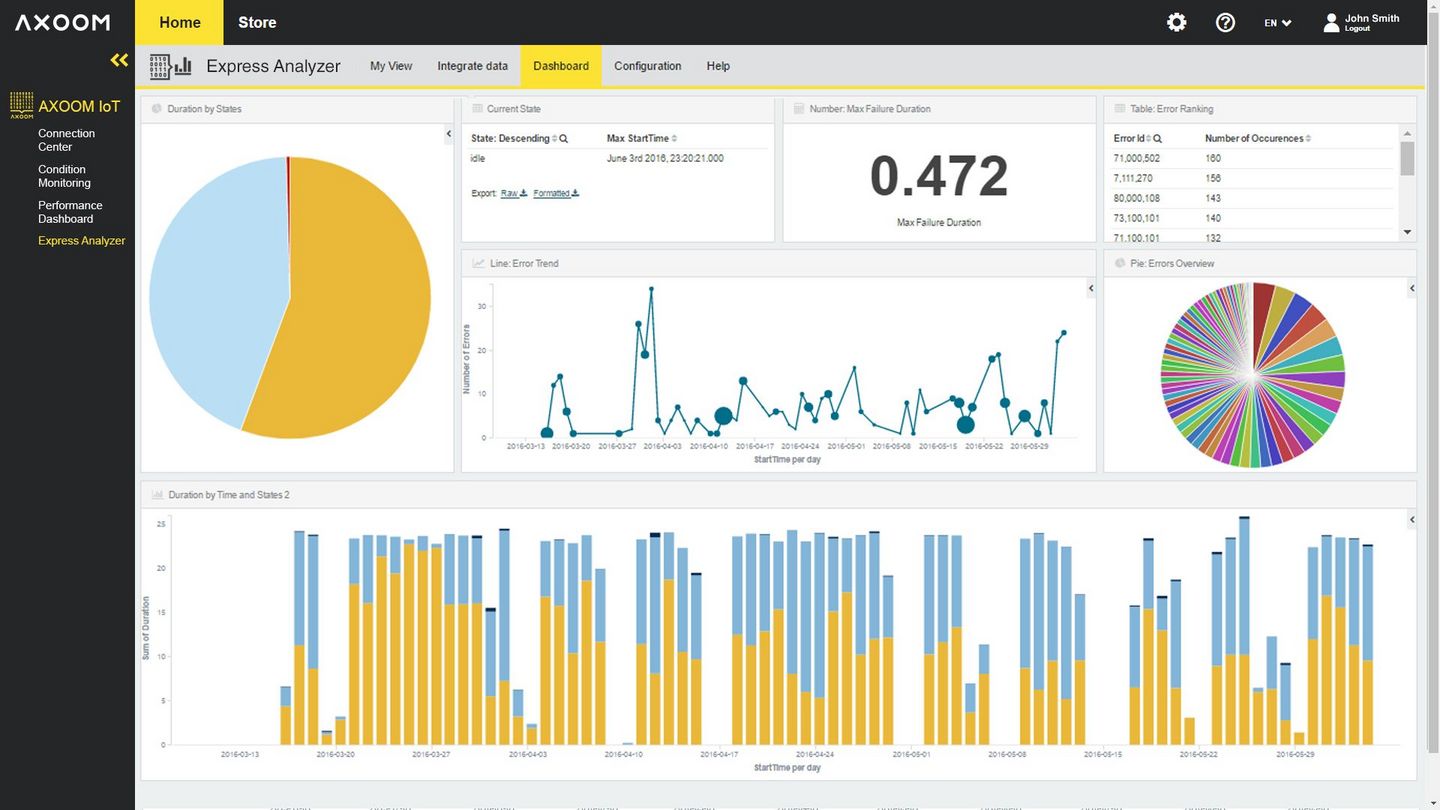

The AXOOM IoT solutions are currently divided into four areas. The Connection Center helps machine manufacturers to connect and manage their devices in the field, in order to improve availability and support. This reduces expensive downtimes for their end-customers. The second area, Condition Monitoring, also offers significant advantages: live status monitoring makes production processes more transparent and predictable for end-users, and machine manufacturers can automatically monitor the behavior of their machines and components. The third area, Remote Services, provides proactive software and machine updates to reduce maintenance costs, and enables configurations, software updates and bug fixes to be carried out remotely. The fourth area, Analytics, provides valuable insights: the analysis of the collected data can help to significantly increase productivity. Machine manufacturers are able to analyze the performance of their plants under real production conditions, and to use the results obtained for product optimization.

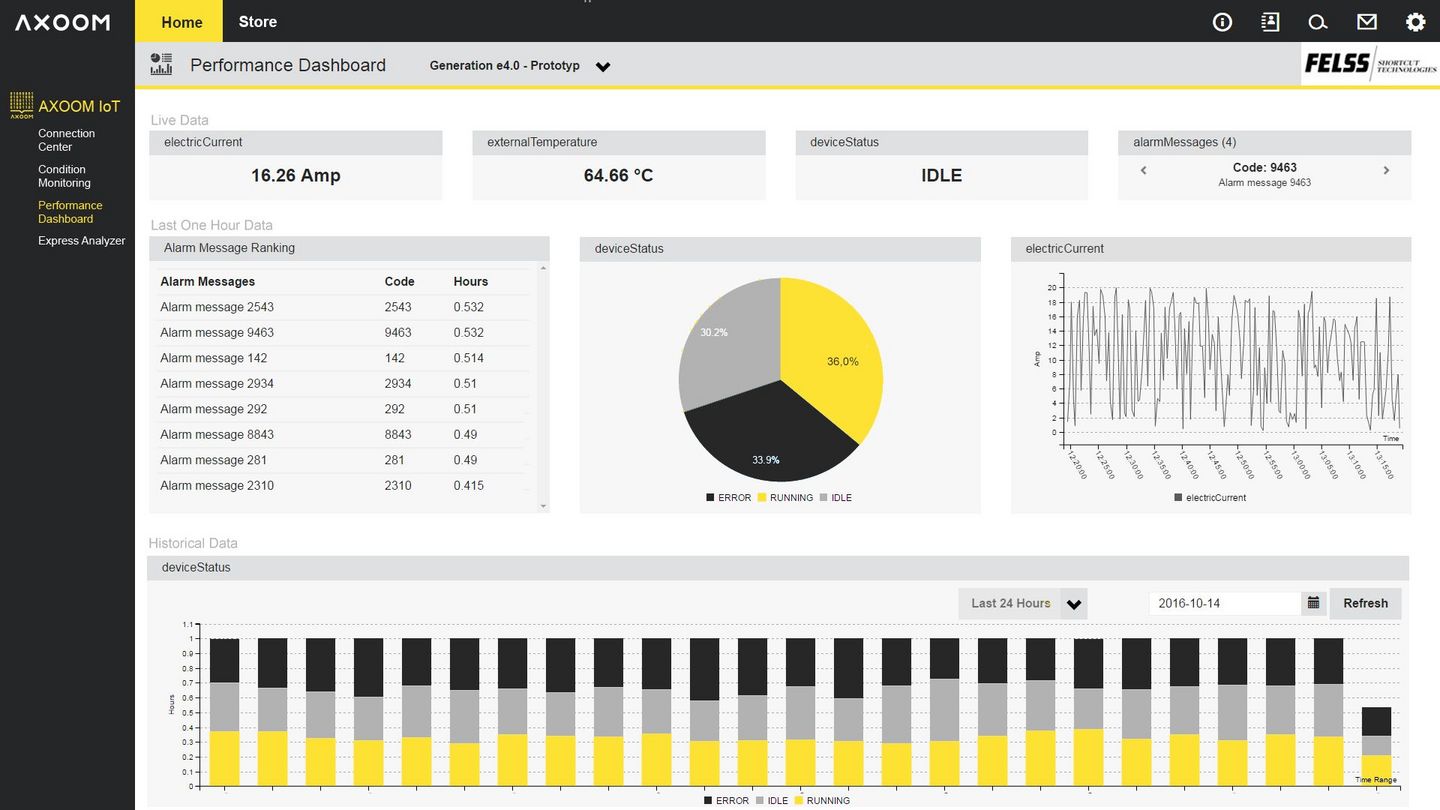

Machine manufacturers can supply their end-customers with data from all these areas in the form of apps. For example, the dashboard templates offered by AXOOM support the quick and easy development of a Performance Dashboard app, enabling machine manufacturers to provide their customers additional benefit in a short amount of time.

Easy entry and maximum data security

For prospective customers, AXOOM offers a special 'AXOOM IoT Starter Kit' for up to five machines. Users can then test for six months at a low price. The offer includes the Connection Center for networking, the Performance Dashboard for machine analysis, and the Condition Monitoring function.

AXOOM attaches great importance to transparency: all involved parties always know where the collected and analyzed data comes from and how it will be used. While the product offerings very quickly reveal numerous potential improvements, manufactures and end-users alike directly recognize the added value derived from the mutual availability of the data. Data is only gathered when a customer has agreed to its collection and actively allowed the data to be used for optimization purposes. This prevents unauthorized access to sensitive company data. If the AXOOM Factory Gate is used as the communication tool for data transmission, the data are transmitted using a level of security that has not yet been reached by many companies.

One of the first partners for the new IoT platform offer from AXOOM is Felss Systems GmbH. The IT specialists from AXOOM have developed for Felss a special dashboard for the Felss company’s rotary kneading machine generation e4.0. Felss CEO Thomas Peter: “We were able to present the Performance Dashboard at the Euroblech for the first time. For us, this solution means service in real time with maximum efficiency.”

The success story continues – with new and powerful apps

Since its founding one year ago, AXOOM – a company of the TRUMPF Group – has been moving forward. In addition to the new IoT solutions, during the summer the Industry 4.0 vendor also launched the AXOOM Store, where users can find a range of powerful apps for use in production environments. This is the basic concept behind AXOOM: an open business platform with integrated and fully interconnected applications for the manufacturing world. There are currently inquiries from more than 300 potential partners. AXOOM is having concrete discussions with about 70 of them for apps or other forms of collaboration, such as implementation services around AXOOM or sales partnerships. The range on offer in the AXOOM Store includes a Linde app that monitors gas-tank filling levels online, an app from Klöckner for ordering steel as production material and an app from VKS (Visual Knowledge Share) enabling the easy creation of work and assembly instructions.

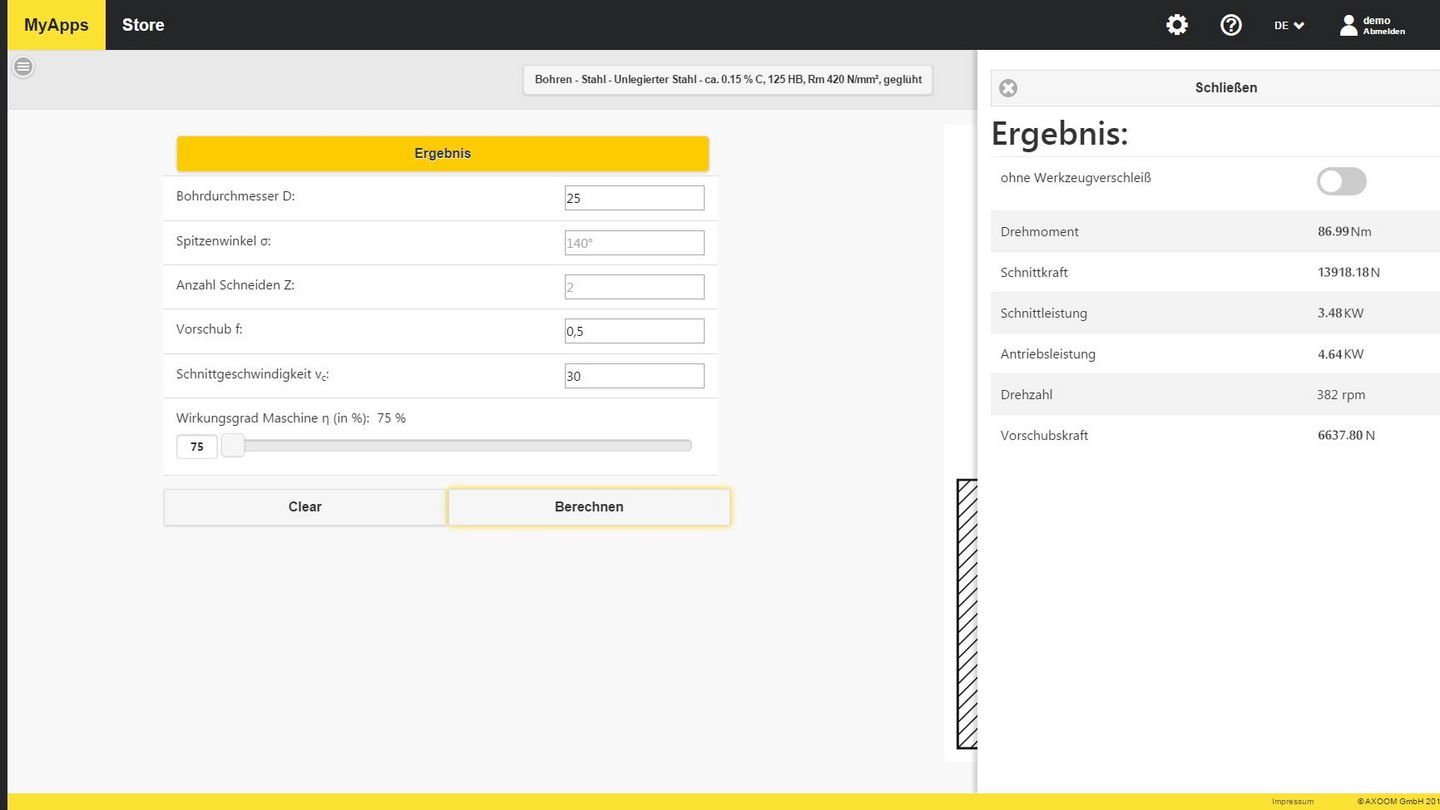

At the Euroblech, AXOOM also introduced several new apps. The precision tool manufacturer Gühring, for example, has introduced an application for the calculation of cutting forces. The easy-to-use solution helps the user to determine the cutting force, torque, feed, speed or cutting performance values of his machining tasks. The user selects the material to be machined and enters various processing parameters. The app displays economical solutions for drilling, milling, turning, tapping and drilling. “Thanks to the cooperation with AXOOM, we can offer cutting-edge manufacturing companies a range of innovative, digital services, so that they can make their daily work more efficient,” explains Dr. Stefan Heizmann, CIO of the Gühring Group.

Clever maintenance with cloud support

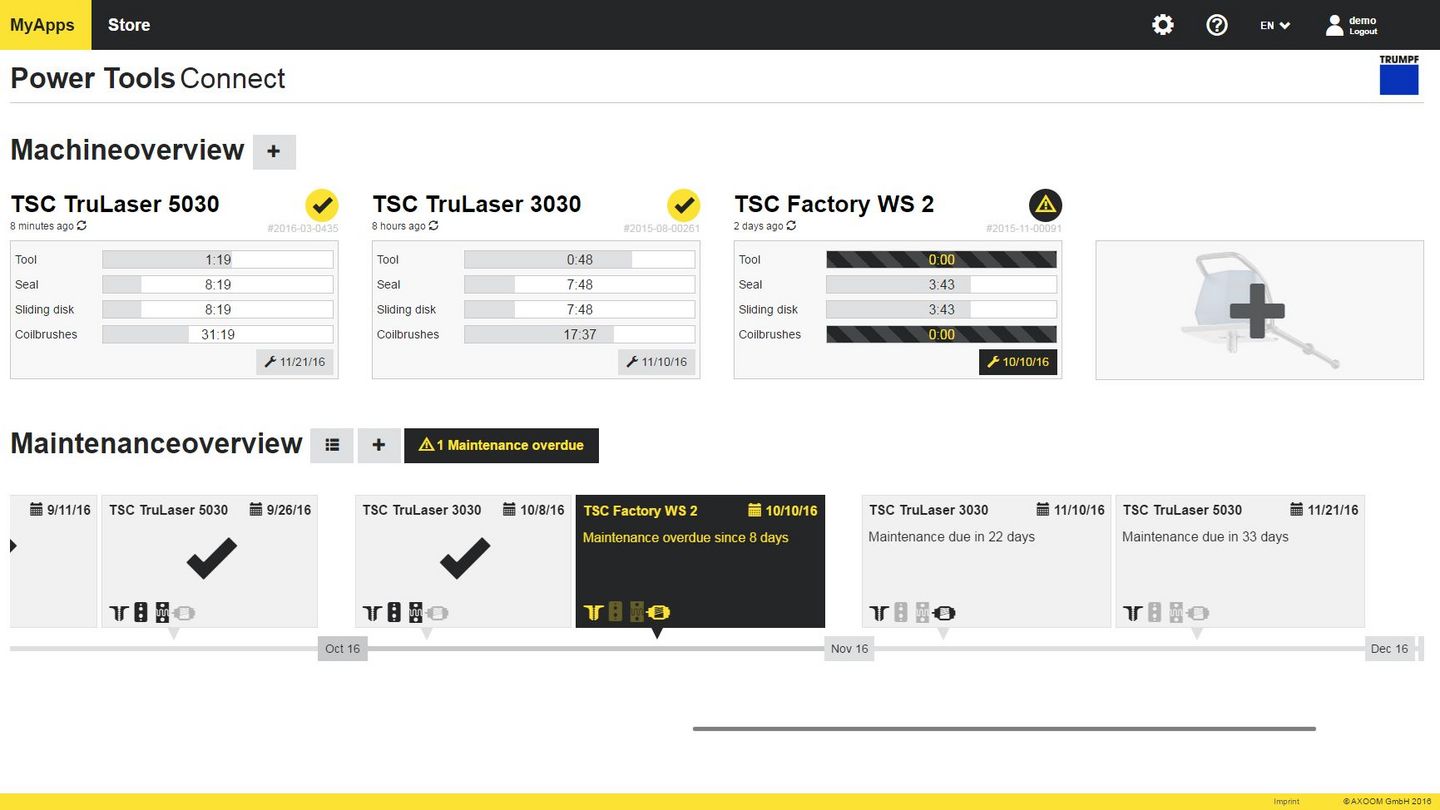

TRUMPF is represented with an app study for the slat cleaner TruTool TSC 100. This power tool reports usage data to AXOOM via a wireless connection. The user receives information about the operating hours of the cleaning tools, seals and carbon brushes via mobile terminals. He knows when maintenance is due, and can intervene quickly to avoid expensive shutdowns. Employees perform maintenance work correctly and rapidly, supported by instructions and videos available on smartphone or PC. The automated maintenance intervals ensure better machine maintenance and longer service life.

The connection of forming technology to Industry 4.0 is driving the machine and component manufacturer Felss. The company wants to offer smart services in the AXOOM Store in order to control complex forming processes in pipe processing. Some examples include an assistant for component and plant engineering and a machine information system, as well as assistance programs for maintenance, production optimization and energy saving. Users can gradually expand their systems with these services – and in this way, forming machines become more productive, avoid errors and save on resources. “Through apps like these, the machines tell us how they’re doing, and we can react quickly to them. We then pass on this knowledge about the machines’ condition to our customers, so that they can produce even more efficiently in the future,” says CEO Thomas Peter.

Through the combination of the apps on offer and the innovative IoT solution, AXOOM is taking cooperation between machine manufacturers and end customers to a new level. “Our goal is to significantly increase productivity in companies,” explains managing director Florian Weigmann. “With our platform and the new products we are one big step closer to achieving that goal.”

Digital photographs in print-ready resolution are available to illustrate this press release. They may only be used for editorial purposes. Use is free of charge when credit is given as “Photo: TRUMPF”.

Persoană de contact